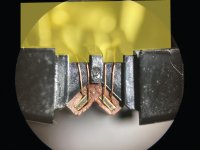

The plastic clip that covers the elements ( “ L “ shape) and wraps around the front should be glued in or removed and covered with nylon mesh. That piece doesn’t touch the SG strip holder either. The blutac is damping this area piece along with the top curved cover plate and most of the “ tin can ringing “signature I think...

All resonant cavity’s. Those 2 wings extending from the cantilever assembly and fit in the 2 troughs of that cover are loose also . A piece of paper can slide in and around them. both should damped together if kept. IMO

The actual wires that wrap around the nose I will speculate actually move a little because of the soft nature of its captured surround.

I am hesitant about firmly anchoring those wires other than further upstream filling everything else with hot melt and maybe covering the wires exiting the SG with a soft foam lightly pressing in on them .

There was a reason why they decided to mount the SG elements in such a gooey soft capture material that maybe should be maintained ? Not certain..,.

Regards

David

All resonant cavity’s. Those 2 wings extending from the cantilever assembly and fit in the 2 troughs of that cover are loose also . A piece of paper can slide in and around them. both should damped together if kept. IMO

The actual wires that wrap around the nose I will speculate actually move a little because of the soft nature of its captured surround.

I am hesitant about firmly anchoring those wires other than further upstream filling everything else with hot melt and maybe covering the wires exiting the SG with a soft foam lightly pressing in on them .

There was a reason why they decided to mount the SG elements in such a gooey soft capture material that maybe should be maintained ? Not certain..,.

Regards

David

The position of the front dampener will need to be investigated too. All the examples are different.

Also the actual beam position in the body. 2 bodies the beams are positioned less than .001 difference. That would be front to back. 3rd is .003 or .004 different.

Also the actual beam position in the body. 2 bodies the beams are positioned less than .001 difference. That would be front to back. 3rd is .003 or .004 different.

Attachments

I snipped the "wings" off of a new bliss stylus. Probably crazy as this one differs from the others in that it has a much lower mass stylus than my other two examples.

Something else, at least with the bliss replacements the SRA may be too extreme, performance seemed a bit better overall with the stylus not fully seated. I may investigate this a bit further. (Seems to reduce the coupler angle relative to the surface of the transducers.)

I did hear one of Dave Slagle's boron/MR retips last week, I believe based on what I had heard in this system previously it was a significant improvement. It was auditioned with one of these strain gauge pre-amps.

I suspect all of this fiddling indicates that for all of the promise there is still a significant problem with these cartridges.

I guess vinyl playback basically sucks, just most other things suck more.. LOL

Something else, at least with the bliss replacements the SRA may be too extreme, performance seemed a bit better overall with the stylus not fully seated. I may investigate this a bit further. (Seems to reduce the coupler angle relative to the surface of the transducers.)

I did hear one of Dave Slagle's boron/MR retips last week, I believe based on what I had heard in this system previously it was a significant improvement. It was auditioned with one of these strain gauge pre-amps.

I suspect all of this fiddling indicates that for all of the promise there is still a significant problem with these cartridges.

I guess vinyl playback basically sucks, just most other things suck more.. LOL

High variability with small changes.. In some ways this is good as it indicates an optimization will result in a better sounding package.

High variability with small changes.. In some ways this is good as it indicates an optimization will result in a better sounding package. In another design I want to make the cantilever variable as to it position where it presses on the elements.

Here is an article of the Winlabs SDT-10-2 / SPG -10 combo from the Audio Critc 1980. Notice the separation figures...,. You might have seen this back in the day. Sound Smith quotes 25 db at 1k for his version.

I am wondering if cutting the elements soft capture down the middle and making its foundation separate would improve these figures so one sides movement will not influence the other.

Regards

David

I am seriously impressed!

Looking forward to hearing what you think of the performance after these modifications. I'm currently having a little angst over the whole strain gauge thing..

I've worn out all of my OEM styli and need to either get more or bite the bullet and get a DS retip.

Looking forward to hearing what you think of the performance after these modifications. I'm currently having a little angst over the whole strain gauge thing..

I've worn out all of my OEM styli and need to either get more or bite the bullet and get a DS retip.

You must be playing a lot of records to wear out the bunch

FWIW

I placed 2 brush hairs (.005” ) between the strain elements and the top cap to see if what I thought was a dead space gap and couldn,t pull them out - so it does touch and noticed the impedance went up on both channels

There is a little rectangular piece sandwiched between on one channel only that might have been some kind of production

error correction on all my versions (speculation only)

One could adjust each channels static impedance by trying different spacers if it would make difference and wonder if the sidecscrews on Sound Smith’s version move the elements around for channel balance ?

