I would also highly recommend keeping the mid and tweeter as close as possible

I have noticed that in a lot of designs the tweeter/mid are close together, but I have not worked out why?

David

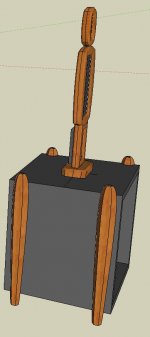

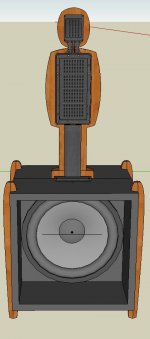

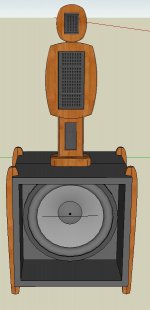

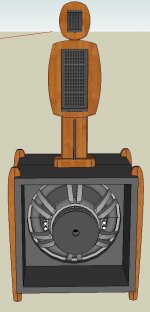

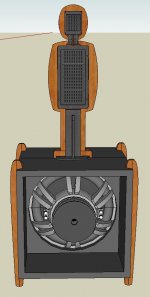

Time To Stop Designing

It's time to start the prototype. The final design has numerous structural challenges that in the end could force a change, there is only one way to find out.

Hopefully I'll get time to start in the week before Christmas.

It's time to start the prototype. The final design has numerous structural challenges that in the end could force a change, there is only one way to find out.

Hopefully I'll get time to start in the week before Christmas.

Attachments

-

10-12-11 The One Final Front With Man.JPG44 KB · Views: 344

10-12-11 The One Final Front With Man.JPG44 KB · Views: 344 -

10-12-11 The One Final Side With Man.JPG59.8 KB · Views: 341

10-12-11 The One Final Side With Man.JPG59.8 KB · Views: 341 -

10-12-11 The One Final Side.JPG40.4 KB · Views: 338

10-12-11 The One Final Side.JPG40.4 KB · Views: 338 -

10-12-11 The One Final Front Section.JPG51.6 KB · Views: 340

10-12-11 The One Final Front Section.JPG51.6 KB · Views: 340 -

10-12-11 The One Final Front.JPG50.4 KB · Views: 330

10-12-11 The One Final Front.JPG50.4 KB · Views: 330 -

10-12-11 The One Final Back.JPG56.8 KB · Views: 60

10-12-11 The One Final Back.JPG56.8 KB · Views: 60 -

10-12-11 The One Final Back Section.JPG58.5 KB · Views: 60

10-12-11 The One Final Back Section.JPG58.5 KB · Views: 60

wow, it almost look like someone standing on top of your sub

Yes, that wasn't the plan but it's growing on me

David

I have noticed that in a lot of designs the tweeter/mid are close together, but I have not worked out why?

David

To minimize lobing of the off axis response. The farther apart the drivers are the more lobing you may have in the off axis response. I think the rule of thumb is to keep driver centers maximum of 1 wavelength but closer is obviously better.

Also, have you considered the potential horn loading effect of the recessed driver in your baffle? I would think you may be better to minimize the depth of your baffle to minimize any potential horn loading effect.

Its looking like a great project. I would love to hear them.... in the alternative I guess your listening impressions will suffice.

To minimize lobing of the off axis response. The farther apart the drivers are the more lobing you may have in the off axis response. I think the rule of thumb is to keep driver centers maximum of 1 wavelength but closer is obviously better.

Also, have you considered the potential horn loading effect of the recessed driver in your baffle? I would think you may be better to minimize the depth of your baffle to minimize any potential horn loading effect.

Its looking like a great project. I would love to hear them.... in the alternative I guess your listening impressions will suffice.

Thank you for the explanation, you say 1 wavelength, I assume that is 1 wavelength at the crossover frequency?

I have no knowledge of what horn loading effect is but will do some research, but as I say for the moment the design is set & I will see (hear) how the prototype goes.

Thanks again

David

wavelength at the crossover frequency?

Yes

I have no knowledge of what horn loading effect is but will do some research

Recommended research method: Cup your hands around your mouth in a horn shape and shout... it can/will be louder than without the "Horn". The longer the horn, the more the gain.

but as I say for the moment the design is set & I will see (hear) how the prototype goes.

Thanks again

David

That is the great part about prototyping; you can easily modify. Quick and dirty tests can provide great value.

- as a preliminary test, before you actually mount the drivers in your baffle, you could simply just try hanging the drivers with stings to minimize/eliminate baffle altogether.

- Flush mount the drivers (I.e use the thing facing the opposite direction as you have illustrated in your diagram)

- At the very least I think you could benefit by using a thinner baffle material and/or sandwich the driver in between 2 identical wood baffles may help to minimize horn loading effect on both sides.

- alternatively, at least use a large radius... I suspect a flat 45degree angle of horn would be worst because sound would reflect directly forward to the listener. Rounded or greater than 60degress angle may be better options.

hope this helps.

Josh

Last edited:

Yes

Recommended research method: Cup your hands around your mouth in a horn shape and shout... it can/will be louder than without the "Horn". The longer the horn, the more the gain.

That is the great part about prototyping; you can easily modify. Quick and dirty tests can provide great value.

- as a preliminary test, before you actually mount the drivers in your baffle, you could simply just try hanging the drivers with stings to minimize/eliminate baffle altogether.

- Flush mount the drivers (I.e use the thing facing the opposite direction as you have illustrated in your diagram)

- At the very least I think you could benefit by using a thinner baffle material and/or sandwich the driver in between 2 identical wood baffles may help to minimize horn loading effect on both sides.

- alternatively, at least use a large radius... I suspect a flat 45degree angle of horn would be worst because sound would reflect directly forward to the listener. Rounded or greater than 60degress angle may be better options.

hope this helps.

Josh

I will give your suggestions a run in the coming days, thanks

The drivers are sandwiched between two identical pieces of wood. Possibly the drawings have been misinterpreted. I have shown them with the driver in place but the back section of the baffle removed. I have drawn it in two sections as that is the way I will build it.

David

The drivers are sandwiched between two identical pieces of wood. Possibly the drawings have been misinterpreted. I have shown them with the driver in place but the back section of the baffle removed. I have drawn it in two sections as that is the way I will build it.

David

I figured that might be the case but I couldn't tell for sure.

I'm curious why you would not just have both drivers in the same "sandwich" instead of stacking two separate sandwiches?

Anyways, I'm sure you will have nice results.... however it could be very difficult to tell the difference between alternate configurations without good measurement tools. Did you manage to get some?

cheers,

Josh

Last edited:

I figured that might be the case but I couldn't tell for sure.

I'm curious why you would not just have both drivers in the same "sandwich" instead of stacking two separate sandwiches?

It's just the way the design evolved really.

Anyways, I'm sure you will have nice results.... however it could be very difficult to tell the difference between alternate configurations without good measurement tools. Did you manage to get some?

cheers,

Josh

I have purchased a Behringer ECM8000 Mic & a M-Audio Pre Mobile. I have been using HolmImpulse, which seems to be working ok. I will give it a go outside as well to see how if I can get better measurements.

David

Great ausie amp modules using VFET!

Holton Precision Audio Online Store - Audio Electronics -

About my vintage VFET amp. Vfet sound recommended.

Repair WEGA V4810 / SONY TA5650 V-FET Solidstate Heaven By Helmuth. - AudioKarma.org Home Audio Stereo Discussion Forums

Repair WEGA V4810 / SONY TA5650 V-FET Solidstate Heaven By Helmuth. - AudioKarma.org Home Audio Stereo Discussion Forums

Service my WEGA T 4710 / sony ST4950 V-fet complete couple - AudioKarma.org Home Audio Stereo Discussion Forums

Holton Precision Audio Online Store - Audio Electronics -

About my vintage VFET amp. Vfet sound recommended.

Repair WEGA V4810 / SONY TA5650 V-FET Solidstate Heaven By Helmuth. - AudioKarma.org Home Audio Stereo Discussion Forums

Repair WEGA V4810 / SONY TA5650 V-FET Solidstate Heaven By Helmuth. - AudioKarma.org Home Audio Stereo Discussion ForumsService my WEGA T 4710 / sony ST4950 V-fet complete couple - AudioKarma.org Home Audio Stereo Discussion Forums

Last edited:

Great ausie amp modules using VFET!

Holton Precision Audio Online Store - Audio Electronics -

About my vintage VFET amp. Vfet sound recommended.

Repair WEGA V4810 / SONY TA5650 V-FET Solidstate Heaven By Helmuth. - AudioKarma.org Home Audio Stereo Discussion Forums

Service my WEGA T 4710 / sony ST4950 V-fet complete couple - AudioKarma.org Home Audio Stereo Discussion Forums

Yes I have looked at those but the price always stops me in the end, maybe in some crazy moment I wont be able to help myself.

Every quality route I follow ends up being more than I want to pay.

You obviously have talents I don't, electronics & I don't go hand in hand

Thanks

David

Last edited:

I see you are using the behringer emc8000. Like I do.

Problem with measuring is to calibrate the measuring level to know the output of the DUT(device under test).

Here a artikel about low cost microphone calibration.

http://www.audioxpress.com/reviews/media/tipton3042.pdf

Gras equipment.

G.R.A.S. Sound & Vibration

http://www.gras.dk/00012/00057/00152/00155/

Problem with measuring is to calibrate the measuring level to know the output of the DUT(device under test).

Here a artikel about low cost microphone calibration.

http://www.audioxpress.com/reviews/media/tipton3042.pdf

Gras equipment.

G.R.A.S. Sound & Vibration

http://www.gras.dk/00012/00057/00152/00155/

Bass Driver Alignment

One thing I have been pondering on is the alignment of the Bass driver in the H frame.

All the things I have read basically indicate that the centre panel is positioned centrally in the length of the H frame, in my case that will leave 187mm each side of the centre panel.

What that will obviously do is position the base of the cone, much closer to the back of the H frame than the front.

I was wondering if perhaps the centre panel should be moved forward to get the base of the cone closer to the centre.

I am not thinking this should be done for driver alignment as I will be able to align the drivers with the DSP. I was just wondering if I would end up with a more balanced sound front & rear.

Any thoughts?

One thing I have been pondering on is the alignment of the Bass driver in the H frame.

All the things I have read basically indicate that the centre panel is positioned centrally in the length of the H frame, in my case that will leave 187mm each side of the centre panel.

What that will obviously do is position the base of the cone, much closer to the back of the H frame than the front.

I was wondering if perhaps the centre panel should be moved forward to get the base of the cone closer to the centre.

I am not thinking this should be done for driver alignment as I will be able to align the drivers with the DSP. I was just wondering if I would end up with a more balanced sound front & rear.

Any thoughts?

I see you are using the behringer emc8000. Like I do.

Problem with measuring is to calibrate the measuring level to know the output of the DUT(device under test).

Here a artikel about low cost microphone calibration.

http://www.audioxpress.com/reviews/media/tipton3042.pdf

Gras equipment.

G.R.A.S. Sound & Vibration

Actuator supply Type 14AA

Hmmm, did you really do all that? I'm not that patient.

I have TrueRTA & I calibrated it using a sound level meter with the mic I'm using. I'm not sure how accurate it really is but it give me some idea.

David

I was wondering if perhaps the centre panel should be moved forward to get the base of the cone closer to the centre.

I am not thinking this should be done for driver alignment as I will be able to align the drivers with the DSP. I was just wondering if I would end up with a more balanced sound front & rear.

You are right in bringing this problem up. But in my experience the solution is easier than the problem

post#7 and #9

Rudolf

I think DQ828 is asking about placement of the woofer in the H-frame instead of the vertical alignment of all the drivers? If yes then....

AC = acoustic center of the driver. MJK refers to where the woofer is located as "the fraction of the length of the front cavity" in his OB worksheets. I recall MJK writing at one point (but don't remember where) that the driver should be moved forward in the H-frame slightly so it's AC is in the middle of the H-frame (but that if the driver is a little too far forward or too far back wouldn't make much difference in the response).

I know that the AC would be somewhere between the dustcap and the surround but have no idea how to work this out. (and its not clear to me how the front AC would be different than the back).

AC = acoustic center of the driver. MJK refers to where the woofer is located as "the fraction of the length of the front cavity" in his OB worksheets. I recall MJK writing at one point (but don't remember where) that the driver should be moved forward in the H-frame slightly so it's AC is in the middle of the H-frame (but that if the driver is a little too far forward or too far back wouldn't make much difference in the response).

I know that the AC would be somewhere between the dustcap and the surround but have no idea how to work this out. (and its not clear to me how the front AC would be different than the back).

Last edited:

I was wondering if perhaps the centre panel should be moved forward to get the base of the cone closer to the centre.

I am not thinking this should be done for driver alignment as I will be able to align the drivers with the DSP. I was just wondering if I would end up with a more balanced sound front & rear.

Hi David,

not sure at what frequency you plan the Xo to the sub but typically the wave is so long at that frequency compared to shifting the woofer a few cm back or forth that it will not matter and you won't hear a difference.

Right now I can only think of one way measuring the right position based on the theoretical model (I just made this up, have never tried it practically): Measure the resonance peak close up to the opening at the front and at the back in a defined spot and constant distance and compare the plots. The peaks should be at the same F and of the same magnitude. This shows whether front and back side of the woofer see the same impedance mismatch at the H frame opening. But again, maybe you only want to bother after all the other issues are solved ;-) So put the sub mounting panel in the middle of the H-frame. That brings the sub slightly forward if not flush mounted and what Rudolf describes should become applicable.

Last edited:

This seems like a re-visit of some of the things I have been through with packaging a driver layout in an aesthetically pleasing tower. I am not sure about obscuring the front of the bass drivers. It seems to me that as long as the crossover point is low enough it shouldn’t be an issue but there are people here that are more qualified than I that can chime in on that issue. One thing I have done in the past that may or may not work for you is to turn the bass drivers sideways so you are looking at them edge-on in front view. This will narrow the baffle greatly, however, if you do this you may need to re think other parts of the design. I am fairly new to OB design and don’t want to talk out of turn. Another option would be to build the bass section separate from the mid high section. That would open up some design possibilities as well. I know what you mean about smaller drivers not getting down to the f3 that you want. I currently am currently working on an OB design that utilizes 8 10” but I still think the lowest f3 will be about 28-30 Hz. Not that 30 Hz is bad. It’s that to get that low with a small driver (10” or less) it seems the efficiency suffers.

MLC

MLC

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- OB Project Design Started, Help Requested.