As Brian refer, this is a more modern model to better take advance of volume space inside cabin, it makes little hard to glue angled panels.

https://freeloudspeakerplan.rf.gd/pages/th-ss2.htm

Below the way I built my box.

It affect compression ratio and the upper range of the frequency response. If considered in the design it will be good, if not and you add it later it may increase the cone stress leading to unwanted noise or reduced life for the cone.

https://freeloudspeakerplan.rf.gd/pages/th-ss2.htm

Below the way I built my box.

It affect compression ratio and the upper range of the frequency response. If considered in the design it will be good, if not and you add it later it may increase the cone stress leading to unwanted noise or reduced life for the cone.

Attachments

Hello folks,

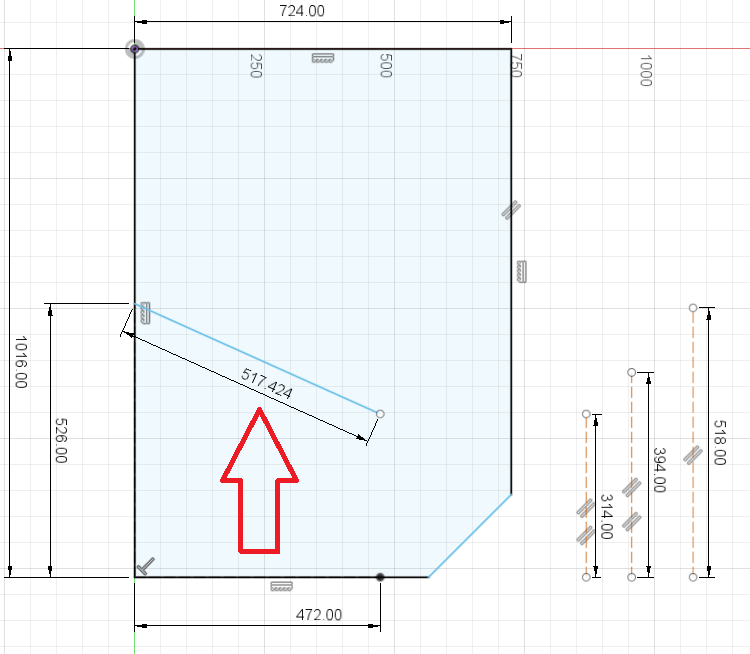

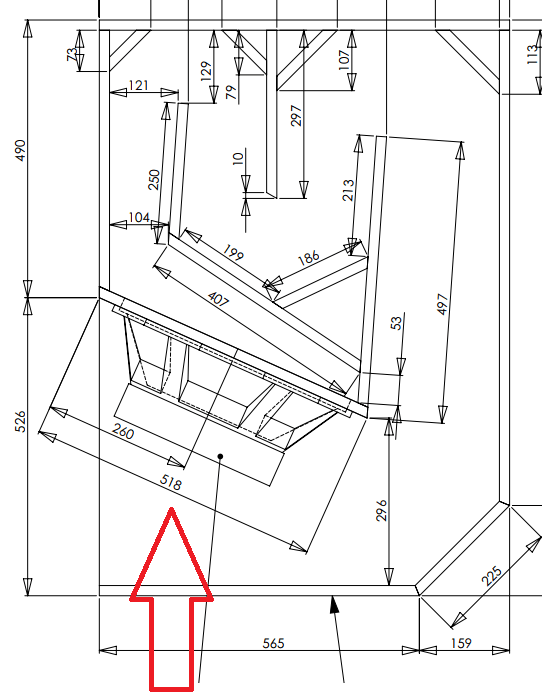

I'm laying out the TH18 side panel in Fusion 360 so I can CNC some side panels, and the measurements in the plan don't always seem to match with reality.

By coincidence, I see that @YoungD has posted just a few days ago with similar concerns about the plans.

For example, when I place this line which will be the bottom face of the speaker baffle, it should be 518mm (as per plan) but in reality, that line measures just over 0.5mm shorter

Does this type of minor discrepancy matter? As long as everything fits, I guess that <1mm differences won't make much of a difference to the frequency response of the cabinet right?

I attached the plan I've used, which appears to be the one which plenty of people used before the discussions about cone correction started.

Thanks!

I'm laying out the TH18 side panel in Fusion 360 so I can CNC some side panels, and the measurements in the plan don't always seem to match with reality.

By coincidence, I see that @YoungD has posted just a few days ago with similar concerns about the plans.

For example, when I place this line which will be the bottom face of the speaker baffle, it should be 518mm (as per plan) but in reality, that line measures just over 0.5mm shorter

Does this type of minor discrepancy matter? As long as everything fits, I guess that <1mm differences won't make much of a difference to the frequency response of the cabinet right?

I attached the plan I've used, which appears to be the one which plenty of people used before the discussions about cone correction started.

Thanks!

Attachments

kindly post measurements of this small thAs Brian refer, this is a more modern model to better take advance of volume space inside cabin, it makes little hard to glue angled panels.

https://freeloudspeakerplan.rf.gd/pages/th-ss2.htm

Below the way I built my box.

It affect compression ratio and the upper range of the frequency response. If considered in the design it will be good, if not and you add it later it may increase the cone stress leading to unwanted noise or reduced life for the cone.

kindly post measurements of this small th

The model is available for download, check the link again in the upper side.

It's a CAD model, so all information is there.

Thanks for the tip. There is still so much to learn and read.This is how I dealt with the "cone compensation" issue with one of my builds. Unfortunately it didn't make to long term use, but that was due to other reasons that had nothing to do with the design .

View attachment 1251849

Still need to learn Hornresp to check the model. I used the excel (that you made, wow!) on DIY Subwoofers.org to check the measurement points on the folded horn. Does this design look viable to you, mostly regarding the corners and overall angles? Also I'm in interested in that are the corners accurate enough or should I try to tweak the dimensions to fit more closely on the 4 degree expansion? All straights are at 4 degree now except the first and the last bit. Cone compensation was measured with a triangle, is there a better way to do it?

Thanks to everyone so far and also in advance.

Alright, here we go with a simple build using 18SW115.

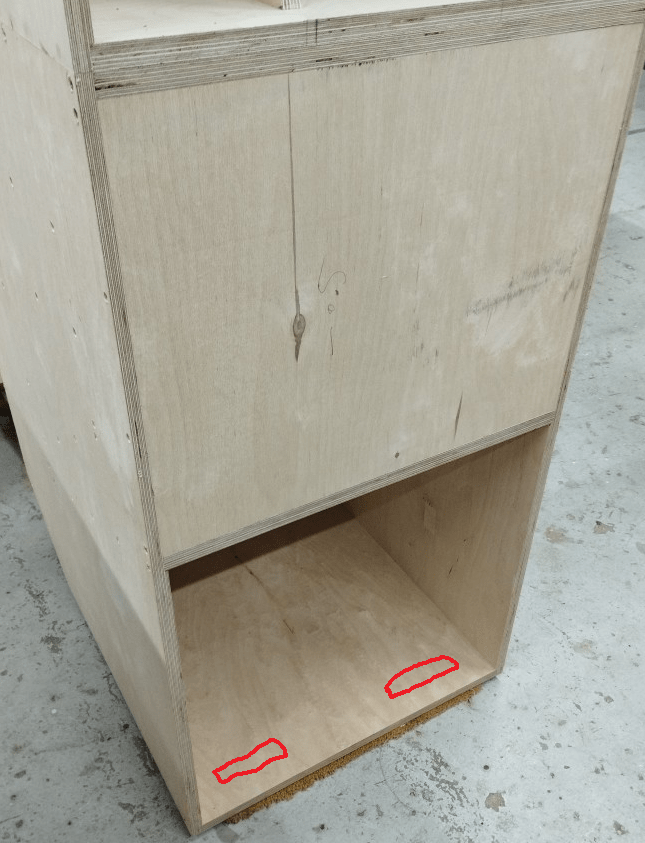

Today's progress - side panels CNCed and other panels cut on cabinet #1 of 2

Test fit looks OK.

Tomorrow I need to

Then I should be ready to glue this one together.

A few photos ....

One question...

In addition to the handle holes at the back, can I also put two hand hole cut outs on the bottom panel as indicated here?

It would help a lot with carrying to have one person at each end, but will these hooes affect the performance of the cabinet when the base panel is flat on the floor?

Cheers!

- reflectors removed

- no cone correction

Today's progress - side panels CNCed and other panels cut on cabinet #1 of 2

Test fit looks OK.

Tomorrow I need to

- cut hand holes in the top / back panel for handles hidden behind the reflector

- Cut a recess for the speakon panel in the back panel

- cut some brace pieces and get those mounted

Then I should be ready to glue this one together.

A few photos ....

One question...

In addition to the handle holes at the back, can I also put two hand hole cut outs on the bottom panel as indicated here?

It would help a lot with carrying to have one person at each end, but will these hooes affect the performance of the cabinet when the base panel is flat on the floor?

Cheers!

Niceeee build!!! How do you cut the plywood?Alright, here we go with a simple build using 18SW115.

- reflectors removed

- no cone correction

Today's progress - side panels CNCed and other panels cut on cabinet #1 of 2

Test fit looks OK.

Tomorrow I need to

- cut hand holes in the top / back panel for handles hidden behind the reflector

- Cut a recess for the speakon panel in the back panel

- cut some brace pieces and get those mounted

Then I should be ready to glue this one together.

A few photos ....

View attachment 1254683

View attachment 1254688

View attachment 1254690

One question...

In addition to the handle holes at the back, can I also put two hand hole cut outs on the bottom panel as indicated here?

It would help a lot with carrying to have one person at each end, but will these hooes affect the performance of the cabinet when the base panel is flat on the floor?

View attachment 1254696

Cheers!

How much the beast weight including the driver?

Hey can you do a freq test when you finish it and last but not least, what amp will drive the Monstaaaa!! ?

PD. I'm seeing a nice shop in the background of the pics , a table saw?

So you a pro woodsmith! 😜

Thank you. I added themThe hole should not have any noticeable impact.

WIll add them afterwards if I feel like they're needed. Lifting it by two people using the handles at the top rear and bottom front actually seems pretty easyConsider putting handles on the sides as well.

Yes, this is an excellent idea.You could always do a test run with the side panel just screwed down with / without reflectors, cone correction etc. to confirm what impact they will have.

I work in a workshop with a big Felder sliding arm table saw so I used that.Niceeee build!!! How do you cut the plywood?

I'll weigh it at the endHow much the beast weight including the driver?

Will try, but it'll be indoorsHey can you do a freq test when you finish it

I'm thinking about Admark AD442.and last but not least, what amp will drive the Monstaaaa!! ?

My day job :So you a pro woodsmith! 😜

Anyway, some photos.

The 1st TH18 is glued together except for one side panel. Number two will follow later this week, when I've cleared some customer work out of the way.

CNC brace parts

Test fit of the braces

Congratulating myself cos I remembered to paint the inner parts of the back handles before glue up

Kicking myself cos I forgot to paint this little triangle on the side panel before glue up haha.

I should be able to get some spray paint through the hand holes to cover this little patch

All internal panels, sides, top, bottom and braces glued and then left for the night. Then I did test fit of the driver just to see how it looks

After some gentle persuasion with a rubber mallet to get the second side panel on, and a few screws in, one TH18 is pretty much done.

My stack as it currently stands. 2 x TH18 subs with 18SW115, 2 x Cubo kicks with 15ND930. Everything's about 80% done at this point.

After a lot of reading and research, I think I'm probably going to go for Syntripps for the tops.

More to follow soon!

Last edited:

Hello TH18 gang! Very interesting thread and super nice cab design, thanks to everyone involved!

I'm planning a build of 3 Th18 loaded with 18SW115. I've got 6 sheets of nice ply but haven't ordered drivers or started making sawdust yet. The goal is to play dub, reggae, dubstep and drum and bass music.

I have some questions related to low end extension, which is the only thing I'm worried about with this choice of cab. I play a lot of sub heavy music with some tracks fundamentals as low as 31hz. I realize the TH18 will struggle with those specific notes (which are quite rare) but I can't store anything bigger and I'm not willing to give up the overall sensitivity of a horn and build reflex. Besides, the sims of 4 cabs with 18sw115 on page 1 show max output of 135db@30hz which is nothing to sneeze at, even if the rolloff below 39hz is very steep.

Does doing the cone correction extend the low frequency response of the cab? If so, roughly how much? I'm debating whether I should attempt to work it out myself or just go with the v1 plan. I care much more about low end extension than 100hz. Has anyone measured v1 vs cone corrected cabs under otherwise identical conditions?

If do try to work it out myself, how much damage can I do to the performance of the cab if I don't get it precisely "right"? I've got the general idea of it but I'm afraid of doing more harm than good to an otherwise good design.

Where should I set my high pass filters and with what slopes in order to keep the drivers from hitting excursion limits or "losing control"? In the best case scenario I'll be running each cab off a proline 3000 that can potentially put 3.5kw into a single 4 ohm driver and I really don't want to damage the drivers. This will also give me an idea of the low end capability of the cab. I'm using a Behringer Ultradrive DCX 2496 as my crossover.

I'm planning a build of 3 Th18 loaded with 18SW115. I've got 6 sheets of nice ply but haven't ordered drivers or started making sawdust yet. The goal is to play dub, reggae, dubstep and drum and bass music.

I have some questions related to low end extension, which is the only thing I'm worried about with this choice of cab. I play a lot of sub heavy music with some tracks fundamentals as low as 31hz. I realize the TH18 will struggle with those specific notes (which are quite rare) but I can't store anything bigger and I'm not willing to give up the overall sensitivity of a horn and build reflex. Besides, the sims of 4 cabs with 18sw115 on page 1 show max output of 135db@30hz which is nothing to sneeze at, even if the rolloff below 39hz is very steep.

Does doing the cone correction extend the low frequency response of the cab? If so, roughly how much? I'm debating whether I should attempt to work it out myself or just go with the v1 plan. I care much more about low end extension than 100hz. Has anyone measured v1 vs cone corrected cabs under otherwise identical conditions?

If do try to work it out myself, how much damage can I do to the performance of the cab if I don't get it precisely "right"? I've got the general idea of it but I'm afraid of doing more harm than good to an otherwise good design.

Where should I set my high pass filters and with what slopes in order to keep the drivers from hitting excursion limits or "losing control"? In the best case scenario I'll be running each cab off a proline 3000 that can potentially put 3.5kw into a single 4 ohm driver and I really don't want to damage the drivers. This will also give me an idea of the low end capability of the cab. I'm using a Behringer Ultradrive DCX 2496 as my crossover.

Not much if at all.Does doing the cone correction extend the low frequency response of the cab? If so, roughly how much?

Don't recall any measurements under otherwise identical conditions, but reports of better "cone control" using "correction" as illustrated in post 1427 have been reported.Has anyone measured v1 vs cone corrected cabs under otherwise identical conditions?

Any air leaks will reduce performance greatly, the throat changes will affect how "clean" the driver sounds at high excursions, and probably extend the driver's suspension life.If do try to work it out myself, how much damage can I do to the performance of the cab if I don't get it precisely "right"?

The Fb/impedance and excursion minima is around 35Hz, a BW24 at around 30Hz will keep low frequency excursion under control even with the EQ required to flatten response to 34-35Hz.Where should I set my high pass filters and with what slopes in order to keep the drivers from hitting excursion limits or "losing control"?

The B&CSW115-4 excursion around 45Hz could be kept under control with peak limiting around 1700 "watts"/82 volts.

Most DJ's driver deaths are due to thermal failures, long term "RMS" limiting with a time constant of longer than 500 ms (milliseconds) should be set to around 850 "watts"/58volts.

Art

Thanks Art

Perfect, then I think I'll stick to the V1 plans since it's less likely that I'll make mistakes with fewer angles to cut. I'll definitely take out the corner reflectors though.

Again many thanks Art and everyone in this thread. I'll post pictures once I start making sawdust.

Not much if at all.

Perfect, then I think I'll stick to the V1 plans since it's less likely that I'll make mistakes with fewer angles to cut. I'll definitely take out the corner reflectors though.

Absolutely. I've spent way too much on this birch ply to put it together with anything other than perfect joints.Any air leaks will reduce performance greatly, the throat changes will affect how "clean" the driver sounds at high excursions, and probably extend the driver's suspension life.

That's great news. 30hz BW24 sounds perfect, I was worried it was going to be higher. I still need to work out the exact limiter settings to use on the Ultradrive but that's a problem for future me that has actually finished building the cabs and bought bigger amps.The Fb/impedance and excursion minima is around 35Hz, a BW24 at around 30Hz will keep low frequency excursion under control even with the EQ required to flatten response to 34-35Hz.

The B&CSW115-4 excursion around 45Hz could be kept under control with peak limiting around 1700 "watts"/82 volts.

Most DJ's driver deaths are due to thermal failures, long term "RMS" limiting with a time constant of longer than 500 ms (milliseconds) should be set to around 850 "watts"/58volts.

Again many thanks Art and everyone in this thread. I'll post pictures once I start making sawdust.

Since this is the DIY forum

and WE the people who can't afford dynacord's ,labgruppen's , Powersoft's (just to name a few)

can get some

Admark, Sanway and CVR as amplification

cause if we can get $5k amps , we just order a turnkey system from Lacoustics, Dbtech or Meyer to say some

in the meantime , second hand , refurbished or no name new is the word

and DIY cabinets

and WE the people who can't afford dynacord's ,labgruppen's , Powersoft's (just to name a few)

can get some

Admark, Sanway and CVR as amplification

cause if we can get $5k amps , we just order a turnkey system from Lacoustics, Dbtech or Meyer to say some

in the meantime , second hand , refurbished or no name new is the word

and DIY cabinets

Thanks for the tip. There is still so much to learn and read.

View attachment 1252808

Thanks to everyone so far and also in advance.

You won't lose much if any low-frequency performance if you build it like the example below, and it should be a slightly easier build, and I suspect a bit safer for the driver as well.

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)