About glueing, has or maybe you guys should do some tests for yourselves to see how much power is in your various glues by lap/face glue some pieces say 6"x12" with 4" face lap on the ends that gives you something to hold onto as you try to tear it apart by hand & then your chisel & hammer. Or some 3/4" end joints glued up a pair of say 12"x12" at right angles to one an other & after it is set up go at it & then finally glue up a 12" or 16" cube with your favourite glue & go at it with a bigger hammer but let them all set up properly. It could help you understand all these questions about glues & fasteners. There just is no replacement for building it & then busting it up to get yourself comfortable with your mediums.

Practically "weld"? - well wouldn't that require the temporary melting, then solidifying of the 3 components? Today's wood glues are pretty good, but they don't exactly do that.

Yesterday somebody showed me this video, its about the lamello wood joining method, which is interesting, although you need some investment there buying the machine and supplies. I never saw this before.

https://www.youtube.com/watch?feature=player_detailpage&v=IecEPB64TgU

Last edited:

Test an end grain to a face for two pieces of mdf.About glueing, has or maybe you guys should do some tests for yourselves to see how much power is in your various glues by lap/face glue some pieces say 6"x12" with 4" face lap on the ends that gives you something to hold onto as you try to tear it apart by hand & then your chisel & hammer. Or some 3/4" end joints glued up a pair of say 12"x12" at right angles to one an other & after it is set up go at it & then finally glue up a 12" or 16" cube with your favourite glue & go at it with a bigger hammer but let them all set up properly. It could help you understand all these questions about glues & fasteners. There just is no replacement for building it & then busting it up to get yourself comfortable with your mediums.

Without screws and/or battens the end grain glued joint is extremely weak.

It was not literally, I meant that a good glue on that setting can do really big thing holding everything together. I think its safer than screws, because when we screw a screw on mdf, the surrounded fibers are just there opened, not really holding anything and with risk of splitting on a hard movement (remember theres the weak point of mdf). When we do dowel, the glue seals the surrounded fibers, avoiding the chance to split while everything is properly merged together.

Yesterday somebody showed me this video, its about the lamello wood joining method, which is interesting, although you need some investment there buying the machine and supplies. I never saw this before.

https://www.youtube.com/watch?feature=player_detailpage&v=IecEPB64TgU

sorry to get all snotty and pedantic about the welding - but I can't quite let the point about splitting / weakness of MDF go without another comment or two - (is there an echo in here?)

Dowels, Lamello (brand name for biscuit jointer tool), Festool Dominos, splines are all good methods of aiding alignment and adding glue surface area along a joint line, and all require some investment in tooling / jigs greater than a tapered countersink bit. The Festool system is by far the best of these three - but the cheapest of the several models is well over $1000 Cdn.

Care need be taken with using biscuits in any manufactured sheet goods - even plywood, as the outside edge of arced slot routed on the flat surface can blow out - most particularly in MDF and PB. Even if sufficient structural integrity in maintained, at the very least that means more time to repair the damage.

Air powered brad nails / staples are great to tack panels together while setting clamps and screws, but I'd be far more confident on properly piloted coarse thread wood screws - with our without battens- to hold a box subject to any rugged use together better than biscuits.

The interior core of MDF is soft enough that you can scratch it with a fingernail, so keep those screws a couple of inches away from a corner, run your drill at low speed and set torque clutch - if present- appropriately, and you'll get good penetration of the screw thread into the core and splitting shouldn't be a problem. I always have two cordless drivers on hand - one for the pilot holes, and one to drive the screws.

I'm starting to think this thread needs a Troll stinking the air up. 23yrs, or 50 who cares. I think it is time for some of us to stop dropping hints about how long they have been doing whatever (I won't be doing it again), just share of their experiences & how they came about it so we can learn together. Not for everyone to be preached at by fathers who know all from their chairs at the end of the table with their eye glazed over from their drunken state of audio ultra intelligence. Encourage experimentation & share of how YOU have learned by scientific method (one small change at a time to understand how something works) Lol

Last edited:

Odoriferous?

Being of a certain age- if I may?- I'll admit to being as detectably flatulent as the next guy / gal (especially after delivering several progeny, some of those muscles never quite regain their tone ) , but I guess a troll can't isolate his own contribution to atmospheric pollution after all.

) , but I guess a troll can't isolate his own contribution to atmospheric pollution after all.

Give it a rest, Air - hardwiring, and many of the other tweaks / "sacred secrets" you'd like to recount and proselytize , the elders have either tried and abandoned, or begrudgingly set back on the "damn, but I wish I didn't have to compromise on that, but I actually have to live in, and share this space with others shelf I have more of those than actual books in my case.

I have more of those than actual books in my case.

As for my comments on age, forgive me for saying this, but many of your posts would suggest an eager neophyte, not alergic to, or having yet had their wallets substantially thinned by decades of kool-aid and edible snake oils. That, and the rambling grammatically awkard construction.

Definitely in full cranky grampa mode now

Being of a certain age- if I may?- I'll admit to being as detectably flatulent as the next guy / gal (especially after delivering several progeny, some of those muscles never quite regain their tone

Give it a rest, Air - hardwiring, and many of the other tweaks / "sacred secrets" you'd like to recount and proselytize , the elders have either tried and abandoned, or begrudgingly set back on the "damn, but I wish I didn't have to compromise on that, but I actually have to live in, and share this space with others shelf

I have more of those than actual books in my case.

I have more of those than actual books in my case.As for my comments on age, forgive me for saying this, but many of your posts would suggest an eager neophyte, not alergic to, or having yet had their wallets substantially thinned by decades of kool-aid and edible snake oils. That, and the rambling grammatically awkard construction.

Definitely in full cranky grampa mode now

Last edited:

No, the awkward ramblings are about folks like yourself reaching out for verification of their being of importance in this particular world right here & dropping how many years they have been doing this or that as if that which brings some relevance, importance or even skill to what they have to say. Yet what I am seeing is "some" guys who are very limited in their scope trying to tell everyone else that if you don't do it my way or see it my way you are not of any relevance in this world or any other, now that is sad buddy. Are we not here to share & learn not judge & ridicule. If folks like yourself could simply use scientific method in the most simplest of ways & share their learnings/findings. Have fun, share. Don't be superior & judgmental.

guys who are trying to tell everyone else that if you don't do it my way or see it my way you are not of any relevance in this world or any other

Lots of those. Kick back and enjoy the music, as after all that is the goal.

dave

Please cite, did I miss something?Don't be superior & judgmental.

Yes, it's called experience and should be utilized. It is also fair to add the fact that you're not reading it from google, rather you are involved in it daily. Problem?how many years they have been doing this or that as if that which brings some relevance, importance or even skill to what they have to say.

Yes very sad buddy. If you haven't had a great deal of experience, you shouldn't add your 2 cents.Yet what I am seeing is "some" guys who are very limited in their scope trying to tell everyone else that if you don't do it my way or see it my way you are not of any relevance in this world or any other, now that is sad buddy.

Not sure what to make of these sentences. I must be reading a different thread. In any event, Cheers.Are we not here to share & learn not judge & ridicule. If folks like yourself could simply use scientific method in the most simplest of ways & share their learnings/findings. Have fun, share. Don't be superior & judgmental.

No, It was chrisb & others being judgmental at me (I have broad shoulders & can take it....toss some back at them too but it's not me to go down to that level), others private messaged me not to waist my time on the guys because they will never hear what I was saying. Now it has come over to another thread but all I am asking for is, if someone has had such strong reactions to various things they have tried in the past or not experienced any results from them? Then why not share what your methodical steps were in trying something. Yet all I get is putdowns about my age, looks, experience, expressive style, then insults & cursing via %@#! but all I was asking in trying to understand how we got to such a state was, how they went about coming up with their experiences. I guess it was taken as a challenge to their audio-manhood or something. It leaves me wondering if there are not a bunch of poseurs amongst us. I don't know everything & am here to learn as well as share. Seems some want to just pontificate about their importance in life & how they have nothing to learn or could from up on high in the ivory cage they congregate in

Last edited:

I'm starting to think this thread needs a Troll stinking the air up. 23yrs, or 50 who cares. I think it is time for some of us to stop dropping hints about how long they have been doing whatever (I won't be doing it again), just share of their experiences & how they came about it so we can learn together. Not for everyone to be preached at by fathers who know all from their chairs at the end of the table with their eye glazed over from their drunken state of audio ultra intelligence. Encourage experimentation & share of how YOU have learned by scientific method (one small change at a time to understand how something works) Lol

No, the awkward ramblings are about folks like yourself reaching out for verification of their being of importance in this particular world right here & dropping how many years they have been doing this or that as if that which brings some relevance, importance or even skill to what they have to say. Yet what I am seeing is "some" guys who are very limited in their scope trying to tell everyone else that if you don't do it my way or see it my way you are not of any relevance in this world or any other, now that is sad buddy. Are we not here to share & learn not judge & ridicule. If folks like yourself could simply use scientific method in the most simplest of ways & share their learnings/findings. Have fun, share. Don't be superior & judgmental.

Is there any paragraph, or sentence, that is on topic?No, It was chrisb & others being judgmental at me (I have broad shoulders & can take it....toss some back at them too but it's not me to go down to that level), others private messaged me not to waist my time on the guys because they will never hear what I was saying. Now it has come over to another thread but all I am asking for is, if someone has had such strong reactions to various things they have tried in the past or not experienced any results from them? Then why not share what your methodical steps were in trying something. Yet all I get is putdowns about my age, looks, experience, expressive style, then insults & cursing via %@#! but all I was asking in trying to understand how we got to such a state was, how they went about coming up with their experiences. I guess it was taken as a challenge to their audio-manhood or something. It leaves me wondering if there are not a bunch of poseurs amongst us. I don't know everything & am here to learn as well as share. Seems some want to just pontificate about their importance in life & how they have nothing to learn or could from up on high in the ivory cage they congregate in

I can't see any mention of glue, nor screws, nor mdf in all of those posts.

Are you suggesting our Forum needs a trol and benefits from their contributions?see, this exactly the kind of communal group therapy than can do all of us some good, from time to time

well, maybe not all of us

Or maybe you're saying we need to step back and think about what this Technical Forum really needs, when we get distracted by off topic posts?

Ok, now that that bit of inclement weather has blown by, let's see if we can pick up this thread again. My first cab build was a 2x16" closed bass guitar cab. Having read much about the importance of weight and stiffness, I built it like the proverbial Brick $#it-house: 9-ply 3/4" eucalyptus plywood, 2x4" battens all around, 2x4 bracing, a gallon of Elmer's and 2" #14 countersunk screws every 6 inches. Even put glue in the screw-holes with a syringe. It broke chunks off concrete steps and bent the steel pipe handrail when it got away from us after a gig on the third floor of a converted warehouse. Luckily, the drummer heard it coming and, hugging his bass drum, leapt the last six steps.... I cut the cab in half soon thereafter. One half still sits where I parked it decades ago. I later made several smaller cabs out of MDF using smaller battens and fewer screws. Still very heavy. My latest cabs are made of 3/4" spruce board, butt-joined with 1"x3/4" battens simply glued and pinned with an air nailer. Much lighter than plywood or MDF, and plenty strong. I'll build my next one even lighter, using 1/2" spruce. I'll X-brace the back panel if it seems too flexible. In my experience, there's little to be gained by building a massive cabinet. Light and stiff works just as well.

Ok, now that that bit of inclement weather has blown by, let's see if we can pick up this thread again. My first cab build was a 2x16" closed bass guitar cab. Having read much about the importance of weight and stiffness, I built it like the proverbial Brick $#it-house: 9-ply 3/4" eucalyptus plywood, 2x4" battens all around, 2x4 bracing, a gallon of Elmer's and 2" #14 countersunk screws every 6 inches. Even put glue in the screw-holes with a syringe. It broke chunks off concrete steps and bent the steel pipe handrail when it got away from us after a gig on the third floor of a converted warehouse. Luckily, the drummer heard it coming and, hugging his bass drum, leapt the last six steps.... I cut the cab in half soon thereafter. One half still sits where I parked it decades ago. I later made several smaller cabs out of MDF using smaller battens and fewer screws. Still very heavy. My latest cabs are made of 3/4" spruce board, butt-joined with 1"x3/4" battens simply glued and pinned with an air nailer. Much lighter than plywood or MDF, and plenty strong. I'll build my next one even lighter, using 1/2" spruce. I'll X-brace the back panel if it seems too flexible. In my experience, there's little to be gained by building a massive cabinet. Light and stiff works just as well.

I concluded in my experience that even 2x2 battens all around its an excess, I used them before just because I thought their mass would be convenient when screwing and joining all the mdf boards together, otherwise I would not use them, for corner bracing I instead would use 3/4x3/4 by some inches or even all section, this being a plus after joining all the boards with miter joints.

Think about this, if we use 3/4 MDF, and do simple joints, the glue touches 19mm section only, but when we do miter joints, the glue now covers 28mm of section!!! which obviously result in a better and stronger joint, now with this simple method, screws would not be necessary at all. Only minor problem with this is that you need at least 2 angles to hold all together while glue dries, but I think is a lot worth it.

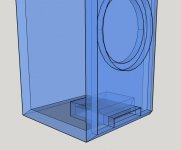

I just designed a one foot enclosure for a 8" subwoofer, and will miter join all the boards, and maybe not necessary but I made some little pieces of 19x19x80mm to brace along the edges.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- No screws on MDF enclosures, but treated area contact ang good glue?