planet10 said:

That is a very interesting analytical result. With the energy available to excite a resonance decreasing at approx the square of the frequency, that gives plywood a 4-fold advantage over the MDF.

I'll let Chris comment of the difference between finishing ply & MDF...

dave

Very interesting indeed, however the real question is how much absolute energy is available to excite resonance at 500 Hz in the first place...

Nevertheless this result causes me to consider plywood as a very attractive alternative. Actually when I look at the mechanical material properties plywood has a superior strength to weight ratio.

chrisb said:

here we go again ...........

my 2 cents worth:

depending on the grade of finish you're looking for, MDF can be as easy as a quick couple of coats of texture spray paint and clear top coat polyurethane, or a whole 'nother world of pain for high gloss "piano" grade finish.

As others have noted extensively in another thread, conditioning, sealing, priming and prepping MDF for a high quality, durable paint job can easily take several times longer than the enclosure fabrication

.....blabla.....

Finishing then becomes a question of stain or not?, and then several spray coats of post catalyzed nitro cellulose lacquer. As Ed Schilling would say: "After over 10 years of doing this, I've found something that works for me - so 'nuff said"

Thank you for the info, based on my experience I agree with you that finishing MDF in a very nice way will indeed be very time consuming, but to me this is'nt a big problem.

The thing is; I have a finish in mind using a part veneered look, and part black paint, something like these:

An externally hosted image should be here but it was not working when we last tested it.

(Or the other way around, black front and veneered back)

I plan on using pre-veneered mdf or plywood for the veneered part.

Furthermore, could you elaborate a bit regarding milling the baffle using plywood?, because that is my main concern, MDF will be very easy and smooth, using plywood I have no idea....

Oh yeah, I take it for granted that shrinking etc. using plywood is just as unimportant as with MDF?

Update!:

In the past days I was busy making a test cabinet, but had some delays due the fact that we needed a new circular saw.

Finished the cabinet yesterday, and today I took them for a spin, on purpose I first tested the fully closed version of 4.5 litre, without any internal stuffing. Off-course this one had a very heavy 100-150 Hz region, and sounded very hollow, but this was quickly solved by adding some stuffing.

Next I made the 7, 13 and finally 20 aperiodic holes , and used the same damping material to create the resistance material (pritex).

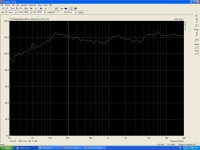

Adding holes did decrease the 'boominess' a bit, but I'm not entirely convinced. Measurements (uncalibrated and cheap mic) showed there is a indeed still a bump in the bass region, and a dip from 500-1000 Hz, this is exactly what I heard, the speaker sounds to muffled for my liking.

Playing dire strait's sultans of swing for example exactly 'attacked' this behavior and the bass line is far top pronounced, while the voices are too muffled. Below some of the measurements, beware that this is measured with not too great accuracy, but they show some of the trends I'm hearing.

Any suggestions as to what I can do next?, I have tried pritex, and real sheep wool (we had sheep 10 years ago ) alone and combined. At the moment I have some piece of pritex pressed against the aperiodic holes. I also have acces to some cork but I have still to try it.

) alone and combined. At the moment I have some piece of pritex pressed against the aperiodic holes. I also have acces to some cork but I have still to try it.

Maybe I make my final version a bit wider and less deep, any comments on how this affects the response?

In the past days I was busy making a test cabinet, but had some delays due the fact that we needed a new circular saw.

Finished the cabinet yesterday, and today I took them for a spin, on purpose I first tested the fully closed version of 4.5 litre, without any internal stuffing. Off-course this one had a very heavy 100-150 Hz region, and sounded very hollow, but this was quickly solved by adding some stuffing.

Next I made the 7, 13 and finally 20 aperiodic holes , and used the same damping material to create the resistance material (pritex).

Adding holes did decrease the 'boominess' a bit, but I'm not entirely convinced. Measurements (uncalibrated and cheap mic) showed there is a indeed still a bump in the bass region, and a dip from 500-1000 Hz, this is exactly what I heard, the speaker sounds to muffled for my liking.

Playing dire strait's sultans of swing for example exactly 'attacked' this behavior and the bass line is far top pronounced, while the voices are too muffled. Below some of the measurements, beware that this is measured with not too great accuracy, but they show some of the trends I'm hearing.

Any suggestions as to what I can do next?, I have tried pritex, and real sheep wool (we had sheep 10 years ago

Maybe I make my final version a bit wider and less deep, any comments on how this affects the response?

Attachments

I just stumbled across the hobbyhifi measurements and the peak between 1000-2000 Hz is clearly a driver property, their measurements do also show the other global properties, so actually there is not much going wrong here. But this doesn't solve the problem although after some more listening, I think that if I can reduce the bass peak I'm rather happy.

Well, the 4.5litre box is definitely a compromise in terms of trying to squeeze maximum performance from this driver.

