Interesting post. I think this is where I get off though, I just don't see much point in doing anything beyond making something similar to a CD-PRO for a CDM-4.

The rather common CDM-12 and all of its derivatives have just five.

AFAIK, 6 diodes in the pd array are mandatory for 3-beam tracking.

The rather common CDM-12 and all of its derivatives have just five.

A quick shot, after reading your post only once:

Maybe we are too close to Philips while reinventing!

Why swing arm? One bearing to care about. More about this later.

Top-Loader: I have a CDP-X5000 for 20 Years. Top-Loader, heavy brass puck, brushless

linear disc motor. While fixing a problem, I disassembled the linear disc motor for cleaning.

For vertical forces, the 6mm steel shaft ends in a blunt cone which is resting one

a glass looking plate, maybe Korundum. Not the slightest sign of wear.

I guess a cheap Mabuchi motor with 2mm shaft (standard in Sony and Philips mechanisms) could be stripped of its cheap housing an get one with better bearings.

Now transmission with linear mechanisms was sometimes strange, sometimes screw drives were used for moving the laser. Maybe a swing arm should be regarded as another

way of transmission in this project. Like in the Denon DCD-1800.

In the Denon, it was poorly made. A rubber disc driving a rubber plated chassis.

Maybe we are too close to Philips while reinventing!

Why swing arm? One bearing to care about. More about this later.

Top-Loader: I have a CDP-X5000 for 20 Years. Top-Loader, heavy brass puck, brushless

linear disc motor. While fixing a problem, I disassembled the linear disc motor for cleaning.

For vertical forces, the 6mm steel shaft ends in a blunt cone which is resting one

a glass looking plate, maybe Korundum. Not the slightest sign of wear.

I guess a cheap Mabuchi motor with 2mm shaft (standard in Sony and Philips mechanisms) could be stripped of its cheap housing an get one with better bearings.

Now transmission with linear mechanisms was sometimes strange, sometimes screw drives were used for moving the laser. Maybe a swing arm should be regarded as another

way of transmission in this project. Like in the Denon DCD-1800.

In the Denon, it was poorly made. A rubber disc driving a rubber plated chassis.

That's exactly how I was remembering the Denon 1800 mech in my head. It was very clunky, but did work well, as long as the non-replaceable rubber drive rim was soft & clean.

As for top loading, I completely disagree with Anatech's notes there, except for some poorly designed system with too heavy a clamping puck for the motor used. Even to a cheap brush motor, the normal forces involved are completely insignificant, and I haven't seen a single case of what you refer to in 30 years of cd servicing. And the single beam NEC's, while very beautifully constructed, have pretty poor long term durability. The KSS151 also has a fairly well-known, though much exaggerated, failure record. Not sure about your statement on laser power of 1beam vs 3beam. The early 1beams were all spec'd for 0.24mW at the lens, whereas 3beams have gotten to progressively lower power specs, now averaging 0.1mW at lens. I can't imagine there is that much optical power loss through the beam splitter to account for that big a difference at the lens.

In any case, the whole point of the thread is as much about very-long-term reliability as it is about trackability. And, as I am sure Salar & I firmly agree, the CDM0-4 series are easily at the top of the list of laser/mechs meeting these two criteria.

As for top loading, I completely disagree with Anatech's notes there, except for some poorly designed system with too heavy a clamping puck for the motor used. Even to a cheap brush motor, the normal forces involved are completely insignificant, and I haven't seen a single case of what you refer to in 30 years of cd servicing. And the single beam NEC's, while very beautifully constructed, have pretty poor long term durability. The KSS151 also has a fairly well-known, though much exaggerated, failure record. Not sure about your statement on laser power of 1beam vs 3beam. The early 1beams were all spec'd for 0.24mW at the lens, whereas 3beams have gotten to progressively lower power specs, now averaging 0.1mW at lens. I can't imagine there is that much optical power loss through the beam splitter to account for that big a difference at the lens.

In any case, the whole point of the thread is as much about very-long-term reliability as it is about trackability. And, as I am sure Salar & I firmly agree, the CDM0-4 series are easily at the top of the list of laser/mechs meeting these two criteria.

The Denon mech could be a start besides the rubber rim.

Could be also done with simple brushed motors.

Are the photodiodes A-D in a single beam laser

laid out in the same pattern as in a 3-beam?

I remember my surprise reading the schematics

of a KSS-123 laser, where the four diodes were

simply paired.

Not much data found about laser heads online.

Here is one, SF HD 850 from Sanyo which combines

cd/dvd in one head:

http://www.farnell.com/datasheets/1668704.pdf

Did i get something wrong? CD tracking seems 3beam but

DVD single beam?

Could be also done with simple brushed motors.

