I'm not exactly making rationale out of it, what's BS ....... not exactly matter of price (every goods is having a customer), more based on amount of Audiophool myths following specific brand

and that trying to differentiate Audiophoolery produced by eager followers and dirty re-sellers, from same produced by manufacturer itself

anyhow - more important criteria ..... I'm strongly single-minded in stance that decent FR doesn't need (with all shortcomings inherent to concept) any sort of passive/active Eq

there are enough specimens , of Yore and present production, not needing that

if you take that criteria and also refusal of drivers needing endless tweaking of phase plugs or whatever physically (in short - they must be good right from the box), choice of proper drivers is even smaller

-take in account that I'm cheap bstrd, not even thinking and far from even being able to buy any of more expensive ones

and that trying to differentiate Audiophoolery produced by eager followers and dirty re-sellers, from same produced by manufacturer itself

anyhow - more important criteria ..... I'm strongly single-minded in stance that decent FR doesn't need (with all shortcomings inherent to concept) any sort of passive/active Eq

there are enough specimens , of Yore and present production, not needing that

if you take that criteria and also refusal of drivers needing endless tweaking of phase plugs or whatever physically (in short - they must be good right from the box), choice of proper drivers is even smaller

-take in account that I'm cheap bstrd, not even thinking and far from even being able to buy any of more expensive ones

Hi ZM,

Thanks for your reply; I´m on your side regarding audiophoolery... but disagree insofar that I think that nearly every decent FR driver benefits from sensible correction by an active or passive filter. And benefits from being relieved of bass duties.

But of course opinions may differ.

Apropos phase plugs - once I made an investigation and measured and listened to 4 different phaseplugs with the same driver. Differences were small only and I was unable to seperate the better from the worse...

All the best

Mattes

Thanks for your reply; I´m on your side regarding audiophoolery... but disagree insofar that I think that nearly every decent FR driver benefits from sensible correction by an active or passive filter. And benefits from being relieved of bass duties.

But of course opinions may differ.

Apropos phase plugs - once I made an investigation and measured and listened to 4 different phaseplugs with the same driver. Differences were small only and I was unable to seperate the better from the worse...

All the best

Mattes

Hi,Are loudspeaker manufacturers willing to sell their product without a permanent magnet?

Probably, if you buy several hundreds of units. If you buy just 2, magnet amputation is your way to get rid of it.

All the best

Mattes

You can buy the parts to drivers fairly easily if you don't mind generics. EBay is a good source, but any place that offers parts to enthusiast builders (quite a few in car audio) or reconing supplies will have what you need. Examples: https://www.gsaudio.it/en/ricambi-altoparlanti.html and https://reconingspeakers.com/product-category/dustcaps-gaskets-cones-spiders-voice-coils/Are loudspeaker manufacturers willing to sell their product without a permanent magnet?

Realize, though, that these are the cheap parts to a driver. The motor is where the cost is. A proper field coil motor will be an expensive proposition as you'll require the services of a machine shop to mill the top plate, pole piece/yoke, shorting rings, etc (even the materials won't be cheap) then a great deal of patience winding a not inexpensive amount of copper magnet wire.

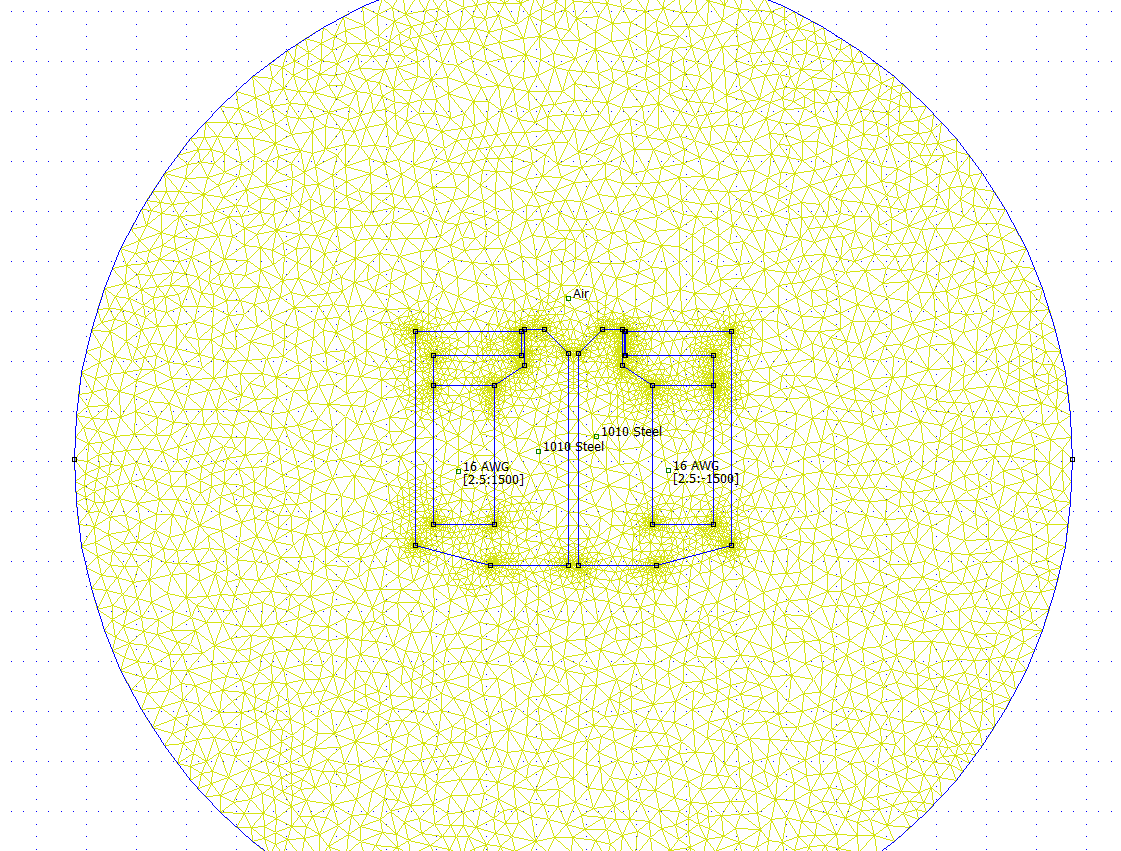

As you'll be building a motor from scratch, you'll need to design it first so you're not throwing money away on a bad design. I'd recommend starting here: https://www.femm.info/wiki/HomePage

you reminded me of something.

when you have an accident with a car you then have to go to a body shop to repair the damage.

if the damage is significant, then the coachbuilder orders original spare parts from the dealer.

Are there ORIGINAL spare parts [not generic] also for the loudspeakers? .

for example I already know that in case of cone breakage there are people who do the repair and maybe they do the same thing a body shop does for cars.

when you have an accident with a car you then have to go to a body shop to repair the damage.

if the damage is significant, then the coachbuilder orders original spare parts from the dealer.

Are there ORIGINAL spare parts [not generic] also for the loudspeakers? .

for example I already know that in case of cone breakage there are people who do the repair and maybe they do the same thing a body shop does for cars.

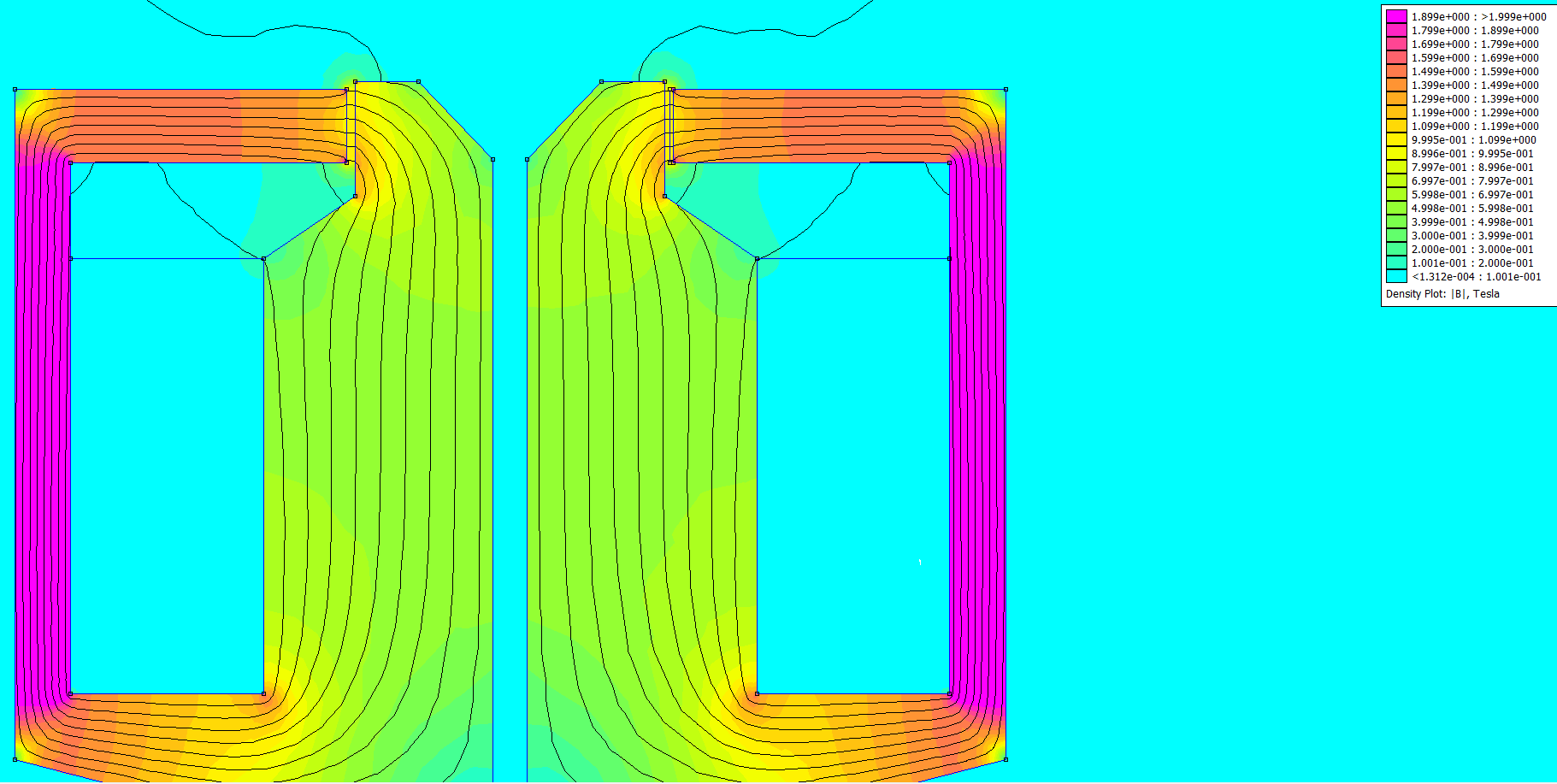

Has anyone replicated the gap parameters as described in the OP? I'm experimenting with FEMM and when I model the FC geometry, including coil inputs (ballpark), my field strength is nowhere near 1.5T in the gap.

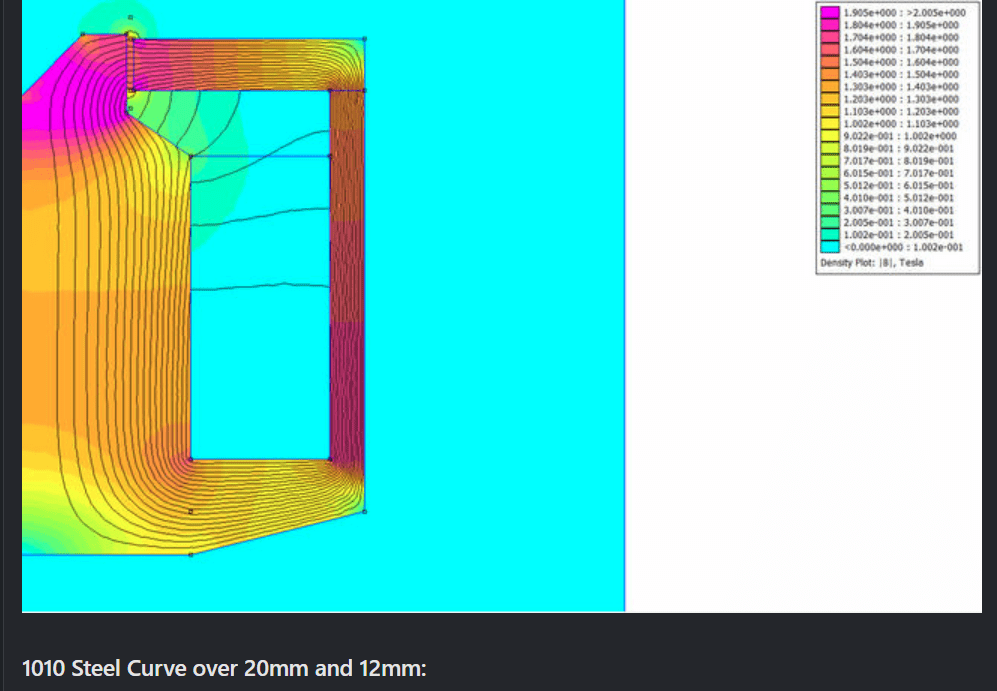

What has me really scratching my head is how the OP hits such high saturation at the center pole region near the gap. Everything I do in FEMM tends to require a much narrower cross-section to achieve those extreme gradients. Normally I would assume my inputs are incorrect but in this instance the extreme gradient to cross-section appears more counter intuitive than the results on my end. IIRC, the 1.5T was verified physically, so I assume my model is lacking some key input? For reference I attached the original simulation (last image)-

What has me really scratching my head is how the OP hits such high saturation at the center pole region near the gap. Everything I do in FEMM tends to require a much narrower cross-section to achieve those extreme gradients. Normally I would assume my inputs are incorrect but in this instance the extreme gradient to cross-section appears more counter intuitive than the results on my end. IIRC, the 1.5T was verified physically, so I assume my model is lacking some key input? For reference I attached the original simulation (last image)-

Depends on the manufacturer and the driver. For some, you can get recone kits or replacement diaphragms (for domes and planars) that are assembled and ready to be dropped into the basket. A very few have the whole top assembly (soft parts and basket), but those are rare drivers. Generally, all of this tends to be for those drivers geared towards the professional market rather than domestic/audiophile. Even if they are available, quite often they're only made so to certified repair centers/dealers rather than just sold as is to anyone. For motor parts, forget it. Motors are the most expensive part of the driver and trickiest to repair. If the motor has been damaged enough to, say, require a new top plate or pole piece then you can forget parts being available to replace just those.you reminded me of something.

when you have an accident with a car you then have to go to a body shop to repair the damage.

if the damage is significant, then the coachbuilder orders original spare parts from the dealer.

Are there ORIGINAL spare parts [not generic] also for the loudspeakers? .

for example I already know that in case of cone breakage there are people who do the repair and maybe they do the same thing a body shop does for cars.

Regardless, this won't help you much. The voice coil will be glued into the cones at the correct height for the gap in the stock motor for the driver. It's very unlikely any field coil you design will end up a perfect match for that. That's not considered an issue for reconing for the most part because, simply put, if you don't have the basic level of knowledge, skill or willingness to learn how to glue together the soft parts in the correct spacing and alignment for a driver, you won't have what's needed to design and build the motor.

this is the response i got from a speaker repairman

if you have a branded product, my spare parts are very often original even if it is not written. This happens because the companies that build the elements do it both for brands, and therefore they are branded, and to sell them on the market to repairers or builders who do not need the brand.

if you have a branded product, my spare parts are very often original even if it is not written. This happens because the companies that build the elements do it both for brands, and therefore they are branded, and to sell them on the market to repairers or builders who do not need the brand.

what about hiperco50 (FeCo) alloys (supermendur) or silicon steel alloy (FeSi) ? .

the saturation of the hiperco50 easily exceeds 2 T and I also believe that it needs much less electric current therefore a smaller coil.

I don't know much about mechanical workability and price.

https://f.hubspotusercontent20.net/...ources/Datasheets/Hiperco_50_Alloy_(E200).pdf

the saturation of the hiperco50 easily exceeds 2 T and I also believe that it needs much less electric current therefore a smaller coil.

I don't know much about mechanical workability and price.

https://f.hubspotusercontent20.net/...ources/Datasheets/Hiperco_50_Alloy_(E200).pdf

Attachments

This model looks wrong - normally for a round motor structure you'd model with rotational symmetry. You would only model the right half of this geometry with the vertical center line down the middle of the motor at x=0.

I'll give that a go. I got the current technique from a tutorial on simming coils. When modelling the left and right you flip the winding directions on each side, i.e. +1400 turns and -1400 turns. As far reaching the gap flux as per the OP, it's becoming my impression (and I'll happily stand corrected) that a neodymium core pole piece can match those values with less material/size/weight. For example, I'm looking at spec for conventional woofers with BLs going above 17. Aside from the ability to make adjustments with a field coil, is there some other advantage beyond not needing to procure a permanent magnet? Adjustment wise you could make a permanent magnet motor with mechanical flux manipulation, such as moving the plates and so on. So I don't see the adjustment factor as being inherently unique to the FC.

@arivel, It's true that those materials offer insane performance, but at an even more insane cost. Like north of 1000$ USD per pound insane 😀

@arivel, It's true that those materials offer insane performance, but at an even more insane cost. Like north of 1000$ USD per pound insane 😀

You can sim coils that way, but I think what you're actually simulating is a long linear coil (going straight into the screen), not a circular coil.

Usually I have seen magnets put into motors in the unmagnetized state. Then you magnetize everything once assembled. For neo magnets, this requires a pretty powerful magnetizer. I have used a capacitor discharge system before. You can assemble charged magnets, but it can be quite difficult to get things aligned and avoid damage depending on the design.

Usually Neo ring magnets are better for making a powerful motor structure than a disc in the pole piece. You can get more surface area of magnet perpendicular to the magnetization direction. It depends on your design whether this is helpful or not. If a center disc is already enough to saturate your motor structure, it probably would not gain you much.

Other than lack of needing a magnetizer, the main advantage we used to talk about with field coils vs permanent magnets was the ability to reduce flux modulation by having a low DCR field coil and constant current PSU powering it. I'm not sure exactly how that would compare against a well designed permanent magnet motor structure. I'd imagine you could find cases that went each way depending on the exact designs.

Usually I have seen magnets put into motors in the unmagnetized state. Then you magnetize everything once assembled. For neo magnets, this requires a pretty powerful magnetizer. I have used a capacitor discharge system before. You can assemble charged magnets, but it can be quite difficult to get things aligned and avoid damage depending on the design.

Usually Neo ring magnets are better for making a powerful motor structure than a disc in the pole piece. You can get more surface area of magnet perpendicular to the magnetization direction. It depends on your design whether this is helpful or not. If a center disc is already enough to saturate your motor structure, it probably would not gain you much.

Other than lack of needing a magnetizer, the main advantage we used to talk about with field coils vs permanent magnets was the ability to reduce flux modulation by having a low DCR field coil and constant current PSU powering it. I'm not sure exactly how that would compare against a well designed permanent magnet motor structure. I'd imagine you could find cases that went each way depending on the exact designs.

Interesting observation. I'm gonna play with the single side, as you suggested 👍long linear coil

Regarding pre-magnetized permanents, I just assume careful work would have to go into fixturing, jigs, and what have you.

Is this a back EMF thing? I'm not quite sure I follow; this is to do with the unwanted interaction of stored energy in the VC (when changing direction) correct? I wonder if you could configure a motor using PMs as the primary field but have smaller FCs, maybe at each end of the travel, that would act like back EMF zappers, or sponges or whatever.reduce flux modulation by having a low DCR field coil and constant current

That did the trick @John Sheerin !

I'm getting a slightly too high gap flux but at this point it's a matter of tinkering with the boundary conditions. Much appreciated 🍻

I'm getting a slightly too high gap flux but at this point it's a matter of tinkering with the boundary conditions. Much appreciated 🍻

I'm rusty on my magnetic theory, but basically a voice coil generates a magnetic field when you run current through it just like a field coil does, but it's an alternating field, not a static dc field. So the voice coil can effect the flux of the motor structure during operation - it can modulate the flux. How much this happens depends on the design of your motor structure and coil and the signal. Shorting rings try to address some of these effects as well.

That's basically the way I understand it too. Apparently the copper will intercept the would-be eddy currents and keep them out of the motor.

I'm no expert, I can not understand one thing.

if the voice coil runs in the air gap, judging from the image of post 787 in this area the lines of force of the magnetic field are orthogonal to the axis of the voice coil and therefore how does the speaker work in the right way?

What am I missing? Someone enlighten me?

if the voice coil runs in the air gap, judging from the image of post 787 in this area the lines of force of the magnetic field are orthogonal to the axis of the voice coil and therefore how does the speaker work in the right way?

What am I missing? Someone enlighten me?

Force on the coil which moves the diaphragm is generated perpendicular to the plane of magnetic flux and electrical current flow. So if lines of flux are oriented radially inward / outward through the gap, current is flowing in a circle around the gap through the voice coil windings, then force is generated in the vertical direction in the images shown. This would push the coil and diaphragm as desired. Here's an image to help visualize: https://commons.wikimedia.org/wiki/File:Right_hand_rule_cross_product_F=J×B.svg

- Home

- Loudspeakers

- Multi-Way

- Project Ryu - DIY Field Coil Loudspeaker