If one has the space that fluffy stuff is probably the only way to create an effective low frequency absorber out of porous material. But now we're talking about a thickness that is measured in meters, not centimeters.

4" Fiberboard (compressed fiberglass?) porous and DENSE enough to absorb low freq. Absorbtion coefficient of .7 at 60 hz ( if my memory serves). Absorbs more than a full octave below the triangular "Sonex" you see in amatuer recording studios.

Last edited:

Originally Posted by Wavebourn View Post

The answer is simple: non-uniform, uneven mix of materials with different speeds of sound propagation, formed without flat surfaces if possible.

Yeah real easy. The answer is simple, the realization ridiculous. Or just use fiberboard.

A theory: The peak is produced like the OB theory says (leave away for now that it's a bit lower than Edge says). The tube forms a halfe-wave resonator with same resonance frequency that absorbs the peak (kind of a TL equivalent of a Helmholtz-Absorber).

Well, I don’t think so and I don't think it could be replicated with predictable and reproducible results.

A resonance or any amplification between two waves works by adding up the two amplitudes resulting in a wave that has greater amplitude than the two initial ones.

The matter whether the two waves will sum or subtract is a matter of 360-degree horizontal dispersion patterns, there would be areas where they add up, other areas where they don't and areas where they subtract. According to your measurements, your sitting position is in a place where the combined room reflections and baffle shape and size create a phenomenon of adding front and back wave and thus the resonance at 200 Hz.

What adding a pipe can do?

For instance, it can obstruct the way of the back wave to a degree that the passage cross section becomes a border between two different mediums, this can lead to direction and phase shift, as well as to dispersion.

I am not sure whether a half pipe can be considered to be a pipe. It looks as a hemispherical mirror to me. In addition, its outer borders form a lens with the U frame.

You have dispersion, obstruction in the way of the back wave and a hemispherical mirror focused at the back of the membrane and the back of the whole baffle.

As we know, sound has solely a wave nature in contrast to the wave and particle nature of light that I'm talking about above. Thus, these results cannot be replicated in another system with different scale, because with pure waves the physical dimensions are the only determinal factor. Additionally sound waves have too big wavelengths at low frequencies with shortest useable fraction being the quarter wavelength.

With the wavelengths of visible light being so short, you can have a very small lens with equal properties to a very large one, both being able to be focused (tuned) in the same way. You can't do the same with enclosures that rely solely on their capacity of being a non transparent border for pure waves. Thus, the dimensions are determinal.

Your achievement is accidental or random and is ad hoc - in these acoustic circumstances with this system.

Best Regards!

Hey, el'Ol, what's happening if you put a board on the top ? I mean something without leakage, supposing that the bottom lying on the floor has no leak too. It could be interesting to measure that.

Wouldn't be possible to shut it more than 20 cm or so because the wings are graded. And I have my measurement equipment put away already, sorry. I am interested whether this would work with a flat OB also. But I know this is not relevant. OB people usually want undisturbed dipolar radiation pattern.

In days of my dipole enthralment  I had been solving similar problem with H-frame woofer. Quarterwave resonace between driver baffle and exit opening. What helped me a lot for the very first moment was change of exit shape perpendicular to baffle and thick T-shirt covering the opening. I did not try to "optimize" the thickness or filling the cover these days. IMO the peak is because of step in radiation impedance, so fabric halps to smear it.

I had been solving similar problem with H-frame woofer. Quarterwave resonace between driver baffle and exit opening. What helped me a lot for the very first moment was change of exit shape perpendicular to baffle and thick T-shirt covering the opening. I did not try to "optimize" the thickness or filling the cover these days. IMO the peak is because of step in radiation impedance, so fabric halps to smear it.

Yes, you keep repeating that but the data disagrees with you. Anechoic chamber wedges (almost always in fiberglass) are very effective and scale to any size. Don't they know better?

David

Dave, the data doesn't disagree. Boards smaller 4" will show the behavior you've mentioned but we were talking about low frequency absorption. Here even 4" is thin. A low frequency absorber that is effective (alpha > 0.8) below 100 Hz has to be thick. 2 meters and more.

Common anechoic chambers aren't anechoic below 100 Hz. They could be made anechoic by using much longer wedges or less dense material. The problem with fluffy material is that it probably won't stay in place over time. Low density foam might work better.

By the way, wedges are used because their flow resistivity would be too high for their thickness. The shape allows sound waves to penetrate the whole absorber.

I'm not making this up Dave. Neither Helmut Fuchs nor Peter D'Antonio are amateurs.

Dave, the data doesn't disagree. Boards smaller 4" will show the behavior you've mentioned but we were talking about low frequency absorption. Here even 4" is thin. A low frequency absorber that is effective (alpha > 0.8) below 100 Hz has to be thick. 2 meters and more.

Common anechoic chambers aren't anechoic below 100 Hz. They could be made anechoic by using much longer wedges or less dense material. The problem with fluffy material is that it probably won't stay in place over time. Low density foam might work better.

