There is no build thread for it anywhere. It only exist in the reviews for the mid. I know Jmorken used this mid, and this guy here did to.

GRS 5SBM-8 5" Sealed Back Midrange

Steve

GRS 5SBM-8 5" Sealed Back Midrange

Steve

Looks great!

If you can't measure right away, here's a tip:

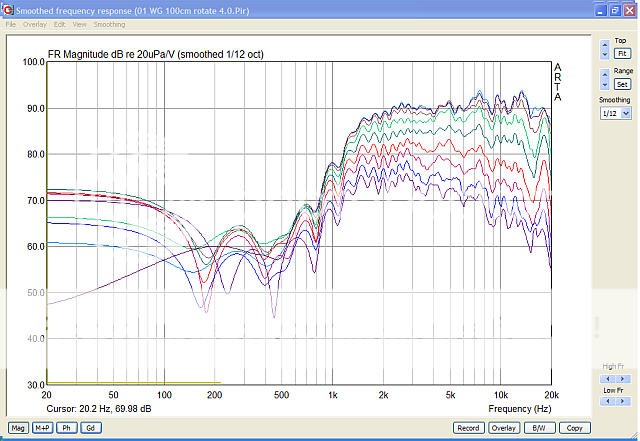

A first order crossover set at 20khz will get you close to flat.

This is because the 'natural' response of the compression driver is falling off across it's entire bandwidth. So when you combine a first order at 20khz with the naturall rolloff, you get close to flat response. For instance, in the pic above, a 1st order at 20khz will be down 27dB at 1250hz, which is just about right.

Many of my Synergy horn crossovers have been a total of one cap and a resistor or two.

Instead of putting in a first order high pass at 20KHz to level the frequency response, I'd recommend using a second order low pass filter set to around 16KHz. This will boost the high frequencies at the expense of lower impedance. This method is used on some of the Synergy horn passive models. The major advantage of this is you don't have to cut down to the output level of the compression driver at 20KHz; you actually boost the output at 20KHz.

Attachments

There is no build thread for it anywhere. It only exist in the reviews for the mid. I know Jmorken used this mid, and this guy here did to.

GRS 5SBM-8 5" Sealed Back Midrange

Steve

jmorken brought up this midrange three years ago, and I never tried it.

I'm wondering if this might be superior to the Pyle PDMR5.

The surround on the Pyle isn't ideal, and the description on the JRS seems to imply that it might be an accordian surround.

Hard to tell without prying off that grille.

I like the sound of the Dayton ND91 a little bit more than the Pyle, but the Pyle definitely has more output and is cheaper. The GRS might be a little bit better, would have to buy some to find out though.

Today I tested Celestion TF0410MR and I got what I missed -AIR! So there is a driver limitation in those little Aura. May be low sensitivity I don't know. But with those Celestion I got liveliness back. Just my IMHO.

Now I should find a Synergy project to use them.

While poking around on the Internets I found a driver that's similar to the Celestion used in the Danley Synergy horns.

I can see why Danley went from the 5" mids used at Sound Physics Labs to the 4" mids used at DSL. The smaller mids make it easier to cross over to the compression driver. Basically you want the mids to be small, but not so small that output and power handling get nuked.

Here's a comparison of the driver I found this morning, and the Celestion:

name : Pyle PDMR5 / Celestion TF0410MR / Power Acoustik XPS-104

size : 5" / 4" / 4"

FS : 465hz / 400hz / ?

voice coil : 1" / 1" / 0.75"

cone : paper / paper / paper

surround : foam / accordian / foam

magnet weight : 15oz / 17oz / 15oz

price : $9.50 / unobtanium / $7.50

I ordered one off of Amazon Prime just to get the T/S params. If it turns out to be superior to the Pyle PDMR5, maybe I'll get a box from MCM (who sells it for less.)

An externally hosted image should be here but it was not working when we last tested it.

Power Acoustik also has an 8" that looks like an interesting candidate for a three way synergy horn. Paper cone and accordian surround says "horn friendly" and the price is good too. Just $22

They run their mouths about the inaudible, then rename and ignore the highly audible.Oh, I'm fully aware and I recognize the ease (and design laziness) that DSP has brought forth. If it is done correctly from the beginning there is little need for such heavy handed measures.

"Not everything that can be counted counts, and not everything that counts can be counted." - William Bruce Cameron

Much of the "issues" Earl and others have been barking about are not audible and are of no consequence.

"Non linear distortion" my all time favorite. Lets never say "harmonic distortion" again as we all know anything but low amounts

are quite audible.

Oh, I'm fully aware and I recognize the ease (and design laziness) that DSP has brought forth. If it is done correctly from the beginning there is little need for such heavy handed measures.

"Not everything that can be counted counts, and not everything that counts can be counted." - William Bruce Cameron

Much of the "issues" Earl and others have been barking about are not audible and are of no consequence.

I *definitely* think that Earl is on to something in regards to HOMs.

Gedlee Summas are my reference loudspeaker, and in many of my Synergy horn projects I'd noticed that my Synergy horns measured well but sounded fatiguing. Basically I'd get things 'dialed in' with the frequency response, but I didn't want to listen to them long-term.

My hunch is that this is HOMs.

But there's a really easy solution to the HOM problem : use a well designed waveguide.

The QSC in the middle and the JBL clone on the right both work well.

To be honest, it bums me out that I seem to be the only person making Synergy horns with factory-built waveguides. I have a feeling that a lot of people are missing out on the smooth frequency response and lack of HOMs that a really well designed waveguide can deliver.

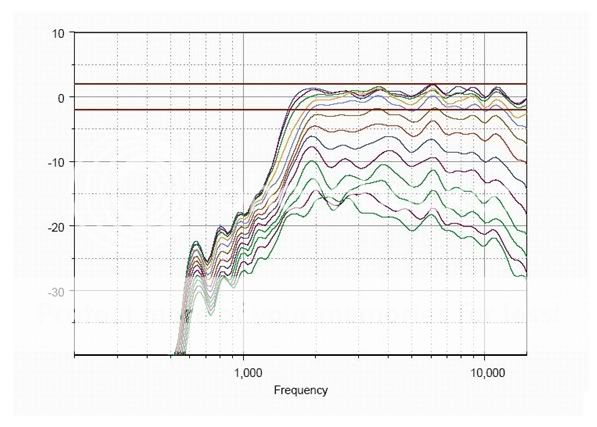

^^ here's three measurements of waveguides, from the 'great waveguide' thread. You can see that the overall response shapes varies from waveguide to waveguide, from driver to driver.

Basically I *do* think it is possible to get GOOD performance out of a handbuilt conical horn. But if you want GREAT performance, it's going to be difficult / impossible to reach the level of performance that is possible with the QSC and the JBL waveguides.

Now I could understand passing on the QSC and the JBL if they cost $200 a pop. But they're $35 and $12, respectively. At these prices, it's a no-brainer.

The obvious argument is that the QSC and the JBL are not large enough. But that's easy to remedy; just extend the flare. HOMs begin at the diaphragm of the compression driver, so the first 3" or so are absolutely CRITICAL. Get it wrong, and you'll never have smooth frequency response, and you'll have HOMs.

Basically if you don't get the first three inches correct, the entire design is compromised.

I do agree with John, that you can 'hide' the midranges though. I've see it in my own measurements; if you get the mids in the right spot the response of the waveguide is virtually identical to what it is *without* the midrange taps. (IE, we're not generating HOMs off the taps if you place them correctly.)

Patrick,I am so with you here!! Making them with factory built waveguides is the *only* thing that makes sense for DIY, other than that just buy Danley stuff.

By the time you put a million hours into DIY projects it all gets silly. This thing really is dead simple. Below the Schroeder there is not a a lot we can do anyway, therfore for home use it's 2-way So what is your favorite 2-way Unity/Synergy using a factory horn?

As far as I am concerned not using DSP is simply silly, Jriver and a multi way pro sound card is all anyone needs.

So that being said what is your favorite design and components featuring a ready made horn with holes drilled and mid speakers placed, that can be horsewhipped into submission by DSP?

By the time you put a million hours into DIY projects it all gets silly. This thing really is dead simple. Below the Schroeder there is not a a lot we can do anyway, therfore for home use it's 2-way So what is your favorite 2-way Unity/Synergy using a factory horn?

As far as I am concerned not using DSP is simply silly, Jriver and a multi way pro sound card is all anyone needs.

So that being said what is your favorite design and components featuring a ready made horn with holes drilled and mid speakers placed, that can be horsewhipped into submission by DSP?

90% of the Synergy horns that I've heard were my own creation.

There's a Grammy award winner in Oregon who was nice enough to let me listen to his Lambda Unity horns.

As far as 'favorite design' goes, a lot would depend on what kind of sound you're after.

Creating The Perfect Soundstage - Car Audio | DiyMobileAudio.com | Car Stereo Forum

^^ this was probably my most 'faithful' Synergy horn project. The entire design was fairly close to a textbook Synergy horn

http://www.diyaudio.com/forums/multi-way/252549-edge-no-control-3.html#post3869846

^^ Probably the best Synergy horn I've ever heard was my cardioid synergy horn. Cardioid midranges just sound magical. The JBL waveguide works well too.

I made some Synergy horns that were similar to that 2nd set, but used the QSC waveguide, and those measured better than the JBL did. The JBL is nice but the QSC is a little bit better I think. But it's a close race.

As you can tell from my various threads, I've tried a ton of things that *didn't* work. All of my biggest flops used horns or waveguides that I built myself. All of my most successful projects, with the exception of that first link, used commercially available waveguides.

I'd love to hear Bill Waslo's Synergy Horn. IMHO his use of small midranges and a small compression driver are a smart choice for a home speaker.

There's a Grammy award winner in Oregon who was nice enough to let me listen to his Lambda Unity horns.

As far as 'favorite design' goes, a lot would depend on what kind of sound you're after.

Creating The Perfect Soundstage - Car Audio | DiyMobileAudio.com | Car Stereo Forum

^^ this was probably my most 'faithful' Synergy horn project. The entire design was fairly close to a textbook Synergy horn

http://www.diyaudio.com/forums/multi-way/252549-edge-no-control-3.html#post3869846

^^ Probably the best Synergy horn I've ever heard was my cardioid synergy horn. Cardioid midranges just sound magical. The JBL waveguide works well too.

I made some Synergy horns that were similar to that 2nd set, but used the QSC waveguide, and those measured better than the JBL did. The JBL is nice but the QSC is a little bit better I think. But it's a close race.

As you can tell from my various threads, I've tried a ton of things that *didn't* work. All of my biggest flops used horns or waveguides that I built myself. All of my most successful projects, with the exception of that first link, used commercially available waveguides.

I'd love to hear Bill Waslo's Synergy Horn. IMHO his use of small midranges and a small compression driver are a smart choice for a home speaker.

I'd love to hear Bill Waslo's Synergy Horn. IMHO his use of small midranges and a small compression driver are a smart choice for a home speaker.

Well, you may get your chance before too long! We'll be moving to Portland OR in August, so not too far away from you.

But my 'listening room' (a.k.a. 'basement') will have only 6.5foot ceilings, so acoustics may be less than stellar. I'm actually plotting a tall Synergy version that has narrow controlled vertical down to schroeder to (I hope) help with that. Will have to see how well the little tool shed I'll have there will do for doing horn piece cutting.

This time around I want to try to use DE5 tweeter and Faital 3FE22 midranges. The DE5 is so small that (with some fussy work with the mounting surfaces) the midranges can be positioned partly over the end of the tweeter driver to allow high crossover. That does require the waveguide to be conical down to the tweeter mounting, though, otherwise a throat transition would eat into the tolerable spacing from mid to the CD diaphram.

I have my current 'CoSyne' synergies now working linear phase (they reproduce decent square waves) using a passive crossover. A very complicated crossover on the tweeter to get that. Sure, it's easier with an active (done that, too) but I wanted to do passive for the challenge and to have a system that isn't too complicated for my wife to be able to turn on! The sound is really, really good (...so says the designer, as usual). I've never heard a real Danley Synergy, nor a Geddes speaker, so not much to compare to like that, other than SEOS-based designs (which were also quite good). I do find I really like the everything-from-a-point sound that Synergy horns give compared to separated 2way waveguide speakers, though maybe some of that is just psychological (because of the engineering elegance).

I have a home in Oregon City (15 min from Portland)

Might be fun to have a get together, maybe get my friend with the Lambda unities to come out

Might be fun to have a get together, maybe get my friend with the Lambda unities to come out

Basically I *do* think it is possible to get GOOD performance out of a handbuilt conical horn. But if you want GREAT performance, it's going to be difficult / impossible to reach the level of performance that is possible with the QSC and the JBL waveguides.

John,

What is the angle at the throat of QSC waveguide?

The reason why I ask is that Earl has told this many times that there has to be a smooth match of the CD with the waveguide so while the QSC will only work with some CDs whose exit angle matches its own, other CDs will require rework at the throat. This mismatch is one of the reasons of HOMs.

I have that JBL clone waveguide but its throat angle is too wide to match my 6 degree (12 degree included) CD making the combination unusable.

I *definitely* think that Earl is on to something in regards to HOMs.

Gedlee Summas are my reference loudspeaker, and in many of my Synergy horn projects I'd noticed that my Synergy horns measured well but sounded fatiguing. Basically I'd get things 'dialed in' with the frequency response, but I didn't want to listen to them long-term.

My hunch is that this is HOMs.

Patrick,

Thank you for sharing many results on using horn-based systems. Your experiences with DIY Synergy horns are particularly interesting. If I may ask, is it possible for you to supply time-domain measurements of your speakers? An impulse response or (better) wavelet diagram.

I think that without those it is impossible to quantify the issue with HOMs or other aberrations. Frequency response plots don't show what exactly is going on, so we are left with subjective assessments. What I have in mind is something like the impulse responses of different horns published by late Mr. Le Cléac'h.

Of particular interest are the applications of foam and measurements of Synergy horns vs standard commercially available OS waveguides vs Summa speakers.

John,

What is the angle at the throat of QSC waveguide?

The reason why I ask is that Earl has told this many times that there has to be a smooth match of the CD with the waveguide so while the QSC will only work with some CDs whose exit angle matches its own, other CDs will require rework at the throat. This mismatch is one of the reasons of HOMs.

I have that JBL clone waveguide but its throat angle is too wide to match my 6 degree (12 degree included) CD making the combination unusable.

In order to reduce diffraction, we want the smoothest possible transition from one angle to another.

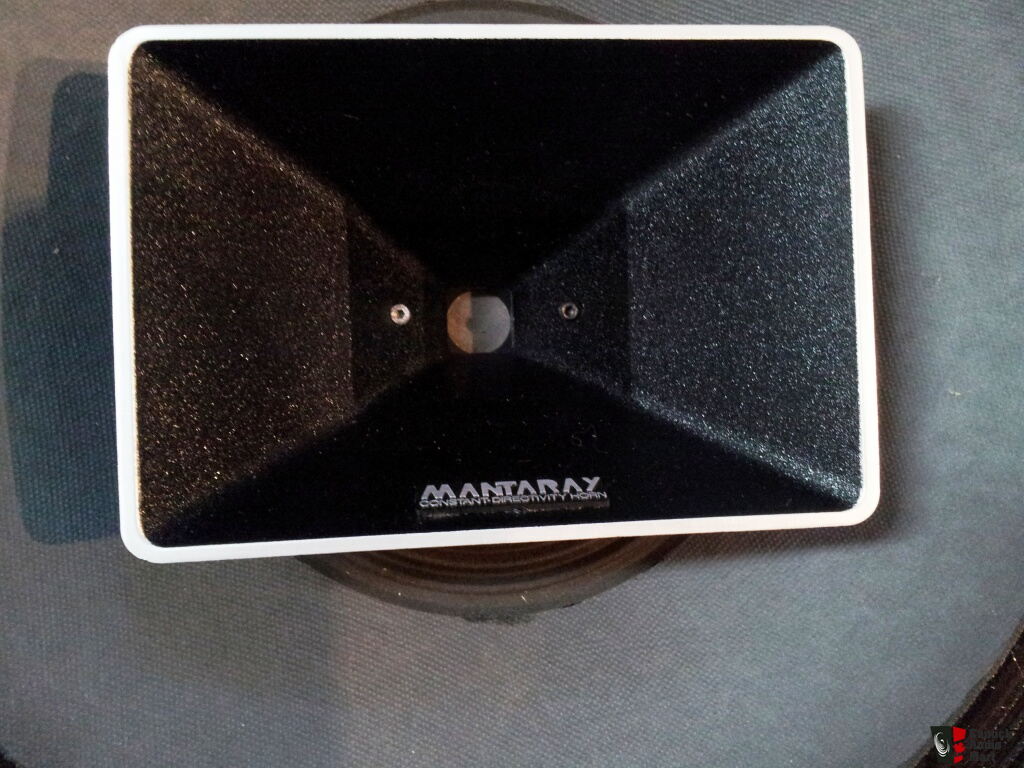

Quick 'jumps' from one angle to another generate diffraction. An extreme case is the Mantaray horn, which sounds famously bad.

An externally hosted image should be here but it was not working when we last tested it.

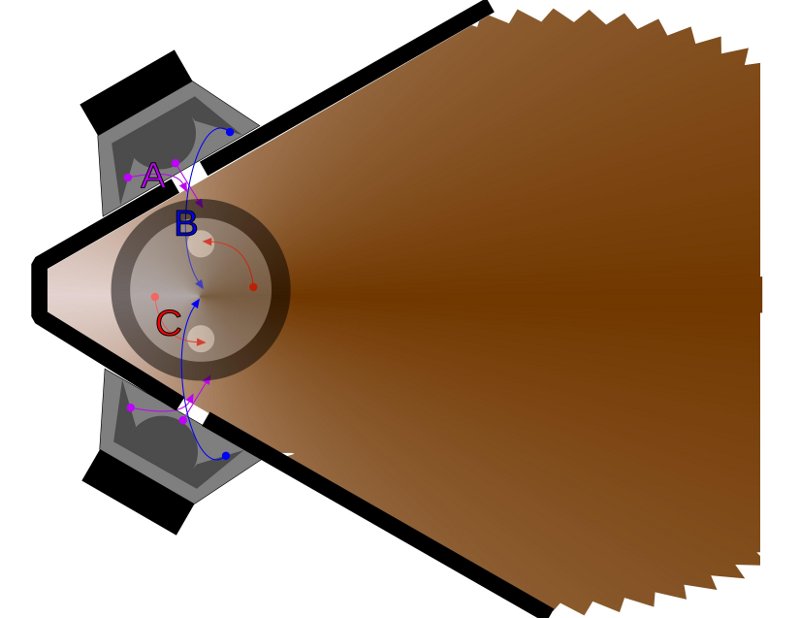

The Danley horns have several 'zones' which may generate diffraction. The first and most serious is at the throat. The transition from the exit of the compression driver to the horn happens over the space of about half an inch. So you have a change in angle from about ten degrees to fifty degrees that happens in one inch.

An externally hosted image should be here but it was not working when we last tested it.

The QSC waveguide looks virtually identical to a conical horn. But the devil is in the details; the transition from the exit of the compression driver to the baffle is absolutely seamless. There isn't even a *hint* of a sharp edge here. It's basically one long spline, from compression driver exit to the baffle.

Will it control directivity down to 500hz? NO.

Does it generate HOMs? Yes, but nowhere near as much as a conical horn.

Another 'nice' thing about the QSC is the build quality. I've bought so many horns, and it seems like at least half of them have a mismatch a the throat. A gap of 1/8" of an inch might not look like much, but it will absolutely ruin your high frequencies. Will make the horn virtually unlistenable. The QSC is molded perfectly, no shrinkage, no gaps. (The 18Sound waveguides are also very well built.)

IMHO, it's really difficult to match this level of build quality when you're building things by hand. At 5khz a variance of an 1/8" makes a difference.

As for the exit angle of the compression driver, I've personally never worried about it. The QSC has an entrance angle of zero, and it sloooooooooooooooooooooooooooooooooooowly transitions to ninety degrees. You can see that in the walls of the waveguide; there's a very very gentle curve there. Compare that to a conical horn, where the walls are perfectly flat. The Celestion CDX1-1425, which the QSC was designed for, has a negative exit angle. IE, it has a converging wave front.

Not saying that the exit angle isn't important; it's just a variable that I can't control unless I start building my own waveguides again. And personally, I think that the consistency and build quality of the factory waveguides provides more benefits than I would realize if I made DIY waveguides with an entrance angle tailored to match the exit angle of my compression driver. And my compression driver is negative, which makes things a little trickier.

Last edited:

Patrick,

Thank you for sharing many results on using horn-based systems. Your experiences with DIY Synergy horns are particularly interesting. If I may ask, is it possible for you to supply time-domain measurements of your speakers? An impulse response or (better) wavelet diagram.

I think that without those it is impossible to quantify the issue with HOMs or other aberrations. Frequency response plots don't show what exactly is going on, so we are left with subjective assessments. What I have in mind is something like the impulse responses of different horns published by late Mr. Le Cléac'h.

Of particular interest are the applications of foam and measurements of Synergy horns vs standard commercially available OS waveguides vs Summa speakers.

Yeah that's definitely something that has interested me.

Pyle sells a 12" horn that has a slower expansion rate than a conical horn but it has straight walls on one side. The straight walls make it a candidate for a Synergy horn.

I did some measurements of the impulse response and the step response of this horn, versus the ubiquitous Econowave JBL waveguide. And I really wanted to see the Pyle come out on top, because I've built some LeCleach horns, and that slower expansion rate definitely changes the sound in an interesting way.

But the JBL just measured better. I didn't even save the results, because the things that I was hoping the Pyle would do just didn't show up in the impulse response. (A horn with a slower expansion rate should theoretically have an impulse response that's closer to perfect than a conical horn.)

TLDR: A horn with a slower expansion, like a LeCleach, should have superior impulse response. A waveguide with a fast expansion, like the JBL waveguide from the econowave, should have sub-optimum impulse response. But my measurements didn't show this; the Pyle clone of the JBL waveguide was far superior in the realm of frequency response smoothness, and in the impulse measurement was about the same.

This is one of those areas where I wish I had a working horn to listen to; the Pyle PH12S doesn't measure badly, it's just that the JBL measures *better.* And when I had that LeCleach synergy, documented in the thread 'monster massive', it definitely did some things that I liked. In particular, it *really* extracts low-level detail out of a recording. Listening to the LeCleach horn was like putting on an album at two o clock in the morning when the world is perfectly quiet, it's just an xray on the details. I *do* wonder if the Pyle PH12S might be able to do some of the same magic.