One of them failed pretty quickly on my 465, compliance too low and tracking force too high. The Bliss or the 46ST are the only ones that work on that cartridge.

The other two got worn out during extensive use during the winter. I average more than 20 hours of listening a week, and these styli are done at around 200 - 250 hours at most. They're not very durable.

I have been focusing on other turntable problems after it dawned on me that perhaps the strain gauge was trying to tell me something about the turntable.

This table has a Papst 3 phase aussenlaufer motor on it with 3 phase power from a modified Siemens Micromaster MM410, a Mirko stainless steel platter with Gem Dandy mat, no slip platter, and of course an ET-2.5 air bearing linear arm. A friend made me a very nice record weight recently. It shows some promise.

Other distractions include the new amps I have just finished, and the crossovers that I have designed and ordered parts for, but have yet to build.

The other two got worn out during extensive use during the winter. I average more than 20 hours of listening a week, and these styli are done at around 200 - 250 hours at most. They're not very durable.

I have been focusing on other turntable problems after it dawned on me that perhaps the strain gauge was trying to tell me something about the turntable.

This table has a Papst 3 phase aussenlaufer motor on it with 3 phase power from a modified Siemens Micromaster MM410, a Mirko stainless steel platter with Gem Dandy mat, no slip platter, and of course an ET-2.5 air bearing linear arm. A friend made me a very nice record weight recently. It shows some promise.

Other distractions include the new amps I have just finished, and the crossovers that I have designed and ordered parts for, but have yet to build.

Attachments

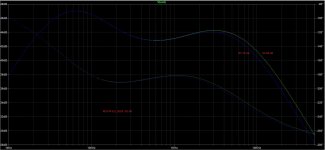

EQ Update: REV.04

As I indicated I will from time to time tweak the EQ and if I think there is an improvement I will share it.

I have concluded that the REV 03 EQ was not quite (to put it mildly) the last word in HF extension.

The new EQ results in a slight boost in response starting at approximately 3kHz and is up approximately 0.8dB at 10kHz which results in somewhat more top end air.

The change is very simple and involves replacing R5 on the plug in EQ card with a new resistor value. (Please use a thin film resistor)

R5 goes from 75.0K to 60.4K, but could depending on preference (and perhaps stylus used) vary from 56K to 75.0K.

Anyone who has not changed the coupling capacitor C2 on the pre-amp board proper from 0.068uF to 0.047uF and finds the bass overcooked should also make this change

As I indicated I will from time to time tweak the EQ and if I think there is an improvement I will share it.

I have concluded that the REV 03 EQ was not quite (to put it mildly) the last word in HF extension.

The new EQ results in a slight boost in response starting at approximately 3kHz and is up approximately 0.8dB at 10kHz which results in somewhat more top end air.

The change is very simple and involves replacing R5 on the plug in EQ card with a new resistor value. (Please use a thin film resistor)

R5 goes from 75.0K to 60.4K, but could depending on preference (and perhaps stylus used) vary from 56K to 75.0K.

Anyone who has not changed the coupling capacitor C2 on the pre-amp board proper from 0.068uF to 0.047uF and finds the bass overcooked should also make this change

Attachments

Hope that was 0.047uF otherwise you have zip for bass.. LOL

The simulations indicated 56K would be fine, will result in very slightly more rise at 10kHz and below.

It is a significant improvement, just a little more air up on top.

I recently had the Windfeld on the ET-2.5 and the one area where the Windfeld definitely betters my 451C is in the extreme treble, this should close the gap a bit more, as does an improved stylus from Dave Slagle. (Have heard one with this pre, but don't have one yet)

The conclusion is that I prefer the strain gauge to the Windfeld in all other areas, but that the stylus quality is really a liability with these cartridges. Imaging, depth, and delineation of detail are vastly better with the strain gauge, the increased resolution is most noticeable in vocals (multi-tracked) and massed strings. It might be the most articulate cartridge I have heard (very limited experience).

All of the above presupposes that you have very good stylus. The OEM replacements have gotten very expensive, so much so that the Jico is a much better deal. They also live short, sometimes inglorious lives. Mine are all dead at an average of 250 hours. The cheap ones are a crapshoot, some are excellent and in the same league as the OEM, and others just.... aren't.

I have starting sticking blu-tak on the inside of the clip between the body and the stylus clip. I also amputate the "wings" - overall I think this works a bit better. The blu-tak makes the stylus extremely stable and provides additional damping. Arms with high effective mass still work best, and the ET-2.5 works really well when configured correctly. (The upper notch on the joint and lots of mass on the counter weight towards the spindle, 2.8 - 3.0gms vtf, vta as needed for record)

Vinyl has been a bit of a headache lately, hammering at things again after the last OEM stylus wore out. I learn from adversity.. LOL

The simulations indicated 56K would be fine, will result in very slightly more rise at 10kHz and below.

It is a significant improvement, just a little more air up on top.

I recently had the Windfeld on the ET-2.5 and the one area where the Windfeld definitely betters my 451C is in the extreme treble, this should close the gap a bit more, as does an improved stylus from Dave Slagle. (Have heard one with this pre, but don't have one yet)

The conclusion is that I prefer the strain gauge to the Windfeld in all other areas, but that the stylus quality is really a liability with these cartridges. Imaging, depth, and delineation of detail are vastly better with the strain gauge, the increased resolution is most noticeable in vocals (multi-tracked) and massed strings. It might be the most articulate cartridge I have heard (very limited experience).

All of the above presupposes that you have very good stylus. The OEM replacements have gotten very expensive, so much so that the Jico is a much better deal. They also live short, sometimes inglorious lives. Mine are all dead at an average of 250 hours. The cheap ones are a crapshoot, some are excellent and in the same league as the OEM, and others just.... aren't.

I have starting sticking blu-tak on the inside of the clip between the body and the stylus clip. I also amputate the "wings" - overall I think this works a bit better. The blu-tak makes the stylus extremely stable and provides additional damping. Arms with high effective mass still work best, and the ET-2.5 works really well when configured correctly. (The upper notch on the joint and lots of mass on the counter weight towards the spindle, 2.8 - 3.0gms vtf, vta as needed for record)

Vinyl has been a bit of a headache lately, hammering at things again after the last OEM stylus wore out. I learn from adversity.. LOL

Yes .047 my error.

Here is a pic of a Slagle rebuild ( nice!) from another forum of the stock housing and I can get a fairly good idea of the length he used since it is a overhead shot instead of an angle.

And the stock length for some kind of reference.

With 2.6 grams thereabouts, wear dictates as clean as you can get records.

I do use LAST every side played and subjectively seems to work ok or just wishful bias..

I have a chance right now to get a 2.5 ET2 not far from me but I have 3 Ets and the added surface area of the sliding bearing is an advantage, but where does this hobby end !!

There are starving children in Africa and here we are complaining !

Back to programming...

I am delaying my project as I am waiting for 2 more boron assemblies coming so I can examine all 3 and go from there.

Regards

David

Here is a pic of a Slagle rebuild ( nice!) from another forum of the stock housing and I can get a fairly good idea of the length he used since it is a overhead shot instead of an angle.

And the stock length for some kind of reference.

With 2.6 grams thereabouts, wear dictates as clean as you can get records.

I do use LAST every side played and subjectively seems to work ok or just wishful bias..

I have a chance right now to get a 2.5 ET2 not far from me but I have 3 Ets and the added surface area of the sliding bearing is an advantage, but where does this hobby end !!

There are starving children in Africa and here we are complaining !

Back to programming...

I am delaying my project as I am waiting for 2 more boron assemblies coming so I can examine all 3 and go from there.

Regards

David

Another EQ Refinement

Sorry guys, I've done it again. There is yet another EQ iteration.

I have increased the boost a bit more, reducing R5 to 49.9K which based on the last measurements (REV 03 EQ) helps to fill in the response trough between 1kHz and 10kHz a bit, it does increase the extreme HF response some as well, but I've found the lack of HF air one of the bigger problems with this EQ so IMO it's is better all around.

I don't think I am ever going to be able to completely flatten out the peak, but killing the upper mid range and lower treble response to control it doesn't sound right either.

Sorry guys, I've done it again. There is yet another EQ iteration.

I have increased the boost a bit more, reducing R5 to 49.9K which based on the last measurements (REV 03 EQ) helps to fill in the response trough between 1kHz and 10kHz a bit, it does increase the extreme HF response some as well, but I've found the lack of HF air one of the bigger problems with this EQ so IMO it's is better all around.

I don't think I am ever going to be able to completely flatten out the peak, but killing the upper mid range and lower treble response to control it doesn't sound right either.

Attachments

- Home

- Source & Line

- Analogue Source

- Playing With Panasonic Strain Gauge Cartridges (And A Dedicated Phono Stage)