Hello,

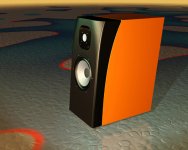

These Nautilus clones are hard work of the friend Alfonso de Rojas

from Barcelona, Spain.

The speakers are at this moment still under construction.

When finished, we would start the new thread about DIY Nautilus,

and there would be some aditional pictures and details about the

construction.

Best regards,

Kristijan Kljucaric

http://web.vip.hr/pcb-design.vip

These Nautilus clones are hard work of the friend Alfonso de Rojas

from Barcelona, Spain.

The speakers are at this moment still under construction.

When finished, we would start the new thread about DIY Nautilus,

and there would be some aditional pictures and details about the

construction.

Best regards,

Kristijan Kljucaric

http://web.vip.hr/pcb-design.vip

Attachments

Future speaker prediction

From the standpoint of today, this sounds pretty off the wall, but I wonder (seriously) if the time will come when we will have self-assembling carbon nanotube boxes. Draw up the box on your "computer"(?) and download the data into a 20kg wad of general purpose molecules you got from the hardware store this morning.

It's far fetched for sure, but comparably, how would the idea of a microcontroller seemed to brass-and-polished-wood electrical dudes 100 years ago.

Of course, there is the would be the extra-cost option of the dynamically re-configurable enclosure that changes it's size according to signal requirments.

From the standpoint of today, this sounds pretty off the wall, but I wonder (seriously) if the time will come when we will have self-assembling carbon nanotube boxes. Draw up the box on your "computer"(?) and download the data into a 20kg wad of general purpose molecules you got from the hardware store this morning.

It's far fetched for sure, but comparably, how would the idea of a microcontroller seemed to brass-and-polished-wood electrical dudes 100 years ago.

Of course, there is the would be the extra-cost option of the dynamically re-configurable enclosure that changes it's size according to signal requirments.

Stero Lythography

In the world of rapid prototyping I think there are likely lots of people who are looking to hit that next level of functionality. Yah sure it sounds a little far fetched, but a dozen years ago watching a 3-d model rise out of a tub of resin as its being scanned by a laser seemed far fetched too.

http://computer.howstuffworks.com/stereolith3.htm

When I was thinking about building resin horns the other day I thought about and rejected stereo lithography as a means of directly creating the horns from the software models. The equipment is more than up to the task, I just couldn’t fathom that I could afford process. This stuff is however getting cheaper all the time, as pragmatic innovations are applied. Roland (yup, the audio guys) makes a tabletop rapid prototyping machine that builds 3-models by cutting and gluing sheets of paper. This machine is almost affordable (I think 5-15k on e-bay?) but a little too small for a descent sized tractix horn w/ a 2" throat.

Those nautilus speakers... I'm amused it took as long as it did for any one to comment on them. I think we were all too amazed and speechless to find the words for even a simple wow. Making us wait until they are done for more information feels cruel, but worth the wait. The shop looks very interesting too.

Future speaker prediction

In the world of rapid prototyping I think there are likely lots of people who are looking to hit that next level of functionality. Yah sure it sounds a little far fetched, but a dozen years ago watching a 3-d model rise out of a tub of resin as its being scanned by a laser seemed far fetched too.

http://computer.howstuffworks.com/stereolith3.htm

When I was thinking about building resin horns the other day I thought about and rejected stereo lithography as a means of directly creating the horns from the software models. The equipment is more than up to the task, I just couldn’t fathom that I could afford process. This stuff is however getting cheaper all the time, as pragmatic innovations are applied. Roland (yup, the audio guys) makes a tabletop rapid prototyping machine that builds 3-models by cutting and gluing sheets of paper. This machine is almost affordable (I think 5-15k on e-bay?) but a little too small for a descent sized tractix horn w/ a 2" throat.

Those nautilus speakers... I'm amused it took as long as it did for any one to comment on them. I think we were all too amazed and speechless to find the words for even a simple wow. Making us wait until they are done for more information feels cruel, but worth the wait. The shop looks very interesting too.

Re: Stero Lythography

I think they look scary enough to give you bad dreams.Da5id4Vz said:Those nautilus speakers... I'm amused it took as long as it did for any one to comment on them.

Re: Stero Lythography

If you can believe, my first words were:

"Wouwww, lo....wait... look what a shop we got here!!!"

I wish I had.....

Da5id4Vz said:

The shop looks very interesting too.

If you can believe, my first words were:

"Wouwww, lo....wait... look what a shop we got here!!!"

I wish I had.....

OH! Those are a pair of great looking speakers in the making!!

I believe i have seen those before in the Discovery channel Hey, I am not kidding, those were carbon fibre composites and used aluminium diaphragms on the drivers. I believe it cost about 20,000 US bucks a pair - So must be pretty hi-tech, huh?. The sultan of Brunei was one of the first ones to own a pair of those. Well he owns a pair of everything there is!

Hey, I am not kidding, those were carbon fibre composites and used aluminium diaphragms on the drivers. I believe it cost about 20,000 US bucks a pair - So must be pretty hi-tech, huh?. The sultan of Brunei was one of the first ones to own a pair of those. Well he owns a pair of everything there is!

I believe i have seen those before in the Discovery channel

About building boxes out of resin, you can cast in all the interior braces, etc. you want. What you do is carve an expendable interior mold (the shape of the interior air space) out of foam and prop it inside your more permanent mold for the exterior shape. Pour the resin and, after it sets, scrape out the interior foam you can reach and dissolve the rest with a solvent that eats the foam but not the resin.

kristijan-k said:Hello,

These Nautilus clones are hard work of the friend Alfonso de Rojas

from Barcelona, Spain.

The speakers are at this moment still under construction.

When finished, we would start the new thread about DIY Nautilus,

and there would be some aditional pictures and details about the

construction.

Best regards,

Kristijan Kljucaric

http://web.vip.hr/pcb-design.vip

Awesome!!!!!

Da5id4Vz said:Resin would be interesting to try for prototyping horns. Foam molds could be made with CNC foam cutter. If the resin really prices out well this could turn out to be a great way of testing horn designs for not too much money. It’s got me curious about what it would cost to have the foam cut from DXF files.

Dave MacPhereson used this technique to hand tune the dispersion on his Monolith loudspeakers. He just tried one horn slope after another untill he found what he liked. This is what is currently in production in the Monoliths.

Cheers,

Zach

Cast from resin

Hi,

I've gathered some experience with building a baffle for a DIY-project, much a la Hales and the like.

My design only allowed for either heavy CNC work or casting the baffle out of resin, and I wound up doing the latter. But I had to have a mold built (consisting of 4 parts bolted together) professionally which wasn't exactly cheap.

First prototypes were cast in some ceramic stuff, the two final ones in an aluminum pellet filled resin, they came out very heavy (about 6 kgs which translates to 13 pounds US) and dense.

Threaded inserts to mount the drivers were cast in, the baffle then glued with resin to the rest of the cabinet.

Casting loudspeakers or even only parts can be a pain in the b... when you have no experience with casting stuff.......the mold has to have a certain amount of taper to get the parts out of the mold, then usually resin heats up while hardening and expands which can make it impossible to get the part out of the mold. That's why I used the aluminum pellet filled resin!

Anyway the result was worth the hard labor, the finished speaker indeed sounds very "inert"!

Pixs attached........

Hi,

I've gathered some experience with building a baffle for a DIY-project, much a la Hales and the like.

My design only allowed for either heavy CNC work or casting the baffle out of resin, and I wound up doing the latter. But I had to have a mold built (consisting of 4 parts bolted together) professionally which wasn't exactly cheap.

First prototypes were cast in some ceramic stuff, the two final ones in an aluminum pellet filled resin, they came out very heavy (about 6 kgs which translates to 13 pounds US) and dense.

Threaded inserts to mount the drivers were cast in, the baffle then glued with resin to the rest of the cabinet.

Casting loudspeakers or even only parts can be a pain in the b... when you have no experience with casting stuff.......the mold has to have a certain amount of taper to get the parts out of the mold, then usually resin heats up while hardening and expands which can make it impossible to get the part out of the mold. That's why I used the aluminum pellet filled resin!

Anyway the result was worth the hard labor, the finished speaker indeed sounds very "inert"!

Pixs attached........

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- resin loudspeaker cabinets