Are the photodiodes A-D in a single beam laser

laid out in the same pattern as in a 3-beam?

I remember my surprise reading the schematics

of a KSS-123 laser, where the four diodes were

simply paired.

Not much data found about laser heads online.

Here is one, SF HD 850 from Sanyo which combines

cd/dvd in one head:

http://www.farnell.com/datasheets/1668704.pdf

Did i get something wrong? CD tracking seems 3beam but

DVD single beam?

Last edited:

Uhm-looks like the Denon solution should be more considered than the Philips-solution. As stated before,in Philips players lateral movement is completely done with the arm, -which is prone to stiction -whereas in the DCD-1800 lateral movement is done with arm and lens - like in linear tracking devices.

The wonderful book "Understanding and Servicing CD-Players" by Ken Clements, published by Newnes in 1994 gives a very good explanation of the Philips mechanisms.

The wonderful book "Understanding and Servicing CD-Players" by Ken Clements, published by Newnes in 1994 gives a very good explanation of the Philips mechanisms.

Attachments

Hi Salar,

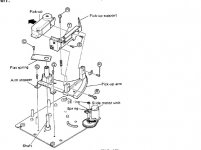

Notice the mechanical mounting, which allows for perfect alignment. You can use gears to drive the head back and forth, and it does have both focus and tracking movements in the actual lens mini-mechanism. What this means is that a normal chip set can function, or a Philips chip set. You just need to change the servo gains and filters to match the dynamics of the larger head.

If you have used a direct mounting for years without these problems - fantastic! Too many people do have a problem with this to allow a service issue to go forward now knowing that it is a problem. All a try needs are teeth ground in the lower surface on the inside and a limit switch. You can then use a motor and gear or belt pulley.

Head power. The Philps are often set for 0.080 mW, I'll have to check that. The OMS -5/7 was set to 270 mW, a better RF amplifier could allow that power to be rolled back.

Because those heads are expensive and out of supply, it is ruled out anyway. I brought it up as an example to show how good a single beam can be. The head I Would choose to use would be the KSS-151A, and I never even hinted that they were not reliable. There are enough Tascam / Denon and other machines that used this to create a supply of mechanisms. I would be very heavily in favor of using that system. Its reliable, quick and quiet in use. Very easy to service too. There is a linear resistive track it uses for positional information. Can we design around that?

In redoing the transport, can be set up mechanical alignments similar to the OMS or Denon swing arm. If we can do that, you will end up with an amazing machine for sure.

Hi amc184,

I have extensive familiarity with all CD transports, as I'm sure stephensank has too. I have seen every weakness (but can't understand why the sliding turntable issue has not been noticed). So lets avoid the known problems and make it better.

The one critical thing I think we have all noticed is the lack of alignment for the head. If we can solve that, then this future machine will have the best tracking and eye pattern than has been seen since the OMS 5/7 or other machines that had complete head alignment possible.

What does everyone think about this?

-Chris

Post #23. That is the best head in the entire world! This is the one I was talking about earlier. It will use a linear mechanism as well as a swing arm. Its high mass would stop me from mounting it an a swing arm. Look at the Philips head assy. That one is very light compared to the NEC head.Here is the Denon DCD-1800 mechanism.

Notice the mechanical mounting, which allows for perfect alignment. You can use gears to drive the head back and forth, and it does have both focus and tracking movements in the actual lens mini-mechanism. What this means is that a normal chip set can function, or a Philips chip set. You just need to change the servo gains and filters to match the dynamics of the larger head.

The normal running forces are of no concern. Its the downward force applied by the human, plus magnetic chuck as the CD is placed onto the turntable. I have corrected this service issue in many and varied transports from the Sanyo SF-90 types, CDM Philips types and also the Sony types. Those are hardened motor shafts, and to tighten the set screws enough means almost stripping the screw and / or threads. Locktight or super glue will fail also.except for some poorly designed system with too heavy a clamping puck for the motor used. Even to a cheap brush motor, the normal forces involved are completely insignificant,

If you have used a direct mounting for years without these problems - fantastic! Too many people do have a problem with this to allow a service issue to go forward now knowing that it is a problem. All a try needs are teeth ground in the lower surface on the inside and a limit switch. You can then use a motor and gear or belt pulley.

Completely disagree. I have repaired many Nakamichi OMS 5 / 7 with few head issues. The issues with those are alignment, and if that isn't done you will never track a CD well. I think the servo board mod turned off the laser when not playing, so that might be where you are assuming those heads have a problem.And the single beam NEC's, while very beautifully constructed, have pretty poor long term durability.

Head power. The Philps are often set for 0.080 mW, I'll have to check that. The OMS -5/7 was set to 270 mW, a better RF amplifier could allow that power to be rolled back.

