How do you fix chip to heatsink?

Okay, now that I know I'll need to look for the non-isolated version, can you tell me what you consider the best inexpensive way to insulate heatsink from chip? I am told mica washers are better conductors (because of their thinness?) than Sil-pads. Also, I feel that Sil-pads will inherently be a worse approach because they are soft and compressible, and the chip comes with a hole for just one screw, right at the top. That way, the bottom of the chip will tend to rise off the heatsink, because the Sil-pad will act as a spring-cushion. I've seen this happen, visually, though I don't know how much this reduces heat conduction.

Also, I presume I'll need a non-conducting shoulder washer to isolate the bolt from the chip? I have drill, drill bits, and taps to tap a threaded hole in the heatsink for a bolt of appropriate size. If I need to fit a shoulder washer, I am using a bolt of thread size 9BA. If I can do away with the washer, I can use a bolt of tap size 3mm. Any comments/recommendations on these?

I ask because I've seen 2SA1943/2SC5200 transistors, and their back plate (metallic) has a fairly wide (2mm radius?) annular gap near the bolt-hole, thus making it very unlikely that the bolt will touch the conducting metal surface. In those cases, I guess I can just use a Sil-pad or mica sheet, but do away with the shoulder washer.

What do you guys recommend?

Thanks once again for all the help. I know I'm asking for micro-guidance, but it's the details which screw up my DIY.

Tarun

PS: I don't know whether the author of the Gainclone FAQ in Decibel Dungeon is reading this. I wish we could ask him to add one little piece on T versus TF chips, and another about the ways of fixing the chip to heatsink.

Thanks, everyone. Got it. I hadn't realised that in order to isolate the back plate, NS was actually putting a layer which was a poor heat conductor. This seems silly, but I guess they have their reasons.Peter Daniel said:Just to let you understand this better, the non insulated version has copper tab exposed, while the insulated is covered with plastic, which is not the best heat transfer material.

Okay, now that I know I'll need to look for the non-isolated version, can you tell me what you consider the best inexpensive way to insulate heatsink from chip? I am told mica washers are better conductors (because of their thinness?) than Sil-pads. Also, I feel that Sil-pads will inherently be a worse approach because they are soft and compressible, and the chip comes with a hole for just one screw, right at the top. That way, the bottom of the chip will tend to rise off the heatsink, because the Sil-pad will act as a spring-cushion. I've seen this happen, visually, though I don't know how much this reduces heat conduction.

Also, I presume I'll need a non-conducting shoulder washer to isolate the bolt from the chip? I have drill, drill bits, and taps to tap a threaded hole in the heatsink for a bolt of appropriate size. If I need to fit a shoulder washer, I am using a bolt of thread size 9BA. If I can do away with the washer, I can use a bolt of tap size 3mm. Any comments/recommendations on these?

I ask because I've seen 2SA1943/2SC5200 transistors, and their back plate (metallic) has a fairly wide (2mm radius?) annular gap near the bolt-hole, thus making it very unlikely that the bolt will touch the conducting metal surface. In those cases, I guess I can just use a Sil-pad or mica sheet, but do away with the shoulder washer.

What do you guys recommend?

Thanks once again for all the help. I know I'm asking for micro-guidance, but it's the details which screw up my DIY.

Tarun

PS: I don't know whether the author of the Gainclone FAQ in Decibel Dungeon is reading this. I wish we could ask him to add one little piece on T versus TF chips, and another about the ways of fixing the chip to heatsink.

I like the idea of lapping.I am building a new design amp with a tda1524a active pre (batt powered) which i call a " buffer" LOL.I have designed in a hold down bar so i can adjust the loading pressure and without even thermal grease the conductance will be greater, sadly the case(hammond) wont allow me to have my vortex cooling tubes as the height is too short.

ron

ron

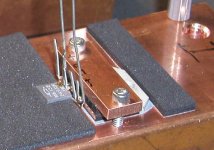

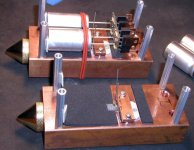

Here's how I attached the chip in my latest amp. I didn't really notice any ill effect on sound from squeezing (although didn't compare), but I also think that comparing to my previous mounting method, this one is definitely more efficient in heat transfer. Although the chassis frame is quite big, it gets pretty warm and I think it's warmer than the previous amps. This could only mean better heat disipation.

Sil-pad was used here.

Sil-pad was used here.

Attachments

Peter Daniel said:This could only mean better heat disipation.

On mine, It meant oscillation

Bricolo said:

On mine, It meant oscillation

On mine, it gets warm only when music is playing

Clamping method

Yes, clamping method will result in better heat transfer, don't forget the clamping bar on top actually behaves as an additional heat sink because the additional surface area of the clamping bar will further aid in heat transfer via convection also the screws coupling the clamping bar and the chunky heat sink below will allow a certain amount of heat transfer via conduction as well. So actually the clamping method is great from a heat transfer point of view. I think a certain amount of tuning is possible as well, anyone still remembers the Michael Green

Peter Daniel said:Here's how I attached the chip in my latest amp. I didn't really notice any ill effect on sound from squeezing (although didn't compare), but I also think that comparing to my previous mounting method, this one is definitely more efficient in heat transfer. Although the chassis frame is quite big, it gets pretty warm and I think it's warmer than the previous amps. This could only mean better heat disipation.

