Earthing (Grounding) Your Hi-Fi - Tricks and Techniques

diode bridge ground stand off and other stuff.

diode bridge ground stand off and other stuff.

no.So something like a 10R 1W in parallel with a 1N5404 and another diode on the other direction. I guess that the voltage rating should be > of the main voltage or of the max voltage that is used in the device.

Correct ?

D.

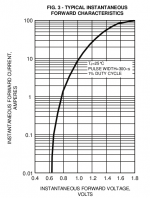

A diode passing tiny current could have Vf~500mV

A diode passing normal current could have Vf~700mV

A diode passing hundreds of amperes of Fault current could have Vf~1500mV.

That's the maximum voltage the little disconnecting network will ever see. But, it won't last very long, 1500mV * 100A ~ 150W instantaneously.

So something like a 10R 1W in parallel with a 1N5404 and another diode on the other direction. I guess that the voltage rating should be > of the main voltage or of the max voltage that is used in the device.

Correct ?

D.

I think that diode would be fine, but the safety police would say the diode should be rated for the same current as your fuse. Since there are 2 diodes back to back under fault conditions or any other conditions the max voltage will be one diode drop.

no, they are not..........there are 2 diodes back to back under .........

I & Nikon have already said "inverse parallel" and "a 1N5404 and another diode on the other direction".

"back to back" implies a series connected pair.

Personally I wouldn't trust a 1N5404 to hold up adequately.

You want diodes that will reliably trip the mains breaker

before they fail. A 35 amp rectifier bridge with the AC pins

connected together and the +/- pins connected together

would about do it.

I have been told that even that could be a little sketchy...

And for the record, the chassis is still hard connected directly

to the Earth ground of the AC outlet. We are talking about

the secondary ground being isolated from that chassis.

You want diodes that will reliably trip the mains breaker

before they fail. A 35 amp rectifier bridge with the AC pins

connected together and the +/- pins connected together

would about do it.

I have been told that even that could be a little sketchy...

And for the record, the chassis is still hard connected directly

to the Earth ground of the AC outlet. We are talking about

the secondary ground being isolated from that chassis.

If anyone is interested, I have a PDF copy of the relevant UL/CE6500 7th edition standards circa 2004. I cannot do anything but give it away and if we can do so on this forum it might save a few lives. For now just PM me with an appropriate email address. The file is 2.6 k in size

The standards for home use, non professional electrical equipment go a bit further than anyone is speaking of, to date.

There is a full unit test requiring an AC voltage withstand of 3750 volts for one minute between mains connection and all surfaces that are user accessible. You will find a series of probes spelled out, that are used to explore this.

There are no exceptions to this unless your unit has it's primary mains connection outside of the DUT. At that point the unit test voltages are scaled to those of a transformer secondary and fall into two classes. One is non safety low voltage, all voltages above 30 VAC rms. This requires a 2750 ac volt withstand from all live circuit components to all user accessible surfaces. Safety low voltage is the second and the voltage withstand is 500 VAC.

Meeting these requirements is not trivial. Not meeting them and having a citizen in the European community die because of it, is an automatic fine of one million dollars. Then the questions of personal retribution are looked into. If you are not living within reach of the laws involved, then anyone who imported your equipment is liable for the fines and retribution. This includes private parties that you sell anything to, including kits and quite possibly, circuit diagrams. Just making them available is potentially a liability issue.

Every power output and choke transformer that we build is designed to meet the CE6500 standards. I do not usually put a thermal fuse in the power transformers, as most actually are for professional use, but I really should and may do so at the beginning of the year. Otherwise, just as with any reputable transformer manufacturer, full creepage and clearance requirements are met and fail safe insulation structures are utilized, with dielectric materials rated at 155 C temperatures, providing 300 k hours of expected MTBF.

Unfortunately there are some companies that do not build to these standards, yet. Do not be fooled by a sticker that provides a UL listed insulation system listing number, as providing safe usage of those materials. This is why all safety agencies require separate testing of the transformer, in addition to the entire unit. Using the correct materials is just the first step.

Bud

The standards for home use, non professional electrical equipment go a bit further than anyone is speaking of, to date.

There is a full unit test requiring an AC voltage withstand of 3750 volts for one minute between mains connection and all surfaces that are user accessible. You will find a series of probes spelled out, that are used to explore this.

There are no exceptions to this unless your unit has it's primary mains connection outside of the DUT. At that point the unit test voltages are scaled to those of a transformer secondary and fall into two classes. One is non safety low voltage, all voltages above 30 VAC rms. This requires a 2750 ac volt withstand from all live circuit components to all user accessible surfaces. Safety low voltage is the second and the voltage withstand is 500 VAC.

Meeting these requirements is not trivial. Not meeting them and having a citizen in the European community die because of it, is an automatic fine of one million dollars. Then the questions of personal retribution are looked into. If you are not living within reach of the laws involved, then anyone who imported your equipment is liable for the fines and retribution. This includes private parties that you sell anything to, including kits and quite possibly, circuit diagrams. Just making them available is potentially a liability issue.

Every power output and choke transformer that we build is designed to meet the CE6500 standards. I do not usually put a thermal fuse in the power transformers, as most actually are for professional use, but I really should and may do so at the beginning of the year. Otherwise, just as with any reputable transformer manufacturer, full creepage and clearance requirements are met and fail safe insulation structures are utilized, with dielectric materials rated at 155 C temperatures, providing 300 k hours of expected MTBF.

Unfortunately there are some companies that do not build to these standards, yet. Do not be fooled by a sticker that provides a UL listed insulation system listing number, as providing safe usage of those materials. This is why all safety agencies require separate testing of the transformer, in addition to the entire unit. Using the correct materials is just the first step.

Bud

Last edited:

Personally I wouldn't trust a 1N5404 to hold up adequately.

You want diodes that will reliably trip the mains breaker

before they fail.

So I'm wrong about the equipment fuse ie it doesn't count in this fault scenerio?

(I have heard of nitwits putting conductors in place of fuses before.)

no, they are not.

I & Nikon have already said "inverse parallel" and "a 1N5404 and another diode on the other direction".

"back to back" implies a series connected pair.

never disagreed, back to pack in parallel, series is clearly not going to work.

CE marking is self certification, unlike UL where things are tested by the UL labs. I wish CE was policed a bit more as quite often you get stuff that no way meets emmisions (EMC part) and from a safety point of view frightens me.

Europe is also covered by the low voltage directive, which is worth a read.

A link to the CE site.

At the end of the day, if you build some equipement whether you are selling it or not it has to be safe and it has to conform to EMC requirements, or if you get cought out you will be in trouble, and if you are selling it into the European or American markets you require certification.

As to protective Earth, the only way to connect it is via a soldid metal to metal connection, iether soldered or a bolted down stud, if it gives you problems engineer a solution, but never break protective earth and its connection.

Some EMC links.

First Link Requires Login

http://www.compliance-club.com/KeithArmstrong.aspx

http://www.compliance-club.com/pdf/EMCTestingPart1.pdf

http://www.compliance-club.com/pdf/EMCTestingPart2.pdf

http://www.compliance-club.com/pdf/EMCTestingPart3.pdf

http://www.compliance-club.com/pdf/EMCTestingPart4.pdf

http://www.compliance-club.com/pdf/EMCTestingPart5.pdf

http://www.compliance-club.com/pdf/EMCTestingPart6.pdf

http://www.compliance-club.com/pdf/EMCTestingPart7.pdf

EMC Design

http://www.compliance-club.com/archive/old_archive/990208.htm

http://www.compliance-club.com/archive/old_archive/990407.htm

http://www.compliance-club.com/currentissue/print_article.asp?artid=500.

http://www.compliance-club.com/archive/old_archive/990810.htm

http://www.compliance-club.com/archive/old_archive/991005.htm

http://www.compliance-club.com/archive/old_archive/991215.htm

Europe is also covered by the low voltage directive, which is worth a read.

A link to the CE site.

At the end of the day, if you build some equipement whether you are selling it or not it has to be safe and it has to conform to EMC requirements, or if you get cought out you will be in trouble, and if you are selling it into the European or American markets you require certification.

As to protective Earth, the only way to connect it is via a soldid metal to metal connection, iether soldered or a bolted down stud, if it gives you problems engineer a solution, but never break protective earth and its connection.

Some EMC links.

First Link Requires Login

http://www.compliance-club.com/KeithArmstrong.aspx

http://www.compliance-club.com/pdf/EMCTestingPart1.pdf

http://www.compliance-club.com/pdf/EMCTestingPart2.pdf

http://www.compliance-club.com/pdf/EMCTestingPart3.pdf

http://www.compliance-club.com/pdf/EMCTestingPart4.pdf

http://www.compliance-club.com/pdf/EMCTestingPart5.pdf

http://www.compliance-club.com/pdf/EMCTestingPart6.pdf

http://www.compliance-club.com/pdf/EMCTestingPart7.pdf

EMC Design

http://www.compliance-club.com/archive/old_archive/990208.htm

http://www.compliance-club.com/archive/old_archive/990407.htm

http://www.compliance-club.com/currentissue/print_article.asp?artid=500.

http://www.compliance-club.com/archive/old_archive/990810.htm

http://www.compliance-club.com/archive/old_archive/991005.htm

http://www.compliance-club.com/archive/old_archive/991215.htm

An important thing to do when submitting to any safety agency is to ask for a pre submittal meeting with your project engineer. This requires you to have signed the contract first. Take your operating physical sample with you, along with the transformer isolation samples you intend to submit and ask to go over the requirements of your specific category. This will allow the engineer to point out things that might not make it through. Some of them will be embarrassingly obvious. Don't argue with him or her!!!!!!

Fix the problems before you submit. Everyone, most especially the marketing weenies, will be pleased with how quickly you receive approval.

Bud

Fix the problems before you submit. Everyone, most especially the marketing weenies, will be pleased with how quickly you receive approval.

Bud

Hi,

we are small start-up company and we create audiophile device. At the moment we are developing a product that uses a Bluetooth apt-x compatible streaming board plus an amplifier board and a power supply 220 AC to 20 DC.

We know that in order to get CE and FCC marks we need a lot of money out of our capabilities. In particular, UL/CSA/VDE certifications requires an outside company testing our products for compliance to their respective standards while CE declaration can also be self declaration if we declare that our product meets requirements set by the appropriate directives. In this case, the CE compliance is the sole responsibility of our company.

In particular, we have to meets two main directives in order to get CE self declaration mark: Low Voltage Directive (LVD) Directive 2014/35/EU and Radio and Telecommunications Terminal Equipment Directive (RTTE) Directive 2014/53/EU. For the former, all we need is to purchase a pre-approved (CE marked and compliant) external AC-DC power supply and ship it with our product. So it is relatively simply to solve.

Regarding the latter directive we cannot afford measurements from external lab. All the electronics board that we use are CE marked. We know that this not guarantee that the whole product respects all the requirements of the directive. So we have to make measurement in our lab and to produce the corresponding documentation. We think that we do not require a Notified Body since the directive states: when the manufacturer did not use Harmonised Standards, or when these do not exist, it must present its technical file to a Notified Body, which will review it.

Do you think that we need a Notified Body?

Do you have any suggestions about how to proceed in order to meet all the requirements?

Thank you

we are small start-up company and we create audiophile device. At the moment we are developing a product that uses a Bluetooth apt-x compatible streaming board plus an amplifier board and a power supply 220 AC to 20 DC.

We know that in order to get CE and FCC marks we need a lot of money out of our capabilities. In particular, UL/CSA/VDE certifications requires an outside company testing our products for compliance to their respective standards while CE declaration can also be self declaration if we declare that our product meets requirements set by the appropriate directives. In this case, the CE compliance is the sole responsibility of our company.

In particular, we have to meets two main directives in order to get CE self declaration mark: Low Voltage Directive (LVD) Directive 2014/35/EU and Radio and Telecommunications Terminal Equipment Directive (RTTE) Directive 2014/53/EU. For the former, all we need is to purchase a pre-approved (CE marked and compliant) external AC-DC power supply and ship it with our product. So it is relatively simply to solve.

Regarding the latter directive we cannot afford measurements from external lab. All the electronics board that we use are CE marked. We know that this not guarantee that the whole product respects all the requirements of the directive. So we have to make measurement in our lab and to produce the corresponding documentation. We think that we do not require a Notified Body since the directive states: when the manufacturer did not use Harmonised Standards, or when these do not exist, it must present its technical file to a Notified Body, which will review it.

Do you think that we need a Notified Body?

Do you have any suggestions about how to proceed in order to meet all the requirements?

Thank you

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Safety issues and CE Certification