Putting a back chamber on an open-backed driver isn't really very hard if you have the right size cardboard or pvc tubes and are good with cutting and cluing hardboard, but it is quite a few extra steps to do, and it might be difficult to assure that each build is similar enough to the original. On the 3FE22, offset loaded onto a SEOS15, the back volume has to be pretty small so even a little variation in construction might cause a lot of change, percentage-wise.

Though the Aurasound Whispers are relatively expensive, sealing off the back yields an Fb of 500hz, just about perfect for a Synergy Horn. Because the enclosure itself is a plastic cylinder, you can seal off the back by simply covering the back with a piece of mortite. Another nice thing is that this is a two-way street; if you decided to use the AuraSounds for something else, just remove the mortite and they're back to normal.

Buy some, measure the T/S, and let us know!

In general, the best candidates have had sealed backs, accordion surrounds, and relatively large magnets. The Pyle seems to be an exception to the rule. Although it has a foam surround, I'm guessing it's relatively large BL is compensating for the higher MMS that comes with a foam surround vs an accordion surround.

In general, the best candidates have had sealed backs, accordion surrounds, and relatively large magnets. The Pyle seems to be an exception to the rule. Although it has a foam surround, I'm guessing it's relatively large BL is compensating for the higher MMS that comes with a foam surround vs an accordion surround.

Though the Aurasound Whispers are relatively expensive, sealing off the back yields an Fb of 500hz, just about perfect for a Synergy Horn. Because the enclosure itself is a plastic cylinder, you can seal off the back by simply covering the back with a piece of mortite. Another nice thing is that this is a two-way street; if you decided to use the AuraSounds for something else, just remove the mortite and they're back to normal.

That would make for a much more repeatable part to start with. The sensitivity of the Whispers is lower than I'd like, though, but not a big deal (particularly if going with active crossover).

That RT4 looks like a likely good one, but is there a reliable source for more than on this ebay store? I've made too many designs that depend on NLA drivers, not gonna do that again!

Thanks Eldam. Flu is over now, I'm just catching up on household projects before getting back to the SmallSyns.

There won't be any licensing on them, I plan to put the whole design, along with building details online. -- As soon as I settle on just what that design will be of course (it's changed a number of times, now after I thought I was nearly done) -- I hope when I test the newest crossover it can be finished up. (Parts are in, along with parts to make a ported version).

Putting a back chamber on an open-backed driver isn't really very hard if you have the right size cardboard or pvc tubes and are good with cutting and cluing hardboard, but it is quite a few extra steps to do, and it might be difficult to assure that each build is similar enough to the original. On the 3FE22, offset loaded onto a SEOS15, the back volume has to be pretty small so even a little variation in construction might cause a lot of change, percentage-wise.

I catched a sort of very light flue in the public transport in Paris 2 weeks ago and this is just the beginning of the summer here (very lighter than NYC) : so I think sort of Sauna not soo good for the human-ants ! (plane, metro, train, bus) ! Unfornatully pollution here doesn't help (because gazoline is not good either, but we are going to follow Tokyo little by little about petrol for cars : no brut diesel anymore little by little !)

.........................

GFAWHSA ("Greenland For All With Hifi Speakers Association" - if you can't pronounce it, just listen to !)

Last edited:

Titan MD-888 a suitable mid?

I picked up 8 of these buyout drivers from PE. I will have to tear them apart and cut down the frames square to get them to fit on my horns. Has anyone tried using these? Any general idea on how these would work before I modify them?

Titan MD-888 5" Sealed Back Midrange Speaker 4 Ohm

Regards,

Nate

I picked up 8 of these buyout drivers from PE. I will have to tear them apart and cut down the frames square to get them to fit on my horns. Has anyone tried using these? Any general idea on how these would work before I modify them?

Titan MD-888 5" Sealed Back Midrange Speaker 4 Ohm

Regards,

Nate

Yes, I tried those.

The hard part is getting the grill off. When I removed the grill from mine, it took the surround off with it and ruined the drivers.

I had luck getting the mid grills off on the GRS 5" sealed back mids with a heat gun, hopefully that works on these without destroying the surrounds.

I did test with a tractrix horn and visaton drivers frm8 and woofers, I ask myself if this not give trouble, I do ask also what will do a constant directivity horn do.

it is little offtopic but was some curious for answers on this, the tractrix is from X.

I did read somewhere that a conic horn is choosen because of the injection ports, who do not as well on a tractrix or others who are not conical, a constant directivity horn is in fact a strange conic horn, with two conic parts.

regards

it is little offtopic but was some curious for answers on this, the tractrix is from X.