Sil-pad was used here.

Yes, clamping method will result in better heat transfer, don't forget the clamping bar on top actually behaves as an additional heat sink because the additional surface area of the clamping bar will further aid in heat transfer via convection also the screws coupling the clamping bar and the chunky heat sink below will allow a certain amount of heat transfer via conduction as well. So actually the clamping method is great from a heat transfer point of view. I think a certain amount of tuning is possible as well, anyone still remembers the Michael Green

Clamping is clearly better than using a single screw. Why? It guarantees better contact since the pressure is more uniform. Using a single screw will distort the soft copper tab and cause the outer parts to rise a bit.

Peter, you amp looks like works of art. However, I'm not sure the copper as you use it is ( monetarily?) effective. Why? The thermal resistance of the copper will be extremely low, but the thermal resistance to the air is high. You'd be much better off fing a U channel or getting someone to mill some grooves into it to increase the surfce area. Or if worse came to worse, clamp it on a drill press and drill some large diameter holes straught thru to induce some convection. My suspicion is that after the first half inch of copper the benefits of copper are 95% there. So if you just use flatter bars you might get the same effect. Maybe the next amps you build can try that.

Peter, you amp looks like works of art. However, I'm not sure the copper as you use it is ( monetarily?) effective. Why? The thermal resistance of the copper will be extremely low, but the thermal resistance to the air is high. You'd be much better off fing a U channel or getting someone to mill some grooves into it to increase the surfce area. Or if worse came to worse, clamp it on a drill press and drill some large diameter holes straught thru to induce some convection. My suspicion is that after the first half inch of copper the benefits of copper are 95% there. So if you just use flatter bars you might get the same effect. Maybe the next amps you build can try that.

Mikett said:

Peter, you amp looks like works of art. However, I'm not sure the copper as you use it is ( monetarily?) effective. Why? The thermal resistance of the copper will be extremely low, but the thermal resistance to the air is high. You'd be much better off fing a U channel or getting someone to mill some grooves into it to increase the surfce area.

Of course drilling holes through copper piece would be a further improvement in heat dissipation, but monetarily, it would increse the cost of the amp. Also, the holes in top panel would create different look, I don't know if desirable. And U channels are not easy to find in copper stock.

I used the chunk of copper for two reasons only. To increase the mass of chip assembly and by attaching spike directly, it creates simple way to release any possible resonannces. I also wanted to try if using different material than aluminum effects the sound, that's why copper. It just seemed convenient to use that type of bar and monetary reasons were not really considered in this project.

Now, to go even further (in materials searching), in the next amp I will be using bronze bar, in place of copper, and aluminum panels will be replaced by copper panels (3" x 1/4"). How's that for extravagance?

Lovely picture, thanks. And I too would have used a bar on top of the chip with two bolts on two sides. Learned this technique from Randy Slone; his power amps all use this approach for clamping power transistors to heatsinks. He uses an aluminium bar, and he also mounts his 75-deg Celcius thermal switch on it. (Of course, separate thermal protection is not needed on a chip amp; that was just an aside.)Peter Daniel said:Here's how I attached the chip in my latest amp.

Would mica be better? Have you tried other material? In fact, is this question about material choice critical at all? I wonder how often Gainclone users actually trigger thermal protection in their amps at their "normal" listening levels?Sil-pad was used here.

Tarun

Thanks

I guess that shoulder washer is needed with the bolt, right? For electrical isolation of bolt and chip? Any comments on the bolt sizes I'm using for chip fixing?

Tarun

Thanks, Peter. I think that's all I needed. I'll certainly use the bar on top. You've confirmed my earlier suspicions that just one bolt on top is no way fix hot components on heatsinks, and Randy too knew this all along, I guess.Originally posted by Peter Daniel I wanted to do it clean, without thermal grease. The bar on top improves further heat transfer. This amp is definitely running warmer than my other ones.

I guess that shoulder washer is needed with the bolt, right? For electrical isolation of bolt and chip? Any comments on the bolt sizes I'm using for chip fixing?

Tarun

on the topic of the original post, the chip is also specified with a single supply operation in which case the tab would be at ground potential. in such cases, the smaller height, slightly lower cost, and improved thermal transfer are useful.

"Now, to go even further (in materials searching), in the next amp I will be using bronze bar, in place of copper, and aluminum panels will be replaced by copper panels (3" x 1/4"). How's that for extravagance?"

-seems it could still be coated in silver and plated in gold...

"Now, to go even further (in materials searching), in the next amp I will be using bronze bar, in place of copper, and aluminum panels will be replaced by copper panels (3" x 1/4"). How's that for extravagance?"

-seems it could still be coated in silver and plated in gold...

Thanks, both. Nice pages, BTW, PerAnders.peranders said:For normal use I think the isolated version is quite sufficient. I'm planning a Gainclone with the "TF" package.

I guess the isolated version is perfectly adequate, specially if we go for bi-amping/tri-amping, and use the isolated chips for the mids/tweeters.

Tarun

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Newbie question: why use non-isolated LM3875?