Well I thought the idea was a more modern test LP that could be used with a sound card, a computer and whatever software the user likes. The original signals could be hosted there. But consideration for old test gear could be made.

As I look at the thread, I keep wanting fewer tracks, not more. With a soundcard and software you can do so much with so few signals. My test LP might have 4 tracks on it, so take that into consideration when reading my posts.

As I look at the thread, I keep wanting fewer tracks, not more. With a soundcard and software you can do so much with so few signals. My test LP might have 4 tracks on it, so take that into consideration when reading my posts.

Do the DMM have a better stamper life? Even if they don't, a mastering plant that has put everything if software before the cut could make another copy easily enough.

I believe the stamper is essentially the same whether a lacquer or metal master. The master makes the stamper.

The stamper may be of higher fidelity, but the wear on the stamper is roughly the same as its the same technology.

You may get more albums from it at an “acceptable” fidelity for mass consumption, but I’m doubtful it would help us for this use case.

I believe the most obsessive of Japanese pressings get about 500 LPs to a stamper. You can get about 10 stampers from a mother.

If I’m not mistaken the process is roughly:

Lacquer makes a father ~1

Father makes a mother ~ 10

Mother makes a stamper ~10

Nonetheless DMM is a good idea.

Anyone know who Cardas used as a pressing plant for the frequency sweep LP?

It is true that you can set a table without using a test lp. It is just personal preference. For me, I use test lp as much as I can. Especially, for diyers, a test lp is a must.

You might have mis-understood. Some claim to use a fresh copy for each client, i.e. lots of test LP's get used.

I was thinking about Scott's locked track click timing and Buchmann+Meyer patterns and wondered if you couldn't make a track for testing the speed of the cutting lathe?

Since the disc should be in exactly the same position every 1.8 seconds, a visual cue could be used. For example; cut a pilot tone of 3150Hz with a marker every 1.8 seconds. If the marker is loud enough, it would be easy to see with a microscope how well each successive marker lines up with the others. If they line up perfectly, then the lathe is precisely at 33 1/3 RPM. This would also include the mastering DAC clock, but it and the lathe will always be used together, so can be considered a system.

Maybe that could be part of the turntable speed stability test track.

Since the disc should be in exactly the same position every 1.8 seconds, a visual cue could be used. For example; cut a pilot tone of 3150Hz with a marker every 1.8 seconds. If the marker is loud enough, it would be easy to see with a microscope how well each successive marker lines up with the others. If they line up perfectly, then the lathe is precisely at 33 1/3 RPM. This would also include the mastering DAC clock, but it and the lathe will always be used together, so can be considered a system.

Maybe that could be part of the turntable speed stability test track.

The W&F test should be longer, as should the reference level. Some THD meters are manual and require time to tune and null. Even the HP 339A takes time to lock up as you drop to lower levels. Then there should be time to remain at that level so you can do other things like extract transport noise in the residual outputs. An FFT can take some time to sweep (looking at the 1KHz signal).

I don't know if a locked track is necessary as it will thump every time the track feeds to the end of the track. I don't have a strong opinion on this either way.

The skating rink won't last very long before you begin following previous tracks. For someone who works with turntables, a glass disc might be the real solution.

-Chris

You can use VideoDisks / Laserdisks as "skating rinks" to test for suitable anti-skating. There are some turntable / tonearm schools of thought that say anti-skating is irrelevant anyway, but for those that prefer to set "something" that can work. Usually around $5 on eBay, assuming this idea doesn't get out into the general public, which in that case I suggest you buy now.

So on further thought I don't feel the real estate and utility justify including it in our project.

Unless you could use a horizontally modulated tone and measure L and R to set anti-skating. Would that work?

But I am still asking for an A-440 tone somewhere.

Last edited:

Yes, the waveforms will get longer and longer as the grove spirals in. But the markers should all start at the same point, shouldn't they?Don't forget the radial velocity of the groove.

I'm not sure I can find you post, but will look for it. Is it worth trying something like this? Otherwise we do not know the actual speed of the lathe. There has been question of the accuracy of the tone generators and lathes used in past test LPs. The generator is no longer a problem, but we don't know about the lathe.

Found your photo of 540 Hz interleaved

http://www.diyaudio.com/forums/anal...al-resonance-mms-post5012003.html#post5012003

And people say the search feature is lame, ha!

http://www.diyaudio.com/forums/anal...al-resonance-mms-post5012003.html#post5012003

And people say the search feature is lame, ha!

Experiment of the day.

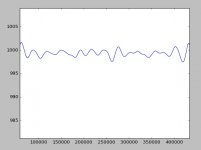

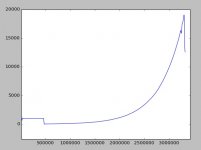

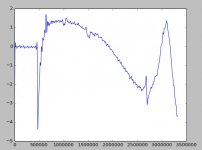

Out of curiosity I used the Hilbert transform technique on the entire 60sec RIAA sweep on the CBS STR130 LP to see what I get.

What I did is take the entire 3,330,000 sample (44.1/16) waveform and compute the instantaneous frequency and amplitude directly using the Hilbert Transform.

The first plot is a blow up of the 1K reference (frequency). The second is the frequency vs sample (each sample is 1/44100 sec) and the third is the amplitude in dB re the 1k tone (40-20k).

The glitches on the amplitude plot are in the data and must be artifacts of their sweep generator (they are exactly the same on all the sweeps) as well as AM from cartridge wobble.

Just an example of what is now possible with a few lines of code and a second or so.

Out of curiosity I used the Hilbert transform technique on the entire 60sec RIAA sweep on the CBS STR130 LP to see what I get.

What I did is take the entire 3,330,000 sample (44.1/16) waveform and compute the instantaneous frequency and amplitude directly using the Hilbert Transform.

The first plot is a blow up of the 1K reference (frequency). The second is the frequency vs sample (each sample is 1/44100 sec) and the third is the amplitude in dB re the 1k tone (40-20k).

The glitches on the amplitude plot are in the data and must be artifacts of their sweep generator (they are exactly the same on all the sweeps) as well as AM from cartridge wobble.

Just an example of what is now possible with a few lines of code and a second or so.

Attachments

Last edited:

How good is Viktor's 1kHz oscillator directly (not master-cut, stamped onto vinyl, then played back thru a cartridge + phonostage)? Does it display drift and glitches like your third plot?

The third plot is a 40-20k sweep we would do this with a digital file hopefully eliminating the aberrations. I think we have a great advantage in technology at this time.

I wonder how difficult (or easy) would be to build an Android/iOS app for turntable instantaneous speed analysis using the 3150 Hz test tone and the mic of the smartphone.

Isn't that what this does?

PlatterSpeed - Vinyl Tool on the App Store

Ditto. Use it to check speed stability quite often. Easy to use, quick and the results correlate closely with those produced on the TT Speed Stability thread.

- Home

- Source & Line

- Analogue Source

- Test LP group buy