Hello peoples,

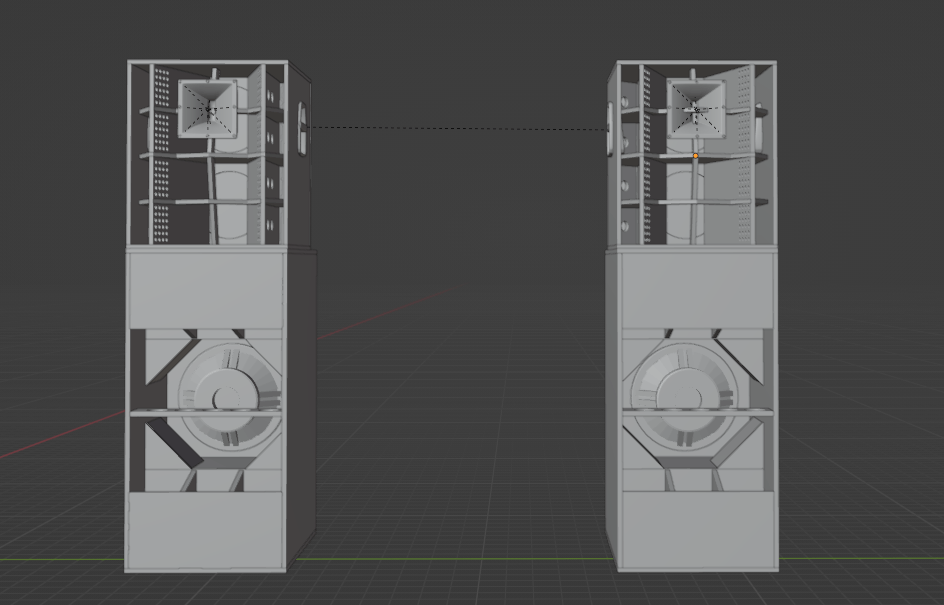

I would like to upgrade the HF section of my system. Currently we have two 2x12 G#1 v2 Kicktops which I really love, as shown in picture one, which play from ~90hz - 20.000. Two B&C 12FW76 (~90hz-900hz) and a BMS4550 with 80w RMS are installed.

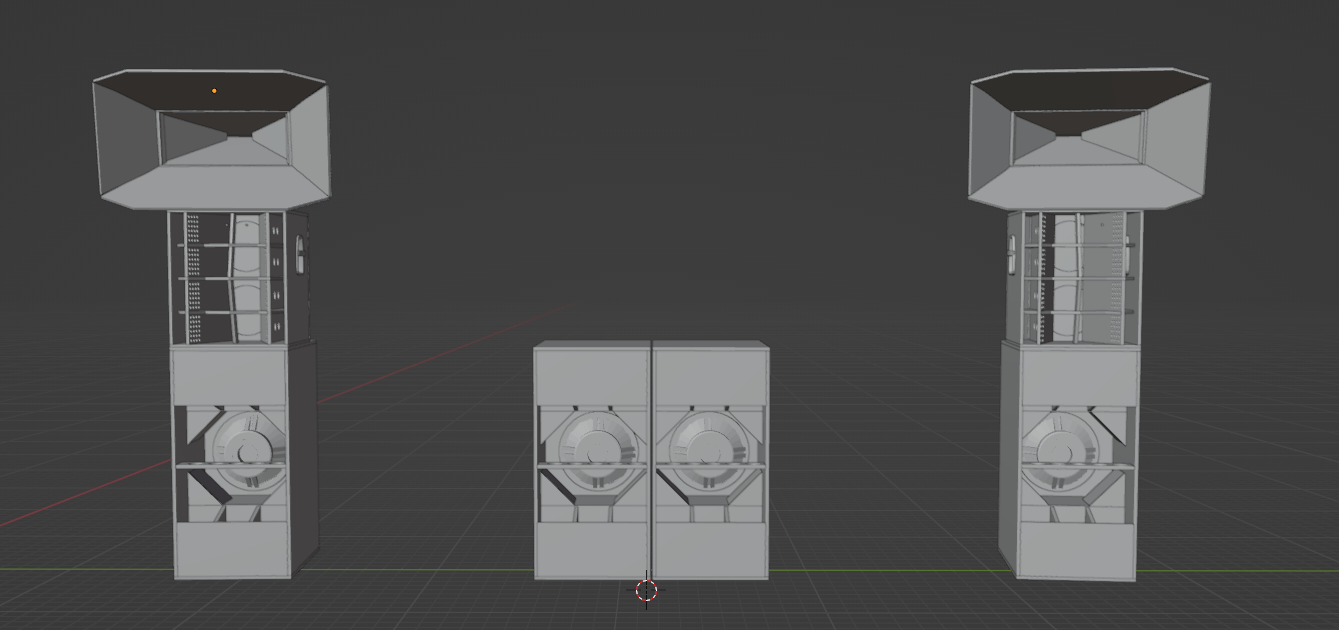

I could of course replace the drivers & horns in the tops, but I was wondering if I could build two Syntripps for the HF as shown in picture two and remove the HF Section from those boxes.

What is your opinion on this? Where would it make sense to set the crossover and would the Syntripp be powerful enough?

Current system:

Possible upgrade? (Syntripp in the render are not 100% to scale)

Greetings

Finn

I would like to upgrade the HF section of my system. Currently we have two 2x12 G#1 v2 Kicktops which I really love, as shown in picture one, which play from ~90hz - 20.000. Two B&C 12FW76 (~90hz-900hz) and a BMS4550 with 80w RMS are installed.

I could of course replace the drivers & horns in the tops, but I was wondering if I could build two Syntripps for the HF as shown in picture two and remove the HF Section from those boxes.

What is your opinion on this? Where would it make sense to set the crossover and would the Syntripp be powerful enough?

Current system:

Possible upgrade? (Syntripp in the render are not 100% to scale)

Greetings

Finn

Hello!

First of all a big thank you to all the contributors to these designs (specially Art). Ive built a pair (without cnc) including secondarys and i am over the moon with the result! As drivers ive used: B&C - 10CL51 8ohm and B&C - DE780TN - 8ohm. The sound is pretty phenomenal. As a sub im using 1x Josh Ricci's CKRAM wich is pairing very nice with the SynTripP's. The CKRAM sounds and measures very flat, same like the SynTripP's. At the moment i have crossed them at 80Hz. For people who are not familliar with Josh Riccis design, have a look on his forum called Databass.

I have a question:

The CKRAM is probably close to the smallest 21" subwoofer design that still makes sense (please correct me if im wrong). It is loaded with a B&C-21SW152-8 and it does sound truly awesome for its size. However, the system was meant to be more portable. The CKRAM weighs in at 56 kilos wich is very light but still quite pushing it ergonomically (lazy). Seeing that im using it upto 80Hz and would offcourse like to minize sacrafice the lower frequencys (within reason):

Could any of you kindly recommend a: tried and true (more) portable design for a 18 or 15" B&C speaker that would compliment the SynTripP's on lazy days. I understand im going to sacrifice some SPL and some low frequencys.

some pictures of my journey

Thanx in advance Lex

PS: for non lazy days im looking into Arts foldable ratchet strap horn for the CKRAM free dB's spl who doesnt love that!

First of all a big thank you to all the contributors to these designs (specially Art). Ive built a pair (without cnc) including secondarys and i am over the moon with the result! As drivers ive used: B&C - 10CL51 8ohm and B&C - DE780TN - 8ohm. The sound is pretty phenomenal. As a sub im using 1x Josh Ricci's CKRAM wich is pairing very nice with the SynTripP's. The CKRAM sounds and measures very flat, same like the SynTripP's. At the moment i have crossed them at 80Hz. For people who are not familliar with Josh Riccis design, have a look on his forum called Databass.

I have a question:

The CKRAM is probably close to the smallest 21" subwoofer design that still makes sense (please correct me if im wrong). It is loaded with a B&C-21SW152-8 and it does sound truly awesome for its size. However, the system was meant to be more portable. The CKRAM weighs in at 56 kilos wich is very light but still quite pushing it ergonomically (lazy). Seeing that im using it upto 80Hz and would offcourse like to minize sacrafice the lower frequencys (within reason):

Could any of you kindly recommend a: tried and true (more) portable design for a 18 or 15" B&C speaker that would compliment the SynTripP's on lazy days. I understand im going to sacrifice some SPL and some low frequencys.

some pictures of my journey

Thanx in advance Lex

PS: for non lazy days im looking into Arts foldable ratchet strap horn for the CKRAM free dB's spl who doesnt love that!

Attachments

-

WhatsApp Image 2024-05-30 at 17.31.57_b24968d0.jpg225.3 KB · Views: 103

WhatsApp Image 2024-05-30 at 17.31.57_b24968d0.jpg225.3 KB · Views: 103 -

WhatsApp Image 2024-05-30 at 17.34.51_c4744e4b.jpg215.4 KB · Views: 89

WhatsApp Image 2024-05-30 at 17.34.51_c4744e4b.jpg215.4 KB · Views: 89 -

WhatsApp Image 2024-05-30 at 17.35.49_15f3fdeb.jpg354.5 KB · Views: 88

WhatsApp Image 2024-05-30 at 17.35.49_15f3fdeb.jpg354.5 KB · Views: 88 -

WhatsApp Image 2024-05-30 at 17.36.28_29e633d1.jpg37.2 KB · Views: 99

WhatsApp Image 2024-05-30 at 17.36.28_29e633d1.jpg37.2 KB · Views: 99 -

WhatsApp Image 2024-05-30 at 17.36.47_22e074f4.jpg183.3 KB · Views: 114

WhatsApp Image 2024-05-30 at 17.36.47_22e074f4.jpg183.3 KB · Views: 114 -

WhatsApp Image 2024-05-29 at 11.20.40_f4cbb751.jpg358.5 KB · Views: 113

WhatsApp Image 2024-05-29 at 11.20.40_f4cbb751.jpg358.5 KB · Views: 113

I'd suggest you pick something smaller with a response you like from something else Josh has measured:

https://data-bass.com/#/systems?_k=vhj336

Otherwise, SS15 or THAM, but after being used to 30Hz response, not going to satisfy you..

https://data-bass.com/#/systems?_k=vhj336

Otherwise, SS15 or THAM, but after being used to 30Hz response, not going to satisfy you..

Hi everybody.

Massive thanks to you, @weltersys for the amazing knowledge and generosity with such, and everybody else for sharing their builds and questions/solutions. I and fellow diyA member @monomer are building a system of Keystones and SynTripPs with the latter being my part of the project.

For these we'll be using the B&C 10CL51s with B&C DE780TN HF drivers (had originally chosen Eminence N314-X but these seem to be on perpetual backorder from PE, and the B&Cs look to have higher power handling).

I've 3D printed the wave guides which have turned out really nicely. It took a long time to get 3D print setting right and initially I'd wanted these in ABS but printing that size without warping proved too difficult so went with PLA+ instead. I doubt these will see temps high enough to compromise that material.

I'll post pictures of everything once I've got them all together, and as the build progresses.

One question:

- has any thought been given to accessing the 10s once everything is assembled? These seem difficult/impossible to get out for repair/replacement with the current design, assuming a full glued/screwed cabinet. I'm thinking of providing removable side panels to achieve this, or at least plugged holes to access the forward-most screws.. (apologies if this question has been asked/answered before)

Massive thanks to you, @weltersys for the amazing knowledge and generosity with such, and everybody else for sharing their builds and questions/solutions. I and fellow diyA member @monomer are building a system of Keystones and SynTripPs with the latter being my part of the project.

For these we'll be using the B&C 10CL51s with B&C DE780TN HF drivers (had originally chosen Eminence N314-X but these seem to be on perpetual backorder from PE, and the B&Cs look to have higher power handling).

I've 3D printed the wave guides which have turned out really nicely. It took a long time to get 3D print setting right and initially I'd wanted these in ABS but printing that size without warping proved too difficult so went with PLA+ instead. I doubt these will see temps high enough to compromise that material.

I'll post pictures of everything once I've got them all together, and as the build progresses.

One question:

- has any thought been given to accessing the 10s once everything is assembled? These seem difficult/impossible to get out for repair/replacement with the current design, assuming a full glued/screwed cabinet. I'm thinking of providing removable side panels to achieve this, or at least plugged holes to access the forward-most screws.. (apologies if this question has been asked/answered before)

Great work octapotamus, glad to read you finally printed the horns.. It took a long time to get 3D print setting right and initially I'd wanted these in ABS but printing that size without warping proved too difficult so went with PLA+ instead.

Last edited:

Here they are. Two of them failed right near the end but I managed to print the remaining sections pretty spot on (you can see in the top pic where one of these separations is), and some jb-weld should have everything solid.

Re the printing:

I feel you there. I probably went through 10kg of filament before I got it right.

I recommend using an enclosure for temp stability. Also make sure your z-offset is sufficient to allow for a good squish on the first layer. Try having cooling turned off for the first few layers too. These all worked for me.

I also used a 0.8mm nozzle which made for much faster print times.

Looking further at the design and assuming the entire rear panel is removable, I think accessing the forward screws on the 10s will be ok, if not a bit fiddly.

I have the 10CL51s in hand, the DE780TNs should arrive this week and I'm picking up the Baltic Birch Friday so will be building in the coming weeks 🤙

Re the printing:

I feel you there. I probably went through 10kg of filament before I got it right.

I recommend using an enclosure for temp stability. Also make sure your z-offset is sufficient to allow for a good squish on the first layer. Try having cooling turned off for the first few layers too. These all worked for me.

I also used a 0.8mm nozzle which made for much faster print times.

Looking further at the design and assuming the entire rear panel is removable, I think accessing the forward screws on the 10s will be ok, if not a bit fiddly.

I have the 10CL51s in hand, the DE780TNs should arrive this week and I'm picking up the Baltic Birch Friday so will be building in the coming weeks 🤙

Thanks,I'd suggest you pick something smaller with a response you like from something else Josh has measured:

https://data-bass.com/#/systems?_k=vhj336

Otherwise, SS15 or THAM, but after being used to 30Hz response, not going to satisfy you..

i didnt know of that list. Also two good suggestions for inteded smaller audience purposes.

Does anyone know of a passive crossover yet? I am aware of the fact there should be a delay, and i have tried a couple of times if i could hear the difference. However i might be a bad listener because i am unable to hear the difference. Have more people tried to take out the delay from the processor and what did they think ?

Thanks in advance for sharing, Lex

If you are asking about a passive crossover for the SynTripP, have not heard of anyone doing one.Does anyone know of a passive crossover yet?

Processing delay (latency) for AD/DA conversion and IIR filters should be under ~2ms, about the length of one foot step. The only way you could notice that delay would be if you were cuing up a source with a headphone on one ear and your other ear in the mouth of the cabinet.I am aware of the fact there should be a delay, and i have tried a couple of times if i could hear the difference. However i might be a bad listener because i am unable to hear the difference. Have more people tried to take out the delay from the processor and what did they think ?

Using FIR filters to completely flatten phase response down to a low frequency could increase latency to a point where it might be a problem in some situations.

That said, it is relatively common to delay the top cabinets by ~6-12ms to time align with horn subwoofers, and delay the entire PA to the depth of the back line instrument amplifiers and drums-which could be 20ms or more.

Art

Installation or removal of the 10" drivers through the SynTripP's back access panel is somewhat difficult, but using ratchet drive tools it is by no means impossible. I've removed and installed speakers in much tighter spaces.has any thought been given to accessing the 10s once everything is assembled? These seem difficult/impossible to get out for repair/replacement with the current design, assuming a full glued/screwed cabinet.

If you need access often enough where the few minutes it takes to install or remove speakers is a problem, you probably need better limiting protection, or cabinets with more output

Art

Hi Art,

Yes i meant the delay in the crossover for the SynTriPs, bottom left row of DSP/processor settings below shows a 0.40 ms delay on the high band. I thought this delay posed the difficulty in designing a passive crossover for between mid and high in the SynTriPs. I would still be using the DSP for the high pass and (less effective) limiting, aswel as equalizing them. And offcourse to cross and protect the subwoofer. In an aim for portability, i could do with two channels less of amplification saving space and weight. Probably i have to venture into it myself then.

Sofar i have no plans for live music amplification but i never even considerde the delay in the DSP/processor!

Novice in DIY here. thanks!

Yes i meant the delay in the crossover for the SynTriPs, bottom left row of DSP/processor settings below shows a 0.40 ms delay on the high band. I thought this delay posed the difficulty in designing a passive crossover for between mid and high in the SynTriPs. I would still be using the DSP for the high pass and (less effective) limiting, aswel as equalizing them. And offcourse to cross and protect the subwoofer. In an aim for portability, i could do with two channels less of amplification saving space and weight. Probably i have to venture into it myself then.

Sofar i have no plans for live music amplification but i never even considerde the delay in the DSP/processor!

Novice in DIY here. thanks!

Attachments

Really great job @octapotamus ! 🙂 To be honest im feeling a bit demoralised now. Third print in a row lifted up 1.5 days in despite a stable enclosure temp between 30-40 C, clean and seemingly level bed. The waste is getting quite expensive now. Im considering cutting it into quarters so i can at least run a brim (no room currently).feel you there. I probably went through 10kg of filament before I got it right.

I recommend using an enclosure for temp stability

Lot's of neat stuff going on here!

We've been VERY busy with our system. We get 95-100dB at about 40' with jaw-dropping bass to 20Hz.

1) We added a Paraflex C3D kicker to cover 90-300Hz, covering the transition from our 20Hz tuned bandpass subs with 21" drivers capable of 3KW RMS. This resulted in a huge incress of about 6DB for total system output, those 10" drivers really like rolling off at 300Hz...

2) We now are running an insane amount of power into the system. For people's consideration, for bass bins we found an amazing amp value, from Rockville RPA-16. Rockville is known for making cheap **** party DJ gear, these class D amps are BOMB. While we wouldn't use them for the tops due to noise and distortion levels, with 3KW RMS and 8KW peak (they spec 10KW, but we measured 8KW on our AP 555B) we're getting a stunning amount of clean bass power, for $389 an amp! None have failed after a year.

3) As the final part of the amplification strategy we're using the gorgeous Hypex amps for the tops. These amps have amazingly excellent SINAD and are easy to deploy in a chassis, offering a huge improvement relative to any comparably priced "pro" amps. Don't bother, if you have the interest in simply adding these amps to a chassis you won't regret it. https://www.hypex.nl/products/amplifier-families/mains-powered-ncore-family/nc502mp-oem which gives us >500W for the mids and compression drivers. The clarity of the tops with these amps has to be heard to be believed.

4) As Art noted, skip the large ports on the horns if you can. Adding the kickers to our system eliminated the need for the ports, and removing the ports slightly decreased THD on the tops. We are going to reprint the interior without the ports.

Here are a few pics from our most recent party at the LA Regional Burn Bequinox...

We've been VERY busy with our system. We get 95-100dB at about 40' with jaw-dropping bass to 20Hz.

1) We added a Paraflex C3D kicker to cover 90-300Hz, covering the transition from our 20Hz tuned bandpass subs with 21" drivers capable of 3KW RMS. This resulted in a huge incress of about 6DB for total system output, those 10" drivers really like rolling off at 300Hz...

2) We now are running an insane amount of power into the system. For people's consideration, for bass bins we found an amazing amp value, from Rockville RPA-16. Rockville is known for making cheap **** party DJ gear, these class D amps are BOMB. While we wouldn't use them for the tops due to noise and distortion levels, with 3KW RMS and 8KW peak (they spec 10KW, but we measured 8KW on our AP 555B) we're getting a stunning amount of clean bass power, for $389 an amp! None have failed after a year.

3) As the final part of the amplification strategy we're using the gorgeous Hypex amps for the tops. These amps have amazingly excellent SINAD and are easy to deploy in a chassis, offering a huge improvement relative to any comparably priced "pro" amps. Don't bother, if you have the interest in simply adding these amps to a chassis you won't regret it. https://www.hypex.nl/products/amplifier-families/mains-powered-ncore-family/nc502mp-oem which gives us >500W for the mids and compression drivers. The clarity of the tops with these amps has to be heard to be believed.

4) As Art noted, skip the large ports on the horns if you can. Adding the kickers to our system eliminated the need for the ports, and removing the ports slightly decreased THD on the tops. We are going to reprint the interior without the ports.

Here are a few pics from our most recent party at the LA Regional Burn Bequinox...

Last edited:

I noted a comment on securing the secondary horns to the tops... What we did is make a printed frame with a threaded bolt and a cam to compress the frame. Secures the tops super well and they go on in seconds, no hassle. Does add some weight though so we put the secondary on last.

PLA is risky because it's easily softened by temps you find in the desert/hauling the system in a truck in the desert.Great work octapotamus, glad to read you finally printed the horns.I must admit I've been at the task for months and still can't get them to work. I've done the braces and pole mount PETG-CF which printed nicely but wasn't happy with the layer adhesion for the horn so trying to do that in PETG. It just keeps lifting, probably when I open the enclosure to change the spool. The body count of failed prints is mounting. It'll be interesting to keep an eye out for creep or stress relaxation with the PLA especially where the drivers are bolted. I'm not sure how PLA+ performs but presume it's better. Your question about unloading the tens is a particularly good one in that context, I'll be watching out for answers to this also. Keep it up, and yes, do post pics as you progress!

We used a carbon PETG for the tops, I think PETG would work too.

Removing the ports increase the midrange output potential considerably, the 3dB gain the ports provide around 90Hz are definitely not worth the -3dB 350 to 475Hz and -10dB cancellation at 700Hz if you are crossing at 100Hz or above.4) As Art noted, skip the large ports on the horns if you can. Adding the kickers to our system eliminated the need for the ports, and removing the ports slightly decreased THD on the tops. We are going to reprint the interior without the ports.

A lot less EQ needed too..

That rig looks fantastic @MrSpeakers ! The Paraflex C3D looks like a very compact way to get more dB out of the SynTripPs higher up.

When I saw Art's comments on the ports I actually had a go at filling them in on the horn body STL but I didn't have much luck in fusion or meshmixer. If you were planning to re-print them and had an STL you'd be willing to add to your dropbox files, that would be truly amazing and very much appreciated. The other advantage of filling in the port is that eliminates one of the thinner, weaker structures on the 3d Printed horn, at least in the orientation I had to print it.

The other advantage of filling in the port is that eliminates one of the thinner, weaker structures on the 3d Printed horn, at least in the orientation I had to print it.

While talking the dropbox files (which are fantatically helpful, thanks!) may I ask did you just use decking screws or similar to fasten the box to the horn? Likewise any advice on the bolts to fasten the compression driver to the horn? I note there's a reference to 35mm M6 bolts which is I think to fasten the rear panel onto the threaded insets in the braces but I'm a bit unsure about the other fasteners. Any hints on screwing it all together using hardware that doesn't split the plastic would be really great because I'm quite nervous about damaging the horn.

When I saw Art's comments on the ports I actually had a go at filling them in on the horn body STL but I didn't have much luck in fusion or meshmixer. If you were planning to re-print them and had an STL you'd be willing to add to your dropbox files, that would be truly amazing and very much appreciated.

While talking the dropbox files (which are fantatically helpful, thanks!) may I ask did you just use decking screws or similar to fasten the box to the horn? Likewise any advice on the bolts to fasten the compression driver to the horn? I note there's a reference to 35mm M6 bolts which is I think to fasten the rear panel onto the threaded insets in the braces but I'm a bit unsure about the other fasteners. Any hints on screwing it all together using hardware that doesn't split the plastic would be really great because I'm quite nervous about damaging the horn.

Nice! I noticed others have had great success with hypex amps. I'm planning to run Pascal modules for my tops if I ever get these built!we're using the gorgeous Hypex amps for the tops.

- Home

- Loudspeakers

- Multi-Way

- SynTripP: 2-way 2-part Virtual Single Point Source Horn