HI All

I may be one of the two late joiners Kevin spoke about a post or two above.

I don't have a Panasonic strain gauge at the moment but I am hopeful I will find one.

What I do have at the moment is a Win Labs Strain Guage and its power supply.

And while I don't now if Kevin's design here is applicable directly to a Win,

maybe if others here who also have the Win might start a dialogue about the possibility of using Kevin's design with the Win.

Just thought I'd throw that out there.

Cheers

Curt

I may be one of the two late joiners Kevin spoke about a post or two above.

I don't have a Panasonic strain gauge at the moment but I am hopeful I will find one.

What I do have at the moment is a Win Labs Strain Guage and its power supply.

And while I don't now if Kevin's design here is applicable directly to a Win,

maybe if others here who also have the Win might start a dialogue about the possibility of using Kevin's design with the Win.

Just thought I'd throw that out there.

Cheers

Curt

Jim and Curt are indeed the "late joiners" I talked about..

Cartridges are available on eBay and elsewhere, currently the prices seem a bit inflated. There is one good deal for a 460C in Japan.

Look at early 1970s Panasonic and Technics turntables and compacts as potential sources for these cartridges as well. (Often quadraphonic gear.)

Cartridges are available on eBay and elsewhere, currently the prices seem a bit inflated. There is one good deal for a 460C in Japan.

Look at early 1970s Panasonic and Technics turntables and compacts as potential sources for these cartridges as well. (Often quadraphonic gear.)

Hi Kevin,

If I understand it correctly, 460C's VTF is 4 g. Is there any possibility to damage record? Also, if I use a stylus to re tip it with modern cantilever such as boron, do you think it will make any difference? Soundsmith uses ruby cantilever. I personally don't like ruby cantilever at all.

Jim

If I understand it correctly, 460C's VTF is 4 g. Is there any possibility to damage record? Also, if I use a stylus to re tip it with modern cantilever such as boron, do you think it will make any difference? Soundsmith uses ruby cantilever. I personally don't like ruby cantilever at all.

Jim

Hi Jim,

I've had a number of Ortofon SPU in recent years that tracked at 4gms and observed no significant problems. I've had a number of heavy tracking cartridges over the years, and had them as a teen, those records are now anywhere from 40 - 50yrs old and are generally fine.

The same stylus design is used across the entire line from the 450C2 to the 465, compliance is dominated by the transducer elements themselves - none are particularly high compliance, and are best on high mass arms.

In terms of styli, a ruby or boron cantilever definitely can't hurt. I currently only have aluminum but have friends who have both of the above. I've heard one, but not sure which...(It was one of the things that persuaded me to design a pre-amp for these cartridges.)

I've had a number of Ortofon SPU in recent years that tracked at 4gms and observed no significant problems. I've had a number of heavy tracking cartridges over the years, and had them as a teen, those records are now anywhere from 40 - 50yrs old and are generally fine.

The same stylus design is used across the entire line from the 450C2 to the 465, compliance is dominated by the transducer elements themselves - none are particularly high compliance, and are best on high mass arms.

In terms of styli, a ruby or boron cantilever definitely can't hurt. I currently only have aluminum but have friends who have both of the above. I've heard one, but not sure which...(It was one of the things that persuaded me to design a pre-amp for these cartridges.)

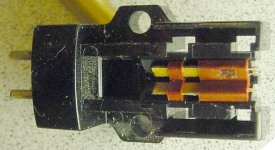

The BBAAADDDD Stylus

This is so bad, it's funny. An aftermarket stylus I bought on eBay. Got a bit less than I bargained for, in addition to lots of corrosion it is clearly missing a critical component.. See if you can figure it out..

I have asked the seller to return it, hopefully he will just refund my money and tell me to toss it. The box is pretty, and unopened.

Might just be better to go to turntableneedles.com for yours or your other favorite reseller.

You just can't make up things like this...

This is so bad, it's funny. An aftermarket stylus I bought on eBay. Got a bit less than I bargained for, in addition to lots of corrosion it is clearly missing a critical component.. See if you can figure it out..

I have asked the seller to return it, hopefully he will just refund my money and tell me to toss it. The box is pretty, and unopened.

Might just be better to go to turntableneedles.com for yours or your other favorite reseller.

You just can't make up things like this...

Attachments

Other than the missing rubber donut that pushes against the SG elements, It belongs to another style of cartridge .

I would like to know where you could get the actual strain gauge strips and build one of these outright. Alot easier than winding coils !!

Regards

David

I would like to know where you could get the actual strain gauge strips and build one of these outright. Alot easier than winding coils !!

