warrjon and Bon-

Thanks for your suggestions. I'll do some more research on removing the electronics to a separate chassis. As its now set up, that shouldn't be too hard. Link to my current build.

Mike

Had a look at your build, nice looking plinth I love the wood. The only suggestion I would make is to remove the brake. All of my SP10's have the brake removed and if I service an SP10 I recommend removing the brake. IMO anything that can vibrate gets removed. I even remove the black aluminium in the center of the motor rotor as it's only held on by 3 bits of double sided tape.

While I had the motor apart I added Blu Tack inside the housing to damp ringing. The second pic shows the bearing brace I made to hold the bottom of the bearing rigidly to the plinth. There are numerous other mods including a brass bush in the rotor so the spindle is press fit.

Moving the electronics to a separate enclosure will also mean 1 less thing that can possibly vibrate. A lot of people underestimate how sensitive a phono cartridge is and we can not hear the direct effect of anything vibrating, but we do hear the result, or more accurately we do not hear the effect as the vibration energy modulates the audio signal causing smearing.

This is my SP10mk2, the electronics are still in the chassis on the first shelf and connected to the motor by an umbilical cord. I do plan to move the electronics into a 2U rack enclosure.

Warrjon,

Great job!

I am thinking of acquiring an SP-10, too. There are two things I dislike about an SP-10.

1. I would like to have a heavy platter. But I don't know how heavy the platter the motor can take.

2. I like screwed-down center weight.

3. I also like to use my current outer ring, which is about 2 lbs. So, the platter will be even heavier.

In addition to the questions above, I don't know if there is any difference in the direct drive motors between a used SP-10 and a brand new SL-1210GR. A brand new SL-1210GR is about $1,600 USD. If there are not much of differences in motors, buying a brand new SL-1210GR may sound like a better option.

Jim

Great job!

I am thinking of acquiring an SP-10, too. There are two things I dislike about an SP-10.

1. I would like to have a heavy platter. But I don't know how heavy the platter the motor can take.

2. I like screwed-down center weight.

3. I also like to use my current outer ring, which is about 2 lbs. So, the platter will be even heavier.

In addition to the questions above, I don't know if there is any difference in the direct drive motors between a used SP-10 and a brand new SL-1210GR. A brand new SL-1210GR is about $1,600 USD. If there are not much of differences in motors, buying a brand new SL-1210GR may sound like a better option.

Jim

Hi Jim.Warrjon,

Great job!

I am thinking of acquiring an SP-10, too. There are two things I dislike about an SP-10.

1. I would like to have a heavy platter. But I don't know how heavy the platter the motor can take.

2. I like screwed-down center weight.

3. I also like to use my current outer ring, which is about 2 lbs. So, the platter will be even heavier.

In addition to the questions above, I don't know if there is any difference in the direct drive motors between a used SP-10 and a brand new SL-1210GR. A brand new SL-1210GR is about $1,600 USD. If there are not much of differences in motors, buying a brand new SL-1210GR may sound like a better option.

Jim

Warrjon made 2 platters for my SP10 mk2. One is SS/POM and weighs 11 kg. I also use a peripheral ring. My SP10 has no issues spinning it up. Maybe fractionally slower than the 3 kg stock platter but still faster than any other turntable I have owned. The W&F remains close to spec. I replaced it with a gunmetal/POM platter weighing 8 kg. I was a little nervous about the effect of the 11 kg platter on the Torlon thrust bearing. I have not checked the wear recently but last check was fine.

Bon

Attachments

Warrjon,

Great job!

I am thinking of acquiring an SP-10, too. There are two things I dislike about an SP-10.

1. I would like to have a heavy platter. But I don't know how heavy the platter the motor can take.

2. I like screwed-down center weight.

3. I also like to use my current outer ring, which is about 2 lbs. So, the platter will be even heavier.

In addition to the questions above, I don't know if there is any difference in the direct drive motors between a used SP-10 and a brand new SL-1210GR. A brand new SL-1210GR is about $1,600 USD. If there are not much of differences in motors, buying a brand new SL-1210GR may sound like a better option.

Jim

Hi Jim,

My platter is just under 10kg and is made from 60mm POM with a gunmetal ring underneath, then the whole assembly is balanced. This platter uses a decoupled spindle so the LP spindle does not touch the motor spindle. I also made the LP spinlde 0.284" which is larger in OD and is what the broadcast standard specifies. My current spindle is not threaded but I have a threaded spindle for a screw down clamp on the TODO list

I don't think mass is the most important thing in a platter. The platters ability to manage the vibration energy from the stylus LP interface is far more important as is rotational stability. Increasing the platters inertia as mine is has effected W&F. From my measurements W&F has decreased but drift has increased slightly.

I have done a lot R&D and modifications to my SP10mk2 all of it is based on sound Physics and mechanical engineering principles. Controlling / damping energy has been the major focus as well as re-engineering some of the short cuts Technics made with the SP10mk2 motor. Like the spindle being glued into the rotor, if you look closely at my motor there is a brass bush that the spindle is now an interference press fit and far more rigid.

IMO the motor has great potential but is hindered by a couple of issues.

1) Very small (9/32) spindle. The small spindle spinning slowly does not generate enough oil whirl to keep the bearing true hydrodynamic and the whole thing precesses. I am of belief Technics knew about this as the bearing in the mk3 is much larger in diameter at 16mm. I have designed an inverted bearing that uses the stock motor housing, I am side tracked ATM building a servo linear tracking tonearm, once this is complete I'll build the inverted bearing with a new platter.

2) Motor housing is not rigid and the bearing housing flexes. This will cause the bearing sleeve to also flex and cause erratic vibrational behavior.

3) Bearing sleeve is not an interference press fit as I have had a few come out when changing the ball and thrust pad.

The photo is Bon's platter on my lathe showing the gunmetal insert in the underneath

I should mention Bon's POM platter is 40mm thick and I think there is no advantage to my 60mm POM platter that I could tell.

I also have a peripheral ring that I don't use now I have gone back to a reflex clamp because my Stanton CS-100 rubs on the ring. I pulled the motor apart after a few hundred hrs and there is virtually no wear on the thrust pad. I installed a new Torlon thrust pad and SI3N4 ball when I built the TT.

The minimum platter thickness to use a de-coupled spindle is 20mm POM on a stock platter. I have now made a few POM/stock platters for other SP10mk2 owners and all of them have reported an improvement in detail and a drop in noise.

With the few mods Bon and I have done to our mk2's they will hold their own against almost any TT out there. They are stunningly good.

I also have a peripheral ring that I don't use now I have gone back to a reflex clamp because my Stanton CS-100 rubs on the ring. I pulled the motor apart after a few hundred hrs and there is virtually no wear on the thrust pad. I installed a new Torlon thrust pad and SI3N4 ball when I built the TT.

The minimum platter thickness to use a de-coupled spindle is 20mm POM on a stock platter. I have now made a few POM/stock platters for other SP10mk2 owners and all of them have reported an improvement in detail and a drop in noise.

With the few mods Bon and I have done to our mk2's they will hold their own against almost any TT out there. They are stunningly good.

one of the FG coil broken confirmed.

If it's an outside winding try unwrapping 1 turn and re-solder. Mine was inside so I had to completely unwind the coil

mine was inside too.

Bugger, if you haven't got enough sticking out to solder to you'll have to re-wind the coil. I bought a counter and made a winding rig. I put the old coil on the rig and counted the turns as I pulled the wire off the bobbin.

Bon and Warrjon,

Thank you for your advice!

What I am thinking is to use the platter of my SME 20 table for SP-10 so there is not too much work involved. I may need a part to fit the platter to the platter of SP-10. Or I may ask Warrjon to make one for me. But the postage may be very high from Australia to New York. In any case, I need to find an SP-10 first.

Jim

Thank you for your advice!

What I am thinking is to use the platter of my SME 20 table for SP-10 so there is not too much work involved. I may need a part to fit the platter to the platter of SP-10. Or I may ask Warrjon to make one for me. But the postage may be very high from Australia to New York. In any case, I need to find an SP-10 first.

Jim

Jim, Bon and my platter will not fit a stock SP10 as they have a flat bottom that doesn't go into the strobe recess in the chassis.

My suggestion would be to build a resin/bento (or Panzerholtz or even good quality plywood) plinth for the motor and have a local machine shop make the platter for you. I can give you a drawing of Bon's platter, mine is the same except it's taller.

Moving the motor to a separate plinth is a massive improvement. The stock chassis is very resonant and has loads of bits including the PCB's that will vibrate. If you've done research on the mk2 you have probably come across the bearing drain that some install. IMO the major improvement people report is not only due to draining energy away but the increase in rigidity of holding the bottom of the bearing housing.

The SP10mk2 is a very competent TT in stock form, but the mods Bon and I have done put is squarely in the upper echelon of TT's. Mine scored a Minus K recently and I made a sand box to increase mass so I was in the weight range for the Minus K. My SP10 is now at the point where I can hear reverberation from a drum skin. I had another SP10 owner over my house a couple of weeks ago for me service his TT, he is a Luthier and his comment to me was how spectrallly accurate my TT is and he's heard TT's worth $100k's so we are on the right track here.

My suggestion would be to build a resin/bento (or Panzerholtz or even good quality plywood) plinth for the motor and have a local machine shop make the platter for you. I can give you a drawing of Bon's platter, mine is the same except it's taller.

Moving the motor to a separate plinth is a massive improvement. The stock chassis is very resonant and has loads of bits including the PCB's that will vibrate. If you've done research on the mk2 you have probably come across the bearing drain that some install. IMO the major improvement people report is not only due to draining energy away but the increase in rigidity of holding the bottom of the bearing housing.

The SP10mk2 is a very competent TT in stock form, but the mods Bon and I have done put is squarely in the upper echelon of TT's. Mine scored a Minus K recently and I made a sand box to increase mass so I was in the weight range for the Minus K. My SP10 is now at the point where I can hear reverberation from a drum skin. I had another SP10 owner over my house a couple of weeks ago for me service his TT, he is a Luthier and his comment to me was how spectrallly accurate my TT is and he's heard TT's worth $100k's so we are on the right track here.

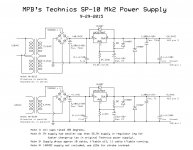

Hi - Apologies for breaking the flow with far less advanced subject matter but I'm building a new PSU for my SP10 mk2, working from a diagram someone had kindly published on the internet (https://sites.google.com/site/mpbarneysources/technics-sp-10-mk2-custom-build).

Parts:

LM317 PCB x2

2x15v talema TRT50215 transformer

2x9v talema PT1209 transformer

Panasonic 6,800uf/80v TSHA cap

F+T 5,600uf/63v cap

Panasonic 1,000uf 25v cap

Panasonic 47uf 50v cap

Panasonic 10uf 50v cap

Vishay 0.1uf 100v film cap x 2

24.335k resistor***

1k resistor***

MUR860 x 8

IN4007 x 6

Lm317HTV x 2

Presumably I can just replace the old strobe lamp with an LED and run it off the 32.5vDC. I wouldn't mind a bit of info on how to do this if anyone feels inclined!

The only parts I have not sourced yet are the 1k and 24.335k resistors - do they need a high power rating or can I get away with using regular 1/2w resistors for this PSU?

Judging by the photos I think the original build had some quite fancy vishay resistors or similar so I just wanted to double check that with you guys about the tolerances before proceeding!

Also thanks to all the contributors on this forum so far, it has been a very informative and interesting read.

Parts:

LM317 PCB x2

2x15v talema TRT50215 transformer

2x9v talema PT1209 transformer

Panasonic 6,800uf/80v TSHA cap

F+T 5,600uf/63v cap

Panasonic 1,000uf 25v cap

Panasonic 47uf 50v cap

Panasonic 10uf 50v cap

Vishay 0.1uf 100v film cap x 2

24.335k resistor***

1k resistor***

MUR860 x 8

IN4007 x 6

Lm317HTV x 2

Presumably I can just replace the old strobe lamp with an LED and run it off the 32.5vDC. I wouldn't mind a bit of info on how to do this if anyone feels inclined!

The only parts I have not sourced yet are the 1k and 24.335k resistors - do they need a high power rating or can I get away with using regular 1/2w resistors for this PSU?

Judging by the photos I think the original build had some quite fancy vishay resistors or similar so I just wanted to double check that with you guys about the tolerances before proceeding!

Also thanks to all the contributors on this forum so far, it has been a very informative and interesting read.

Attachments

Presumably I can just replace the old strobe lamp with an LED and run it off the 32.5vDC. I wouldn't mind a bit of info on how to do this if anyone feels inclined!

The only parts I have not sourced yet are the 1k and 24.335k resistors - do they need a high power rating or can I get away with using regular 1/2w resistors for this PSU?

Judging by the photos I think the original build had some quite fancy vishay resistors or similar so I just wanted to double check that with you guys about the tolerances before proceeding!

