Sub platter/platter

By this stage I couldn't hold myself back, everything had to finished, so I quickly recleaned the sub platter and platter and wacked them on........................

And I know the Tone arm is no where near ready to go on, I couldn't wait any longer, so off came the perpex protection sheet.

By this stage I couldn't hold myself back, everything had to finished, so I quickly recleaned the sub platter and platter and wacked them on........................

And I know the Tone arm is no where near ready to go on, I couldn't wait any longer, so off came the perpex protection sheet.

Attachments

Spinning

The platter spins nicely and is very quiet.............

I will have to mess around the tone arm for a while. I ordered a protractor to set it up but it seems as though this web site is a bit of a rip -off................turntablebasics............ordered it two months ago and it never turned up. So I will just have to see if someone has got something I can use instead of paying out more money

The platter spins nicely and is very quiet.............

I will have to mess around the tone arm for a while. I ordered a protractor to set it up but it seems as though this web site is a bit of a rip -off................turntablebasics............ordered it two months ago and it never turned up. So I will just have to see if someone has got something I can use instead of paying out more money

Attachments

Hi,

make your own protractor.

A piece of card with a few lines at right angles.

Add a cat's whisker across the front of your cartridge. Straight and black is ideal.

It makes it very easy to SEE if the front of the cartridge is truly at right angles to the tangents of the two radii that you select for zero tracking error.

Yes, use the two radii method.

make your own protractor.

A piece of card with a few lines at right angles.

Add a cat's whisker across the front of your cartridge. Straight and black is ideal.

It makes it very easy to SEE if the front of the cartridge is truly at right angles to the tangents of the two radii that you select for zero tracking error.

Yes, use the two radii method.

Re: Spinning

http://www.diyaudio.com/forums/showthread.php?postid=1147402#post1147402

enzedone said:The platter spins nicely and is very quiet.............

I will have to mess around the tone arm for a while. I ordered a protractor to set it up but it seems as though this web site is a bit of a rip -off................turntablebasics............ordered it two months ago and it never turned up. So I will just have to see if someone has got something I can use instead of paying out more money

http://www.diyaudio.com/forums/showthread.php?postid=1147402#post1147402

cheers

Andrew thanks for that, but I'm new to all this TT stuff. And I think that yours, allthough probably more accurate, is just beyond me at this stage. i have tried printing the one off The vinyl engine so many times, but just can't get it to print to the right ratio..........

Zen Mod, I will try to print the one from 'enjoy the music' and see if it comes out better than my others.........

Watch this space,.........

Andrew thanks for that, but I'm new to all this TT stuff. And I think that yours, allthough probably more accurate, is just beyond me at this stage. i have tried printing the one off The vinyl engine so many times, but just can't get it to print to the right ratio..........

Zen Mod, I will try to print the one from 'enjoy the music' and see if it comes out better than my others.........

Watch this space,.........

forget that enjoy the music protractor.

It's far too complicated.

draw a radius from the hole (drill it last).

mark on the two test radii.

mark crosses through the test radii.

draw a series of lines parallel to the first radius.

now drill that hole (is it 5/16ths?)

place the stylus tip on the cross.

is the cat's whisker parallel to the parallel lines?

repeat for the second cross.

adjust until perfect.

go to the vinyl engine and scroll down to Heybrook.

it looks similar to that but without all the short lines. Just draw the LONG lines parallel to the first radius through the hole.

It's far too complicated.

draw a radius from the hole (drill it last).

mark on the two test radii.

mark crosses through the test radii.

draw a series of lines parallel to the first radius.

now drill that hole (is it 5/16ths?)

place the stylus tip on the cross.

is the cat's whisker parallel to the parallel lines?

repeat for the second cross.

adjust until perfect.

go to the vinyl engine and scroll down to Heybrook.

it looks similar to that but without all the short lines. Just draw the LONG lines parallel to the first radius through the hole.

cheers

I have a bit of time before i start this tone arm deal, so it will give me time to think all this over. I probably wont get to it this weekend, as it's easter weekend and we are out looking for strollers for the new boy...........hopefully I'll get one on special.

I still have to do some playing around with what was the arm lift, as this is now just a support for the tone arm. But I need to check that all the heigths will be ok. And also do some more filing to fit the original tone arm base into the new plinth. I'm still not happy with the tone arm holder that I made up, so may play around with that also........................Hey! does anyone have an arm lift out there, that they are not using, or know where I can get one really cheap(thats cheap in NZD)?.

looking back, if I had the money, ........................ah if.

I would like to have fitted a really nice motor. But this was really about trying to build a reasonable TT with what I basically had.

I feel another project coming on.......................

I have a bit of time before i start this tone arm deal, so it will give me time to think all this over. I probably wont get to it this weekend, as it's easter weekend and we are out looking for strollers for the new boy...........hopefully I'll get one on special.

I still have to do some playing around with what was the arm lift, as this is now just a support for the tone arm. But I need to check that all the heigths will be ok. And also do some more filing to fit the original tone arm base into the new plinth. I'm still not happy with the tone arm holder that I made up, so may play around with that also........................Hey! does anyone have an arm lift out there, that they are not using, or know where I can get one really cheap(thats cheap in NZD)?.

looking back, if I had the money, ........................ah if.

I would like to have fitted a really nice motor. But this was really about trying to build a reasonable TT with what I basically had.

I feel another project coming on.......................

AndrewT said:forget that enjoy the music protractor.

It's far too complicated.

you lost me there............

simple geometry can't be complicated.

key is in understanding ; then you can use any protractor,even draw one by your self....

Re: explain please

http://www.vinylengine.com/manuals_tonearm_protractors.shtml

http://www.vinylengine.com/articles.shtml

for start

enzedone said:I would really love someone to explain it all to me, (who is a real newbee)................................

Like in real simple terms...........

http://www.vinylengine.com/manuals_tonearm_protractors.shtml

http://www.vinylengine.com/articles.shtml

for start

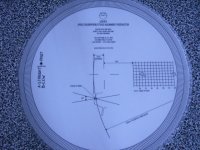

Thanks to Alan, a fellow member from Auckland. He lent me his Lynn Alignment protractor. I haven't been able to start on this part yet as I was sick for 2 weeks.

Question. I will be using a cartridge off my Dual. It's an Audio Technica 110E. But the mounts are at the top as apposed to the really old and totally munted Sure.

Can you get new screws for the Head shell, as I'm going to have to cut these down so I can screw them into the head shell, at the moment they are far too long.

Question. I will be using a cartridge off my Dual. It's an Audio Technica 110E. But the mounts are at the top as apposed to the really old and totally munted Sure.

Can you get new screws for the Head shell, as I'm going to have to cut these down so I can screw them into the head shell, at the moment they are far too long.

Attachments

Hi,

screws used to be available in a range of lengths. Maybe more difficult to source now that vinyl is less popular.

The really hard steel used in a 12.9 cap screw will not be easy to cut/file/saw. And when you have managed to saw it using the incorrect technique your saw will be useless for the second screw.

Then you have to file and/or grind the damaged end to allow the nut to fit well. A thread file will not look at 12.9, if you can find one with a fine enough matching pitch.

I don't know if they are metric or imperial, but 2.5mm does fit.

The problem then is finding a wholesaler willing to sell two of each length.

screws used to be available in a range of lengths. Maybe more difficult to source now that vinyl is less popular.

The really hard steel used in a 12.9 cap screw will not be easy to cut/file/saw. And when you have managed to saw it using the incorrect technique your saw will be useless for the second screw.

Then you have to file and/or grind the damaged end to allow the nut to fit well. A thread file will not look at 12.9, if you can find one with a fine enough matching pitch.

I don't know if they are metric or imperial, but 2.5mm does fit.

The problem then is finding a wholesaler willing to sell two of each length.

enzedone said:

.........

Can you get new screws for the Head shell, as I'm going to have to cut these down so I can screw them into the head shell, at the moment they are far too long.

if screw' aren't too heavy in original length,just place nuts on top of HS and screws from bottom ...ie-upside down.

in fact-that's correct way of mounting

Length

Alan, good question. I'm not really sure as they will only need to go through the cartridge and then they screw into the headshell. The headshell is only very thin, so I would say only about 4-6,7,8mm. Just guessing here, as I haven't measured it.

If I end up getting a good cartridge, do they supply screws? Or do you have buy your own?

Alan, good question. I'm not really sure as they will only need to go through the cartridge and then they screw into the headshell. The headshell is only very thin, so I would say only about 4-6,7,8mm. Just guessing here, as I haven't measured it.

If I end up getting a good cartridge, do they supply screws? Or do you have buy your own?

Hi,

some cartridges have tapped blind holes in the top for mounting purposes.

One must be very careful to ensure that the securing bolts/screws do not bottom in the holes when tightening. The risk of damaging the plastic casing is quite high if bolts/screws are too long.

Some cartridge manufacturers supply suitable/unsuitables fixings. Most arm manufacturers supply a range of fixing lengths.

some cartridges have tapped blind holes in the top for mounting purposes.

One must be very careful to ensure that the securing bolts/screws do not bottom in the holes when tightening. The risk of damaging the plastic casing is quite high if bolts/screws are too long.

Some cartridge manufacturers supply suitable/unsuitables fixings. Most arm manufacturers supply a range of fixing lengths.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- New plinth for TD160