The 'drape molding' method that Dave Pellegrene invented might offer the best of both worlds. If you look at Dave's waveguides, the transition from throat to mouth is nearly perfect, and similar to the QSC. Basically the walls have that gentle curve we want, the walls are a spline.

But Dave's method is applicable to any size; there's nothing stopping you from making a 30" waveguide with Dave's method. Or you could also make a two-stage horn; use Dave's drape molding method at the throat, where HOMs start, and transition to a wooden conical horn for the last 6-12".

Dave said he spent ten minutes to make his first one! If I understand the process correctly, you basically get a sheet of plastic and a wood dowel, then apply pressure to the plastic while pressing down on it with the dowel. Dave applies heat with a heat gun. I think you could probably do the same thing with a pot of boiling water or with steam. (Need to determine what temperature the plastic gets soft.)

Last edited:

The QSC waveguide looks virtually identical to a conical horn. But the devil is in the details; the transition from the exit of the compression driver to the baffle is absolutely seamless. There isn't even a *hint* of a sharp edge here. It's basically one long spline, from compression driver exit to the baffle.

Will it control directivity down to 500hz? NO.

Does it generate HOMs? Yes, but nowhere near as much as a conical horn.

Another 'nice' thing about the QSC is the build quality. I've bought so many horns, and it seems like at least half of them have a mismatch a the throat. A gap of 1/8" of an inch might not look like much, but it will absolutely ruin your high frequencies. Will make the horn virtually unlistenable. The QSC is molded perfectly, no shrinkage, no gaps. (The 18Sound waveguides are also very well built.)

IMHO, it's really difficult to match this level of build quality when you're building things by hand. At 5khz a variance of an 1/8" makes a difference.

As for the exit angle of the compression driver, I've personally never worried about it. The QSC has an entrance angle of zero, and it sloooooooooooooooooooooooooooooooooooowly transitions to ninety degrees. You can see that in the walls of the waveguide; there's a very very gentle curve there. Compare that to a conical horn, where the walls are perfectly flat. The Celestion CDX1-1425, which the QSC was designed for, has a negative exit angle. IE, it has a converging wave front.

Not saying that the exit angle isn't important; it's just a variable that I can't control unless I start building my own waveguides again. And personally, I think that the consistency and build quality of the factory waveguides provides more benefits than I would realize if I made DIY waveguides with an entrance angle tailored to match the exit angle of my compression driver. And my compression driver is negative, which makes things a little trickier.

I sure do love my QSC waveguides! I use BMS 4550 on them, which has a 14° exit angle. Visually, it seems to me the QSC has a certain entrance angle, but I believe you have once taken a mold of it and may know better than me. I've wanted to mold mine to verify this before.

Yes, at no point are the walls straight, yet I would not call this an effective flare.

I sure do love my QSC waveguides! I use BMS 4550 on them, which has a 14° exit angle. Visually, it seems to me the QSC has a certain entrance angle, but I believe you have once taken a mold of it and may know better than me. I've wanted to mold mine to verify this before.

Yes, at no point are the walls straight, yet I would not call this an effective flare.

nah I'm guessing on the entrance angle of the QSC. It's noticeably narrower than the JBL pt waveguides.

I have always been curious about using fiberglass or CF over a wooden horn. Because it looks pretty and seems to flow better in my head. But I thought I heard the corners are a good thing in the SH?

I know the transition from CD to square will be the most important but I figured I would do my best on the whole thing. I will be trying to build a small 2way SH using 3.3" mids. Might not be ideal drivers but I have them already and want to build something to learn from. Probably a small horn just slightly bigger than the QSC WG.

I know the transition from CD to square will be the most important but I figured I would do my best on the whole thing. I will be trying to build a small 2way SH using 3.3" mids. Might not be ideal drivers but I have them already and want to build something to learn from. Probably a small horn just slightly bigger than the QSC WG.

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn