Nice work guys! I like the pickup tests, especially.

The lack of vibrations on certain panels is curious, because even panels across the room will vibrate with some bass. All by simple air transmission.

The magnet mounting is cool, but good results can also be had with a thick baffle and some decoupling. As simple as gasket material between driver and baffle and rubber grommets between bolt head and driver. Perhaps not the ultimate, but works well in a practical sort of way.

The lack of vibrations on certain panels is curious, because even panels across the room will vibrate with some bass. All by simple air transmission.

The magnet mounting is cool, but good results can also be had with a thick baffle and some decoupling. As simple as gasket material between driver and baffle and rubber grommets between bolt head and driver. Perhaps not the ultimate, but works well in a practical sort of way.

Great read but have not had time to read all the post. A friend and I will be building OB LAs this weekend with 8 4" drivers per side. My idea before reading these posts was to use a piece of 1" x 4" aluminum "L" or angle iron (but really aluminum) down the back of the baffle board inline with the mount holes on one side of each driver. That means drilling 16 holes on each piece of angle. One side of each driver would mount through the MDF and the other side would bolt through the MDF then the Angle.

I have the angle and was going to try it just for kicks but now that this thread has started, what do you think of the idea? Cheers.

I have the angle and was going to try it just for kicks but now that this thread has started, what do you think of the idea? Cheers.

Maybe because the baffle is located at the dipole null?The lack of vibrations on certain panels is curious, because even panels across the room will vibrate with some bass. All by simple air transmission.

Anyone build an H-baffle with a sand filled base?

I use an H-baffle with two Lambda TD15_dipoles for bass up to 100Hz, and I am thinking of adding a sand chamber to the bottom to reduce vibrations through weight and sand friction.

The no-baffle dipole midbass and ribbon tweeter are attached to a steel frame that is attached to a board under the H-baffle, but separated by a bicycle intertube to isolate H-baffle vibration.

floor--> wood base for mid+tweet frame --> intertube --> H-baffle

I have not experimented with swing mounting the mid+tweet yet.

I use an H-baffle with two Lambda TD15_dipoles for bass up to 100Hz, and I am thinking of adding a sand chamber to the bottom to reduce vibrations through weight and sand friction.

The no-baffle dipole midbass and ribbon tweeter are attached to a steel frame that is attached to a board under the H-baffle, but separated by a bicycle intertube to isolate H-baffle vibration.

floor--> wood base for mid+tweet frame --> intertube --> H-baffle

I have not experimented with swing mounting the mid+tweet yet.

I have rather large H-baffles, 60x60x112 cm, with two 21" woofers in them. They are build from 25 mm MDF and reinforced by a circumferal frame and a crossbar made from oak. They are floated on bicycle tubes. I have absolutely no vibration problems with them.

Maybe making them stiffer instead of using damping is better? Increasing the stiffness will move resonances upwards in frequency, up above your XO at 100 Hz.

Maybe making them stiffer instead of using damping is better? Increasing the stiffness will move resonances upwards in frequency, up above your XO at 100 Hz.

Hey Line, can I assume from the details of your design, a baffle board is not neccassarey above 100hz?

There is no baffle above 100Hz, just a nude Lambda TD10_Dipole midbass and a 4" x 0.7" DIY dipole ribbon tweeter crossed at 1,400Hz attached to a steel skeleton. I also tried a Tang Band W8-1808 midrange that is more dynamic and musical than the Lambda, but not as durable.

I wanted to get an education in using my PC for digital source, crossover, and equalization, and I have been using this simple 3-way dipole for experiments.

djn,

I used Linkwitz's SPL spreadsheet to estimate the maxium SPL from the two TD15Ds on an H-baffle, and the nude TD10D midbass. The 10" TD10D with 12mm Xmax can produce 109db in the 100Hz-128Hz fEqual frequency range.

Smaller diameter and lower Xmax speakers will require either a higher Xover frequency or a much larger baffle to reproduce 100-110db SPLs often required for transients.

All of my natural sounding speakers are 3-way designs using a wide bandwidth midbass.

I used Linkwitz's SPL spreadsheet to estimate the maxium SPL from the two TD15Ds on an H-baffle, and the nude TD10D midbass. The 10" TD10D with 12mm Xmax can produce 109db in the 100Hz-128Hz fEqual frequency range.

Smaller diameter and lower Xmax speakers will require either a higher Xover frequency or a much larger baffle to reproduce 100-110db SPLs often required for transients.

All of my natural sounding speakers are 3-way designs using a wide bandwidth midbass.

Attachments

Maybe because the baffle is located at the dipole null?

Good point. Could be, could be.

D'oh, I've devoted a fair amount of attention to similar problems in power supplies but never connected the same dots for drivers! I take it your measurements indicate a distortion boost roughly equal to the amount of equalization applied? The data I have supports this but I thought the distortion rise was just SnR limitations in the bass; on a reexamination it does suggest there's more going on than just SnR problems.Regarding bass and no-baffle. Problem is not sufficient SPL, but distortion.

I'll have to do a few more sweeps next time I have the measurement gear out to confirm. The quad W26s and your comments about the 21s hardly moving make more sense now as well.

I'll have to do a few more sweeps next time I have the measurement gear out to confirm. The quad W26s and your comments about the 21s hardly moving make more sense now as well.Member

Joined 2009

Paid Member

8. Same as above, but the baffle is now a sandwich of two sheets of ordinary window glass, with one side plain and the other side textured, naturally, with the plain sides glued together with a smear of Silicone.

Virtually no detectable vibrations.

If you mean the baffle was glass and there was a circular hole in it for the driver to mount to - how on earth did you cut a circular opening in the glass ?

OB vibes

Bigun,

Easy-- I got the local glazier to cut a few holes in larger off-cuts of window glass with a diamond scriber that they usually use, and then made the cuts to make it 'baffle size'.

You are sure to get better results in all probability with granite or marble. But I wanted to test the sandwich. A single sheet of glass is highly elastic and it can vibrate at higher frequencies. But a damping layer in between works wonders. Probably you can even try dissimilar materials like a sheet of acrylic/polycarbonate and a sheet of glass laminated together; this would make it a 'safer' alternative with good anti-vibe qualities.

I have been experimenting with elastic 'suspension' for the entire assembly that looks to hold more promise. More about it later when I have got some presentable observations.

Great vibes to all!

Bigun,

Easy-- I got the local glazier to cut a few holes in larger off-cuts of window glass with a diamond scriber that they usually use, and then made the cuts to make it 'baffle size'.

You are sure to get better results in all probability with granite or marble. But I wanted to test the sandwich. A single sheet of glass is highly elastic and it can vibrate at higher frequencies. But a damping layer in between works wonders. Probably you can even try dissimilar materials like a sheet of acrylic/polycarbonate and a sheet of glass laminated together; this would make it a 'safer' alternative with good anti-vibe qualities.

I have been experimenting with elastic 'suspension' for the entire assembly that looks to hold more promise. More about it later when I have got some presentable observations.

Great vibes to all!

An externally hosted image should be here but it was not working when we last tested it.

Stout wooden frame, polystyrene baffles, magnet mounts.

Here's what I did for my dipole woofers.

I installed the drivers at a 35 degree angle. This structure gives me two advantages:

- the structure in itself is stronger than just one front plate

- the woofers are at a 70 degree angle to each other, so the vibrations that they both create are in different directions and are not summed together.

I first planned to install the drivers at 45 degrees, but the magnet structure would touch the sidewalls.

The idea for this comes from GR research, their V2 is similar but with 45 degree angles.

Regards,

Danny

I installed the drivers at a 35 degree angle. This structure gives me two advantages:

- the structure in itself is stronger than just one front plate

- the woofers are at a 70 degree angle to each other, so the vibrations that they both create are in different directions and are not summed together.

I first planned to install the drivers at 45 degrees, but the magnet structure would touch the sidewalls.

The idea for this comes from GR research, their V2 is similar but with 45 degree angles.

Regards,

Danny

Attachments

OB vibes

Nuuk and Danny,

I am so happy that you have moved to address the one bugbear of OBs! Good implementation there, Nuuk. And Danny, kudos for a novel approach, though you have developed a borrowed idea.

In fact all of us 'builders' knows that baffle vibes are greatest at the lowest octave that we can reach. When we are using a full-range, the ill-effects of baffle vibes become all too readily 'hearable' as the contribution made by the baffle becomes comparable to that of the drivers, and often colours the outputs at mid and high frequencies. This leads to what we often call 'muddiness' and ultimately to aural fatigue when the listening sessions are long and the levels high. Hence the need for banishing baffle vibes at all costs, before everything, and dealing with it before it raises its ugly head.

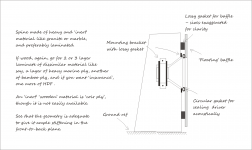

I have a feeling (to Nuuk) that you might reap better results if your spine was in one piece and made out of a more 'inert' material, and with its geometry offering front-to-back stiffening. In my experience this was what offered the best results. The sketch makes it clear, I guess.

