I saw some threads on the K-12G, but nothing specifically speaking of the audio quality.

Is this a reasonable choice for setting up a low-level "audiophile" type system? I'm not looking for "reference" quality, but I sure want a good improvement from my sony 3 disc changer all-in-one-box model mhc-gx40

I intend to build some ported loudspeakers using a 3'' driver (or thereabouts) and use the much debated playstation1 model 1001 as the input, at least for the time being.

I expect to have a slight lack of bass, but really want some clearer mids & highs. Nice midbass would be good, too but I suspect that's more a characteristic of my speakers.

Thanks for the input

Is this a reasonable choice for setting up a low-level "audiophile" type system? I'm not looking for "reference" quality, but I sure want a good improvement from my sony 3 disc changer all-in-one-box model mhc-gx40

An externally hosted image should be here but it was not working when we last tested it.

I intend to build some ported loudspeakers using a 3'' driver (or thereabouts) and use the much debated playstation1 model 1001 as the input, at least for the time being.

I expect to have a slight lack of bass, but really want some clearer mids & highs. Nice midbass would be good, too but I suspect that's more a characteristic of my speakers.

Thanks for the input

http://www.s5electronics.com/gtube.html

I said S5's K-12G, maybe these amplifiers aren't as common on this board as others.

I said S5's K-12G, maybe these amplifiers aren't as common on this board as others.

The current speaker plan is either the single or double bass reflex cabinet as shown here, with the FE127E drivers

https://www.madisound.com/pdf/fostexcabs/127e_revencl.pdf

https://www.madisound.com/pdf/fostexcabs/127e_revencl.pdf

These kit's have been discussed extensively. Run a search for more details, but basically they are a really good bang for the buck. I have a K-502, which is it's predasessor(it may still be available from www.tubesandmore.com). The sound will spank your sony boom-box internal amplifier.

Of course there are other options, but there are no other kit's in that price range. Though you may also be able to pick up a vintage tube amp in need of some restoration for the same price. You can't really go wrong either way.

Of course there are other options, but there are no other kit's in that price range. Though you may also be able to pick up a vintage tube amp in need of some restoration for the same price. You can't really go wrong either way.

Thanks jeb.

I actually placed my order last night- looking forward to it!

I am planning on one of the two designs for the FE127E drivers, as above.

Does anyone know the results of using 6ohm speakers to test everything out before I build the actual speakers for it? I have some sitting around, but It seems to be designed for an 8ohm driver.

I actually placed my order last night- looking forward to it!

I am planning on one of the two designs for the FE127E drivers, as above.

Does anyone know the results of using 6ohm speakers to test everything out before I build the actual speakers for it? I have some sitting around, but It seems to be designed for an 8ohm driver.

Hi guys,

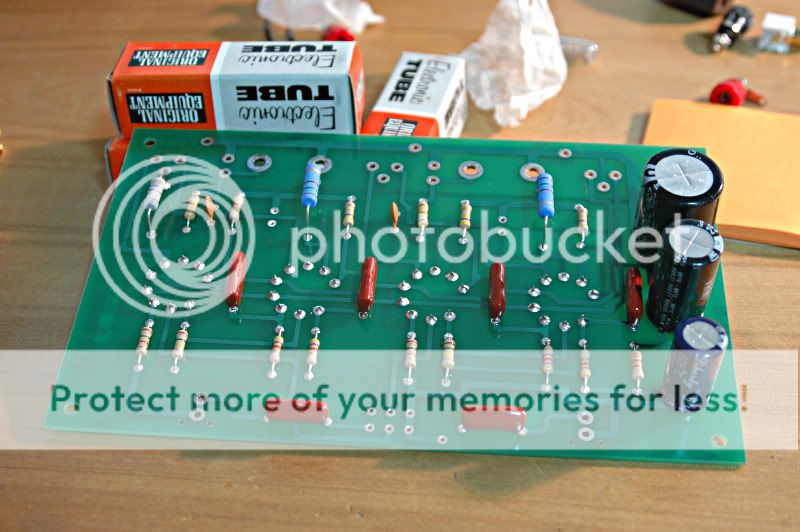

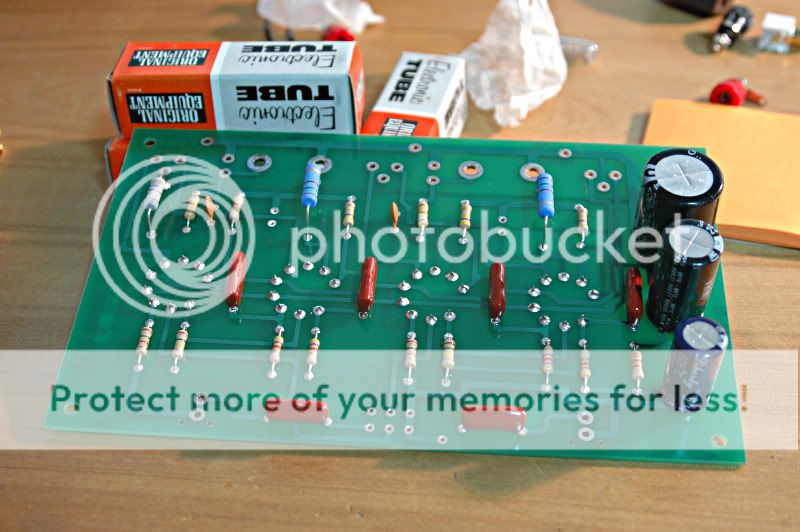

Got my kit today- already half done! It took the short side of 2 hours to read the instructions twice, check off the components, and solder all the resistors/caps/tube bases on the board.

Looking for input on mounting the volume control elsewhere.

Is it OK to use some 12G hookup wire to allow me to mount it to any part of the chassis? Don't want to create extra noise by doing something like that.

I've built the board with every component save the tube holders & the DB1 chip on the bottom, so I can mount it with the tubes sticking through the top. Doesn't work very well for me to have the volume knob awkwardly sticking out like that.

Same question for the input & output jacks. 12g wire ok to the back of the chassis that I'll build for both?

Also, I don't expect to need to, but could I extend the transformer's wires with the same?

Oh, and is it OK to touch the tubes with bare fingers? I know some car headlight bulbs don't do well with the oils from your hands. Not sure how hot the tubes get.

Thanks again.

Got my kit today- already half done! It took the short side of 2 hours to read the instructions twice, check off the components, and solder all the resistors/caps/tube bases on the board.

Looking for input on mounting the volume control elsewhere.

Is it OK to use some 12G hookup wire to allow me to mount it to any part of the chassis? Don't want to create extra noise by doing something like that.

I've built the board with every component save the tube holders & the DB1 chip on the bottom, so I can mount it with the tubes sticking through the top. Doesn't work very well for me to have the volume knob awkwardly sticking out like that.

Same question for the input & output jacks. 12g wire ok to the back of the chassis that I'll build for both?

Also, I don't expect to need to, but could I extend the transformer's wires with the same?

Oh, and is it OK to touch the tubes with bare fingers? I know some car headlight bulbs don't do well with the oils from your hands. Not sure how hot the tubes get.

Thanks again.

xxguitarist said:The current speaker plan is either the single or double bass reflex cabinet as shown here, with the FE127E drivers

There are a lot of FE127 designs that are a whole lot better than the factory BR boxes you've linked too. Nice driver to work with and can get a whole lot better with a little attention.

DAVE

planet10 said:

There are a lot of FE127 designs that are a whole lot better than the factory BR boxes you've linked too. Nice driver to work with and can get a whole lot better with a little attention.

DAVE

Could you share one?

Preferably not too big- under two feet in height or so ideally.

xxguitarist said:Any of them? or is there one in particular that you'd recommend most strongly? I'm capable of building any of them I believe.

Fonken (aka FonkenPrime) is the best sonically... the rest all take a form based on some other constraint (ie smaller, floorstander, easier to build)

dave

Dave, Thanks again.

I assume the plans are to be mirror imaged, is the central brace offset to the right or left for the right speaker?

Additionally, could that center brace be made of the same 1/2'' BB ply? I see a note about making it 2x 1/2'' instead. I could laminate two sheets of 1/2'' easily if this is preferable.

I assume the plans are to be mirror imaged, is the central brace offset to the right or left for the right speaker?

Additionally, could that center brace be made of the same 1/2'' BB ply? I see a note about making it 2x 1/2'' instead. I could laminate two sheets of 1/2'' easily if this is preferable.

xxguitarist said:Dave, Thanks again.

I assume the plans are to be mirror imaged, is the central brace offset to the right or left for the right speaker?

Additionally, could that center brace be made of the same 1/2'' BB ply? I see a note about making it 2x 1/2'' instead. I could laminate two sheets of 1/2'' easily if this is preferable.

The only assimmetry is the brace. You could mirror image it. The Fonken i just installed drivers in (our 2nd or 3rd pair) were not mirror imaged.

The brace is 12mm BB ply (1/2"). It is optional to use 2x12mm on the front baffle instead of 1x18mm (not everyone has the luxury of building enuff speakers to justify having a sheet of 18mm lying around. Our latest builds have been 15mm + 18mm (to economize on material we are trying (unsuccessfully) to standardize on 15mm as our main material.

The spacers are 3/8" (9.5mm) mdf, althou we have made some with fatter material run thru the big thickness sander. We are also playing with the idea of rebating the "bread" part of the sidewall sandwich a 1/16" to ease assembly of the sides (and using 12mm spacers).

dave

Thanks. I'll laminate an extra two layers of my 1/8'' BB scrap onto the face of the speaker, then. What kind of joint is preferred for the corners? Simple butt joint & screws, 45 bevel, or something routed? I've had very good luck with titebond3, so I'll be using that here as well regardless.

I'll also just make some 3/8'' BB spacers of my 1/8'' scrap. Lots left over from vacuum lamination projects.

Thanks

I'll also just make some 3/8'' BB spacers of my 1/8'' scrap. Lots left over from vacuum lamination projects.

Thanks

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Quality of S5's K-12G in proposed system