Trobbins, offcourse an opt is a different pair of shoes but what is the harm in mentioning the shielding of the fb winding?

People interrested in shielding transformers windings migth also be interrested in shielding of windings in an opt, no?

Capacitive coupling may or may not be a problem, if it is easely intercepted at low cost and without any other negative effect, why not?

But in a toroid, first it is not so easy, and second it is less effective because of the unavoidable high inductance of a multiturn shield.

People interrested in shielding transformers windings migth also be interrested in shielding of windings in an opt, no?

Capacitive coupling may or may not be a problem, if it is easely intercepted at low cost and without any other negative effect, why not?

But in a toroid, first it is not so easy, and second it is less effective because of the unavoidable high inductance of a multiturn shield.

It just seems to me to introduce a whole new discussion vector that is perhaps better explored in a new thread, rather than a thread that has been started for mains transformers.

The topic of how a shield on a toroid may be significantly different to a shield on a common E-I core, is interesting and well worth fleshing out more. If the mains winding is innermost, then a toroidal construction with outer shield appears to me to do a much better job of electrostatic shielding unless the primary winding for an E-I core is totally wrapped in a shield (I think some specialist application transformers do that, but not for general applications). I can see that the extremities of a shield may introduce some more parastic inductance for a toroid, depending on how any lead wire is attached to the screen.

The topic of how a shield on a toroid may be significantly different to a shield on a common E-I core, is interesting and well worth fleshing out more. If the mains winding is innermost, then a toroidal construction with outer shield appears to me to do a much better job of electrostatic shielding unless the primary winding for an E-I core is totally wrapped in a shield (I think some specialist application transformers do that, but not for general applications). I can see that the extremities of a shield may introduce some more parastic inductance for a toroid, depending on how any lead wire is attached to the screen.

I had a solid state headphone amp and forgot to tie the screen to ground. I listened to it play and was taping it on and off to ground and could not hear any difference. I think the quality of the transformer and proper mounting and orientation play a more important role. If you can it is always a good idea to move the transformer around the project before it is cased to make sure not to pick up indused hum.

Hmmm.... have a look at AC VSD grounding principles. That will tell you the proper way to ground a static shield is to use a fairly thick braided static shield wire tail (at the factory - if the manufacturing crew is serious about their product). Then, the ground connection should be short and of the largest possible contact area. Soldering should not be done if lugs are used - just a firm crimp on bare wire strands. The RF rubbish that causes havoc when AC VSDs are used (whenever they are used, in general, and they are used everywhere - they are terrible), is of the same frequency spectrum the static shield should snub to the ground in amplifiers (and other audio gear). Then repeat the test, and do A/B comparison... but listen to the whole track in between comparisons. See if you can tell the difference.

Everyone hears different, back in the eighties they ran a A/B test were they added a few db of hiss and about 70% of the people thought it sounded better. I even had people buy equipment they thought sounded great then read a negative review and insisted on returning it. Then there is intellectually knowing it is better from an engineering standpoint ( this one bites me) But can’t hear the difference .

Last edited:

It's a copper foil intended to be connected to safety earth. It's located between primary and secondary windings, and it's there for improved safety. Obviously not for blocking magnetic force, as that would stop the transformer from normal operation.

There are two types of screens. One is a safety screen, usually prevalent in medical applications, to ensure it will fail safe and not affect the patient. The other is an electrostatic screen, or Faraday shield, located between strategic windings. The idea is to shunt noises and transients to ground, to reduce winding coupling. Though this sounds somewhat counter intuitive, it is an effective method to reduce the interplay between secondary windings.

Always prefer the sound of toroids with a screen.

Static electricity is an electrical charge without a conductive path to discharge. Hence it can't exist on a coductive wire.There are two types of screens. One is a safety screen, usually prevalent in medical applications, to ensure it will fail safe and not affect the patient. The other is an electrostatic screen, or Faraday shield, located between strategic windings. The idea is to shunt noises and transients to ground, to reduce winding coupling. Though this sounds somewhat counter intuitive, it is an effective method to reduce the interplay between secondary windings.

Last edited:

A non magnetic space in a device that functions because of coupling electromagnetic forces by means of magnetism. Forgive me but it sounds like BS.A shield introduces a non magnetic space between primary and secondary windings, which results in a reduced coupling. Can't understand why it sounds better.

In an audio setting, the electrostatic screen is an old-school response to old-school radio designs. It wasn't even necessary for some of those. If you have a decent powersupply, it shouldn't matter unless you are replicating an architecture from the early days of radio.

Of course, there are audiophiles who believe they can hear almost anything, from spraying speaker cable with lacquer upwards. So ask for opinion and you'll get the entire spectrum.

A safety screen is different. Where the equipment is in an unearthed case, or where the low voltage side isn't earthed (potentially quite beneficial for ma

ins hum or ground loops) a stronger means of isolating mains voltage from reaching the secondary windings can be beneficial or required. In some countries this is part of the "double insulated" criteria.

Of course, there are audiophiles who believe they can hear almost anything, from spraying speaker cable with lacquer upwards. So ask for opinion and you'll get the entire spectrum.

A safety screen is different. Where the equipment is in an unearthed case, or where the low voltage side isn't earthed (potentially quite beneficial for ma

ins hum or ground loops) a stronger means of isolating mains voltage from reaching the secondary windings can be beneficial or required. In some countries this is part of the "double insulated" criteria.

Last edited:

Static screen, besides providing additional safety, reduces capacitive coupling between primary and secondary. As that capacitance is low, only high frequency noise (MHz range) can be affected by screen.

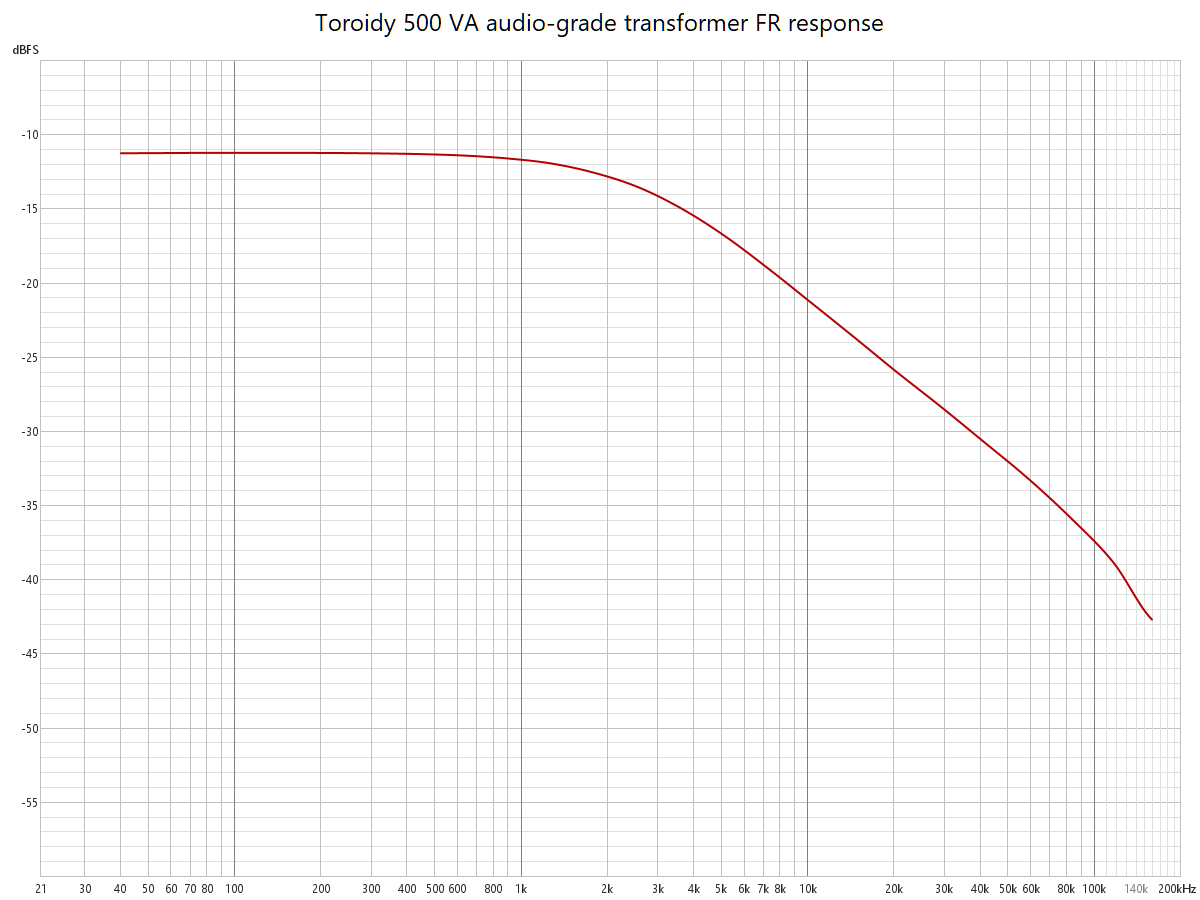

Here is measurement taken on the audio grade 230 V / 500 VA toroidal PS transformer. Primary was driven from high bandwidth amplifier and secondary was loaded with some 80 mΩ resistor. Actual transferred power was only 2 W, but enough for a meaningful measurement.

Connecting static screen to PE ground, didn’t change result even for a fraction of dB. Looks like static screen would have no effect on possible SMPS noise.

I was before also examining power supply noise spectrum up to 380 kHz (LNA + ADC + REW) and there was no difference at all, in that frequency range, disabling RF mains filter (Schurter) or disconnecting static screen on transformer.

However, I’m certain that differences in the MHz range would be considerable.

Here is measurement taken on the audio grade 230 V / 500 VA toroidal PS transformer. Primary was driven from high bandwidth amplifier and secondary was loaded with some 80 mΩ resistor. Actual transferred power was only 2 W, but enough for a meaningful measurement.

Connecting static screen to PE ground, didn’t change result even for a fraction of dB. Looks like static screen would have no effect on possible SMPS noise.

I was before also examining power supply noise spectrum up to 380 kHz (LNA + ADC + REW) and there was no difference at all, in that frequency range, disabling RF mains filter (Schurter) or disconnecting static screen on transformer.

However, I’m certain that differences in the MHz range would be considerable.

The screen is there to reduce the capacitance between the primary and the secondary. I’ve measured it and on my exemplar it went from 1.2nF to less than 100 pF. The screen is there to reduce common mode capacitive coupling, but it can also help with HF series mode noise. If used in conjunction with an x-cap, series mode coupling is reduced, but if used with say 10 nF y-caps to ground, common mode HF noise will be reduced by >20 dB and can be as good as 30 or 40 dB. The screen must always be attached to the incoming earth (safety ground). I’ve never heard of using the screen as a safety mechanism. Usually the manufacturer will use Kapton tape between the windings- one or two layers of that will offer very good insulation.

For medical grade systems, things may be a bit different, but I suspect the screen is different than an electrostatic screen. That said, ECG and brain wave monitors typically have to deal with very small signals in the presence of large common mode noise, so any way to reduce this with screening of course offers benefits.

I’m travelling for the next 9 days, but when I get back I’ll put some sims up to show how the electrostatic screen reduces HF noise - I only touch on it in the Ground Loops’ presentation.

For medical grade systems, things may be a bit different, but I suspect the screen is different than an electrostatic screen. That said, ECG and brain wave monitors typically have to deal with very small signals in the presence of large common mode noise, so any way to reduce this with screening of course offers benefits.

I’m travelling for the next 9 days, but when I get back I’ll put some sims up to show how the electrostatic screen reduces HF noise - I only touch on it in the Ground Loops’ presentation.

Last edited:

Looking back at some jobs from long ago. There was a well known US manufacturer of car test equipment, and PS transformers had a screen for workplace safety. There was a manufacturer of electroencephalography equipment and PS transformers had a screen for patient safety, it was also required by regulations. There was a manufacturer of high frequency antenna amplifiers and we did not use screening on the transformer. The amps were fed by a phantom system over the coax. Now and then an antenna mast was was hit by lightning and the amp toasted.

Last edited:

For a screen to be effective, it needs to dump the crap it intercepts somewhere; lots of people think that PE is ideally suited to that purpose, but PE is generally as dirty or dirtier than its companion mains: they follow the same route, are heavily inductively and capacitively coupled, and in addition PE is used to conveniently dump the crap collected by omnipresent Y caps.

What a screen can do is to convert all the differential perturbations into common-mode ones; is it useful? It was when AM radio sets ruled, but nowadays, CM problems have become the hardest to solve.

The best option, if you really want to use screens is to have a primary and secondary screen: the primary screen is connected to the PE or to two X or Y connected to the mains, and the secondary screen is connected to the secondary GND.

If the PE is connected to GND (like in class I devices), dual screens make no sense.

For an effectiveness measurement to make sense, it needs to measure the conversion from primary CM to the secondary DM, and the secondary DM is not the secondary winding (which can be shunted by a 100n ceramic anyway), but the signal of the secondary-fed circuitry; much less obvious, and much trickier

What a screen can do is to convert all the differential perturbations into common-mode ones; is it useful? It was when AM radio sets ruled, but nowadays, CM problems have become the hardest to solve.

The best option, if you really want to use screens is to have a primary and secondary screen: the primary screen is connected to the PE or to two X or Y connected to the mains, and the secondary screen is connected to the secondary GND.

If the PE is connected to GND (like in class I devices), dual screens make no sense.

For an effectiveness measurement to make sense, it needs to measure the conversion from primary CM to the secondary DM, and the secondary DM is not the secondary winding (which can be shunted by a 100n ceramic anyway), but the signal of the secondary-fed circuitry; much less obvious, and much trickier

I did a comparison with a meter between the Antek AN and AS transformers

One has the shield and another does not

There is a difference

I suspect that the primary and secondary windings are most likely wound in opposite orders (one over the other) between models, so that could also affect the readings

S

Antek AN and AS compared

One has the shield and another does not

There is a difference

I suspect that the primary and secondary windings are most likely wound in opposite orders (one over the other) between models, so that could also affect the readings

S

Antek AN and AS compared

- Home

- Amplifiers

- Power Supplies

- No electrostatic screen on toroid