FWIW, having built a few of them, I think the best sounding Planet10 enclosure for either the FR125 (or the Fostex FE127E), in terms of extension and smooth control of bass roll-off in the smallest cabinet, is the mini-onken / Fonken. It is however, several times the net cubic volume of this little guy.

Measurements are fun, but for a quick test to verify if what you're hearing is the box or the driver, I'd suggest quickly mounting them on a small open baffle ( 4ft^2 or so - even stiff cardboard would suffice for low volume levels). All "full-range" speakers have some degree of compromise, and it could be that some of what you're missing from the vocal projection is inherent in the driver.

FWIW, having built a few of them, I think the best sounding Planet10 enclosure for either the FR125 (or the Fostex FE127E), in terms of extension and smooth control of bass roll-off in the smallest cabinet, is the mini-onken / Fonken. It is however, several times the net cubic volume of this little guy.

Measurements are fun, but for a quick test to verify if what you're hearing is the box or the driver, I'd suggest quickly mounting them on a small open baffle ( 4ft^2 or so - even stiff cardboard would suffice for low volume levels). All "full-range" speakers have some degree of compromise, and it could be that some of what you're missing from the vocal projection is inherent in the driver.

Yes I can understand that, and I do not expect a perfect speaker, maybe I'm just to accustomed to my other speakers. I've to say that these FR125's do immediately reveal if a recording is clipped even the slightest bit. I first thought foobar's replay gain plugin messed my music collection up

, but comparing the files with the ones on my 20 gb mp3 (wich I've not updated for several months) revealed I was mistaken.

, but comparing the files with the ones on my 20 gb mp3 (wich I've not updated for several months) revealed I was mistaken.  (I'm not totally sure however)

(I'm not totally sure however)

, but comparing the files with the ones on my 20 gb mp3 (wich I've not updated for several months) revealed I was mistaken.

, but comparing the files with the ones on my 20 gb mp3 (wich I've not updated for several months) revealed I was mistaken. Well it is time for an update

Last weeks I was busy buying materials and getting my hand dirty....

so here we go...

First of all, I choose 10 mm birch plywood for the cabinet, except the baffle which is 12 mm.

Then I choose to veneer the baffle with watery (don't know if this is the correct english term) maple. The maple sheets were just a little wider then my baffle so that was very handy.

I'm compressor spray painting the remainder of the cabinet satin black.

Some pictures:

The test cabinet:

The veneered baffle:

The 'watery' effect:

The cabinets in my paint 'room'

Monitoring temperature and humidity to prevent paint surprises

TEASER; laying out the parts for the accompanying amplifier ;

To do list:

- Finishing the paint job

- Sanding an applying danish oil to the veneer ,any tips to what the finest grade sandpaper is I should use?.

- Testing these cabinets and determining final stuffing

- Manufacturing the case of my amplifier project

- Finish and listen

Last weeks I was busy buying materials and getting my hand dirty....

so here we go...

First of all, I choose 10 mm birch plywood for the cabinet, except the baffle which is 12 mm.

Then I choose to veneer the baffle with watery (don't know if this is the correct english term) maple. The maple sheets were just a little wider then my baffle so that was very handy.

I'm compressor spray painting the remainder of the cabinet satin black.

Some pictures:

The test cabinet:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

The veneered baffle:

An externally hosted image should be here but it was not working when we last tested it.

The 'watery' effect:

An externally hosted image should be here but it was not working when we last tested it.

The cabinets in my paint 'room'

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Monitoring temperature and humidity to prevent paint surprises

An externally hosted image should be here but it was not working when we last tested it.

TEASER; laying out the parts for the accompanying amplifier ;

An externally hosted image should be here but it was not working when we last tested it.

To do list:

- Finishing the paint job

- Sanding an applying danish oil to the veneer ,any tips to what the finest grade sandpaper is I should use?.

- Testing these cabinets and determining final stuffing

- Manufacturing the case of my amplifier project

- Finish and listen

Speedsmile said:- Sanding an applying danish oil to the veneer ,any tips to what the finest grade sandpaper is I should use?.

When doing an oil finish, I quit at 220 grit. Between coats, I rub with 0000 steel wool.

Bob

Speedsmile said:Ha ha, just too late, but thanks anyway, I have sanded them now, ended at 400 grit very nice and smooth now.

Great! The only problem of going that high is that if staining a hard, non-porous wood, the stain may not penetrate very well.

Bob

Yes I expected that, but I don't think it will be a problem in this case, however I suspect that if you are a real diehard you could let maple look like a mirror....

Anyway because it is too rainy (humidity too high) to paint I couldn't resist and took one of the cabinets out of my paint room, lay the baffle on top of it, including the driver, and I'm already very pleased with the look:

Anyway because it is too rainy (humidity too high) to paint I couldn't resist and took one of the cabinets out of my paint room, lay the baffle on top of it, including the driver, and I'm already very pleased with the look:

An externally hosted image should be here but it was not working when we last tested it.

Speedsmile said:...........I'm already very pleased with the look:..........

DUH!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- The CSS-FR125S in 4.5 litre aperiodic (planet10 design)