I'm highly skeptical a nickel core can be degraded by measuring via a multimeter. The claim is that the ohmmeter's DC current will saturate the core. However, we're talking about a soft magnetic material. I have some 80% nickel around my workshop, so I'm willing to attempt the test using a high-DC current.

I'm not reporting any permeability loss from slamming 70mA into an EI core 1.8cm2 Afe 80% nickel with 1050 turns. Before Idc application, L = 50.0H. After DC application, L = 50.6H. I find the reason for the increase of inductance is the Idc attraction of the I laminations closer to the E laminations.

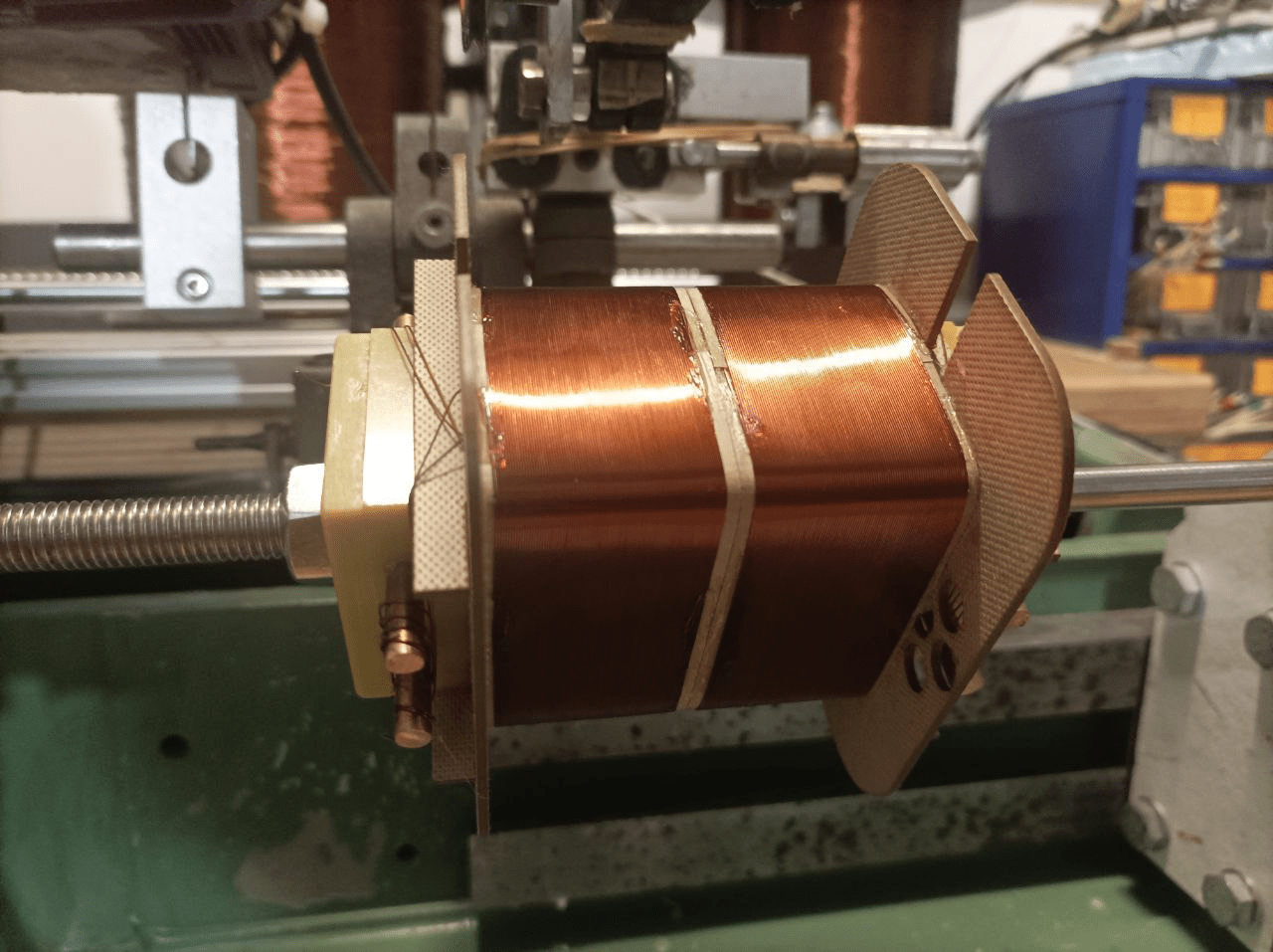

I'm currently winding the previously quoted phase splitter transformer. Just finished doing 1/2 of the secondaries, now screens are to be placed.

I'm currently winding the previously quoted phase splitter transformer. Just finished doing 1/2 of the secondaries, now screens are to be placed.

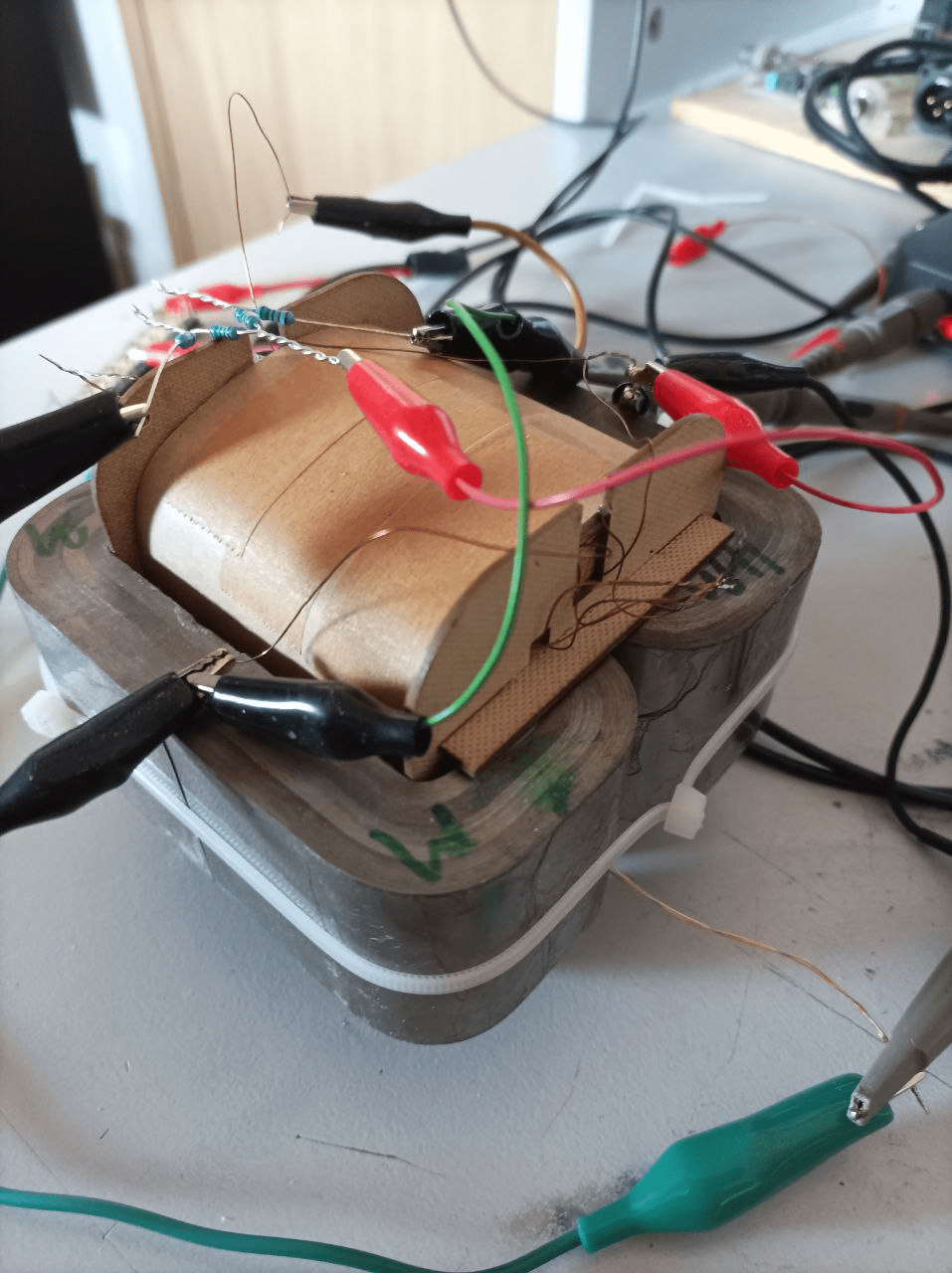

I made 1 prototype of PP transformer with nanocrystalline core. In short - I don't think its worth it due to massive increase of dimensions, and therefore, parasitic parameters. Amorphous, may be, but not nanocrystalline.And nanocrystaline core? Lundhall offer some of its transformer with nanocrystaline option, cost is at double double the standard one. Some users reported a substantial improvement compare to the silicone steel version.

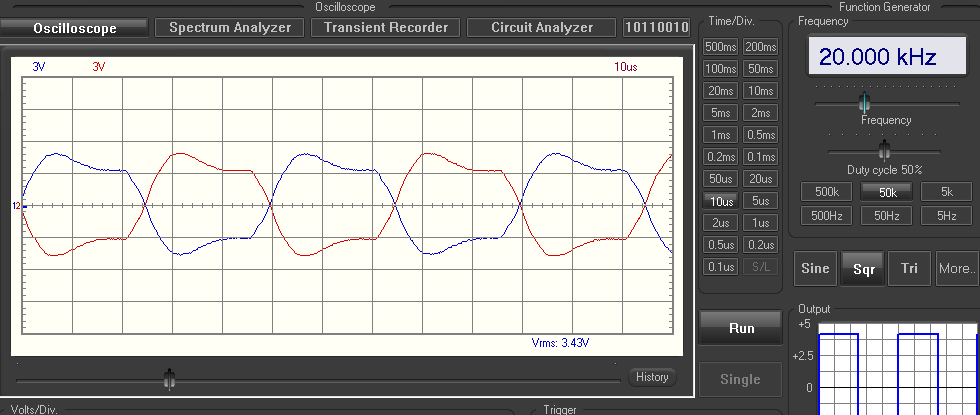

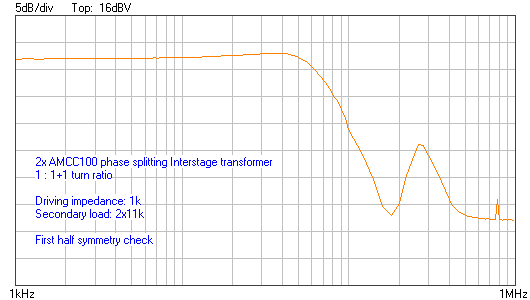

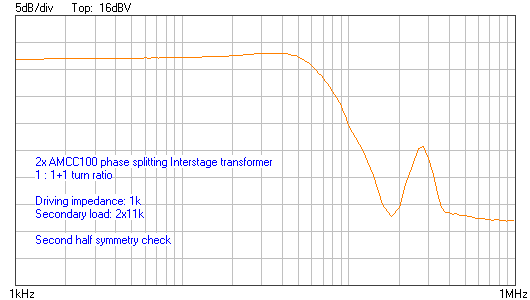

First measurements of the protype phase splitter. I feell happy. The symmetry between the halves is satisfactory. There is a peaking resonance at ~40kHz, which is easy to flatten using a higher secondary load or increasing driving impedance. I will experiment further by grounding the core, which theoretically if left floating, can lead to some asymmetry, which is still observable in the frequency responses. The cause could also be physical distance asymetry of the core related to the outer windings, or small winding asymmetries.

Last edited:

Hi

It's a beautyful work.

It's like very heavy for a TI with AMCC-100.

May I ask you for C core supplier ?

Is it :

https://french.alibaba.com/p-detail/AMCC100-60783389205.html?spm=a2700.details.0.0.8d223733OvqGNh

Yan

It's a beautyful work.

It's like very heavy for a TI with AMCC-100.

May I ask you for C core supplier ?

Is it :

https://french.alibaba.com/p-detail/AMCC100-60783389205.html?spm=a2700.details.0.0.8d223733OvqGNh

Yan

Hi Yan,

These are from KingMagnetics.

This specific IT is heavy, because it requries being driven from a 300B with 40mA Idc current and a large voltage swing, like 100Vrms on the primary and 2x100Vrms on the secondary. But the whole concept can be scaled down to smaller cores if lower requirements are to be needed.

All the best,

Alexander.

These are from KingMagnetics.

This specific IT is heavy, because it requries being driven from a 300B with 40mA Idc current and a large voltage swing, like 100Vrms on the primary and 2x100Vrms on the secondary. But the whole concept can be scaled down to smaller cores if lower requirements are to be needed.

All the best,

Alexander.

Hi

Thanks for the feedback

I bought amcc63 in order to build transformers for a circlotron of 6P36c about 40 - 50 watt.

Tramy is made with 4 C core : Zp : 850 Ohm, Aréa15.6cm2, 936 turns, arrangement s p ss p ss p s and 2 columms

I have the same problem with the air gap which is too wide, I lack self inductance and the amp sounds with tight bass

I'll try to grind the surface like you like this thread

Yan

Thanks for the feedback

I bought amcc63 in order to build transformers for a circlotron of 6P36c about 40 - 50 watt.

Tramy is made with 4 C core : Zp : 850 Ohm, Aréa15.6cm2, 936 turns, arrangement s p ss p ss p s and 2 columms

I have the same problem with the air gap which is too wide, I lack self inductance and the amp sounds with tight bass

I'll try to grind the surface like you like this thread

Yan

Last edited:

Your work as always looks very neat and well done.

I see you have a replacement turns counter on the Meteor winder, is that something you have made yourself or one that is off the shelf/commercial, I would like to replace the old mechanical counter on my Aumann, it's good in one respect in being mechanical as I can power off the winder and it doesn't lose the number of turns so if I replaced it with an electronic counter that feature would be nice.

I see you have a replacement turns counter on the Meteor winder, is that something you have made yourself or one that is off the shelf/commercial, I would like to replace the old mechanical counter on my Aumann, it's good in one respect in being mechanical as I can power off the winder and it doesn't lose the number of turns so if I replaced it with an electronic counter that feature would be nice.

I would like to replace the old mechanical counter

You could use a magnet, reed switch and an old calculator -

or go all fancy with an Arduino, OLED display and an IR sensor (or a Hall effect sensor) - small mod needed for the code at this link below to count turns instead of RPM -

Here's an example of my recent work, it's not a audio OPT but a replacement mains tfmr for a Tektronix 585A oscilloscope. I built the bobbin by hand with files etc out of FR4 board. I've yet to wind it, but am making progress. This is my second attempt to wind it. See -

& -

it's a very challenging wind, multiple windings, 19 in all. I'm using a very basic winder.

Andy.

Andy.

Attachments

We have a local supplier in Bulgaria.50AE, where did you order your presspan for bobbins? Our domestic supplier dropped this product. Thanks.

Looking forward to the winding video!Here's an example of my recent work, it's not a audio OPT but a replacement mains tfmr for a Tektronix 585A oscilloscope. I built the bobbin by hand with files etc out of FR4 board. I've yet to wind it, but am making progress. This is my second attempt to wind it. See -& -it's a very challenging wind, multiple windings, 19 in all. I'm using a very basic winder.

Andy.

I watched your videos and I'll also keep a lookout for the actual winding video.

Regarding the heavier copper wire - you'd think that running the heavier copper wire over and under some rollers would make it more maleable/supple but in fact it has the opposite effect, copper 'work hardens' - every time it's bent it becomes a little harder until it reaches a maximum point, winding thicker wire is a PIA and I don't know of an easy way to get the wire to lay flat other than to work it with your hands as the turns go down, the upside is that usually thicker wire means low turns count so it's done reasonably quickly - maybe other forum members have some good tips/ideas on getting heavier wire to lay flat.

Regarding the heavier copper wire - you'd think that running the heavier copper wire over and under some rollers would make it more maleable/supple but in fact it has the opposite effect, copper 'work hardens' - every time it's bent it becomes a little harder until it reaches a maximum point, winding thicker wire is a PIA and I don't know of an easy way to get the wire to lay flat other than to work it with your hands as the turns go down, the upside is that usually thicker wire means low turns count so it's done reasonably quickly - maybe other forum members have some good tips/ideas on getting heavier wire to lay flat.

Started filming, so shouldn't be long. I know about work hardening metal, in this case copper, not sure if the two rollers will harden it much but it's a fair point. I'm using a glove on my right hand to fettle it more between two fingers. I've got the first layer of one half of the primary on, 64T. The original had 23T per inch, the bobbin I built is 2 7/8" wide, so 64T is ok.

Not sure if this is the right place for this Q, but here goes. The spec is for two 110v primarys, 172T each. There is also a buck/boost pri winding of 20T total. For a mains V of 245/250v all of these are in series, so pri wndg = 364T or 0.68v per turn. Core is 1 3/8" by 2 7/8" What I intend to do is leave off the buck/boost wndg's, the tfmr will only be used in the UK, but just add 20T onto the primary, this will make better use of the window space. 192T = 3 layers.

Question - I was intending to add an insulation layer between each primary layer, IE Nomex 4 thou thick, but this is a bobbin wind so could I get away without using this for each half of the primary? Worried about window space.

Andy.

Not sure if this is the right place for this Q, but here goes. The spec is for two 110v primarys, 172T each. There is also a buck/boost pri winding of 20T total. For a mains V of 245/250v all of these are in series, so pri wndg = 364T or 0.68v per turn. Core is 1 3/8" by 2 7/8" What I intend to do is leave off the buck/boost wndg's, the tfmr will only be used in the UK, but just add 20T onto the primary, this will make better use of the window space. 192T = 3 layers.

Question - I was intending to add an insulation layer between each primary layer, IE Nomex 4 thou thick, but this is a bobbin wind so could I get away without using this for each half of the primary? Worried about window space.

Andy.

Attachments

Even if rewinding a transformer I still go through same procedure as if it is a new design, part of this is checking for fill of the winding window space, not sure if you have done this but if not I would recommend you do it, it's quite simple to add up the space taken up by the wire and all of the insulation and then calculate it as a percentage of the winding window, for me if the fill factor of the winding window is around 75% I know my proposed turns insulation etc will easily fit into the winding space - even up to 80% is ok, over 85% and things will get tight, at 90% then danger ! there is every chance I won't be able to get the laminations on without resorting to the use of clamps/vice to squash the windings down, not an ideal situation. I'm guessing this percentage amount will vary from person to person depending on their experience and technique.

- Home

- Amplifiers

- Tubes / Valves

- Show your transformer work (gallery)