Thanks again sir.

An update... I went to the hardware store and bought 10 sheets of 3/4 5 ply birch plywood (buy 9 get 1 free) for $408 dollars.

I decided that double thick was not necessary and went back to the original 19" wide version that is 64" long. I dont think that changes the baffle as it is just the width that changes. Thanks for all your help and I will update the page as we go on.

Thanks again!

An update... I went to the hardware store and bought 10 sheets of 3/4 5 ply birch plywood (buy 9 get 1 free) for $408 dollars.

I decided that double thick was not necessary and went back to the original 19" wide version that is 64" long. I dont think that changes the baffle as it is just the width that changes. Thanks for all your help and I will update the page as we go on.

Thanks again!

Hi 2MuchRiceMakesMeSick,

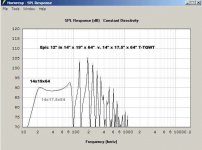

Going back to 19" you are just about matching bjorno's suggestion in Post #30. He used slightly different T/S parameters, and you can see how that impacts the response. Your final outcome will depend on the T/S parameters of your actual drivers and the construction. You are correct, 0.7" or 0.72" will not make any measureable difference in this construction. I'll attach a Hornresp SPL graph showing the difference between 17.5" and 19".

He used slightly different T/S parameters, and you can see how that impacts the response. Your final outcome will depend on the T/S parameters of your actual drivers and the construction. You are correct, 0.7" or 0.72" will not make any measureable difference in this construction. I'll attach a Hornresp SPL graph showing the difference between 17.5" and 19".

Please, take note that the stuffing in these enclosures is not just decorative, but is an integral part of the design, and most definitely impacts the response; and it's called stuffing, not just lining. You are filling the complete cross-section of the duct with e.g.: fiberfill; starting with a slightly higher density in the S1/S2 area, and tapering the density down to the end of the indicated fill area. This is not like a bass-reflex where you may or may not use acoustic absorption/lining. The stuffing will strongly affect the sound quality. You should construct-at least the first test box-of the enclosure with some means to tune the amount and location of the stuffing. Here is some advice from bjorno: http://www.diyaudio.com/forums/subwoofers/203827-20-30hz-tapped-horn-studio-ande-drivers-13.html, see Post #122.

Pictures will be great.

Regards,

Going back to 19" you are just about matching bjorno's suggestion in Post #30.

Please, take note that the stuffing in these enclosures is not just decorative, but is an integral part of the design, and most definitely impacts the response; and it's called stuffing, not just lining. You are filling the complete cross-section of the duct with e.g.: fiberfill; starting with a slightly higher density in the S1/S2 area, and tapering the density down to the end of the indicated fill area. This is not like a bass-reflex where you may or may not use acoustic absorption/lining. The stuffing will strongly affect the sound quality. You should construct-at least the first test box-of the enclosure with some means to tune the amount and location of the stuffing. Here is some advice from bjorno: http://www.diyaudio.com/forums/subwoofers/203827-20-30hz-tapped-horn-studio-ande-drivers-13.html, see Post #122.

Pictures will be great.

Regards,

Attachments

Hi,

That was 2lbs.3oz for the 80" version, and 2lbs.2oz for the 64" version. Yes, PE sells one version (somewhat pricey, but especially developed for these applications): Acousta-Stuf Polyfill 5 lb. Bag 260-330. I have always been able to find fiberfill at Walmart, a quick search on their website shows a number of solutions, e.g.: Mountain Mist Fiberloft Polyester Stuffing, something like that seems to work just fine.

Regards,

That was 2lbs.3oz for the 80" version, and 2lbs.2oz for the 64" version. Yes, PE sells one version (somewhat pricey, but especially developed for these applications): Acousta-Stuf Polyfill 5 lb. Bag 260-330. I have always been able to find fiberfill at Walmart, a quick search on their website shows a number of solutions, e.g.: Mountain Mist Fiberloft Polyester Stuffing, something like that seems to work just fine.

Regards,

Hi,

I hope you ordered a woofer tester too. Sooner or later, it would be nice to have measured T/S parameters.

Regards,

Woofer tester? LOL its out of stock too

Dayton Audio WT3P WT3 Bundled with Precision Scale 390-803

64" on this one. I just cut the boards and glued the bottom, one side, and one end together and then I had to leave. I still need to research some slick ways of making access panels

I will probably do something like this

http://forums.klipsch.com/forums/storage/6/1666210/CompleteAccess.jpg

but it looks a bit weak to me

I will probably do something like this

http://forums.klipsch.com/forums/storage/6/1666210/CompleteAccess.jpg

but it looks a bit weak to me

Last edited:

Also, do I need to cut the 'triangle' boards that go in the corner to help curve the sound. (sorry I do not know what they are called. but they are the boards cut at 45 degrees to make a 'triangle shape in the corners)

http://img14.imageshack.us/img14/8076/182pb.jpg

http://img14.imageshack.us/img14/8076/182pb.jpg

Hi,

Even one of the 64" subs should be quite impressive. The only reason I can think of for corner reflectors in this type of sub is to reinforce the corner. You can do that with some simple blocking. It cannot do any harm.

I'll attach an access doodle.

Regards,

Even one of the 64" subs should be quite impressive. The only reason I can think of for corner reflectors in this type of sub is to reinforce the corner. You can do that with some simple blocking. It cannot do any harm.

I'll attach an access doodle.

Regards,

Attachments

Hi,

Just another doodle on braces, and access. It's really important to maintain access to the stuffing on the first test enclosure. Even with about half the length you'll have enough access to modify the stuffing density. You could start with e.g.: 0.2 lbs/ft^3 for the whole length of stuffing, and then experiment with higher density towards the S1 area.

Regards,

Just another doodle on braces, and access. It's really important to maintain access to the stuffing on the first test enclosure. Even with about half the length you'll have enough access to modify the stuffing density. You could start with e.g.: 0.2 lbs/ft^3 for the whole length of stuffing, and then experiment with higher density towards the S1 area.

Regards,

Attachments

Do you have any measurements of cabinets "with" and "without" stuffing?Hi,

You could start with e.g.: 0.2 lbs/ft^3 for the whole length of stuffing, and then experiment with higher density towards the S1 area.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Suggestions Creating Subwoofer Box(s) - 56 cuft available