Regards

David

Last edited:

SO, that brings up an interesting point and one that I have been thinking about ever since I learned about strain guage cartridges.

I can visualize at this point what a moving coil cart and a moving magnet cart looks like with regards to the arrangement of parts to generate a current.

But I would really like to know how a strain guage is built. I mean, when I look at the Win Labs cart, I see a fairly generic looking rubber tube surrounding the shaft of the cantilever which then interfaces with a nice looking rubber yoke. The yoke seems to be attached to one end of each strain guage, there being two in total, one each for each channel.

Seems like a lot of rubber that is in between the diamond at the end of the cantilever and the device (strain guage) that actually produces the signal output of the cartridge.

I know its in effect a variable resistor across a bias supply and that is where the signal is derived from.

Anyway, just curious about how all this works and the mechanical arrangement of the parts that make up a strain guage cartridge.

Curt

P.S> Pics (of Win Cartridge) to follow shortly.

I can visualize at this point what a moving coil cart and a moving magnet cart looks like with regards to the arrangement of parts to generate a current.

But I would really like to know how a strain guage is built. I mean, when I look at the Win Labs cart, I see a fairly generic looking rubber tube surrounding the shaft of the cantilever which then interfaces with a nice looking rubber yoke. The yoke seems to be attached to one end of each strain guage, there being two in total, one each for each channel.

Seems like a lot of rubber that is in between the diamond at the end of the cantilever and the device (strain guage) that actually produces the signal output of the cartridge.

I know its in effect a variable resistor across a bias supply and that is where the signal is derived from.

Anyway, just curious about how all this works and the mechanical arrangement of the parts that make up a strain guage cartridge.

Curt

P.S> Pics (of Win Cartridge) to follow shortly.

Last edited:

Take a look at earlier posts in the thread as I have posted the mechanical details of the Panasonic SG cartridges. I will repost here.

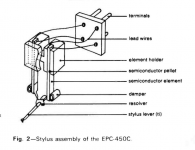

The 450C is representative of earlier versions of the strain gauge.

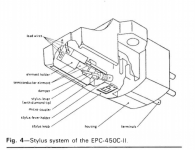

The 450CII is representative of the later 451C, 460C and 465C.

The 450C is representative of earlier versions of the strain gauge.

The 450CII is representative of the later 451C, 460C and 465C.

Attachments

Here is a picture of an original Panasonic stylus next to an aftermarket that has an alignment issue. It is properly centered side to side so it could appear correct to someone who did not have a good reference to go by. How much VTA adjustment does this need?

It is also showing a ring of crusty adhesive around the bonded tip that I was told was the adhesive crystallizing as it was breaking down.

I am not sure what brand this was.

It is also showing a ring of crusty adhesive around the bonded tip that I was told was the adhesive crystallizing as it was breaking down.

I am not sure what brand this was.

Attachments

The Stylus issue is interesting. I don't like the NOS Panasonic ones (sample of 2) I have on hand that much, and the Jico while much better is outperformed by a no name mystery stylus I believe was made by Bliss.

It makes a pretty big difference. The biggest problem with the Jico is that it does not fit tightly enough. (Sample of 1)

The stylus really makes or breaks these cartridges, I don't think many would find that surprising.

It makes a pretty big difference. The biggest problem with the Jico is that it does not fit tightly enough. (Sample of 1)

The stylus really makes or breaks these cartridges, I don't think many would find that surprising.

Interesting the Win attaches the rubber to the ends of the SG elements without the cantilever donut.

And the later Panasonics have the donut/cantilever pressing on the middle portion of each element.

Seems there is more mass (rubber) to be moved with the Win, but all things considered, Sao Win was the expert on so many other levels, I would consider it the best version to use considering his reputation.

Seeing how they are quite different in construction, I would image they vary in frequency-response between the design decisions

That low compliance along with a removable tip means I will be laying a bead of hot glue along the outside ridges to remove any doubt it will sing along

Should be fairly easy to remove afterwards.

Now to find a Win also...,

Regards

David

And the later Panasonics have the donut/cantilever pressing on the middle portion of each element.

Seems there is more mass (rubber) to be moved with the Win, but all things considered, Sao Win was the expert on so many other levels, I would consider it the best version to use considering his reputation.

Seeing how they are quite different in construction, I would image they vary in frequency-response between the design decisions

That low compliance along with a removable tip means I will be laying a bead of hot glue along the outside ridges to remove any doubt it will sing along

Should be fairly easy to remove afterwards.

Now to find a Win also...,

Regards

David

- Home

- Source & Line

- Analogue Source

- Playing With Panasonic Strain Gauge Cartridges (And A Dedicated Phono Stage)