This is an exciting day for me - I picked these beauties up last evening (hope the attachment shows up). Thank you so much for sharing your designs, Hentai - and to everyone on this thread for all the inspiration it's provided. You guys are amazing.

Attachments

Oh, Look great Gromper ! This is for midrange or tweeter design. How about the voltage to supply to field coil ?

Here is the tweeter of my past design, sound is very good.

Here is the tweeter of my past design, sound is very good.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Oh wow gomper. Very nice execution.

Haven't checked in here for a while.

I need to update this since i see you guys are busy doing great things.

Have you built the field coil yet gomper?

Fieldcoil Adventure thats very nice work on the field coil. What is the dc resistance?

Haven't checked in here for a while.

I need to update this since i see you guys are busy doing great things.

Have you built the field coil yet gomper?

Fieldcoil Adventure thats very nice work on the field coil. What is the dc resistance?

Thanks very much, guys - great looking work FieldCoil!

As Hentai knows from prior private messages, I face an important challenge as I push forward on this project: I don't actually know what I'm doing, and I have no formal background in any of the disciplines that may lead to informed decisions or success.

I'm not letting that discourage me, and am ordering thousands of feet of 18AWG copper wire today to wind the coils. I think I did the basic calculations correctly this weekend on how many windings I'm going to need to get an 8 Ohm result... feeling reasonably confident there.

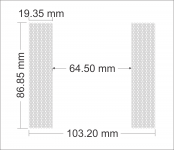

On the other hand, I don't know whether the dimensions of the wound coil itself are important. I've done my initial calculation of windings informed in part by the amount of space I'm filling inside the motor, about a 20mm gap between the pole and casing, and 86mm to the top of the main body of the pole from the bottom. I assume I want a reasonably snug fit within that space, but I don't know if or how much it matters.

This was my last finished project, a set of speakers made with padauk, brass and Tang Band drivers. That's where my love of full-range drivers got started, and what led me to want to build my own.

As Hentai knows from prior private messages, I face an important challenge as I push forward on this project: I don't actually know what I'm doing, and I have no formal background in any of the disciplines that may lead to informed decisions or success.

I'm not letting that discourage me, and am ordering thousands of feet of 18AWG copper wire today to wind the coils. I think I did the basic calculations correctly this weekend on how many windings I'm going to need to get an 8 Ohm result... feeling reasonably confident there.

On the other hand, I don't know whether the dimensions of the wound coil itself are important. I've done my initial calculation of windings informed in part by the amount of space I'm filling inside the motor, about a 20mm gap between the pole and casing, and 86mm to the top of the main body of the pole from the bottom. I assume I want a reasonably snug fit within that space, but I don't know if or how much it matters.

This was my last finished project, a set of speakers made with padauk, brass and Tang Band drivers. That's where my love of full-range drivers got started, and what led me to want to build my own.

Attachments

Thanks Hentai! I'm unsure how I'll to power them honestly, although I liked your novel idea of using an IBM laptop power supply. Were you pleased with the results? In the longer term, it seems like it would be nice to have some kind of rheostat between the motor and the power supply to control the amount of power, ideally accessible from the back of the cabinet.

In any case, if you saw good results with a particular power supply in your own work, I'd welcome your recommendations. I'm thinking about hopping onto eBay one of these days soon and buying an old, reasonably inexpensive vintage field coil driver to just disassemble and closely study. Lots of great lessons to be had via that kind of hands-on examination, I'm betting...

In any case, if you saw good results with a particular power supply in your own work, I'd welcome your recommendations. I'm thinking about hopping onto eBay one of these days soon and buying an old, reasonably inexpensive vintage field coil driver to just disassemble and closely study. Lots of great lessons to be had via that kind of hands-on examination, I'm betting...

Hi gomper,

I only used a laptop power supply just to show you can do it even with a switching power supply. As long as it satisfies the power requirements it should be fine.

In my tests i usually use an adjustable bench supply.

Something that deserves attention and testing is a constant current supply. Its on my to do list but i haven't gotten to it yet.arget

But you need to size the coil so you need to settle on the power requirements. I will post an example for field coil you could use with that motor soon when i get home.

I only used a laptop power supply just to show you can do it even with a switching power supply. As long as it satisfies the power requirements it should be fine.

In my tests i usually use an adjustable bench supply.

Something that deserves attention and testing is a constant current supply. Its on my to do list but i haven't gotten to it yet.arget

But you need to size the coil so you need to settle on the power requirements. I will post an example for field coil you could use with that motor soon when i get home.

Hi Gomper,

For design of field coil speaker, first of all that you need planing of DC power supply for the field coil. After that, calculating for the field coil, it depend on the dimensions of motor, gap inside of the driver, also diameter of coil winding ,, and so on.

For the power supply, you can buy some type of power supply such as Kikusui DC power supply. This kind can be adjusted the DC voltage output, so you can fixed the correct voltage output during testing that you feel be satisfied with the sound when hearing.

I have a pair of the DC power supply for my system speaker. (Kikusui PMC 18-5A for subwoofer),

I think the DC power supply from laptop device is not good for a long time using. Maybe it can be damaged, and can not be safety .

Hi Hentai ,

The field coil that shown above for tweeter motor with 15.8 Ohms measured.

I was pleased with the pair of speakers. Now I have another FC tweeter better.

Thank you.

For design of field coil speaker, first of all that you need planing of DC power supply for the field coil. After that, calculating for the field coil, it depend on the dimensions of motor, gap inside of the driver, also diameter of coil winding ,, and so on.

For the power supply, you can buy some type of power supply such as Kikusui DC power supply. This kind can be adjusted the DC voltage output, so you can fixed the correct voltage output during testing that you feel be satisfied with the sound when hearing.

I have a pair of the DC power supply for my system speaker. (Kikusui PMC 18-5A for subwoofer),

I think the DC power supply from laptop device is not good for a long time using. Maybe it can be damaged, and can not be safety .

Hi Hentai ,

The field coil that shown above for tweeter motor with 15.8 Ohms measured.

I was pleased with the pair of speakers. Now I have another FC tweeter better.

Thank you.

Hi guys,

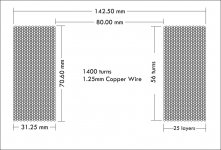

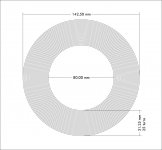

Almost forgot about the field coil sketches. Gomper here is an example, which if i remember correctly will work well with that structure.

Very nice FieldCoil Adventure, will love to see more of your work.

Almost forgot about the field coil sketches. Gomper here is an example, which if i remember correctly will work well with that structure.

Very nice FieldCoil Adventure, will love to see more of your work.

Attachments

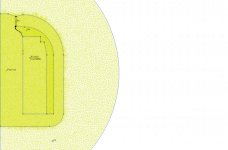

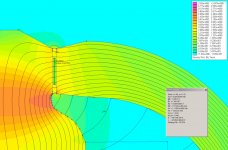

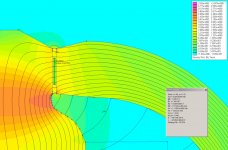

FYI: A field coil (driver) can be simulated in FEMM, here's an example:

FEMM will perform all the calculations for you:

Total current = 0.5 Amps

Voltage Drop = 22.0545 Volts

Flux Linkage = 20.9956 Webers

Flux/Current = 41.9911 Henries

Voltage/Current = 44.109 Ohms

Power = 11.0272 Watts

The voice coil can also be simulated:

Total current = 1 Amps

Voltage Drop = 6.4751 Volts

Flux Linkage = 0.110242 Webers

Flux/Current = 0.110242 Henries

Voltage/Current = 6.4751 Ohms

Power = 6.4751 Watts

Lorentz force (acting on the voice coil):

r-component: 0 N

z-component: -13.7351 N

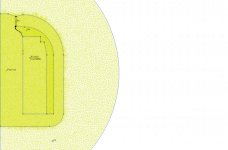

For simulations of the air gap do not let the application choose the mesh size for the air in the gap, create a separate region of air in the gap and choose a (very) small mesh size (0.1mm or so) to achieve sufficiently high resolution.

regards,

Gerrit

P.S. For these simulations I used pure iron as the material for the motor but later I learned that pure iron in this context means electrolytically deposited iron which has to be annealed in a hydrogen atmosphere after machining, now I just use 'warm rolled steel' or 'cold rolled steel' in the simulations.

FEMM will perform all the calculations for you:

Total current = 0.5 Amps

Voltage Drop = 22.0545 Volts

Flux Linkage = 20.9956 Webers

Flux/Current = 41.9911 Henries

Voltage/Current = 44.109 Ohms

Power = 11.0272 Watts

The voice coil can also be simulated:

Total current = 1 Amps

Voltage Drop = 6.4751 Volts

Flux Linkage = 0.110242 Webers

Flux/Current = 0.110242 Henries

Voltage/Current = 6.4751 Ohms

Power = 6.4751 Watts

Lorentz force (acting on the voice coil):

r-component: 0 N

z-component: -13.7351 N

For simulations of the air gap do not let the application choose the mesh size for the air in the gap, create a separate region of air in the gap and choose a (very) small mesh size (0.1mm or so) to achieve sufficiently high resolution.

regards,

Gerrit

P.S. For these simulations I used pure iron as the material for the motor but later I learned that pure iron in this context means electrolytically deposited iron which has to be annealed in a hydrogen atmosphere after machining, now I just use 'warm rolled steel' or 'cold rolled steel' in the simulations.

Hi Gerrit,

Indeed been using FEMM from the beginning. You are definitely right about mesh size for increased resolution but ofc it comes with the cost of increased simulation time. I usually run simulations first with default mesh size and when i am closer to what i like i increase it.

I am glad you brought it up as it reminded me that i havent showed yet some scripts i made for FEMM last year.

They are available on GitHub (link below) and one can use it to generate a motor structure based on user input data.

https://github.com/Taur-Tech/Project-Ryu---Loudspeaker-Drivers/tree/master/FEMM_Scripts

I invite everyone who wants, to contribute.

You can find a description in the repository and i also wrote an article last month for better understanding:

PROJECT RYU Lua Scripts for FEMM to aid Electrodynamic Loudspeaker Motor Design

So please guys use it, test it and if you find any bugs let me know. I will submit a revised version until summer.

Indeed been using FEMM from the beginning. You are definitely right about mesh size for increased resolution but ofc it comes with the cost of increased simulation time. I usually run simulations first with default mesh size and when i am closer to what i like i increase it.

I am glad you brought it up as it reminded me that i havent showed yet some scripts i made for FEMM last year.

They are available on GitHub (link below) and one can use it to generate a motor structure based on user input data.

https://github.com/Taur-Tech/Project-Ryu---Loudspeaker-Drivers/tree/master/FEMM_Scripts

I invite everyone who wants, to contribute.

You can find a description in the repository and i also wrote an article last month for better understanding:

PROJECT RYU Lua Scripts for FEMM to aid Electrodynamic Loudspeaker Motor Design

So please guys use it, test it and if you find any bugs let me know. I will submit a revised version until summer.

Hi Gerrit,

Indeed been using FEMM from the beginning. You are definitely right about mesh size for increased resolution but ofc it comes with the cost of increased simulation time. I usually run simulations first with default mesh size and when i am closer to what i like i increase it.

I am glad you brought it up as it reminded me that i havent showed yet some scripts i made for FEMM last year.

They are available on GitHub (link below) and one can use it to generate a motor structure based on user input data.

https://github.com/Taur-Tech/Project-Ryu---Loudspeaker-Drivers/tree/master/FEMM_Scripts

I invite everyone who wants, to contribute.

You can find a description in the repository and i also wrote an article last month for better understanding:

PROJECT RYU Lua Scripts for FEMM to aid Electrodynamic Loudspeaker Motor Design

So please guys use it, test it and if you find any bugs let me know. I will submit a revised version until summer.

I didn't follow this thread from the start so I missed that. Just thought I'd mention it for others who dropped in at a later stage just like me.

Keep up the good work!

regards,

Gerrit

Gerrit, Hentai and FieldCoil, I can't thank you enough for all of your very generous feedback and recommendations. I have installed FEMM this morning and just cloned your repo a few minutes ago, Hentai. I'm somewhat familiar with Lua, and I'd of course love to reach a level of acumen in this endeavor to be able to make some useful contributions to your scripts.

Your timing with the smaller coil diagram is perfect, by the way. I was just at this moment working through what the conductor length would be for the coil using 1.02mm wire wound in 18 layers at an 86mm height. I meant to order my wire earlier this week, but am only getting around to it today. This is the stuff I'm looking at, hoping if I order today it will arrive by the middle of next week and I can wind them next weekend:

I meant to order my wire earlier this week, but am only getting around to it today. This is the stuff I'm looking at, hoping if I order today it will arrive by the middle of next week and I can wind them next weekend:

Essex Magnet Wire 18 AWG Heavy Build, 200 Degree Celsius 11 LB Spool - CMS Magnetics, Inc

I apologize in advance for delays in my responses on this thread - between work and life generally, it can be hard to find the time I'd like to devote to this project... but you should know I greatly appreciate all the guidance. Really looking forward to doing some FEMM simulations this evening.

Best,

Ken

Your timing with the smaller coil diagram is perfect, by the way. I was just at this moment working through what the conductor length would be for the coil using 1.02mm wire wound in 18 layers at an 86mm height.

Essex Magnet Wire 18 AWG Heavy Build, 200 Degree Celsius 11 LB Spool - CMS Magnetics, Inc

I apologize in advance for delays in my responses on this thread - between work and life generally, it can be hard to find the time I'd like to devote to this project... but you should know I greatly appreciate all the guidance. Really looking forward to doing some FEMM simulations this evening.

Best,

Ken

Hi Hentai, Gromper and All.

Here is a pair of field coil subwoofer 15 inches, that I made them three year ago, these FC speakers to be supplied with DC 16.8 Volt. I was very pleasant with the pair for along time hearing music from the subwoofer. The sound is excited. I took the picture during testing, so at that time, dust cover was still not installed.

Now I have a plan to make subwoofer bigger from 18 inches and more.

Dear Gromper,

Do you finish widing of field coil for you project ?

Here is a pair of field coil subwoofer 15 inches, that I made them three year ago, these FC speakers to be supplied with DC 16.8 Volt. I was very pleasant with the pair for along time hearing music from the subwoofer. The sound is excited. I took the picture during testing, so at that time, dust cover was still not installed.

Now I have a plan to make subwoofer bigger from 18 inches and more.

Dear Gromper,

Do you finish widing of field coil for you project ?

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Project Ryu - DIY Field Coil Loudspeaker