By the way, wedges are used because their flow resistivity would be too high for their thickness. The shape allows sound waves to penetrate the whole absorber.

I'm not making this up Dave. Neither Helmut Fuchs nor Peter D'Antonio are amateurs.

A couple of points.

If 4" of fiberglass works to alpha 0.99 at 125 Hz, then It isn't risky to predict that 8" would be good at 63. More than 2 meters required for below 100Hz doesn't ring true (show me your data).

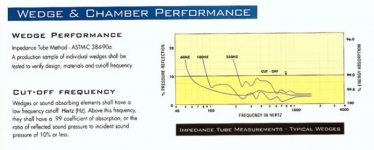

I've attached a figure from an Eckle (anechoic chambers) brochure. I believe they took it from the Beranek/Sleeper 1946 paper. It shows performance of a 60Hz wedge which is 1.5 m long, I believe. These were measured in a standing wave tube. The wedge shape gives the impacting wave an acute angle so any reflection at all bounces further into the wedge. I do know that fiberglass density was part of the experiment and many (in the thousands) samples were tried.

The original question was whether polyester wadding (pillow stuffing) had any special absorptive qualities. You maintain that it is better than fiberglass for very low frequency use (due to lower flow resistance). Every measure at every thickness that I've seen published shows that fiberglass is far superior. Is there a crossover point where polyester is better? Is there a phenomanon that prevents fiberglass performance from scaling to larger and larger sizes? Perhaps, but not that I have seen in the dimensions we use. It doesn't show in speaker cabinet dimensions or practical room treatment thicknesses, or even in anechoic chamber wedges of over 1 meters thick.

Send me the data or graphs from the papers you reference. I'd be interested in seeing it.

David

Attachments

The original question was whether polyester wadding (pillow stuffing) had any special absorptive qualities. You maintain that it is better than fiberglass for very low frequency use (due to lower flow resistance).

I maintain that any porous material needs to show a decreased density (i.e. flow resistivity) when the aborber needs to become very thick for very low frequency absorption. It really doesn't matter if it's fiberglass or polyester or open-cell foam, ...

Quickly skipped through D'Antonio "Acoustic absorbers and diffusers" and it looks like the math is in there.

By the way, today there are better ways to build low frequency absorbers: IBP - Compound Baffle Absorbers

The broadband version (metal plate sandwiched between layers of foam) looks like this:

An externally hosted image should be here but it was not working when we last tested it.

At what depth does polyester performance exceed fiberglass? If you can't answer that then we are talking hypothetically.

David S.

Dave, may I repeat myself: it doesn't matter what porous material the absorber is made of. The major factor is flow resistivity. You can have fiberglass with low or high density just as polyester can have high or low density just as foam ...

None of these materials is acoustically best per se. It's just about the right properties.

And it bugs me that the standard absorbtion coefficient charts only go down to 120 hz. What happened to the bottom 2 octaves?

This is because the common way of measuring isn't applicable at lower frequencies. There is a paper by Zha et al. in Rundfunktechnische Mitteilungen 1996. Sorry, only available in German. Here's the summary in English:

An externally hosted image should be here but it was not working when we last tested it.

The other reason why measurements stop at 120 Hz is that most of the people interested in the data are doing building noise control. They worry about voice frequencies (which are all that are averaged into the NRC noise reduction coefficient). They also know that Fletcher Munsen effects mean that lower frequency noise is typically not a cause of complaints.

This is changing though. Due to big bass problems in cinema and home theaters, I see some trend to taking TL (wall transmission loss) numbers for lower frequencies.

Markus is also correct that most chambers will have standing wave problems that make 32 and 63 Hz measurments on materials difficult or suspect.

David S.

This is changing though. Due to big bass problems in cinema and home theaters, I see some trend to taking TL (wall transmission loss) numbers for lower frequencies.

Markus is also correct that most chambers will have standing wave problems that make 32 and 63 Hz measurments on materials difficult or suspect.

David S.

A low frequency absorber that is effective (alpha > 0.8) below 100 Hz has to be thick. 2 meters and more.

When theory dosnt fit measurement, you throw out the theory. 4" of fiberboard is .95 at 120 hz ( 2 meter? wave lenght ). why woudnt 8" be .95 at 60 hz. Does something happen to sound between 120 hz and 60 hz?

Here even 4" is thin. A low frequency absorber that is effective (alpha > 0.8) below 100 Hz has to be thick. 2 meters and more.

I didn't have a thorough look at the absorbtion tables, and 125 Hz isn't 100 Hz, but i did a quick scan for UltraTouch, the recycled cotton damping we have a affinity for, and both the 3.5 & 5.5" material are 0.97+ at 125 Hz. I was happy to see that.

They would not hold themselves up in a big anechoic wedge.

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- remove standing waves without damping

for being naughty lad

for being naughty lad