I did read somewhere that a conic horn is choosen because of the injection ports, who do not as well on a tractrix or others who are not conical, a constant directivity horn is in fact a strange conic horn, with two conic parts.

regards

Attachments

Last edited:

Buy some, measure the T/S, and let us know!

I thought that was your role, John

No seriously, I would gladly do that though if I hadn't just bought a pair of 4550 to go with the eight TF0410K I picked up a couple of weeks ago - and still need a lot of 10" woofers to complete the kit....

I see shipping to Europe is cost prohibitive too, quadrupling the unit cost of the drivers.

What I could do though is get another TF0410K (back in stock now at Blue Aran for £25 each), try to open up it up and measure the TSP. Maybe that would give a better clue of what to look for in an open driver that one intends to seal up.

Yeah, I actually used those on my design. The grille is a pain in the ***. I pried them off and used a bead of superglue around the edge of the surround to make sure it wasn't going anywhere. The curvature of the frame and the fact that it's nearly flush with the surround are also things that make them a pain in the ***. That said, they're cheap AF and work decently enough. I really need to fill in the mid chambers on mine. They're rolling off at 800hz and I'm hoping for something closer to twice that. But they are pretty large chambers currently.I picked up 8 of these buyout drivers from PE. I will have to tear them apart and cut down the frames square to get them to fit on my horns. Has anyone tried using these? Any general idea on how these would work before I modify them?

Titan MD-888 5" Sealed Back Midrange Speaker 4 Ohm

Regards,

Nate

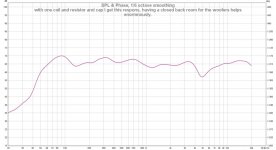

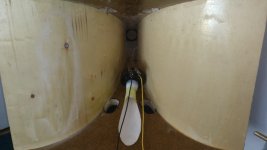

Guess this is a good a time as any for an update. I finally assembled it with all 4 mids and frustums on the ports. Now I just need to reduce the chamber volume to bump up the high corner. EQing the response flat is trivial because there's tons of headroom, but it's something I'll have to address eventually. Also noticed that my distortion figures on the CD were pretty high in the higher frequencies. What kind of figures should I be looking for?

The pattern control is amazing as always

https://youtu.be/gxZFNINsBqo

Really love the sound. Can't wait to have these things FINISHED. Extremely rewarding but man are they a pain to build. I set out to demonstrate that you could make a very good synergy speaker with very cheap drivers, and I think that's been accomplished. But now that I've put all the time and effort into building it, I feel like taking the absolute cheapest route on drivers is difficult to justify.

Were I to start again I think I'd like to try 4x Pyle PDMR5 and PRV Audio D290Py-B per side.

Last edited:

Really love the sound. Can't wait to have these things FINISHED. Extremely rewarding but man are they a pain to build. I set out to demonstrate that you could make a very good synergy speaker with very cheap drivers, and I think that's been accomplished. But now that I've put all the time and effort into building it, I feel like taking the cheap route on drivers is difficult to justify.

One of these days I should design a waveguide for a Synergy Horn and upload it to Shapeways.

I've been building these things for close to ten years now, and I *really* have it down to a science, at least when it comes to doing it quickly.

Off the top of my head, here's how long it took me to do various iterations:

1) My first Unity horn in 2006 took about two weeks to fabricate. The biggest "time-sink" was building a mold. I made the molt out of cardboard pieces that were individually printed on my laser printer, one by one. The horn shape was elliptical oblate spheroidal. All told, about sixty hours of work just for the horn. (The crossover took quite a while, that's not in the sixty hours.)

2) I think my second was the most successful. I re-used the mold, and the whole thing came together fairly quickly. Probably about 40 hours, without the xover.

Once I started using commercially available waveguides, that *really* sped things up. My 'Monster Massive' project came together over one weekend and a few nights. Probably 24 hours total, and that includes the xover work, because MiniDSP takes the pain out of Synergy Horn xovers

If you want a Synergy Horn quickly, nothing beats 3D printing. By molding the woofer chambers right into the waveguide, you cut out a lot of time consuming crap. For instance, in a wooden Synergy horn you have to drill sixteen holes for the woofers. In a 3D printed horn, there's no drilling at all. In a 3D printed horn, you don't have to make the mounting plates for the midranges, or wait for the glue to dry. You just bolt all the drivers together. Unfortunately there's no way to 3D print the wiring, so you still have to deal with *that* hassle.

Long story short, a 3D printed waveguide for Synergy Horn projects could be a real boon for everyone, even those of us with the skillset and know-how to build our own Synergy Horns.

I really need to fill in the mid chambers on mine.

A quick, cheap, (and reversible!) way to accomplish that would be with some plumbers' putty from about any hardware store. I used it in my SmallSyns and it worked great.

A problem with 3D printed Synergy horns at present is that 3D printers that can do large dimensions are rare and expensive. I hope and expect that will change in the not too distant future, but for now the only ones in my price range might be good for at most a throat adaptor...

A quick, cheap, (and reversible!) way to accomplish that would be with some plumbers' putty from about any hardware store. I used it in my SmallSyns and it worked great.

A problem with 3D printed Synergy horns at present is that 3D printers that can do large dimensions are rare and expensive. I hope and expect that will change in the not too distant future, but for now the only ones in my price range might be good for at most a throat adaptor...

I agree.

And even if I had a printer that *could* print a two cubic foot waveguide, I wouldn't use it. Because it would take a week to print the waveguide, and odds are good that something would go wrong at some point. (Even with months of practice, I still 'lose' about 30% of my prints due to various issues.)

So if you tried to print something huge, it's nearly certain it would fail.

Due to that, I've been going a 'hybrid' route, where the first few inches are 3D printed and the next few inches are wood.

I have a laser cutter, and I'd really like to take things to the next level, basically 3D print the throat and laser-cut the rest.

I haven't set up the laser cutter yet though, too busy.

I've wondered for a while if there's a market for laser or CNC cut baltic birch flatpacks for conical horns. You could offer a few basic variations of throat size, coverage angle, and mouth size. You'd have the opportunity to add finger joints or similar to make sure the dimensions are perfect and easy to assemble with nothing but glue. Obviously you'd have a long way to go to get a synergy horn, but having a nice easy and high quality starting point would be great. I'd certainly be willing to pay for that.A problem with 3D printed Synergy horns at present is that 3D printers that can do large dimensions are rare and expensive. I hope and expect that will change in the not too distant future, but for now the only ones in my price range might be good for at most a throat adaptor...

If somebody could create a good model I am very sure I could get them cut on a CNC machine and shipped very cheap.

I have a local sign business that has a 2D CNC machine. They cut out letters and what not and vacuum form plastic over that to create the shapes on their signs. They run the machine for $100 per hour. I get extremely cheap shipping via my business account and could ship out a few packs ( I can not ship out 100 units! But 10-20 seems possible)

These would be made as horns only. No midrange ports. Not sold as synergy horns just wooden triangles basically. They might not want to cut plywood as they only run MDF on it at this time.

I have a local sign business that has a 2D CNC machine. They cut out letters and what not and vacuum form plastic over that to create the shapes on their signs. They run the machine for $100 per hour. I get extremely cheap shipping via my business account and could ship out a few packs ( I can not ship out 100 units! But 10-20 seems possible)

These would be made as horns only. No midrange ports. Not sold as synergy horns just wooden triangles basically. They might not want to cut plywood as they only run MDF on it at this time.

I'm looking for a midrange cone, up to 6.5"dia to fit into a Bandpass enclosure which will fire into an odd unity horn (odd because its being re-shaped to fit into a car, but its using the unity concept).

Basically (I think) I need a midrange driver with a relatively high Fs and low Qt, to work in a 4th order bandpass (sealed rear chamber and ported front) and give me a lower cut off of about 200Hz and upper cut of of 1400Hz (-6db) if I can get more bandwidth all the better.

I'd like to go for a single 6.5" driver or smaller, multiple 2" or 3" drivers would be quite acceptable. I would ideally like something that is available in the UK though, importing from the states is an option but something easily available would be prefered. Someone is having reasonable success with multiple AuraSound NS2 'Whisper' drivers, I'm looking at the Eminence Alpha6 as they are cheap and easily available. any other suggestions please?

Someone is (finally) stocking drivers for Unity and Synergy Horns.

Every single option we've had so far has had drawbacks:

1) The Misco driver is about as good as it gets, but they're not stocked by any retailers. I kinda feel bad making them build four drivers for a silly DIY project

2) The Pyle drivers are *almost* right, but they're a little bit too big and the Qb is really high

3) The Aurasound Whispers work, but the efficiency is low and you have to build an enclosure. This is a real p.i.t.a. when you're using eight midranges

4) The TangBand 2" works, but has the same issues as the AuraSound

But have no fear, we can FINALLY buy the real deal. Only took ten years

P.S. I'm not listing the retailer because I figure they're going to sell out really fast, but a Google search will turn 'em up

1) The Misco driver is about as good as it gets, but they're not stocked by any retailers. I kinda feel bad making them build four drivers for a silly DIY project

You referring to the 3" or Danley's original 5"?

Sheldon

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn.