Awesome!

I have looked up the Tangband W8-1772, because i didn´t know that driver.

looks like what the Visaton BG20 wants to be.

But it is 25€ vs 200€.

I have wood from a construction site.

but it doesn´t fit the size of the mltl.

maybe enough for a durable bl-horn.

i´m still waiting for a wardrobe on the bulk trash.

I have looked up the Tangband W8-1772, because i didn´t know that driver.

looks like what the Visaton BG20 wants to be.

But it is 25€ vs 200€.

I have wood from a construction site.

but it doesn´t fit the size of the mltl.

maybe enough for a durable bl-horn.

i´m still waiting for a wardrobe on the bulk trash.

Hi,Hi all!

See and enjoy!!

Whether someone has made this speakers cabinet?

How it sounds?

What crossover to this project fits?

thanks

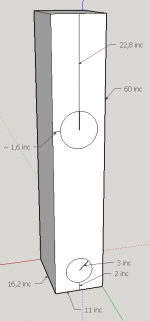

I'm planning on making speaker according to measurements that GM kindly provided in post #5

I have made a quick sketch about the speaker. Dimensions are for insides. My concern is the port length. I will be using 22 mm (0.866 inc) thick MDF. Should I change the port diameter and if yes then what would be more optimal? I´m guessing smaller diameter is the right direction, but how small? I would also be very happy to know how this is calculated for future purposes.

I think little bracing inside of the cabinet wouldn't hurt.

All notes and suggestions about the plan are very welcome and needed.

Thank you.

I have made a quick sketch about the speaker. Dimensions are for insides. My concern is the port length. I will be using 22 mm (0.866 inc) thick MDF. Should I change the port diameter and if yes then what would be more optimal? I´m guessing smaller diameter is the right direction, but how small? I would also be very happy to know how this is calculated for future purposes.

I think little bracing inside of the cabinet wouldn't hurt.

All notes and suggestions about the plan are very welcome and needed.

Thank you.

Attachments

Vents are normally flush with the baffle face, so if you choose to mount it to the rear, then subtract the baffle thickness from it and if you do a large round-over/flare to the baffle face, don't subtract any length.

In your case then, either doing a 3/4" round-over to the face or backside will get you close enough, though the slightly lower tuning of just a hole will be inaudible in-room, so your call as to which to choose.

That said, I always do, and periodically recommend, that even with a simple baffle hole vent, it's best to go bigger and use a vent tube to adjust tuning in-room at the listening position. Since the next size tube in my locale is 8", the vent would obviously be quite a bit bigger/ longer, so normally I would start by cutting a hole to slide a 6"/whatever tube in and use this oversize for the initial tuning and if I want to tune it lower, then insert a 6"/whatever x 3" and if it's tuned too low, shorten it as required.

Note that there's no need to shove the tube in flush, so leave enough extended to both temporarily seal it airtight and be able to pull it out.

GM

In your case then, either doing a 3/4" round-over to the face or backside will get you close enough, though the slightly lower tuning of just a hole will be inaudible in-room, so your call as to which to choose.

That said, I always do, and periodically recommend, that even with a simple baffle hole vent, it's best to go bigger and use a vent tube to adjust tuning in-room at the listening position. Since the next size tube in my locale is 8", the vent would obviously be quite a bit bigger/ longer, so normally I would start by cutting a hole to slide a 6"/whatever tube in and use this oversize for the initial tuning and if I want to tune it lower, then insert a 6"/whatever x 3" and if it's tuned too low, shorten it as required.

Note that there's no need to shove the tube in flush, so leave enough extended to both temporarily seal it airtight and be able to pull it out.

GM

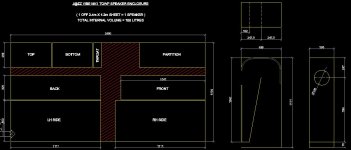

Gonna build this design

Well after an absence (last time I built some Tqwt's was in the 90's! re. the single driver site) I woke up with a hankering to built another pair. I always championed the "poor man's high end" approach so in tradition sought a cheap driver. After a good hunt I found the Visaton BG20 which from the knowledge gained looks a venerable and popular model. So here i am! Ebay to the rescue allowed me to secure a pair of drivers and thx to old pal and contributor Scottmoose for his kung fu will be building them shortly. I include a CAD plan for any other interest

Well after an absence (last time I built some Tqwt's was in the 90's! re. the single driver site) I woke up with a hankering to built another pair. I always championed the "poor man's high end" approach so in tradition sought a cheap driver. After a good hunt I found the Visaton BG20 which from the knowledge gained looks a venerable and popular model. So here i am! Ebay to the rescue allowed me to secure a pair of drivers and thx to old pal and contributor Scottmoose for his kung fu will be building them shortly. I include a CAD plan for any other interest

OK, I had a couple of minutes so here are some (more) dimensions for you, for a Weems style folded conical horn like the one you drew above.

Please don't ask me to draw a diagram. I don't have the time (or talent). If you don't know what some of the words mean, a very little searching / research will give you the answers, and you might get a better understanding.

This is based on a T/S max-flat volume alignment assuming the parameters on the Visaton website. All dimensions are internal. I assumed 3/4in building material.

-Cabinet height = 40.25in

-Width = 12in

-Total internal cabinet depth = 19.5in

-Throat depth = 4in

-Taper ratio = 1:4

-Height of vent = 2.75in

-Zd (distance of the centre of the drive unit from the throat) 31.125in

-Top of internal baffle centred equidistant from the internal top, back and front

-Line the front and top of the box around the fold with damping material. This should be continued for 10in down the back of the enclosure. Adjust to requirements from there. A removable back to the cabinet would be useful to allow easy stuffing adjustment.

Attachments

After a long pause the project is again moving forward. After starting the assembly I fully realised the size of the speaker boxes.  I truly hope bigger is better in this case.

I truly hope bigger is better in this case.

I'm wondering how much do I need damping/stuffing material inside the box. Just a little behind the speaker element or gently fill the whole box?

Should I add some kind of bracing? MDF is 22 mm thick, so the boxes are going to be quite stiff and heavy as they are now.

I'm wondering how much do I need damping/stuffing material inside the box. Just a little behind the speaker element or gently fill the whole box?

Should I add some kind of bracing? MDF is 22 mm thick, so the boxes are going to be quite stiff and heavy as they are now.

Attachments

I would think 2-3 "H" braces or "8" braces should be added. To stiffen those large side panels and brace them to each other to reduce their tendency to boom/move on lower notes.

I can confirm that MDF can be heavy. I'm building MLTLs in 25mm MDF. The cabs are now sealed and they weigh a lot. So much so that I'm considering adding carry handles and maybe wheels!

I can confirm that MDF can be heavy. I'm building MLTLs in 25mm MDF. The cabs are now sealed and they weigh a lot. So much so that I'm considering adding carry handles and maybe wheels!

After a long pause the project is again moving forward. After starting the assembly I fully realised the size of the speaker boxes.I truly hope bigger is better in this case.

I'm wondering how much do I need damping/stuffing material inside the box. Just a little behind the speaker element or gently fill the whole box?

Should I add some kind of bracing? MDF is 22 mm thick, so the boxes are going to be quite stiff and heavy as they are now.

Yes, those boxes really are massive.

I'm also in a BG20 project right now (quite a bit smaller, slightly tapered box that sims "flat" down to 55Hz), and wonder if you addressed mid and HF issues of this driver, plan to use electronics or leave it "raw"?

I would think 2-3 "H" braces or "8" braces should be added. To stiffen those large side panels and brace them to each other to reduce their tendency to boom/move on lower notes.

Thanks for the tip. I'm planning to add two braces. One would be 40cm from the top and the other would be 50cm from the bottom. This will leave bit over 60cm between the braces.

...wonder if you addressed mid and HF issues of this driver, plan to use electronics or leave it "raw"?

I think I will leave them "raw", at least there won't be additional passive components inside the box. At some point I might try playing with miniDSP or passive line-level XO. But of course I'm open to all suggestions.

I'm sure it will sound great.

Everytime i get back to the BG20 i'm amazed by its pleasing sound.

Thank you for your kind words. I will try my best to stay optimistic.

The right amount of stuffing is still a mystery for me.

Attachments

The right amount of stuffing is still a mystery for me.

Did you figure out how much it needs?

Can you already report something about the sound of the speaker?

The right amount of stuffing is still a mystery for me.

Most times it's just enough to remove any obvious resonant/'hollow' sound, so start by listening to it with none and go from there and a good reason to have a removable gasketed vent, bottom or back access panel as removing the driver repeatedly can result in tiny leaks that ruins your efforts.

GM

...a good reason to have a removable gasketed vent, bottom or back access panel as removing the driver repeatedly can result in tiny leaks that ruins your efforts.

Have to implement that to the next speaker project, if I ever stumble upon one again. This time I only have one shot with the side panel.

I would so much like to here about the results of the build!!!

PLEASE!

Sorry to disappoint you, but the project was again moving a bit slowly.

I read somewhere that stuffing should reach from top to few inches below speaker element. I used loose polyester mat to prevent stuffing from falling to the bottom part of the box. I think I will add an another mat and divide the space into two sections. Size of the section is about (70x41x28) cm giving a volume of about 83 litters.

After filling the section very loosely I weighted the used stuffing material. The total for one box was 250g of 100% polyester stuffing.

I really don't have any idea how much stuffing I should use, but my biggest concern is resonant with too little stuffing. After that comes damping the bass with too much stuffing. Oh what a dilemma.

Attachments

Delays, delay, this project is taking forever.

Some updates:

Added speaker wires and I have now finished stuffing the boxes. I used total of 350g polyester stuffing for each box. I will wrap some polyester mat around the lower brace also.

I think I will be able to close the boxes soon (a week?).

All ideas and questions all always welcome and thank you for all the help.

Some updates:

Added speaker wires and I have now finished stuffing the boxes. I used total of 350g polyester stuffing for each box. I will wrap some polyester mat around the lower brace also.

I think I will be able to close the boxes soon (a week?).

All ideas and questions all always welcome and thank you for all the help.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- TL-box for BG20 Visaton