...and it keeps your coffee warm as well.moe29 said:coolZen as coffee table!

Yep...you get to sit in a zen position too while drinking coffee. For now it keeps my daughter's bottom warm. This Zen stands on its back too so it can function as a room heater during hard use.

I'm planning to polish the hsinks to a chrome-like shine, any suggestions? The wood is going to be stained leather-brown so I won't have to up-holster it

I'm planning to polish the hsinks to a chrome-like shine, any suggestions? The wood is going to be stained leather-brown so I won't have to up-holster it

update on project

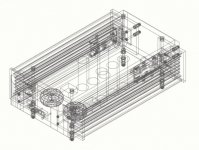

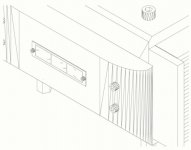

Here are more pictures of my Zv4. Some chassis design facts: It was designed using AutoCAD which I had to self-learn. The dimension of the chassis is 26”x15.5”x9.5” (WxDxH) -staying close to the Golden Ratio for aesthetic reasons. The current weight with 2 toroids and 6 electrolytic caps is 60 pounds. The beveled front panel, made of two ¾” thick oak boards, of course got its inspiration from Nelson’s XA series. The curved faceplate was inspired from what I usually see in the DIYAudio.com and PassDIY.com pages – FLAT front panels. With that I declare the DIY audio world is NOT FLAT. I can also easily replace the curved front panel with something exotic like cocobolo or bubinga hardwoods…but for now the growth rings of oak looks nice and I own the bragging rights (in all audio world?) for the thickest faceplate at 2 INCHES! Between the curved front panel and the ½” thick aluminum that serves as additional heatsink but more as carry-around-the-house finger grips will be super bright blue and green LEDs. Blue will be for normal operation and green will be for standby/nightlight. The 23.5” long heatsinks are from ThermaFlo, with thermal specs of 1.44 C/W/3”. I plan to try running 2.8A bias per channel…if it gets too hot I’ll lower it. The beveled back panel is equipped with 1” coupling nuts. These allow it to also stand on its back in party mode. I guess the heatsinks will dissipate heat better vertically. The legs of the amp in the Zen position are ½”x1.5” steel chrome lug nuts, I got from NAPA, usually reserved for SUV wheels. Popping the hood shows the legs extending to the top panel via threaded rods. The four rods are tipped with coupling nuts where the oak top panel sits and fastened with ½”x1” cap hex bolts. As can be seen from the pictures, the big cap hex bolts add nicely to the overall look…this is from watching American Chopper and Monster Garage. My concern though is once the amp is running and in heat J the top panel might warp. I won’t fret much if it warps like the sides of Rushmore. I’ll just say it was inspired . A Zen logo in what I think is in its simplest form sits nicely on the front panel. The chassis’s wood is finished with several coats of Watco Teak oil and Minwax Golden Oak. The wood, bolts, nuts, screws and other hardware are from Home Depot, Lowes and Tacoma Screw. With the Zen engine under the hood soon…I would already have created a musical instrument with the legendary Nelson Pass.

. A Zen logo in what I think is in its simplest form sits nicely on the front panel. The chassis’s wood is finished with several coats of Watco Teak oil and Minwax Golden Oak. The wood, bolts, nuts, screws and other hardware are from Home Depot, Lowes and Tacoma Screw. With the Zen engine under the hood soon…I would already have created a musical instrument with the legendary Nelson Pass.

Here are more pictures of my Zv4. Some chassis design facts: It was designed using AutoCAD which I had to self-learn. The dimension of the chassis is 26”x15.5”x9.5” (WxDxH) -staying close to the Golden Ratio for aesthetic reasons. The current weight with 2 toroids and 6 electrolytic caps is 60 pounds. The beveled front panel, made of two ¾” thick oak boards, of course got its inspiration from Nelson’s XA series. The curved faceplate was inspired from what I usually see in the DIYAudio.com and PassDIY.com pages – FLAT front panels. With that I declare the DIY audio world is NOT FLAT. I can also easily replace the curved front panel with something exotic like cocobolo or bubinga hardwoods…but for now the growth rings of oak looks nice and I own the bragging rights (in all audio world?) for the thickest faceplate at 2 INCHES! Between the curved front panel and the ½” thick aluminum that serves as additional heatsink but more as carry-around-the-house finger grips will be super bright blue and green LEDs. Blue will be for normal operation and green will be for standby/nightlight. The 23.5” long heatsinks are from ThermaFlo, with thermal specs of 1.44 C/W/3”. I plan to try running 2.8A bias per channel…if it gets too hot I’ll lower it. The beveled back panel is equipped with 1” coupling nuts. These allow it to also stand on its back in party mode. I guess the heatsinks will dissipate heat better vertically. The legs of the amp in the Zen position are ½”x1.5” steel chrome lug nuts, I got from NAPA, usually reserved for SUV wheels. Popping the hood shows the legs extending to the top panel via threaded rods. The four rods are tipped with coupling nuts where the oak top panel sits and fastened with ½”x1” cap hex bolts. As can be seen from the pictures, the big cap hex bolts add nicely to the overall look…this is from watching American Chopper and Monster Garage. My concern though is once the amp is running and in heat J the top panel might warp. I won’t fret much if it warps like the sides of Rushmore. I’ll just say it was inspired

Attachments

faustian b., thanks...i tried "dispsilh 1" in the command line and it worked...removing the mesh lines in curved surfaces.

tobias s., I'll try your suggestion too andsee the effect.

i basically learned using cad by playing with it...although what i know now must be just the tip of the iceberg. I'm trying to learn rendering finishes on solids...any advice? how does layering work?

tobias s., I'll try your suggestion too andsee the effect.

i basically learned using cad by playing with it...although what i know now must be just the tip of the iceberg. I'm trying to learn rendering finishes on solids...any advice? how does layering work?

I plan to try running 2.8A bias per channel…if it gets too hot I’ll lower it.

Blue!! Did you manage to run your zen v4 with R0 at 0.47 ohms? More importantly, was there any improvement in sound quality?

When adjusting R4 (25Kohm pot), what voltage did you set your amp at? Did you get a regulated voltage of 42 volts?

I've finished building my twin block zen v4 and pretty sure i've over heatsinked it. I hope to post pictures soon but want to make these simple changes before posting.

BQ

Sad to say I haven't done much of the amp part yet...I will soon

Looking at your webpage...are your heatsinks one block of Al or was connected with one large Al plate. It looks like the latter judging from the silicon grease on the surfaces. With good surface contact, it will definitely be enough for 2.8A bias. You must have tried running them with 2A by now. What is the temp rise from ambient? From 1.5A bias to 2.8A, the difference will definitely be noticeable...from 2A, I'll let you find out...let me know . Increasing the bias of the buffer will do it good IMO...as Panelhead(?) found out...I'll do that too. Are you running 2 channels bridged? How did you wire this? Nice piece of work you have there, mate!

. Increasing the bias of the buffer will do it good IMO...as Panelhead(?) found out...I'll do that too. Are you running 2 channels bridged? How did you wire this? Nice piece of work you have there, mate!

Looking at your webpage...are your heatsinks one block of Al or was connected with one large Al plate. It looks like the latter judging from the silicon grease on the surfaces. With good surface contact, it will definitely be enough for 2.8A bias. You must have tried running them with 2A by now. What is the temp rise from ambient? From 1.5A bias to 2.8A, the difference will definitely be noticeable...from 2A, I'll let you find out...let me know

Heatsinks are connected to one large plate on each side. Don't have a temperature probe to measure how hot they are. Just only know that the heatsinks barely get warm.

Depending on the occasion, I would probably run them balanced all the time. Unless I bring one over to a friend's place that only has RCA gear - then each monobloc can be operated in 2 channel. Havn't worked out 2 channel bridge yet.

BQ

Depending on the occasion, I would probably run them balanced all the time. Unless I bring one over to a friend's place that only has RCA gear - then each monobloc can be operated in 2 channel. Havn't worked out 2 channel bridge yet.

BQ

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Still in production Zen v4