Perceived difference is more complicated after a long time, because two

phenomenon are involved - Potential differences due to long term

operation of the amplifier and internal adjustment on the part of the

listener. Of those, it seems that the latter is usually a bigger effect.

works for wife too..

I'm confident that, in the last 25 years or so, more than one Class A amplifier manufacturer has shipped a Review Unit to a Big Important Reviewing Person who writes for a Very Influential Magazine ... ... where the manufacturer took special pains to run that Review Unit for hundreds and hundreds of hours before shipping it to the Reviewer. You know, to guarantee reliability and to assess Very Long Term bias stability and other unassailably plausible, realistic explanations.

I'm confident that more than one printed final review of such a unit has stated "the amplifier sounded like complete crap for the first 3 hours, until after I burned it in thoroughly," much to the amusement of the manufacturer who had already burned in the amplifier more than 150 hours. But why would the mfr actually divulge this? To embarrass the reviewer? That would be suicidal. No, they would keep it to themselves and (maybe!) share the story with other manufacturers at the bar of the AES convention (or the Munich audio show), sometime after 1:00AM.

I'm confident that more than one printed final review of such a unit has stated "the amplifier sounded like complete crap for the first 3 hours, until after I burned it in thoroughly," much to the amusement of the manufacturer who had already burned in the amplifier more than 150 hours. But why would the mfr actually divulge this? To embarrass the reviewer? That would be suicidal. No, they would keep it to themselves and (maybe!) share the story with other manufacturers at the bar of the AES convention (or the Munich audio show), sometime after 1:00AM.

I'm confident that, in the last 25 years or so, more than one Class A amplifier manufacturer has shipped a Review Unit to a Big Important Reviewing Person who writes for a Very Influential Magazine ... ... where the manufacturer took special pains to run that Review Unit for hundreds and hundreds of hours before shipping it to the Reviewer. You know, to guarantee reliability and to assess Very Long Term bias stability and other unassailably plausible, realistic explanations.

I'm confident that more than one printed final review of such a unit has stated "the amplifier sounded like complete crap for the first 3 hours, until after I burned it in thoroughly," much to the amusement of the manufacturer who had already burned in the amplifier more than 150 hours. But why would the mfr actually divulge this? To embarrass the reviewer? That would be suicidal. No, they would keep it to themselves and (maybe!) share the story with other manufacturers at the bar of the AES convention (or the Munich audio show), sometime after 1:00AM.

Man, I’d love to be a fly on the wall for some of these stories!

It's a controversial subject, to say the least. I understand that mechanical pieces require some burn in, like speaker diafragms. But I have always wondered why audio is the only 'realm' where burn in happens and why doesn't the same principles apply to other disciplines: why a TVs color does not change in the first days, or why a computer is able to run to its full specs from the first millisecond, or a microwave! Yet, audio requires for the components to change during the first hundreds of hours.

I would like a scientific explanation. If someone says that the dielectric in a capacitor changes over the first few hours, or that a transistor's response curve is different after a few days, then I am all ears. But most every 'scientific' minds usually say it is you who are 'burning in' to the sound of the amp: your brain learning to 'decode' the abstraction of sound that is the sum of sounds a system puts out.

That, I can truly believe: animals are not able to abstract the sounds... a dog barking through speakers will fool no dog, a cat complaining over speakers will never grab my cats attention. Our brain needs to learn how to interpret the sound into instruments and voices, and that probably does require burn in.

But again, if there is scientific reasons behind burn in, I'd love to learn about them! It's an interesting subject, perhaps not one to discuss here?

Best regards,

Rafa.

Ps: of course, heating up a component is thoroughly documented, and that is no 'audio voodoo'. Components need to warm up to reach stable performance.

On one of the Stereophile test disks there is a dog barking for one test or the other. When that came over the speakers, all 3 cats went about 3 feet high...

Russellc

Yes, this... exactly!It is of course a fact that amplifiers change as they warm up, easily

documented by measurements. Toward that end, we want to think in

terms of an hour+ of operating time if we are doing our most critical

listening. One could argue that it might sound better cold, but there

is a good reason why they usually don't - typically the bias of output

stages is low at turn-on and increases as they warm up. Your better

high end manufacturers will adjust and re-adjust bias after some hours

of operation.

Perceived difference is more complicated after a long time, because two

phenomenon are involved - Potential differences due to long term

operation of the amplifier and internal adjustment on the part of the

listener. Of those, it seems that the latter is usually a bigger effect.

You are truly an inspiration Mr. Pass! Thanks for all that you share and teach. I can't wait to hear one of your amps... the DIY first, and, hopefully some day, one of their 'bigger' brothers.

Best regards,

Rafa.

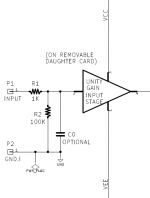

Can all these daughter cards be used as a stand alone buffer preamp? I kind of like the sound of Mountain views.

And I figure, the 220uf combines with resistance of primary coil 600R, form a highpass filter with cut-off frequency around 1.2hz, if we reduce output C to 100uf or even 47uf the cut-off frequency goes up to 3-5Hz, that is still low enough for audio right? Is there something else behind 220uf?

And I figure, the 220uf combines with resistance of primary coil 600R, form a highpass filter with cut-off frequency around 1.2hz, if we reduce output C to 100uf or even 47uf the cut-off frequency goes up to 3-5Hz, that is still low enough for audio right? Is there something else behind 220uf?

Last edited:

Maybe a buffer preamp might need an Input Stage daughter card and also components R1, R2, C0 from the M2x main amplifier board. This would depend upon the implementation details of the rest of the preamp, such as input selection, volume control, stereo/mono switching, muting to prevent turn on/off thumps, and so forth.

Please feel free to select component values and/or part types however you wish. The hobby is, after all, Do It Yourself audio. Want to change the low frequency roll-off? Do it! Want to get rid of the MV5075C red LED in Mountain View with its super annoying "Do Not Substitute!" directive? Redesign it! Do it! Do you prefer a TI video speed buffer chip for Norwood, rather than the Harris HA5002? Change it! Experiment and have fun.

~

Please feel free to select component values and/or part types however you wish. The hobby is, after all, Do It Yourself audio. Want to change the low frequency roll-off? Do it! Want to get rid of the MV5075C red LED in Mountain View with its super annoying "Do Not Substitute!" directive? Redesign it! Do it! Do you prefer a TI video speed buffer chip for Norwood, rather than the Harris HA5002? Change it! Experiment and have fun.

~

Attachments

SOLD OUT ... SOLD OUT ... SOLD OUT ... PRE-PRODUCTION M2x BOARD SETS

PCB will be available in the diyAudio Store in the not-to-distant future. Watch this thread for more info!

any update?

Does anyone have the transformer's model parameters? I was fooling around with driving the center tap and making the top half of the primary part of the autoformer, this gives ~22dB step up at ~.25 the input impedance. The Norwood should have no problem with this. Now just using an ideal transformer to compute the values.

Scott, I have extra transformers, want me to mail you three of them? One to measure and two to build a stereo amplifier.

They are brand new PC600-15K Edcors, shipped straight to me from the factory in January 2018.

edit- BTW, edcor's website has downloadable measurement data including frequency response, but I wasn't able to make a lumped parameter model from their published curve. Maybe you'll have better ideas about what to try and how to interpret the data.

They are brand new PC600-15K Edcors, shipped straight to me from the factory in January 2018.

edit- BTW, edcor's website has downloadable measurement data including frequency response, but I wasn't able to make a lumped parameter model from their published curve. Maybe you'll have better ideas about what to try and how to interpret the data.

Last edited:

Edcor must have made up a few of the transformers. Ordered on Sunday, shipping notice on Tuesday. Website still says it could take up to 8 weeks.

I ordered the previous Saturday, and they were on my doorstep in 6 days!

as this would be my first firstwatt amp i have a few questions regarding the power supply. how much power do i need for each channel? would it be appropriate to follow one of 6L6's build guides (f5 for example) and build the supply accordingly?

i noticed that in the build guides often diyAudio Psu boards are used without the discrete diode bridge. instead bridge rectifiers are used. whats the reason to choose one over the other?

i noticed that in the build guides often diyAudio Psu boards are used without the discrete diode bridge. instead bridge rectifiers are used. whats the reason to choose one over the other?

To build a suitable power supply for two channels of M2x amplifier you need

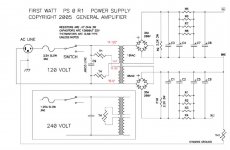

The schematic of the power supply that Nelson Pass / First Watt installed in the M2 amplifiers he sold to paying customers, is attached below. It specifies electrolytic capacitors rated 25VDC but I admit, the ones I bought for my M2x build are rated 35 volts. I like a big safety margin, myself.

I use GBPC3510 bridge rectifier blocks in my M2x build, because I like bolting them to the chassis floor for heat dissipation. I also like the safety margin of using 35A rectifiers when 8A would have been enough. I happen to approve of transformer snubbers* and use them {2C,1R topology} in my M2x supply, but others feel transformer snubbers are a waste of time. To each his own.

Good old 6L6 enthusiastically recommends the Universal PSU boards sold by the diyAudio store, and in fact that's what HE used to build HIS M2x. You can view post #2 of this thread to see nice photos of his M2x amp. If you look closely you can spot the bridge rectifier assemblies in his M2x, bolted to the chassis floor, partly obscured by the orange wires and the yellow wires.

*diyAudio search term is "Quasimodo". Honest.

_

- A 300VA mains transformer with dual 18VAC secondaries (Antek AS-3218 (link))

- Rectifiers rated 8 amperes or more, continuous forward current

- Suitable electrolytic capacitors

I use GBPC3510 bridge rectifier blocks in my M2x build, because I like bolting them to the chassis floor for heat dissipation. I also like the safety margin of using 35A rectifiers when 8A would have been enough. I happen to approve of transformer snubbers* and use them {2C,1R topology} in my M2x supply, but others feel transformer snubbers are a waste of time. To each his own.

Good old 6L6 enthusiastically recommends the Universal PSU boards sold by the diyAudio store, and in fact that's what HE used to build HIS M2x. You can view post #2 of this thread to see nice photos of his M2x amp. If you look closely you can spot the bridge rectifier assemblies in his M2x, bolted to the chassis floor, partly obscured by the orange wires and the yellow wires.

*diyAudio search term is "Quasimodo". Honest.

_

Attachments

Last edited:

Thank you very much for your time to explain!

Could one also use the rectifier part of the diyAudio PSU board instead of the bridge blocks you recommend? In fact the bridge blocks seem to be more *plug and play* and thus more appealing to me - just curious why one would choose them instead of the other option.

Regarding snubbers i yet have to research what they actually do before i can decide whether or not i need them . i'll search quasimodo.

. i'll search quasimodo.

nelson pass seems to specify 15000uF caps, seems like a lot of people use 22000uF - a matter of more is better?

Could one also use the rectifier part of the diyAudio PSU board instead of the bridge blocks you recommend? In fact the bridge blocks seem to be more *plug and play* and thus more appealing to me - just curious why one would choose them instead of the other option.

Regarding snubbers i yet have to research what they actually do before i can decide whether or not i need them

nelson pass seems to specify 15000uF caps, seems like a lot of people use 22000uF - a matter of more is better?

- Home

- Amplifiers

- Pass Labs

- The diyAudio First Watt M2x