Yes you can swap the neon for LED's I did this in one of my SP10's, you can take the 5v for the LED's off the 5v rail on a PCB.

You don't need fancy resistors in this PS 1/4 watt will be fine and the 24k335 and 2k87 resistors I would swap for 50k and 5k trim pots so the output voltage's are adjustable.

Last edited:

Dear SP-10 mk2 fans,

I'm unsure if it is appropriate to post my question in this thread, but it seems a lot of competent people contribute here!

My TT is an SP-10 II mounted on an SH-10B2 plinth and equipped with an EPA-500 armsytem (i.e. an SL-1000 II with EPA-500 instead of the EPA-100). If I slightly knock on the plinth with the cartride tip on a record, but the platter standing still, I can clearly hear the knocking through the speakers even at normal (not loud!) volume level.

My question: Is this normal? A known issue? What, if anything, can be done to make the TT less sensitive against touch-noise? Or should I just not care?

I have heard that other TTs do not show this kind of sensitivity or at least to a lesser degree.

Any help how to mend this issue is much appreciated!

Regards,

Winfried

I'm unsure if it is appropriate to post my question in this thread, but it seems a lot of competent people contribute here!

My TT is an SP-10 II mounted on an SH-10B2 plinth and equipped with an EPA-500 armsytem (i.e. an SL-1000 II with EPA-500 instead of the EPA-100). If I slightly knock on the plinth with the cartride tip on a record, but the platter standing still, I can clearly hear the knocking through the speakers even at normal (not loud!) volume level.

My question: Is this normal? A known issue? What, if anything, can be done to make the TT less sensitive against touch-noise? Or should I just not care?

I have heard that other TTs do not show this kind of sensitivity or at least to a lesser degree.

Any help how to mend this issue is much appreciated!

Regards,

Winfried

Hi Winfried,

This is the perfect place to ask such a question.

It is normal to hear a knock through the speakers when you tap the plinth with the stylus on the record. A phono cartridge is very sensitive. The better the plinth the less you will hear through the speakers. I am not familiar with the Technics plinth I have only seen one and not done any testing on it.

What I can tell you with certainty is placing the SP10 motor unit (that's the whole chassis) in a resin / bentonite (R/B) plinth is a worthwhile upgrade. My first SP10mk2 was in a Lead Console plinth and I also had another SP10mk2 which I mounted in the R/B plinth which was far better damped than the Lead Console.

Improving the SP10 plinth does improve its performance. It all depends on what you want and how much DIY skills you have to build a better plinth. There are a couple of us here that have significantly modified our SP10mk2's going so far as to remove the DD motor from the motor unit chassis and install it separate from the electronics in a R/B plinth. If you decide to improve your SP10 there are a few folk here that would be happy to assist. There is also a writeup some pages back about building a R/B plinth.

This is a photo of my SP10mk2, it's the most highly modified SP10mk2 I know of. There are significant internal modifications to the DD motor to increase stiffness and damp the motor housing. The motor is mounted in a R/B plinth with a 50mm tall Acetal platter.

This is the perfect place to ask such a question.

It is normal to hear a knock through the speakers when you tap the plinth with the stylus on the record. A phono cartridge is very sensitive. The better the plinth the less you will hear through the speakers. I am not familiar with the Technics plinth I have only seen one and not done any testing on it.

What I can tell you with certainty is placing the SP10 motor unit (that's the whole chassis) in a resin / bentonite (R/B) plinth is a worthwhile upgrade. My first SP10mk2 was in a Lead Console plinth and I also had another SP10mk2 which I mounted in the R/B plinth which was far better damped than the Lead Console.

Improving the SP10 plinth does improve its performance. It all depends on what you want and how much DIY skills you have to build a better plinth. There are a couple of us here that have significantly modified our SP10mk2's going so far as to remove the DD motor from the motor unit chassis and install it separate from the electronics in a R/B plinth. If you decide to improve your SP10 there are a few folk here that would be happy to assist. There is also a writeup some pages back about building a R/B plinth.

This is a photo of my SP10mk2, it's the most highly modified SP10mk2 I know of. There are significant internal modifications to the DD motor to increase stiffness and damp the motor housing. The motor is mounted in a R/B plinth with a 50mm tall Acetal platter.

one of the FG coil broken confirmed

broken or interrupted?

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread