I have alluded to a pair of subs for a FAST system with any of the Alpair drivers. Well, here they are!!

Since the subs are intended to be stands for the satellite speakers, the physical dimensions are dictated by function. The subs are 24" high and 12" wide to provide a relatively small visual appearance, which forces the depth to be 17". This models out to be a Qtc of 0.7 with moderate stuffing. Oh, yes. The drivers are the Dayton RS315HF-4's. This gives F3=39Hz and F10=24Hz. At 250w/ch they will do 100dB@23Hz. At a modest 75w/ch, they will do 90dB@18hz.

I have yet to do any measurements or play with the XO point/slope or EQ yet (miniDSP). I just pulled the Goldwood 18" H-frames and stuck the Dayton in. The XO is LR4@250Hz and there is a brickwall at 25Hz, so the Dayton's aren't getting to the bottom yet. The brickwall was necessary with the Goldwood's because of their Xmax is a measly 2mm. The Daytons are 14mm.

The tops are a pair of BR's I am working on for the A10P. They show real promise, but that is another story.

Regardless of the work I need to do with the XO/EQ, the XO is seamless. 'Cellos and bassoons go through the XO with no complaints. I think I have a winner here.

I can't get decent 18mm material out here in the wilderness, so I am stuck with 12mm Russian birch plywood. Not thinking that 12mm plywood would be the best thing for a sub box, I laminated up 24mm panels. That should do it! And how! These suckers weight 65lb a piece. I did put a brace above the driver side-to-side, not that it needed it.

The first picture is an oblique of the sub. Next, the sub with the A10P BR on top. Last, the pair in place. Note that I toe the BR's out ~10*. This seams to work best for me.

Bob

Since the subs are intended to be stands for the satellite speakers, the physical dimensions are dictated by function. The subs are 24" high and 12" wide to provide a relatively small visual appearance, which forces the depth to be 17". This models out to be a Qtc of 0.7 with moderate stuffing. Oh, yes. The drivers are the Dayton RS315HF-4's. This gives F3=39Hz and F10=24Hz. At 250w/ch they will do 100dB@23Hz. At a modest 75w/ch, they will do 90dB@18hz.

I have yet to do any measurements or play with the XO point/slope or EQ yet (miniDSP). I just pulled the Goldwood 18" H-frames and stuck the Dayton in. The XO is LR4@250Hz and there is a brickwall at 25Hz, so the Dayton's aren't getting to the bottom yet. The brickwall was necessary with the Goldwood's because of their Xmax is a measly 2mm. The Daytons are 14mm.

The tops are a pair of BR's I am working on for the A10P. They show real promise, but that is another story.

Regardless of the work I need to do with the XO/EQ, the XO is seamless. 'Cellos and bassoons go through the XO with no complaints. I think I have a winner here.

I can't get decent 18mm material out here in the wilderness, so I am stuck with 12mm Russian birch plywood. Not thinking that 12mm plywood would be the best thing for a sub box, I laminated up 24mm panels. That should do it! And how! These suckers weight 65lb a piece. I did put a brace above the driver side-to-side, not that it needed it.

The first picture is an oblique of the sub. Next, the sub with the A10P BR on top. Last, the pair in place. Note that I toe the BR's out ~10*. This seams to work best for me.

Bob

Attachments

Right. When designing an XO, one would like at least an octave of overlap, preferably two. Using a BR on top, it I reach Xmax at 30w around 60 Hz. Sealed, F3 and Xmax would occur at 100Hz. The sub reaches Xmax at 250w at 10Hz (it will take 400w, but maxes out at 35Hz.) Sealed subs generally work better for music than BR's, particularly BR's tuned low. The Dayton doesn't start to break up until ~1kHz, so arbitrarily, it is goo to 500Hz.

So. I can reasonably cross these two speakers anywhere frm 100-500Hz. I may get som play time with them this afternoon.

Bob

So. I can reasonably cross these two speakers anywhere frm 100-500Hz. I may get som play time with them this afternoon.

Bob

Tube amp? Where? Oh -- that tube amp. That's a custom built (Jef Larson) I got several years ago primarily for shows. You know, if it isn't tubes, it can't be HiFi. It has 6BQ7's PP, about 9w/ch. I asked Jef to build me a tube amp that sounded like a SS amp. Came pretty close. Rolls off a bit at the top, and bloats a bit at the bottom, but hey! It's tubes.

Left to right: Jef's 6BQ7, Dayton APA-150 for the subs, Topping TP-60, Topping D20 DAC on top of the TP-60, and finally an old Yamaha 5.1 I use as a tuner.

Bob

Left to right: Jef's 6BQ7, Dayton APA-150 for the subs, Topping TP-60, Topping D20 DAC on top of the TP-60, and finally an old Yamaha 5.1 I use as a tuner.

Bob

It has 6BQ7's PP, about 9w/ch.

Looks more like PP 6V6GT to me. The 6BQ7's would be the driver tubes.

jeff

Shows you what I know about tube amps. The output tubes are 6BX7. I can't read the numbers off of the driver tubes. I fire this amp up every one in a while just to convince myself that I am not missing anything compared to a decent class D amp. There is no accounting for personal taste, but I simply don't like to euphonic sound of small SET's.

BTW, Jef's site returns a blank page. I know he was having medical problems.

Bob

BTW, Jef's site returns a blank page. I know he was having medical problems.

Bob

Now that the magnet issue is kinda sorted any advise on attaching grill cloth, can,t say i like the idea of hot glue and staples and to complicate that more i wanted to use solid wood matching frame with the cloth attached to the inside of the frameI also note a tube amp in one of the photos - wassup with that Bob?

and yup, with the right sized brad point bit, you can get a dead perfect flush on the magnets ( I use the 1/4" x 1/4" from Lee Valley myself)

think i need a smaller workshop and a bigger beer fridge, hmmmmmm beer

Last edited:

Paul,

I build grill frames from 12mm BB 1" wide, but you can assemble the stick frame from whatever is handy. I run the frame through the table saw with a standard width blade, not a thin kerf blade. I make the kerf 1/4" in from the edge and 1/4" deep. I stretch the grill cloth over the frame and secure the cloth with 1/8" window screen spline. You will need a tool to install the spline. Should be available at the same store you find the spline.

You imply that you want to run the grill cloth under the frame. I've never done that. I always run the cloth over the frame, but I see no reason why that won't work.

Bob

I build grill frames from 12mm BB 1" wide, but you can assemble the stick frame from whatever is handy. I run the frame through the table saw with a standard width blade, not a thin kerf blade. I make the kerf 1/4" in from the edge and 1/4" deep. I stretch the grill cloth over the frame and secure the cloth with 1/8" window screen spline. You will need a tool to install the spline. Should be available at the same store you find the spline.

You imply that you want to run the grill cloth under the frame. I've never done that. I always run the cloth over the frame, but I see no reason why that won't work.

Bob

Played with them a while yesterday. EQ'd the sub to ~flat to 200Hz. In-room F3=20Hz. Drops like a rock below that, but who cares! I now have the XO at 200Hz, LR8. Had to invert the phase, but I still have a minor phase problem, so I'll need to play with the delay. It is working well, though. I tested with the Plant/Kraus "Your Long Journey". The XO is right in the middle of Plant's range. I don't hear any problems.

Bob

Bob

Paul - re attaching fabric - after several aborted attempts at it myself, I get a buddy of mine who's been a car installer for over 30yrs to do that. He uses spray adhesive for fabric with masking to eliminate over spray on the frames, and careful stretching of the fabric around the frame and finishes off by trimming with utility knife.

Bob - your rubber spline sounds like a great trick - I should try that myself.

Bob - your rubber spline sounds like a great trick - I should try that myself.

I would prefer not do them at all, but with customer demand and the fragility of the drivers it is probably going to be a must.

Chris i think i like the window spline idea, at least I can remove it if I don,t get it right the first time and try again.

I think i here Mr keiths calling me, time to sweep up and call it a day, I will ponder over the ideas as i rehydrate

thanks fellows

Chris i think i like the window spline idea, at least I can remove it if I don,t get it right the first time and try again.

I think i here Mr keiths calling me, time to sweep up and call it a day, I will ponder over the ideas as i rehydrate

thanks fellows

OK, play time.

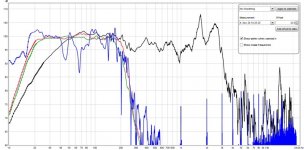

The black trace is the raw nearfield of the Dayton. It took maybe five minutes to EQ the nearfield to flat 20-200Hz with a LR24 XO at 200Hz. Red is right, green is left. Then I did an in-room at 2.4m -- blue. I am still trying to figure out what to do with this! (Traces normalized to 100dB.)

Bob

The black trace is the raw nearfield of the Dayton. It took maybe five minutes to EQ the nearfield to flat 20-200Hz with a LR24 XO at 200Hz. Red is right, green is left. Then I did an in-room at 2.4m -- blue. I am still trying to figure out what to do with this! (Traces normalized to 100dB.)

Bob

Attachments

For many years I've used metal window framing for lightweight speaker grills. Home Depot , Lowes, and other home centers have a 5/16" thick aluminum frame which is 3/4" wide. There is a trench into which you roll the grill cloth and 1/8" rubber spline. I cut the metal with straight cuts and use the plastic corner pieces to connect the sections of the grill together. One set of magnets are embedded into the enclosure (can be placed under veneer or laminate for a hidden look. A second set of magnets (I'm assuming that you carefully observe magnet polarity when you do this) are spaced and glued inside the cavity in each corner piece. The frame is placed over the fabric with 2-3 inches extra length in all dimensions. Then you wrap the cloth over the frame and roll the spline with the cloth into the groove on the rear of the frame. An inexpensive roller tool is sold to help the rolling process. Once you secure the cloth into the grooves, you can trim the excess cloth for a nice finished look. No spray glue involved and if you mess-up you can rework before you trim the cloth. Presto! You have slick looking grills that magnetically attract to the enclosure.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Stands for my A10P's