Danny, your 35+35 degree idea is great--with your permission, I might also try that ;-) --, but here again I guess if you go in for a spine and then magnet-mount the driver, with the spine 'grounded' to the cabinet top and bottom, and also have the driver rim decoupled from the front baffle plate with rubber gaskets, the results could be an order better.

Experimentation is perhaps the only way we can eliminate unwanted vibes.

Sincere vibes to all.

Nuuk and Danny,

I am so happy that you have moved to address the one bugbear of OBs! Good implementation there, Nuuk. And Danny, kudos for a novel approach, though you have developed a borrowed idea.

In fact all of us 'builders' knows that baffle vibes are greatest at the lowest octave that we can reach. When we are using a full-range, the ill-effects of baffle vibes become all too readily 'hearable' as the contribution made by the baffle becomes comparable to that of the drivers, and often colours the outputs at mid and high frequencies. This leads to what we often call 'muddiness' and ultimately to aural fatigue when the listening sessions are long and the levels high. Hence the need for banishing baffle vibes at all costs, before everything, and dealing with it before it raises its ugly head.

I have a feeling (to Nuuk) that you might reap better results if your spine was in one piece and made out of a more 'inert' material, and with its geometry offering front-to-back stiffening. In my experience this was what offered the best results. The sketch makes it clear, I guess.

Danny, your 35+35 degree idea is great--with your permission, I might also try that ;-) --, but here again I guess if you go in for a spine and then magnet-mount the driver, with the spine 'grounded' to the cabinet top and bottom, and also have the driver rim decoupled from the front baffle plate with rubber gaskets, the results could be an order better.

Experimentation is perhaps the only way we can eliminate unwanted vibes.

Sincere vibes to all.

Attachments

OB vibes

Sorry, gents, I was not following the thread closely as I was travelling a bit.

Panomaniac, your gasket, bolt isolation etc idea works well to cut down baffle vibes. Good practice as I too had found out with my friend's concrete sub--here the woofer was mounted on a small plywood sub-baffle screwed to a frame in the concrete.

Trusound, you are a minimalist 'artist'! Great artistry there!

DJN, by all means try your aluminium angle 'iron' idea. Surely the L shape will give it good stiffening. My suggestion: use a couple of Ls on both sides of the drivers (16 holes each ), then stiffen the top of the L's with a slanted back support. Use a short piece of L as the base, so that the whole assembly looks triangular looked sideways. Pour some concrete to make the base heavy. And last, but not the least, 'float-mount' the baffle in front of the drivers. I hope my sketch from the previous post helps you.

Let us know about the outcome and post some detailed pics too, please.

Best vibes to all!

Sorry, gents, I was not following the thread closely as I was travelling a bit.

Panomaniac, your gasket, bolt isolation etc idea works well to cut down baffle vibes. Good practice as I too had found out with my friend's concrete sub--here the woofer was mounted on a small plywood sub-baffle screwed to a frame in the concrete.

Trusound, you are a minimalist 'artist'! Great artistry there!

DJN, by all means try your aluminium angle 'iron' idea. Surely the L shape will give it good stiffening. My suggestion: use a couple of Ls on both sides of the drivers (16 holes each ), then stiffen the top of the L's with a slanted back support. Use a short piece of L as the base, so that the whole assembly looks triangular looked sideways. Pour some concrete to make the base heavy. And last, but not the least, 'float-mount' the baffle in front of the drivers. I hope my sketch from the previous post helps you.

Let us know about the outcome and post some detailed pics too, please.

Best vibes to all!

have a feeling (to Nuuk) that you might reap better results if your spine was in one piece and made out of a more 'inert' material, and with its geometry offering front-to-back stiffening.

The problem then is that you are coupling the two drivers with vibration from the woofers able to affect the higher frequency drivers. I do understand that the effect will be somewhat lessened by the high damping value if the spine is granite or similar. As ever, it's all a matter of compromise with anything hi-fi!

I should have said in my original post that the woofer magnet mount is bolted to a 50mm thick slab of granite.

Hello Prof,

You certainly have my permission to make something alike

When I made them I also sent some pictures to GR Research, they liked it too

The wood I used is birch multiplex, stronger than the usual MDF and nude it looks great, no need to veneer or paint.

Nice idea of you to add a spine, a spine will also act as bracing.

Regards,

Danny

You certainly have my permission to make something alike

When I made them I also sent some pictures to GR Research, they liked it too

The wood I used is birch multiplex, stronger than the usual MDF and nude it looks great, no need to veneer or paint.

Nice idea of you to add a spine, a spine will also act as bracing.

Regards,

Danny

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Open Baffle Vibrations