O.K. I want to make jbell's single sheet TH, in a not so single sheet way. I would like to use 18mm ply and use bracing like in the Tuba24 - running through the cabinet, a little off centre and with holes throughout to allow for movement of air through the 2 halves of the cabinet.

My question is, what are the optimal dimensions, not minding that a cab takes more than one sheet?

My question is, what are the optimal dimensions, not minding that a cab takes more than one sheet?

These are the optimum dimensions.

If you use 18mm ply then you will have to recalculate the internal panel points. I made mine with 18mm outer panels and made the sides a half inch bigger in both dimensions to accommodate that. then used half inch ply for internals to keep it the same inside. Worked for me but i am yet to test them and see if they have turned out as good as Jims.

If you use 18mm ply then you will have to recalculate the internal panel points. I made mine with 18mm outer panels and made the sides a half inch bigger in both dimensions to accommodate that. then used half inch ply for internals to keep it the same inside. Worked for me but i am yet to test them and see if they have turned out as good as Jims.

These are the optimum dimensions.

If you use 18mm ply then you will have to recalculate the internal panel points. I made mine with 18mm outer panels and made the sides a half inch bigger in both dimensions to accommodate that. then used half inch ply for internals to keep it the same inside. Worked for me but i am yet to test them and see if they have turned out as good as Jims.

I just finished my second one. 3/4" exterior panels( 1/2" over on exterior dimensions also ), and 5/8" internal panels . internal dimensions were kept the same and results are very good. I did have to change the baffle corner to back panel dimension from 9.07" inches to 9 1/2" though. The math doesn't add up for me any other way. Unless i'm missing something.

Hi runrod 1948,

When you put a design into Hornresp (or even better int AkAbak) you can check which dimensions are critical, and which can be varied widely. Jbell hit a home run with this one, which doesn't mean you cannot fiddle with it in Hornresp if you are willing to relax the single sheet requirement, but sometimes it is best to leave well enough alone.

Regards,

When you put a design into Hornresp (or even better int AkAbak) you can check which dimensions are critical, and which can be varied widely. Jbell hit a home run with this one, which doesn't mean you cannot fiddle with it in Hornresp if you are willing to relax the single sheet requirement, but sometimes it is best to leave well enough alone.

Regards,

Thanks everyone for your responses. Did anyone add internal bracing and compensate in internal volume for the braces as well? As I already mentioned, I want to run a brace right through the cross-section, a little off centre, and drill about 3"-4" holes to allow for free movement of air between the two halves.

I also plan to use tar-felt for all internal panels, secured with rubber adhesive. I have found that the panels become very stiff and you can hardly feel any vibrations on the outside of the panels.

I also plan to use tar-felt for all internal panels, secured with rubber adhesive. I have found that the panels become very stiff and you can hardly feel any vibrations on the outside of the panels.

To brace or not to brace.

Hi Samuel Jayaraj,

I just entered the data into my Hornresp model to reflect an internal solid center brace. In other words, reduce the internal width by 1/2". There is virtually no difference in the resulting curves between brace or no brace.

Regards,

Hi Samuel Jayaraj,

I just entered the data into my Hornresp model to reflect an internal solid center brace. In other words, reduce the internal width by 1/2". There is virtually no difference in the resulting curves between brace or no brace.

Regards,

Oliver, thanks. This is very good news. In your sim, if a solid centre brace does not result in any difference in the curves, in reality, an offcentre brace with enough holes for cross-movement of air should pose no problems and reduce panel flex as well. So it does appear that the internal panels will have to be 1/2", external panels 3/4" (adding the extra 1/4" per panel to the external dimension) and increase internal width by a little less than 1/2" to compensate for an 1/2" solid holey brace.

After making a few of the t48s I was dubious about the lack of bracing in the SS15, but having made a pair with the 18mm outer panels and no internal braces, I have to say it is still one solid box. I've gigged with them for a couple of weeks now, (that's almost 30 different bands in that time) and they have shown no problems so far. Crowds up to 200.

After making a few of the t48s I was dubious about the lack of bracing in the SS15, but having made a pair with the 18mm outer panels and no internal braces, I have to say it is still one solid box. I've gigged with them for a couple of weeks now, (that's almost 30 different bands in that time) and they have shown no problems so far. Crowds up to 200.

If you look at the ss15, the most 'unbraced' panels are the top, back and bottom. My 2 little braces tie those together, and while it doesn't completely eliminate flex, it reduces it to very livable levels. 18mm exterior ply would obviously help over 12mm.

Remember my original goal was the lightest, loudest cabinet I could reasonably install. When you are on a lift 20' - 30' in the air, 150lb subs suck. Auroco ply is 42lbs per sheet, 7lb 3015lf driver = 50lb total cabinet, and a happy back at the end of the day. I've actually (before adding grill) carried my ss15's around by the cast aluminum driver frame. (yea I actually use the driver frame as a handle... they are really that light.)

Glad you like your new subs dave.

Hi Samuel Jayaraj,

What I tried to indicate is that the material thickness seems to have no discernible impact on the SPL curve. You don't need to make the box wider, you can use 1/2" or 5/8" or 3/4" for the inside, or for the outside, it does not affect Hornresp.

That does not mean that it does not affect the audible/measureable results, only building/listening/measuring can tell you that. My guess is that a more solid construction will help the horn output to be closer to the model, but as I'm getting older I agree with jbell: "...lighter is better..".

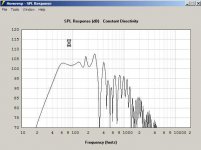

I'll attach the Hornresp SPL graph for a standard 1/2" wall model and a model with a 1.5" thick center brace. You have to look closely to see the differences.

Regards,

What I tried to indicate is that the material thickness seems to have no discernible impact on the SPL curve. You don't need to make the box wider, you can use 1/2" or 5/8" or 3/4" for the inside, or for the outside, it does not affect Hornresp.

That does not mean that it does not affect the audible/measureable results, only building/listening/measuring can tell you that. My guess is that a more solid construction will help the horn output to be closer to the model, but as I'm getting older I agree with jbell: "...lighter is better..".

I'll attach the Hornresp SPL graph for a standard 1/2" wall model and a model with a 1.5" thick center brace. You have to look closely to see the differences.

Regards,

Attachments

and a happy back at the end of the day..)

and thank you for that!

So next question is what is the difference in weight?

1 or 2 lbs - IF that?

My Apache's are about 40-45 lbs (estimate) compared to my THMini clones which are about 65-70 lbs. The big deal there is that the Apaches are 3-4 times the size! Major difference is driver. Material is different also. THMini Clones are 2-MDF and other 2 13 ply birch. Apaches are 3/4 cabinet grade from

Home Depot.

The SS15 is slightly smaller than the Apache.

That should make a rather light box.

1 or 2 lbs - IF that?

My Apache's are about 40-45 lbs (estimate) compared to my THMini clones which are about 65-70 lbs. The big deal there is that the Apaches are 3-4 times the size! Major difference is driver. Material is different also. THMini Clones are 2-MDF and other 2 13 ply birch. Apaches are 3/4 cabinet grade from

Home Depot.

The SS15 is slightly smaller than the Apache.

That should make a rather light box.

I'd say a cluster of 4 would do 300 indoors ok. I would always keep them stacked centrally if at all possible. I'll have to see how the larger numbers work out. I don't have many shows that need more than 300 crowd indoors so I wouldn't want to speculate.

This is what jbell wrote in the other thread, "jbell's set of four tapped...."

Hate to tell you this, but the best upgrade for the big cabinet. (if you don't need mid 30's response) is to put your current drivers in the smaller ss15, and buy a couple more 3015lf's, and have a fleet of 4 ss15's. They will fit in your van...

The big cab is about 102db from 60hz on up, the ss15 is 105db from 60hz on up. So a pair of ss15's vs a pair of big cab's is +6db in that range. It's in the 38-42hz range that the big cabinet really shines, so depending on the music you play, depends on which cabinet is best.

So, a pack of 4 ss15's vs a pair of big cabinets should get you +12db, and be flat to 40 doing it. (and the ss15 is only 50lbs a cabinet... that's the part I really love)

This has left me wondering thus, if jbell is powering a stadium with 4 of the big cabs, I'd expect the small cabs to do better.

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge