The 4BQ7 serves a specific purpose. Its heater runs on the 5V winding of the PT, so there are no problems with H-K insulation.

That makes sense now. The earlier schemo didn't include the PS.

I don’t worry much about which tube or that may ‘sound’ better. IMO, an amplifier should & can be a piece of wire with gain. Any imperfection will be reduced provided it is inside a stable NFB loop. Microphonics are a problem that can be avoided. But they may add to the sound of a rock musicians performance!

That's pretty much how I design. However, more linear (and better sounding) VTs reduce the errors that need correcting. NFB should improve a good sounding open loop design, not cover up for a poor one.

A while back in one of my projects I did objective A vs B tests on the ‘BQ7 family when compared to the rather expensive 6SL7 / 6SN7 family. The THD & IMD results would surprise many! But I didn’t have any problem with microphonic ‘BQ7s.

Good loadlines aren't so easy to find for 6BQ7s, but you can find ones that predict better performance than some of the triodes you see frequently in audio designs. I get good performance with them, and you definitely don't see 'em as often as you should. Maybe that's because the spec sheet doesn't mention audio at all? The cascode LTP splitter used in the Le Renard design measured quite clean.

All the 6BQ7s that have series connected heaters are nastily microphonic. You can recognize these by the thin bit of filament running between cathodes. Those with parallel connected heaters haven't given me any problems with microphonics.

Bootstrapped 6SN7 driver plate loads. I would guess those UL taps are providing more voltage swing than required however, giving some positive Fdbk.

It might be interesting to replace the 6SN7 drivers with some pentodes, using the same cross UL bootstrapped plate load idea. But add UL tap Neg. feedbacks to the driver g2's as well to provide some local Neg. Fdbk. A UL driver stage if you will. Likely have to use some R dividers to attenuate the Neg Fdbks and reduce the DC voltage for the driver screens.

A while back I used what is left of my math skills to come up with a solution to the +ve FB question. All attached here. Actual measurements showed it to be never more than 1.5 to 2 db.

I tried OPTs with both 20% & 43%. For the 6AS7/6080 version the 43% solution was needed. The 20% worked but not nearly as well. The 20% solution would be OK for a pair of the 2A3 family.

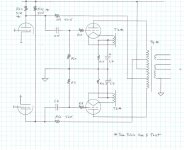

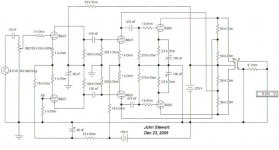

The next version I built avoided the UL OPT entirely. See attached the original hand drawn version setup for 2A3s. And another easier to visualize done with Electronic Workbench software & a 6BQ7 diff amp front end. This one wastes more of the output power in the bootstrapping connexion.

When dealing with the 6AS7/6080 one needs to be careful with the biasing. Each grid needs to be biased separately by cathode biasing. Otherwise thermal runaway is a sure thing. I found out the hard way. Otherwise a bias servo for each grid.

The THD result on the previous post had a pair of 6080’s as the OP. Running thru a special wound Hammond 1600 Series of 2150 ohms. I used a Pico Technology ADC-100 to get that result.

Just realized I wasn’t with R&S at that point but rather Navair Div of Field Aviation. So was pushing IFR (now Aeroflex). Aside from cell site test, spec A’s & so on not much tubes or hifi! I had managed to avoid both for about 40 years.

Attachments

Isn't this thread about TV tubes? The most popular TV tube is our friend the horizontal (line) output tube.....they like plenty of voltage too.

As mentioned tube cascodes were used in RF. Common applications were TV and FM radio tuners and Tektronix scopes. The 6BQ7 was popular in TV and early Tek scopes. Tek later switched to the 6DJ8. The cascade was popular to approximate pentode operation with low capacitance triodes.

The TEK 543 I used at the Graduate Lab at U of T Physics had something like 14 tubes in the final vertical PP amp. A travelling wave amplifier, delay lines & all. And got to only 30 MHz. But got a lot done, anyway. Today I use something that is 250 MHz, 2-channel, fits in the palm of your hand & runs into the laptop. Big change in 50 years

I also have a very similar amp design under construction using pentodes. The cross coupled local feedback goes to the driver tube screens. The cathode followers driving the output tubes are replaced with mosfets. Output tubes are TV sweep tubes.....not decided on which ones yet....or just which grids are being driven.

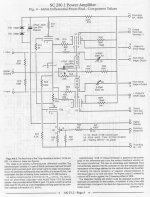

Pearl in Calgary did some of those NFB to input screens back about 20 years ago. See attachment. His stuff was top of the line. Same guy that marketed the tube coolers. The Cascode front end I posted is easily converted to a pair of pentodes. But would have to take into screen loading of the NFB network, both AC & DC. The cascode avoids that.

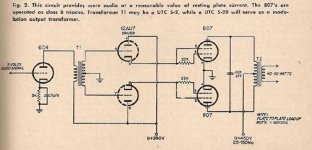

Class B Zero Bias, Screen driven pentodes were common with amateurs as modulators. 807s were plentiful. A few tried direct coupling. That lifts the grids off ground so there is less distortion. But the added B+ current was not popular for mobile work.

They are on my short list. I want at least 100 WPC which the 13GB5's can easily do. I have 3300 ohm OPT's and the B+ will be in the 500 to 600 volt range.

I forgot about that one. I got serial #001 way back when they cost $100. It was in an SSE until I stole the OPT's for another project. It's around here somewhere. It would need a small boost transformer to generate 600 volts.

Attachments

Hi,

i built a 12W6 pp amp, G2 regulated using 0A2(150v) and working at plate B+ of 300 volts dc..

the amp is a mullard 5-20 implementation, used the 5693 as LTP, and 12at7 inputs...

the amp is now with me to fix some issues...

gain is way too high so took care of that,

the 0A2 regulator blinks, a sign that is it is

running out of current on music peaks,

took care of that too..

noticed that one sylvania 12W6 red plates at 15 volts bias,

so i replaced the entire set with RCA 12EN6's,

no more red plates....

note that even if the RCA 12EN6 is rated for 7 watts compared to 12W6's 10 watts, no difference was noted in actual use...

i still have the GE 12W6 cleartop quads to try out...

the current setup now is, 12EN6 output tubes, 5814 long tail pair phase inverter,

and 12AV7 as input tube....although the JJ 12at7 and siblings had more gain and decent sound,

i found out that 12AV7 is even better in that spot, perhaps because the 12AV7 has lower rp than the

12at7.....so i am working the amp real hard now.....

i built a 12W6 pp amp, G2 regulated using 0A2(150v) and working at plate B+ of 300 volts dc..

the amp is a mullard 5-20 implementation, used the 5693 as LTP, and 12at7 inputs...

the amp is now with me to fix some issues...

gain is way too high so took care of that,

the 0A2 regulator blinks, a sign that is it is

running out of current on music peaks,

took care of that too..

noticed that one sylvania 12W6 red plates at 15 volts bias,

so i replaced the entire set with RCA 12EN6's,

no more red plates....

note that even if the RCA 12EN6 is rated for 7 watts compared to 12W6's 10 watts, no difference was noted in actual use...

i still have the GE 12W6 cleartop quads to try out...

the current setup now is, 12EN6 output tubes, 5814 long tail pair phase inverter,

and 12AV7 as input tube....although the JJ 12at7 and siblings had more gain and decent sound,

i found out that 12AV7 is even better in that spot, perhaps because the 12AV7 has lower rp than the

12at7.....so i am working the amp real hard now.....

You know, it's a shame that tube R&D has basically died out. The frame grid was such a great innovation! I've thinking about how to improve the frame grid even further. For example, instead of wires stretched over a frame, you could use a metal foil that has many thousand micro perforations. You could use perforated graphene as well! I'm sure you could make many very precise holes in the foil with lasers. Just some ideas I have kicking around.

Yeah, but hey what do you need a tube for in the world of cheap sillicon?

The only advantages of tubes are its immunity to EMP pulses and that they are very forgiving of overloads. That led to their continued use into the 90s in soviet electronics.

Anyway, tubes are likely going to be around for a few decades, that is for transmitting and industrial heating applications. The only bottleneck I see is that there are no people receiving education on how to build and design whit them.

The only advantages of tubes are its immunity to EMP pulses and that they are very forgiving of overloads. That led to their continued use into the 90s in soviet electronics.

Anyway, tubes are likely going to be around for a few decades, that is for transmitting and industrial heating applications. The only bottleneck I see is that there are no people receiving education on how to build and design whit them.

Anyway, tubes are likely going to be around for a few decades, that is for transmitting and industrial heating applications.

Maybe not so ...

AM transmitters - so they still exist - are already completely solid state nowadays. A 600kW unit consists of 12 cabinets filled with 600 identical switching LDMOS power modules, each card complete with SMPS, modulator, oscillator, driver, outputs, filter.

Similar for FM, up to 100kW.

Even UHF transmitters have gone solid state at least up to 40kW, where the traditional inductive output tube (IOT or klystrode) is being replaced by MOS modules. Introduction of DTV / DVB was a good opportunity to replace tube equipment there.

So what rests ... satellite uplink and maybe the magnetron for industrial due to its simplicity.

Sad

For some reason, this makes me feel the same way I felt when they decommissioned the USS Enterprise. I hated every minute I served on that ship, but when I heard she was being torn apart for scrap, I almost felt like writing my congressman and saying she belongs as a museum piece. A world without tubes.... Although I appreciate modern technology, I wonder if it hasn't been more of a curse than a boon. I enjoy the fact that tubes hold their own sonically even though they are "obsolete."

Maybe not so ...

AM transmitters - so they still exist - are already completely solid state nowadays. A 600kW unit consists of 12 cabinets filled with 600 identical switching LDMOS power modules, each card complete with SMPS, modulator, oscillator, driver, outputs, filter.

Similar for FM, up to 100kW.

Even UHF transmitters have gone solid state at least up to 40kW, where the traditional inductive output tube (IOT or klystrode) is being replaced by MOS modules. Introduction of DTV / DVB was a good opportunity to replace tube equipment there.

So what rests ... satellite uplink and maybe the magnetron for industrial due to its simplicity.

For some reason, this makes me feel the same way I felt when they decommissioned the USS Enterprise. I hated every minute I served on that ship, but when I heard she was being torn apart for scrap, I almost felt like writing my congressman and saying she belongs as a museum piece. A world without tubes.... Although I appreciate modern technology, I wonder if it hasn't been more of a curse than a boon. I enjoy the fact that tubes hold their own sonically even though they are "obsolete."

Yeah, but hey what do you need a tube for in the world of cheap sillicon?

The only advantages of tubes are its immunity to EMP pulses and that they are very forgiving of overloads. That led to their continued use into the 90s in soviet electronics.

Anyway, tubes are likely going to be around for a few decades, that is for transmitting and industrial heating applications. The only bottleneck I see is that there are no people receiving education on how to build and design whit them.

For the little info it's worth - I was on the last class of students that learn't about tubes at Royal Melbourne Institute Of Technology ( RMIT as it was known back then in Melbourne, Australia) in 1977. The radio school which also trained our military guys was dumping the tube subjects after our lot graduated. I recall seeing the old 833a 3XY AM Radio Transmitter in their Museum and the massive Mercury Tube Power Supply to run it. Since then I've always wanted to build an 833 audio amp. Fortunately for me, I had a reasonable knowledge of such technology before I did my class studies as an apprentice back in the 70's. Their level of tube training at that time was very good, but still basic.

Today students in electronics only know about PICs, Micros, IT and Software design ( which in my opinion is not true Electronics, but more IT. Many have never heard of a transformer either - let alone used one.

( I now have an Electronics Engineer at work who is much younger than me and ironically my Boss. He is fresh out of Uni and grapples to use basic hand tools or a soldering-iron. Most practical jobs he delegates to me - despite me being over loaded with other repair work as it is as know else knows how to do the work. He comes to me every day with basic questions and for me to check his work before submitting it to his Boss - yet he is paid twice my salary because he has piece of paper - yet I carry 40+ years experience. So what does that tell you about the so called new comers in the Electronics - sorry I meant I.T - Industry ! )

Last edited:

I hear you

My brother owns a good-sized business that started out manufacturing and selling custom computer cable and just grew from there. I worked for him for a year. I worked alongside my father, (master mechanic and then some), joined the Navy, took electronics (tubes and solid state and even magnetic amplifiers), and learned computers. Anyway, my brother hired a kid out of college with a mechanical engineering degree. what a joke. He didn't know anything of practical value. He didn't even know the diff between a Phillips and flat-blade. At that point, my brother's business included CNC mills. you'd think a guy with a mechanical engineering degree would be of some use in that situation in a shop with three vertical CNC mills, but, sadly, no. WTH are they teaching in college these days? Seriously?For the little info it's worth - I was on the last class of students that learn't about tubes at Royal Melbourne Institute Of Technology ( RMIT as it was known back then in Melbourne, Australia) in 1977. The radio school which also trained our military guys was dumping the tube subjects after our lot graduated. I recall seeing the old 833a 3XY AM Radio Transmitter in their Museum and the massive Mercury Tube Power Supply to run it. Since then I've always wanted to build an 833 audio amp. Fortunately for me, I had a reasonable knowledge of such technology before I did my class studies as an apprentice back in the 70's. Their level of tube training at that time was very good, but still basic.

Today students in electronics only know about PICs, Micros, IT and Software design ( which in my opinion is not true Electronics, but more IT. Many have never heard of a transformer either - let alone used one.

( I now have an Electronics Engineer at work who is much younger than me and ironically my Boss. He is fresh out of Uni and grapples to use basic hand tools or a soldering-iron. Most practical jobs he delegates to me - despite me being over loaded with other repair work as it is as know else knows how to do the work. He comes to me every day with basic questions and for me to check his work before submitting it to his Boss - yet he is paid twice my salary because he has piece of paper - yet I carry 40+ years experience. So what does that tell you about the so called new comers in the Electronics - sorry I meant I.T - Industry ! )

At that point, my brother's business included CNC mills. you'd think a guy with a mechanical engineering degree would be of some use in that situation in a shop with three vertical CNC mills, but, sadly, no. WTH are they teaching in college these days? Seriously?

You don't hire a mechanical engineer to run CNC's, you hire a CNC machinist. Engineers aren't trained to be machinists, although there may be a few who could do it if need be.

jeff

u should be a sports announcer.

Thanks for stating the obvious. I'm a trained CNC machinist. I'm aware of that. if you were a CNC machinist, you'd understand the train of thought. There is a lot to being a machinist that isn't taught in machinist school, you pick it up with experience, like building jigs to hold the parts. Would a mechanical engineer be any help with that? Do they understand metallurgy at all?

I AM curious just what the mechanical engineer curriculum involves. I don't have one and built an electric car out of a VW Beetle and it wasn't as tough as it sounds. Just what ARE they capable of when they graduate? Just curious, if you don't know, don't answer

You don't hire a mechanical engineer to run CNC's, you hire a CNC machinist. Engineers aren't trained to be machinists, although there may be a few who could do it if need be.

jeff

Thanks for stating the obvious. I'm a trained CNC machinist. I'm aware of that. if you were a CNC machinist, you'd understand the train of thought. There is a lot to being a machinist that isn't taught in machinist school, you pick it up with experience, like building jigs to hold the parts. Would a mechanical engineer be any help with that? Do they understand metallurgy at all?

I AM curious just what the mechanical engineer curriculum involves. I don't have one and built an electric car out of a VW Beetle and it wasn't as tough as it sounds. Just what ARE they capable of when they graduate? Just curious, if you don't know, don't answer

Just curious, if you don't know, don't answer

You're obviously so smart, you look it up.

jeff

in the semicon company i used to work in many years ago,

we hire engineers even if the position called for a technician,

and our reasoning then, was that these engineers will gain experience,

can be trained, and later on move up the corporate ladders...

to us then, hiring engineers was making a wise investment...

we hire engineers even if the position called for a technician,

and our reasoning then, was that these engineers will gain experience,

can be trained, and later on move up the corporate ladders...

to us then, hiring engineers was making a wise investment...

Just this past Friday I was tentatively hired ("We'll give you a few weeks to show us what you can do . . .") as an Electronic Assembly Technician at a flat US$13.00/hr. (No health or disability insurance, no retirement or profit sharing, no paid vacation or holidays, etc.) They put me to work right away - I spent Friday afternoon crimping contacts onto cable assemblies. This is the first income I've earned in over a year.. . . we hire engineers even if the position called for a technician . . .

I earned a B.S. in Electrical Engineering in 1973, and completed the M. S. in 2003.

During the interviews they mentioned that over 300 people had applied and asked if I could explain why they had applications from over a dozen people with graduate degrees in electrical engineering. Allegedly I was selected based on breadth of prior experience, plus an ability to compose complete sentences and assemble them into coherent paragraphs.

The only stated requirements for this entry-level job were the ability to do simple soldering (1/4 watt resistor an a PWB) and identify common thru-hole electronic components ("Those are resistors - look like 1/4 W and 1/10 W; this polarized capacitor is an electrolytic type; that thing in the 16-pin DIP package is an IC, probably a logic chip but I can't read the marking in this light; and that TO-92 is probably a transistor, but might be a regulator, voltage reference or something else."). In the soldering test I asked if they were using lead-free solder and the assembly foreman didn't know. While assembling wire harnesses I asked why they crimped terminals with common pliers rather than the Molex hand crimping tools, and they weren't aware such things existed.

Dale

Re: Lead-free solder. Because of ROHS, if whatever you are assembling is headed for the EU, you will be using lead-free. We switched to lead-free years ago because of ROHS. 13 an hour in this economy, not bad. my first machine shop job was 15.50 and I was just hired to be a button-pusher. Similar to your experience, my supervisor had zero machine shop experience, his expertise was in "moving material?" not quite sure what he meant by that. I rather thought machines had replaced most assembly work? Or is that just SMD?Just this past Friday I was tentatively hired ("We'll give you a few weeks to show us what you can do . . .") as an Electronic Assembly Technician at a flat US$13.00/hr. (No health or disability insurance, no retirement or profit sharing, no paid vacation or holidays, etc.) They put me to work right away - I spent Friday afternoon crimping contacts onto cable assemblies. This is the first income I've earned in over a year.

I earned a B.S. in Electrical Engineering in 1973, and completed the M. S. in 2003.

During the interviews they mentioned that over 300 people had applied and asked if I could explain why they had applications from over a dozen people with graduate degrees in electrical engineering. Allegedly I was selected based on breadth of prior experience, plus an ability to compose complete sentences and assemble them into coherent paragraphs.

The only stated requirements for this entry-level job were the ability to do simple soldering (1/4 watt resistor an a PWB) and identify common thru-hole electronic components ("Those are resistors - look like 1/4 W and 1/10 W; this polarized capacitor is an electrolytic type; that thing in the 16-pin DIP package is an IC, probably a logic chip but I can't read the marking in this light; and that TO-92 is probably a transistor, but might be a regulator, voltage reference or something else."). In the soldering test I asked if they were using lead-free solder and the assembly foreman didn't know. While assembling wire harnesses I asked why they crimped terminals with common pliers rather than the Molex hand crimping tools, and they weren't aware such things existed.

Dale

photomultipliers, and yes those magnetrons.Maybe not so ...

AM transmitters - so they still exist - are already completely solid state nowadays. A 600kW unit consists of 12 cabinets filled with 600 identical switching LDMOS power modules, each card complete with SMPS, modulator, oscillator, driver, outputs, filter.

Similar for FM, up to 100kW.

Even UHF transmitters have gone solid state at least up to 40kW, where the traditional inductive output tube (IOT or klystrode) is being replaced by MOS modules. Introduction of DTV / DVB was a good opportunity to replace tube equipment there.

So what rests ... satellite uplink and maybe the magnetron for industrial due to its simplicity.

cant live without microwave ovens

WTH are they teaching in college these days? Seriously?

Destruction of brain cells, with an emphasis on gaining an entitled attitude.

Destruction of brain cells, with an emphasis on gaining an entitled attitude.

Ding! Ding! Ding! We have a winner!

And here I thought I was the only one who thought this was the case... I was once told that vacuum tube amplifiers are a dying breed, a "dead end to electronics and amplification", and why bother with it even as a hobby? Needless to say, it was a short conversation. If they could see some of the pictures on this forum.

So much more could be taught for the high price of education.

- Home

- Amplifiers

- Tubes / Valves

- Those Magnificent Television Tubes