This is good advice. Modern electrolytics on tagstrip is easy and cheap, and sounds better than multiple section types. The multi-sections often have ripple-current ratings of only 200 .. 300mA, which is not enough for larger amps, and short life results.

JJ claims a 1,000 hour life for their 40, 20, 20, 20 can cap. They claim a typical 2,000 life for their "snap in" caps. I've converted over from axial leads to snap in type. I build turret board but place two eyelets spaced 10mm apart and the caps just snap in and hold well enough that I can flip the board over and they stay in. Then I solder them to the eyelets. I think snap ins work the best for amateur style construction. I can "dense pack" them using eyelets as tight as with a PCB. The snap in type tend t always have the best specs and prices because that is what is most used today

But 1,000 hours is a long type for a stereo amp and JJ is one of the best companies to get can caps from

JJ claims a 1,000 hour life for their 40, 20, 20, 20 can cap. They claim a typical 2,000 life for their "snap in" caps. I've converted over from axial leads to snap in type. I build turret board but place two eyelets spaced 10mm apart and the caps just snap in and hold well enough that I can flip the board over and they stay in. Then I solder them to the eyelets. I think snap ins work the best for amateur style construction. I can "dense pack" them using eyelets as tight as with a PCB. The snap in type tend t always have the best specs and prices because that is what is most used today

But 1,000 hours is a long type for a stereo amp and JJ is one of the best companies to get can caps from

1000 hours is 3 hours a day for 1 year. Could put the date in a calendar. The JJ300B DHT seems to last 5000 hours or more, so in a 300B-SE, you would expect to change the caps 5 times for each valve swap!

I think the JJ 40, 20, 20, 20 can cap is really intended for table radios, or 2..5W EL84-SE amps.

1000-hours is also a guide lifetime, based on temperature and ripple current. For the JJ 40, 20, 20, 20 can cap the 40 can do 160mA, the others 80mA.

160mA is just about enough to support the rectifier-cap a 70mA-idling 300B-SE, and not enough for any application that draws more...

In an amp, the ripple current is low, except for the cap at the rectifier, if you have one. In this position, I believe it is worth choosing a cap with ripple handling 3x to 5x the dc draw, since the ac ripple is about 2x the dc current, for cap-input power supply, and lifetime is strongly dependent on ripple ( as % of rated).

Huge capacitors

You just have to shunt tube rectifiers under their sockets with solid state 3 or 5 amp diodes, and it will do the trick... This will definitely preserve your valves, and you'll keep your huge capacitors. I've been using this solution for years, and I never encountered any problem. Alain F6FKN

You just have to shunt tube rectifiers under their sockets with solid state 3 or 5 amp diodes, and it will do the trick... This will definitely preserve your valves, and you'll keep your huge capacitors. I've been using this solution for years, and I never encountered any problem. Alain F6FKN

I think the spacing of the mounting tabs is standard but checking that dimension is a good idea.

If the outer diameter is the same then it should fit.

The only precaution to using larger values for the filter capacitors is that vacuum tube rectifiers have a specified maximum capacitance they want to see directly connected. So if it is the first filter after the rectifier it should stay the same. Any thing further away will have current limiting inductance or resistance to protect the rectifier tube.

I'm buying typical 3000 hour minimum 2000 hour 105 deg C caps from Newark or mouser for my organs and amps. Surplus electrolytics, even if unused, have had the rubber seals exposed to the oxygen in the atmosphere just as long as used ones. Had a friend that bought a "cherry" 1974 hammond H300 organ, "practically unused" that sounded pretty good at the antique mall. It has 70 electrolytics, just like the one I bought that sounded like a kazoo when I bought it. After a month of playing the "unused" hammond, my friend has reported the kazoo effect has taken charge. My theory is the water was in there due to never being exposed to running temperature, but a few hours of use boiled it out past the bad seals in the electrolytics.

http://www.tubebooks.org/tubedata/HB-3/Receiving_Tubes_Part_1/6AX5-GT.PDF

Here is the data sheet for exact rectifier tube that I am using.

Here is the data sheet for exact rectifier tube that I am using.

I didn't suggest keeping the old cap(s) connected, that would have been retarded...If you use the old can as a tie point without removing the contents, it can still short and explode. Forget Mastodon's advice, cleaning up after a cap explosion is not worth it.

I didn't suggest keeping the old cap(s) connected, that would have been retarded...

The main risks for an electrolytic exploding is excessive temperature from high ambient plus ripple current, source resistance, and age of a cap. If the cap is not tooo old (say 70's on) then bypassing an old with a new cap will dramatically lower the ripple in the old cap. Depending on the mix of issues, bypassing can be quite a convenient technique.

I wouldn't recommend it in this situation, as the age looks like late 50's to early 60's.

Ciao, Tim

I can't seem to find any info on the 40-20-20 multisection from CE Manufacturing. Ok so we know that the JJ's 40 section is rated for 160ma. I was curious on how it compares to the CE Manufacturing 40 section. I was also looking at Sprague Atom (if I go the terminal strip route) and can't find info on them either.

What range in milliamps would be good (not to low and not overkill) for the first cap after the rectifier. Is the JJ 160ma sufficient, I looked at the rating chart on the 6AX5GT data sheet and I guess I would need to know AC voltage per plate to calculate DC output in milliamps.

What range in milliamps would be good (not to low and not overkill) for the first cap after the rectifier. Is the JJ 160ma sufficient, I looked at the rating chart on the 6AX5GT data sheet and I guess I would need to know AC voltage per plate to calculate DC output in milliamps.

I can't seem to find any info on the 40-20-20 multisection from CE Manufacturing. Ok so we know that the JJ's 40 section is rated for 160ma. I was curious on how it compares to the CE Manufacturing 40 section. I was also looking at Sprague Atom (if I go the terminal strip route) and can't find info on them either.

What range in milliamps would be good (not to low and not overkill) for the first cap after the rectifier. Is the JJ 160ma sufficient, I looked at the rating chart on the 6AX5GT data sheet and I guess I would need to know AC voltage per plate to calculate DC output in milliamps.

DC current output would be the most useful measurement. We can guess the value by knowing the output stage tube-type and if it's PP or SE, and the voltage rating on the caps installed today.

As a guide, High quality 450V snap in caps [Nichicon, Panasonic] at their smallest 450V value [47 or 56uF 450V] can usually do about 500mA at 105 deg C, and well over 1A at 50 deg C.

DC current output would be the most useful measurement. We can guess the value by knowing the output stage tube-type and if it's PP or SE, and the voltage rating on the caps installed today.

As a guide, High quality 450V snap in caps [Nichicon, Panasonic] at their smallest 450V value [47 or 56uF 450V] can usually do about 500mA at 105 deg C, and well over 1A at 50 deg C.

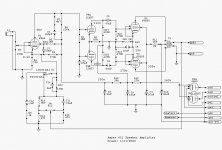

It is a 6V6 PP amp, here is the schematic:

Attachments

R4 tells the tale. A 360R common cathode resistor for 6V6 PP. Labelled as 25V, too, which means 70mA idle current [about 11.5W per 6V6 anode, so OK].

With the other valves, it looks like about 75mA or so, so we should design for 150mA of ac -ripple in the 40uF. The JJ 40-20-20 etc would be OK, here if the amp doesn't run too many hours in the day, but the lifetime on load will not be much more than the 1000 hours rated.

Keeping the cap away from any hot tubes would be necessary.

Personally, I'd prefer Nichicon KX in 47uF 450V in this position, since the sound quality will hold up for longer. Tired electrolytics sound dreadful!

With the other valves, it looks like about 75mA or so, so we should design for 150mA of ac -ripple in the 40uF. The JJ 40-20-20 etc would be OK, here if the amp doesn't run too many hours in the day, but the lifetime on load will not be much more than the 1000 hours rated.

Keeping the cap away from any hot tubes would be necessary.

Personally, I'd prefer Nichicon KX in 47uF 450V in this position, since the sound quality will hold up for longer. Tired electrolytics sound dreadful!

The ripple current I calculated in the last post assumed most of the amp's time was idle, or playing quietly.

If your listening time features a lot of LOUD passages, the dc current will spend time near the 90 ..100 mA dc of run current in a PP 6V6. In this case, the ac ripple is above the rated 160mA.

This does not mean the cap will blow up - but the lifetime may only be around 1000 hours, if the cap is kept below 60 deg C.

If your listening time features a lot of LOUD passages, the dc current will spend time near the 90 ..100 mA dc of run current in a PP 6V6. In this case, the ac ripple is above the rated 160mA.

This does not mean the cap will blow up - but the lifetime may only be around 1000 hours, if the cap is kept below 60 deg C.

The ripple current I calculated in the last post assumed most of the amp's time was idle, or playing quietly.

If your listening time features a lot of LOUD passages, the dc current will spend time near the 90 ..100 mA dc of run current in a PP 6V6. In this case, the ac ripple is above the rated 160mA.

This does not mean the cap will blow up - but the lifetime may only be around 1000 hours, if the cap is kept below 60 deg C.

Can't find KX series in a 47uf only 56uf, I tried mouser and newark. The amps will not see too much use and I could always upgrade in the future. I don't have a lot of money to throw at these, I just want them to be functional.

As indicated previously, C10 is the high ripple capacitor that will typically have the shortest lifetime of all the caps due to internal temperature rise, although in a combo can all the other capacitors somewhat see a temperature rise too. If you go to individual caps, rather than a can, then the capacitor may have a lower or higher ambient temperature depending on the location of local heating sources and airflow.

A lifetime spec of say 1,000 hrs at 105C has an approximate doubling of life for each 10C drop in temp, if operating at continuous max ripple. Tube amps, whether above or below chassis, could easily sit a cap at 50-80C once the amp is warmed up. In a PP configuration, your use will determine what average of time is spent at the higher ripple level. Some cap specs give a lifetime versus % of ripple curve, and ambient temp curve - there are also many good app notes.

One crude technique to extend lifetime is to series two caps - a lower voltage cap at twice the capacitance typically has a significantly higher ripple rating, and is sometimes easier to procure - but balacing resistors are needed, although they can become the default cap discharge load.

A lifetime spec of say 1,000 hrs at 105C has an approximate doubling of life for each 10C drop in temp, if operating at continuous max ripple. Tube amps, whether above or below chassis, could easily sit a cap at 50-80C once the amp is warmed up. In a PP configuration, your use will determine what average of time is spent at the higher ripple level. Some cap specs give a lifetime versus % of ripple curve, and ambient temp curve - there are also many good app notes.

One crude technique to extend lifetime is to series two caps - a lower voltage cap at twice the capacitance typically has a significantly higher ripple rating, and is sometimes easier to procure - but balacing resistors are needed, although they can become the default cap discharge load.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Recapping old tube amp