I recently got the small Yamaha S301 to have something steady as my baseline and to have something to listen to music while my gazillion of projects are waiting their turn

I must say that so far I really like it, although I have mixed feelings for its construction.

I am not posting schematics or the service manual. It's was quite easy to get if you are interested

First of all, I really dislike the heavy use of digital circuitry. It uses an integrated IC for the DSP, EQ, source select and volume. The volume is motorized which makes sense for the remote control, but then, it's single-gang, so it just controls the IC. Which is weird as a choice... And while the amp has a direct bypass, it leaves you wondering since audio still goes in the IC. The S701 has a "direct CD" button. Which is poorly named as a feature. Isn't "pure direct" the directest? But I guess it also does some extra stuff by converting the CD line into balanced before it enters the IC. The amp also has lots of heat sensors and also checks its mini-boards so that it can put the amp into emergency mode if a fault is detected. It's probably going to be rough if you want to service it in the future.

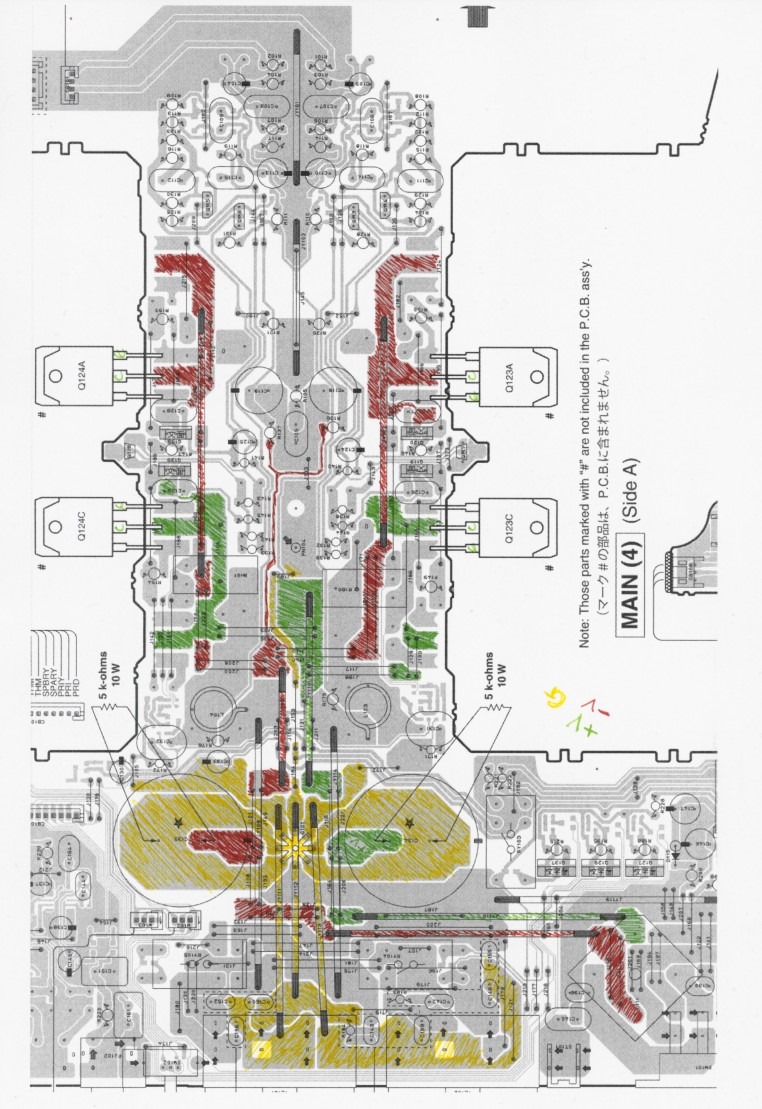

The pcbs are one-layer and use lots of jumpers. I can't really stomach this in 2024. As a DIYer I can order nice two-layer pcbs for peanuts but Yamaha still has to juggle jumpers?

The amp itself uses opamps for the pre stages and bipolars for the power amp. It looks pretty usual. A long tailed pair input with a CCS driving more transistors etc.

And then we have the usual choices made purely to put products in steps and upsell you the bigger ones

The most blatant one is probably the PSU capacitors C134 and C135. At 6800uf they are probably starving the amp at higher volumes and during dynamic passages. This is probably the easiest upgrade. 10mF caps should easily fit on the pcb. And there is lots of space if you want to add some motor-run caps or some more mFs. The inrush might start becoming a problem even though the bridge is rated quite high.

One weird choice are caps C119 and C118. At 470uF, they sit between the negative rail and the ground for the two channels. And there is no corresponding pair for the positive rail. Any ideas as to why this asymmetry?

Another "ugly" choice is the electrolytic capacitor on the amp's input (C103-C104). They look like nichicons, but at 10uF/16V these should be easy to replace with some nicer films. The same goes for the output of the phono (C629-C639) if you care to use it

The speaker relays are also smaller on the S301, but I do not really care since I doubt I am using more than 5Ws

The pres might also by an area that could use some easy help. Like better bypassing the opamps to clear things up a bit more.

Any other ideas? The amp seems to be popular, but I have not found many mods for it

I must say that so far I really like it, although I have mixed feelings for its construction.

I am not posting schematics or the service manual. It's was quite easy to get if you are interested

First of all, I really dislike the heavy use of digital circuitry. It uses an integrated IC for the DSP, EQ, source select and volume. The volume is motorized which makes sense for the remote control, but then, it's single-gang, so it just controls the IC. Which is weird as a choice... And while the amp has a direct bypass, it leaves you wondering since audio still goes in the IC. The S701 has a "direct CD" button. Which is poorly named as a feature. Isn't "pure direct" the directest? But I guess it also does some extra stuff by converting the CD line into balanced before it enters the IC. The amp also has lots of heat sensors and also checks its mini-boards so that it can put the amp into emergency mode if a fault is detected. It's probably going to be rough if you want to service it in the future.

The pcbs are one-layer and use lots of jumpers. I can't really stomach this in 2024. As a DIYer I can order nice two-layer pcbs for peanuts but Yamaha still has to juggle jumpers?

The amp itself uses opamps for the pre stages and bipolars for the power amp. It looks pretty usual. A long tailed pair input with a CCS driving more transistors etc.

And then we have the usual choices made purely to put products in steps and upsell you the bigger ones

The most blatant one is probably the PSU capacitors C134 and C135. At 6800uf they are probably starving the amp at higher volumes and during dynamic passages. This is probably the easiest upgrade. 10mF caps should easily fit on the pcb. And there is lots of space if you want to add some motor-run caps or some more mFs. The inrush might start becoming a problem even though the bridge is rated quite high.

One weird choice are caps C119 and C118. At 470uF, they sit between the negative rail and the ground for the two channels. And there is no corresponding pair for the positive rail. Any ideas as to why this asymmetry?

Another "ugly" choice is the electrolytic capacitor on the amp's input (C103-C104). They look like nichicons, but at 10uF/16V these should be easy to replace with some nicer films. The same goes for the output of the phono (C629-C639) if you care to use it

The speaker relays are also smaller on the S301, but I do not really care since I doubt I am using more than 5Ws

The pres might also by an area that could use some easy help. Like better bypassing the opamps to clear things up a bit more.

Any other ideas? The amp seems to be popular, but I have not found many mods for it

What would be the goal of the project?Any other ideas? The amp seems to be popular, but I have not found many mods for it

You can swap capacitors in signal path but - as you write - it will still be a "digital thingie".

Experimentation and DIY.What would be the goal of the project?

The amp is shamelessly gimped so they can upsell its cousins for a few bigger parts. From a quick look, a-s701 also uses the same power section. Probably more if we care to check.

it will still be a "digital thingie".

The same digital parts are also used at least up to a-s701. They are not THAT bad.

And even this can be fixed with enough courage or audacity. The power amp section exposes its inputs very nicely on a header. All we got to do is select our favorite preamp circuit and slap it on the front.

I guess for me this would be the only reasons justifying this hurdleExperimentation and DIY.

But keep us posted about the progress...

An idea from my side (provided the amp is A-S501) - the load capacitor in phono stage C605 is 470pF which is too much. I would take it down to 150 or 220 pF.

Replacing lytics in sgnal path with film caps is a trivial thing not worth mentioning.

Also RMAA or REW measurements could be interesting - the before and after versions.

Last edited:

Hurdle? I love doing that kind of easy stuff. Not to mention I learn a lot from the schematics.I guess for me this would be the only reasons justifying this hurdle

It's a 301, but it uses the same phono and cap. Yeah that's already on my todo list. I just have to finish re-wiring my turntable first and see what I have to work withAn idea from my side (provided the amp is A-S501) - the load capacitor in phono stage C605 is 470pF which is too much. I would take it down to 150 or 220 pF.

Now that's a hurdleAlso RMAA or REW measurements could be interesting - the before and after versions.

which equal fun!Experimentation and DIY.

I like to give them the benefit of the glass being half full and they scrounged and saved pennies everywhere they could to make it as good as it is for that price. Especially with an actual distribution network and factory warranty that doesn't require shipping it half way around the world if it breaks.The amp is shamelessly gimped so they can upsell its cousins for a few bigger parts. From a quick look, a-s701 also uses the same power section. Probably more if we care to check.

That would be part of another thread but once you are doing that then the only correct result would be the outgoing signal cable being soldered directly to tonearm wires and being detached from turntable chassis groundI just have to finish re-wiring my turntable first

One more look at the schematics - C635 in phono stage output is something Yamaha likes to place and I usually remove.

Last edited:

True, but they put the power supply capacitor values right in their advertising write-up on them so they aren't sneaking that in. And who buys the 60 watt model if they are into listening to their music loud? Plus, I can't even remember when they started making the these models so if they can save $10 per amp by putting cheaper components, that work fine for 90+% of the buyers, over all that time it really adds up. I've seen other people complain about the single layer PCB too but as a company why spend money redoing something that already works and is slightly cheaper and they don't need more room in the case?Strong brands will hamper lower models to make them not too competitive with more expensive. Its seen countless times.

I found some time to work a bit on the amp

The one thing I have to say is that it definitely was not designed with servicing in mind. Even the daughterboards are not easy to work with. Even if you pull them out by force, you cannot really push them back in because the connector does not align because of the RCA connectors, and the side-mother-board is too flexible. So you end up having to at least unscrew the side-board to align the connectors properly. And then you still cannot make the connector clip because of the flexibility. I ended up using an angled allen key to provide some support from below. Ideally you would want to unscrew and remove the whole board set like the service manual suggests. But I really did not want to disassemble more than I had to. The amp really has a gazillion connectors going back and forth all over the place.

The good thing is that the pcb seems to be of decent quality. The solder mask seems a bit thin and easy to scratch. But at least you do not lift pads just by looking at them intensely.

The worse part is that in order to replace the psu caps, you literally have to disassemble everything. And I mean everything. So I am looking for alternative ways to just mount the caps externally. For now I am thinking to keep the existing caps in place, and either add extra ones on the beefy jumper wires, or directly on the transistor legs. I will have to give it some thought though to find a way to make this effective and easy to work with. perhaps with some extra pcb attached to the heatsinks.

The one thing I have to say is that it definitely was not designed with servicing in mind. Even the daughterboards are not easy to work with. Even if you pull them out by force, you cannot really push them back in because the connector does not align because of the RCA connectors, and the side-mother-board is too flexible. So you end up having to at least unscrew the side-board to align the connectors properly. And then you still cannot make the connector clip because of the flexibility. I ended up using an angled allen key to provide some support from below. Ideally you would want to unscrew and remove the whole board set like the service manual suggests. But I really did not want to disassemble more than I had to. The amp really has a gazillion connectors going back and forth all over the place.

The good thing is that the pcb seems to be of decent quality. The solder mask seems a bit thin and easy to scratch. But at least you do not lift pads just by looking at them intensely.

The worse part is that in order to replace the psu caps, you literally have to disassemble everything. And I mean everything. So I am looking for alternative ways to just mount the caps externally. For now I am thinking to keep the existing caps in place, and either add extra ones on the beefy jumper wires, or directly on the transistor legs. I will have to give it some thought though to find a way to make this effective and easy to work with. perhaps with some extra pcb attached to the heatsinks.

Extra caps wont do much.

if no hum there is no hum.

Caps are not only filters. Local bypass action and reduced ESR will also fight the inductance and resistance of all those thin traces and jumpers in the gimped PCB.

does it have soft start.

or just trying to explode rectifier

The bridge is rated at 200A. That's more than twice the inrush with the caps that I plan to use. And if it overheats, I can always replace it with a proper big one (planning to do this anyway eventually).

- Home

- Amplifiers

- Solid State

- Tinkering with the Yamaha S301