Because those heads are expensive and out of supply, it is ruled out anyway. I brought it up as an example to show how good a single beam can be. The head I Would choose to use would be the KSS-151A, and I never even hinted that they were not reliable. There are enough Tascam / Denon and other machines that used this to create a supply of mechanisms. I would be very heavily in favor of using that system. Its reliable, quick and quiet in use. Very easy to service too. There is a linear resistive track it uses for positional information. Can we design around that?

In redoing the transport, can be set up mechanical alignments similar to the OMS or Denon swing arm. If we can do that, you will end up with an amazing machine for sure.

Hi amc184,

This idea is simply a rebuild of an existing transport then. You don't need to design anything. All you need to do for bliss is to fix an existing machine. I think if you keep an open mind, you would be pleased with whatever Salar's team here comes up with.I just don't see much point in doing anything beyond making something similar to a CD-PRO for a CDM-4.

I have extensive familiarity with all CD transports, as I'm sure stephensank has too. I have seen every weakness (but can't understand why the sliding turntable issue has not been noticed). So lets avoid the known problems and make it better.

The one critical thing I think we have all noticed is the lack of alignment for the head. If we can solve that, then this future machine will have the best tracking and eye pattern than has been seen since the OMS 5/7 or other machines that had complete head alignment possible.

What does everyone think about this?

-Chris

Despite having serviced hundreds of dvd players by now, I'm slightly embarassed to realise that I've never had the need to read up on differences in their optical systems vs cd. But, yes, that particular(awful) Sanyo dvd/cd laser definitely uses single beam for dvd & triple for cd. Don't know if that means all dvd pu's are same, but does suggest that.

As for the pd array, I've only ever seen the a-d in a quad, as in that Sanyo datasheet.

With the tiny ball bearing point mounting of the arm, as in the cdm-4, it takes *extreme* grease hardening to cause sticking of tracking as you describe, and it's pretty darn rare in any of the radial cdm mechs, in my experience. I don't see any problem with staying with the radial motor system, but I can see a LOT of potential for problems with any sort of improved Denon style mech. First of all, the motor to drive it, short of finding an exotic one, will be a brush motor, which will inevitably wear out, and, since, unless quite geared down, will move very slowly, promoting commutator arc'ing & thus earlier demise from carbon buildup(Nakamichi gear-drive reel motors spring to mind). Secondly, a gear rim drive will have play/friction issues, which a countersprung gear rack will be unsuitable for, due to the curved gear rack. Which leads then to some sort of friction drive, like the actual Denon system. And we'd also still have the concern about pivot point friction, which the Denon solved only by being a very, very 'high pressure' drive system, i.e., a real brute-force rim drive for that massively heavy assembly. I just don't see this as anything but a)hugely more complicated, b)far less reliability potential, and c)no better trackability than going with radial motor(which, remember, is fundamentally a super-low-friction version of a linear motor).

I've been Nakamichi warranty service since 1983, so probably know the OMS5/7 better than anyone outside it's designers(at Kyocera). When you properly check the laser power, by *both* current draw & optical output, you find out just how badly those NEC lasers age. It's extremely rare, IME, even going back 15 years, to test one that hasn't needed at least 30% over rated current to reach proper 0.24mW output, and usually >50% more, which always progresses to even worse over time, whereas the KSS123 used in the second generation would often sag, but once readjusted after a few years, rarely ever needed adjusting again. And this was with the Kyocera design of the player running the laser as little as possible, thanks to having a photo-interrupter setup in the drawer to tell the unit if a disc was inserted before searching for it with the laser.

The Denon 1800, like the Yamaha CD1, and numerous other 1st gen players, used a Toshiba laser that looks nearly identical to the NEC, both inside & out, but is positively different. Whether NEC ripped off Toshiba or vice-versa, I don't know. This Toshiba laser was far from super-reliable, but it was at least less prone to age decay of the laser diode than the NEC by far. Major problem, aside from reliability, with these otherwise gorgeously built pu's was the relatively enormous distance between laser, lens & pd array, which would be a major obstacle to running them on lower power.

The only problem I have ever seen, as far as the comments about top loading downward forces, is slippage of the platter on the motor shaft. IME, this ONLY ever happens with plastic press-fit platters, generally only when the plastic cracks, and I have seen this FAR more often with tray load players than with top loaders. In any case, it's not due to anything but poor design of the platter mounting.

As for the pd array, I've only ever seen the a-d in a quad, as in that Sanyo datasheet.

With the tiny ball bearing point mounting of the arm, as in the cdm-4, it takes *extreme* grease hardening to cause sticking of tracking as you describe, and it's pretty darn rare in any of the radial cdm mechs, in my experience. I don't see any problem with staying with the radial motor system, but I can see a LOT of potential for problems with any sort of improved Denon style mech. First of all, the motor to drive it, short of finding an exotic one, will be a brush motor, which will inevitably wear out, and, since, unless quite geared down, will move very slowly, promoting commutator arc'ing & thus earlier demise from carbon buildup(Nakamichi gear-drive reel motors spring to mind). Secondly, a gear rim drive will have play/friction issues, which a countersprung gear rack will be unsuitable for, due to the curved gear rack. Which leads then to some sort of friction drive, like the actual Denon system. And we'd also still have the concern about pivot point friction, which the Denon solved only by being a very, very 'high pressure' drive system, i.e., a real brute-force rim drive for that massively heavy assembly. I just don't see this as anything but a)hugely more complicated, b)far less reliability potential, and c)no better trackability than going with radial motor(which, remember, is fundamentally a super-low-friction version of a linear motor).

I've been Nakamichi warranty service since 1983, so probably know the OMS5/7 better than anyone outside it's designers(at Kyocera). When you properly check the laser power, by *both* current draw & optical output, you find out just how badly those NEC lasers age. It's extremely rare, IME, even going back 15 years, to test one that hasn't needed at least 30% over rated current to reach proper 0.24mW output, and usually >50% more, which always progresses to even worse over time, whereas the KSS123 used in the second generation would often sag, but once readjusted after a few years, rarely ever needed adjusting again. And this was with the Kyocera design of the player running the laser as little as possible, thanks to having a photo-interrupter setup in the drawer to tell the unit if a disc was inserted before searching for it with the laser.

The Denon 1800, like the Yamaha CD1, and numerous other 1st gen players, used a Toshiba laser that looks nearly identical to the NEC, both inside & out, but is positively different. Whether NEC ripped off Toshiba or vice-versa, I don't know. This Toshiba laser was far from super-reliable, but it was at least less prone to age decay of the laser diode than the NEC by far. Major problem, aside from reliability, with these otherwise gorgeously built pu's was the relatively enormous distance between laser, lens & pd array, which would be a major obstacle to running them on lower power.

The only problem I have ever seen, as far as the comments about top loading downward forces, is slippage of the platter on the motor shaft. IME, this ONLY ever happens with plastic press-fit platters, generally only when the plastic cracks, and I have seen this FAR more often with tray load players than with top loaders. In any case, it's not due to anything but poor design of the platter mounting.

Hi stephensank,

I thought Nakamichi USA did everything in-house.

I have not seen any brand but Sony have stiff grease trouble in CD players. Tascam had "green grease syndrome" with their open reel machines, Dual in their tables but not much else. I have never seen a linear tracking CD player with stiff grease, not ever - Sony exempted. (Their ES series was horrible for that).

I have repaired tons of CD players without cracked spindle motor turntables for turn table sliding issues. Some folks don't catch them because it looks like a focus offset problem. I guess some techs just tweek and go.

I think those NEC lasers could run at lower current. That is very likely the one reason you see so many weak ones. Tell me, did you ever get the manual for the servo PCB rebuild? That made a massive difference to the performance of the OMS-5/7 players. I have only replaced my laser head once, and it is still fine. Yes, I check the current and output power on all heads. As for the distance between the laser diode and disc surface, that doesn't require much, or any increased power. Only optical components will cause a loss with focused beams and small distances. I'd have to look, but that head might have a secondary lens to seal the inside of the optics. Another optical loss. Personally, I think it was just a new format that no one had mastered. NEC decided to blast the CD with a strong beam (270 mW per the manual) when it wasn't required. I'll bet that with technology today in LEDs, they could produce the same output levels at very low power. Those diodes probably wouldn't wear out. Remember, Philips use a 0.08 mW beam. I'll have to check my laser power meter to refresh my memory on the power levels as I am reasonable sure i have made an error here, but the main points are still valid.

As for disc motors, whatever you want. Nakamichi used a special one. Most used little brush motors that seemed to last okay unless the customer used the "random" button. That would tear up those little motors. Maybe what you see down there is due to the constant heat, but here in Canada our experiences differ from yours quite a bit.

As for experience, I serviced those things since day 1. Trained at Philips, Revox, Studer, Denon, Yamaha, Mission, Carver, Nakamichi and everywhere else. We had a wide range of warranty contracts and did most everything out of warranty. There isn't much we haven't seen and I was the main CD tech. I still have all those test CDs. Same for the jigs, some of which I built. I changed jobs just about when DVDs came out, so you have me on those.

I should state that I do not suggest rim drive or any other weirdness. Either use gears, belts or a linear transverse motor to move the head. These components are reliable in operation.

-Chris

I thought Nakamichi USA did everything in-house.

I have not seen any brand but Sony have stiff grease trouble in CD players. Tascam had "green grease syndrome" with their open reel machines, Dual in their tables but not much else. I have never seen a linear tracking CD player with stiff grease, not ever - Sony exempted. (Their ES series was horrible for that).

I have repaired tons of CD players without cracked spindle motor turntables for turn table sliding issues. Some folks don't catch them because it looks like a focus offset problem. I guess some techs just tweek and go.

I think those NEC lasers could run at lower current. That is very likely the one reason you see so many weak ones. Tell me, did you ever get the manual for the servo PCB rebuild? That made a massive difference to the performance of the OMS-5/7 players. I have only replaced my laser head once, and it is still fine. Yes, I check the current and output power on all heads. As for the distance between the laser diode and disc surface, that doesn't require much, or any increased power. Only optical components will cause a loss with focused beams and small distances. I'd have to look, but that head might have a secondary lens to seal the inside of the optics. Another optical loss. Personally, I think it was just a new format that no one had mastered. NEC decided to blast the CD with a strong beam (270 mW per the manual) when it wasn't required. I'll bet that with technology today in LEDs, they could produce the same output levels at very low power. Those diodes probably wouldn't wear out. Remember, Philips use a 0.08 mW beam. I'll have to check my laser power meter to refresh my memory on the power levels as I am reasonable sure i have made an error here, but the main points are still valid.

As for disc motors, whatever you want. Nakamichi used a special one. Most used little brush motors that seemed to last okay unless the customer used the "random" button. That would tear up those little motors. Maybe what you see down there is due to the constant heat, but here in Canada our experiences differ from yours quite a bit.

As for experience, I serviced those things since day 1. Trained at Philips, Revox, Studer, Denon, Yamaha, Mission, Carver, Nakamichi and everywhere else. We had a wide range of warranty contracts and did most everything out of warranty. There isn't much we haven't seen and I was the main CD tech. I still have all those test CDs. Same for the jigs, some of which I built. I changed jobs just about when DVDs came out, so you have me on those.

I should state that I do not suggest rim drive or any other weirdness. Either use gears, belts or a linear transverse motor to move the head. These components are reliable in operation.

-Chris

I have the Nakamichi OMS-7II with KSS-123A and Toshiba XR-Z70 with OPH-32.

The Tosh tracks CD-Rs better.

The Philips way is still an option? But to overcome "stiction", could it also be possible to have the fine lateral movements done by the laser lens?

Looks like Philips never did it this way and left the lateral movement completely

to the swing arm, thus an oscillating movement was needed.

About the brute forces done by humans on the disc platter:

I would prefer brushless motors, they seem to be better built. First (I guess Pioneer) Super Drive in my 15 years old Powermac G4 is a brushless dream.No play at all, shaft seems about 4mm. The platter could have a blind hole,thus it can´t sag. The platter does not need to be adjusted, this is a swing arm! Alternitavely, not the platter but the whole arm could be raised/lowered for aligning the distance to the cd-surface - if needed.

Aligning the laser head in three axis is a great option, but maybe useless for the diyers without a proper jig?

So, what do we have:

As a start, we have to find out who still builds single beam lasers / laser heads. Then there are finished servo electronics at hand to tweak.

BTW my contribution to this project can be to do the CAD drawings and to hire someone to do the milling.

All the best,Salar

The Tosh tracks CD-Rs better.

The Philips way is still an option? But to overcome "stiction", could it also be possible to have the fine lateral movements done by the laser lens?

Looks like Philips never did it this way and left the lateral movement completely

to the swing arm, thus an oscillating movement was needed.

About the brute forces done by humans on the disc platter:

I would prefer brushless motors, they seem to be better built. First (I guess Pioneer) Super Drive in my 15 years old Powermac G4 is a brushless dream.No play at all, shaft seems about 4mm. The platter could have a blind hole,thus it can´t sag. The platter does not need to be adjusted, this is a swing arm! Alternitavely, not the platter but the whole arm could be raised/lowered for aligning the distance to the cd-surface - if needed.

Aligning the laser head in three axis is a great option, but maybe useless for the diyers without a proper jig?

So, what do we have:

As a start, we have to find out who still builds single beam lasers / laser heads. Then there are finished servo electronics at hand to tweak.

BTW my contribution to this project can be to do the CAD drawings and to hire someone to do the milling.

All the best,Salar

Last edited:

Hi Salar,

Any head type should be considered. Anything currently produced is fair game. Swing arms are hell to set up. Just wait until you do your first one!

The head can be aligned without special jigs for a linear tracking transport. Aligning a radial arm is beyond most people, for good reason. If the head is aligned in all planes, the performance will then automatically be superior to anything else out there. The only other option would be to use a CDROM drive. That is not DIY or good.

Have a look in the OMS-7 manual (or OMS-5) and it will take you through the procedure.

At this point I have no real head preferences. I do think we need a transverse (linear) transport that has the adjustments for all planes. One problem with a radial arm is that set screw movements are amplified so much that setting one up is difficult. This is in addition to using the glass disc. You need to use a glass disc to perform this alignment on a radial arm. Also, the table height is adjusted using the spindle motor shaft. DOing it this way allows the adjustment to take place in real time (watch the focus error DC level). I still think we need a DVD head in order to get a quality pickup head. I would have liked to have been wrong on that point. Any head that will bolt to a carrier. At that point we can control the rest. Transport cast and milled? That would be nice.

-Chris

Any head type should be considered. Anything currently produced is fair game. Swing arms are hell to set up. Just wait until you do your first one!

The head can be aligned without special jigs for a linear tracking transport. Aligning a radial arm is beyond most people, for good reason. If the head is aligned in all planes, the performance will then automatically be superior to anything else out there. The only other option would be to use a CDROM drive. That is not DIY or good.

Have a look in the OMS-7 manual (or OMS-5) and it will take you through the procedure.

You can't blame that on the head. The MKII series had a transport that was overly simplified and far too bouncy! The KSS-123A does have an evil failure mode. The center post gets sticky. To repair it, you have to desolder the coils on the lens, then remove the lens assy. After that you can properly clean that damn post. Reassemble and you're good to go. Even new heads can be sticky on the post.I have the Nakamichi OMS-7II with KSS-123A and Toshiba XR-Z70 with OPH-32.

The Tosh tracks CD-Rs better.

At this point I have no real head preferences. I do think we need a transverse (linear) transport that has the adjustments for all planes. One problem with a radial arm is that set screw movements are amplified so much that setting one up is difficult. This is in addition to using the glass disc. You need to use a glass disc to perform this alignment on a radial arm. Also, the table height is adjusted using the spindle motor shaft. DOing it this way allows the adjustment to take place in real time (watch the focus error DC level). I still think we need a DVD head in order to get a quality pickup head. I would have liked to have been wrong on that point. Any head that will bolt to a carrier. At that point we can control the rest. Transport cast and milled? That would be nice.

-Chris

Thanks for the OMS-5 offer, but I sold this one some years ago!

The gear driving a geared rim could be also countersprung. Nakamichi did use countersprung gears in both versions of the OMS 7&5 whereas Sony used countersprung gear racks. No need for friction drives. No clue why Denon did not use this, maybe because of gear transmission ratio...?

(Don´t forget if we shared a repair shop I would be the one responsible for the coffe-because thats the only thing I could do)

A little bit of a problem with a traditional linear drive to me is that there is too much already "done" : Plastic heads that have plastic holes for steel rods,

calles a bearing, theres is simply no space to improve this with better bearings. (But at least the possibility to use these plastic bearings to align in x axis)

Imagine this project develops so far that it might even get into mass-production. YALD- yet another linear drive. Nothing to distinguish it from other transports. But recognizing an arc - shaped hole is a little bit of advertisment

If it was linear i could live much better with Sony´s linear drives used in second generation Sony players and later in Acccuphase players.

Secondly, a gear rim drive will have play/friction issues, which a countersprung gear rack will be unsuitable for, due to the curved gear rack. Which leads then to some sort of friction drive, like the actual Denon system. And we'd also still have the concern about pivot point friction, which the Denon solved only by being a very, very 'high pressure' drive system, i.e., a real brute-force rim drive for that massively heavy assembly. I just don't see this as anything but a)hugely more complicated, b)far less reliability potential, and c)no better trackability than going with radial motor(which, remember, is fundamentally a super-low-friction version of a linear motor).

The gear driving a geared rim could be also countersprung. Nakamichi did use countersprung gears in both versions of the OMS 7&5 whereas Sony used countersprung gear racks. No need for friction drives. No clue why Denon did not use this, maybe because of gear transmission ratio...?

(Don´t forget if we shared a repair shop I would be the one responsible for the coffe-because thats the only thing I could do)

A little bit of a problem with a traditional linear drive to me is that there is too much already "done" : Plastic heads that have plastic holes for steel rods,

calles a bearing, theres is simply no space to improve this with better bearings. (But at least the possibility to use these plastic bearings to align in x axis)

Imagine this project develops so far that it might even get into mass-production. YALD- yet another linear drive. Nothing to distinguish it from other transports. But recognizing an arc - shaped hole is a little bit of advertisment

If it was linear i could live much better with Sony´s linear drives used in second generation Sony players and later in Acccuphase players.

Last edited:

Hi Salar,

Linear transports. As soon as you produce a cast or milled base, you have been differentiated. As soon as you can adjust the head completely, you are apart from everyone else in the world. The last completely adjustable drive was the OMS-5/7. As far as heads are concerned, it doesn't matter if they have bearings or not, because you will bolt that to the precision sled. That is the only way to ensure proper head alignment. You can use bearings for the sled, or magnetic repulsion. If you are really demented, use "air bearings". That will buy you many headlines.

Don't forget, the selling point for this is performance. No one else can compete unless they travel the same road that you do.

Another benefit for the sled. Other heads can be used by changing the sled, or by mounting the head via the rods and clamping them down (just used for head mounting). Your transport only needs to be designed one time. So now it is future proof too.

-Chris

Perfect! We belong in business together, because if there is anything I do really well, it's drinking coffee!(Don´t forget if we shared a repair shop I would be the one responsible for the coffe-because thats the only thing I could do)

Linear transports. As soon as you produce a cast or milled base, you have been differentiated. As soon as you can adjust the head completely, you are apart from everyone else in the world. The last completely adjustable drive was the OMS-5/7. As far as heads are concerned, it doesn't matter if they have bearings or not, because you will bolt that to the precision sled. That is the only way to ensure proper head alignment. You can use bearings for the sled, or magnetic repulsion. If you are really demented, use "air bearings". That will buy you many headlines.

Don't forget, the selling point for this is performance. No one else can compete unless they travel the same road that you do.

Another benefit for the sled. Other heads can be used by changing the sled, or by mounting the head via the rods and clamping them down (just used for head mounting). Your transport only needs to be designed one time. So now it is future proof too.

-Chris

Uhm... I will think about it. BTW there does not seem much heads to choose from. Checked Vasiltechs DAC/Transport list, it really looks like the Sanyo SF-HD850, Sony KHM-230, KHM-313 are used often.

I have heard that production of the KHM-313 was stopped.

CD-Pro2 (don´t know the name of the laser head)s is not in production anymore. Do Pioneer and TEAC do OEM?

I have heard that production of the KHM-313 was stopped.

CD-Pro2 (don´t know the name of the laser head)s is not in production anymore. Do Pioneer and TEAC do OEM?

I would NEVER consider using any KHM series Sony or any post-SF-P101 Sanyo, as reliability on both tanked hard, and they discontinue them about as fast as they bring out the next one. And the oxymoronically-named "CDPro2" and all of that Daisy Laser cdm12/vam12 garbage is a total joke. Maybe 60% last more than a year or two, and the build quality is abominable.

I think you, Salar, make an *excellent* point about the perception aspect. Even if tray-loading, that arc shaped opening tells even the "unwashed rabble" that this is not just some $12 piece of junk cdm12 in a fancy wrapper, but something special. EVERY reviewer will pick up on this. While something like a Sony CDP302 linear motor mech is absolutely drop-dead gorgeous to people like us, the consumer is only going to see a cutout in the cd tray that looks like every other junk player.

Incidentally, if I were to say we go linear motor, I would choose the whole drive/laser/loader assembly out of the Pioneer PDR-09 recorder, which is a very significant cut above the PD-S95/PD-75 mech. Just gorgeous, and with a super-reliable Sony KRS200 laser(actually a variant built specifically for linear motor, just as the KSS123 was adapted into the CDP302/BU1 drive), but we have far less chance of pulling that off than we do a variation on the CDM1mkII(my firm choice for cdm to base this project on, as I said before).

I think you, Salar, make an *excellent* point about the perception aspect. Even if tray-loading, that arc shaped opening tells even the "unwashed rabble" that this is not just some $12 piece of junk cdm12 in a fancy wrapper, but something special. EVERY reviewer will pick up on this. While something like a Sony CDP302 linear motor mech is absolutely drop-dead gorgeous to people like us, the consumer is only going to see a cutout in the cd tray that looks like every other junk player.

Incidentally, if I were to say we go linear motor, I would choose the whole drive/laser/loader assembly out of the Pioneer PDR-09 recorder, which is a very significant cut above the PD-S95/PD-75 mech. Just gorgeous, and with a super-reliable Sony KRS200 laser(actually a variant built specifically for linear motor, just as the KSS123 was adapted into the CDP302/BU1 drive), but we have far less chance of pulling that off than we do a variation on the CDM1mkII(my firm choice for cdm to base this project on, as I said before).

Hi Salar,

Well, I guess you have to decide. Do you want a curved cutout, or a transport that actually performs at a higher level with an open head requirement? We aren't designing this for the average Joe, because the price will exclude that buyer.

I still think we should use a tray. Keep them fingies out of that area! If you use a slab or extruded metal tray, no further explanation is required. If its that important, put a clear top on the damn thing. Blue LEDs to impress those who buy these things for the wrong reasons. Don't forget to include green LEDs firing at the CD! Must have those. Complete the mess with a "stable platter". That should remove the last bit of performance, but by god it will look so special and sexy!

So, performance with some head options, or just be another sexy waste of money? I have zero patience for this kind of decision making as you know.

-Chris

-Chris

Well, I guess you have to decide. Do you want a curved cutout, or a transport that actually performs at a higher level with an open head requirement? We aren't designing this for the average Joe, because the price will exclude that buyer.

I still think we should use a tray. Keep them fingies out of that area! If you use a slab or extruded metal tray, no further explanation is required. If its that important, put a clear top on the damn thing. Blue LEDs to impress those who buy these things for the wrong reasons. Don't forget to include green LEDs firing at the CD! Must have those. Complete the mess with a "stable platter". That should remove the last bit of performance, but by god it will look so special and sexy!

So, performance with some head options, or just be another sexy waste of money? I have zero patience for this kind of decision making as you know.

-Chris

-Chris

Frankly I prefer the curved cutout. It sells. It reminds everyone around in his 50´s on better times. It can be done using the Denon principle with gears and simple motors. The Mabuchi motors of an OMS-7II from 1985 are still in production. You will probably need two milled blocks of aluminium

and only care about even planes, a bent gear and one absolutely perpendicular bearing.

But: it looks like there is no head option. The only originally manufactured heads available are the Sanyo SF-HD 65 / 850.

Haven´t found any other manufacturer yet. No hints on the TEAC or Pioneer company pages that the do OEM. Sony or Philips are copies.

The Sanyos also seem to be the only ones with available datasheets and dimensional drawings besides the VAMs from Philips.

Thus, if it was a linear drive or radial drive: How should this head be mechanically aligned?

The "chassis" has only the bearings for fixing this head to a base

and only care about even planes, a bent gear and one absolutely perpendicular bearing.

But: it looks like there is no head option. The only originally manufactured heads available are the Sanyo SF-HD 65 / 850.

Haven´t found any other manufacturer yet. No hints on the TEAC or Pioneer company pages that the do OEM. Sony or Philips are copies.

The Sanyos also seem to be the only ones with available datasheets and dimensional drawings besides the VAMs from Philips.

Thus, if it was a linear drive or radial drive: How should this head be mechanically aligned?

The "chassis" has only the bearings for fixing this head to a base

Attachments

Last edited:

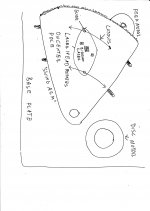

This drawing looks ridicilous also the angles/relations are not correct.

The disc motor is of course at the end of the arc drawn by the laser, not next to

the swing arm´s gear. But I have no time to correct this an rescan.

To minimize the angle error of the E/F diodes in an arc, the laser

could be on a turntable/bearing on the swing arm. Cut out guides beneath the turntable. correct the angle relatively to the grooves of a CD. The angle.of the guides would not be parallel to the swing arms direction like in this drawing. Taking a second look i am sure only one guide/groove is needed.

Friction - no idea.

Rubbish?

The disc motor is of course at the end of the arc drawn by the laser, not next to

the swing arm´s gear. But I have no time to correct this an rescan.

To minimize the angle error of the E/F diodes in an arc, the laser

could be on a turntable/bearing on the swing arm. Cut out guides beneath the turntable. correct the angle relatively to the grooves of a CD. The angle.of the guides would not be parallel to the swing arms direction like in this drawing. Taking a second look i am sure only one guide/groove is needed.

Friction - no idea.

Rubbish?

Attachments

Last edited:

Hi Salar,

Mount whatever head you can get onto your own carriage. This releases you from being "stuck" with one head type. You can use the rail holes to mount the heat to your carriage, the head itself would not be free to move. You no longer have to worry about bearing types in the head you wish to use. A new type of head only needs gain and filter adjustments, and possibly new mounting holes in the carriage.

Now, your carriage can use whatever system you can dream up to be moved from inside the CD to the outside tracks. Being metal, you can be assured of consistent alignment. If you change head types, your alignment process doesn't change, just how the new head would mount to the carriage. How is that for sidestepping supply problems?

-Chris

Mount whatever head you can get onto your own carriage. This releases you from being "stuck" with one head type. You can use the rail holes to mount the heat to your carriage, the head itself would not be free to move. You no longer have to worry about bearing types in the head you wish to use. A new type of head only needs gain and filter adjustments, and possibly new mounting holes in the carriage.

Now, your carriage can use whatever system you can dream up to be moved from inside the CD to the outside tracks. Being metal, you can be assured of consistent alignment. If you change head types, your alignment process doesn't change, just how the new head would mount to the carriage. How is that for sidestepping supply problems?

-Chris

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Digital Source

- Reinventing the Swing Arm Mechanism - looking for allies!