Hi for a project i need mylar that does shrink, i have tensilised mylar wich does not shrink it rather gets more sloppy when heat treated. thats good for most projects, but because i have an unusual form now i cant stretch it on a table so i have to put it on by hand then heat shrink it.

any one have a source of mylar that shrinks more then 2 percent ? and is around 6 um

any one have a source of mylar that shrinks more then 2 percent ? and is around 6 um

Hi for a project i need mylar that does shrink, i have tensilised mylar wich does not shrink it rather gets more sloppy when heat treated. thats good for most projects, but because i have an unusual form now i cant stretch it on a table so i have to put it on by hand then heat shrink it.

any one have a source of mylar that shrinks more then 2 percent ? and is around 6 um

Acoustat used DuPont HS65, which you may have trouble finding in small quantities. Acoustat bought 500-pound rolls, and even in that high-volume environment, a roll lasted a VERY long time.

You might check some of the sources listed on www.audiocircuit.com. I recall that there are several sources listed that sell small DIY quantities of various films.

aha so this is shrinkable ? i've seen somehwere on the net that moray james had some laying around , will try to send him a message.

because my project is round i cant use a stretch table

or if someone has a genius idea to aply mylar on a cylindrical stator? (or rahter 8 small flat stators i one go)pls let me know.

because my project is round i cant use a stretch table

or if someone has a genius idea to aply mylar on a cylindrical stator? (or rahter 8 small flat stators i one go)pls let me know.

Attachments

Last edited:

aha so this is shrinkable ? i've seen somehwere on the net that moray james had some laying around , will try to send him a message.

because my project is round i cant use a stretch table

or if someone has a genius idea to aply mylar on a cylindrical stator? (or rahter 8 small flat stators i one go)pls let me know.

Yes, the HS65 is heat-shrinkable (hence the 'HS' in the part number). After gluing the mylar to the frame, Acoustat used an industrial heatgun to shrink the mylar to the proper tension. The conductive coating was applied after shrinking.

Model Airplanes coverings are the type of Mylar that shrinks.

It is what I used to make my very first ESL!!

I still have the stuff.

There are different gauges and the stuff I used was the thinnest I could find at about .5 mil to .75 mil after it was shrunk by being heated.

You can also wash off the extra heat glue backing with acetone and that helps a little bit

jer

It is what I used to make my very first ESL!!

I still have the stuff.

There are different gauges and the stuff I used was the thinnest I could find at about .5 mil to .75 mil after it was shrunk by being heated.

You can also wash off the extra heat glue backing with acetone and that helps a little bit

jer

Regular Mylar C will shrink, they claim 50% when dipped in boiling water.(!!)

Unless I'm missing some information.

Check out the pictures in post #41 in this thread (mine)... the first pic is all wrinkled and dimpled, the second is the same application of Mylar, just heated with a standard variable heat gun...

This is 6um stuff

http://www.diyaudio.com/forums/planars-exotics/243508-building-large-curved-esl-2.html

Hope this helps.

Unless I'm missing some information.

Check out the pictures in post #41 in this thread (mine)... the first pic is all wrinkled and dimpled, the second is the same application of Mylar, just heated with a standard variable heat gun...

This is 6um stuff

http://www.diyaudio.com/forums/planars-exotics/243508-building-large-curved-esl-2.html

Hope this helps.

Last edited:

Calvin does it shrink ?

Datasheet says only 2 percent

http://www.audiocircuit.com/A-PDF/A...it-THV/Hostaphan_RE________-B-EN1-841-THV.pdf

Datasheet says only 2 percent

http://www.audiocircuit.com/A-PDF/A...it-THV/Hostaphan_RE________-B-EN1-841-THV.pdf

Last edited:

well i finished one of these round stators as menbrame i took some present wrapping  verry thick but it whas the only stuff that shrunk. and i wanted to see if i could do it if i had the correct foil. and apprantly yes. it is now playing in the living room. crossed at 1 Khz , for the next one i want to make the cilinder a tiny bit bigger so i can squeeze some more menbrame in there, so the angle will decrease. it weird to have highs al around the room wherever i sit. i put some rockwool in the cylinder and some felt on the front. i thought it would not be a good idea to close the top and bottom of the cylinder, but after measurements it has the best results in distortion and in low frequency responce. next time i will ad a tiny dot of silicone to increase stability of the menbrame so i can increase the bias to gain some more sensitivity. for now i hope thinner foil will give me some increase in sens.

verry thick but it whas the only stuff that shrunk. and i wanted to see if i could do it if i had the correct foil. and apprantly yes. it is now playing in the living room. crossed at 1 Khz , for the next one i want to make the cilinder a tiny bit bigger so i can squeeze some more menbrame in there, so the angle will decrease. it weird to have highs al around the room wherever i sit. i put some rockwool in the cylinder and some felt on the front. i thought it would not be a good idea to close the top and bottom of the cylinder, but after measurements it has the best results in distortion and in low frequency responce. next time i will ad a tiny dot of silicone to increase stability of the menbrame so i can increase the bias to gain some more sensitivity. for now i hope thinner foil will give me some increase in sens.

it has some suck out or cancelation around the 10Khz if i decrease angles this will be less. as for hearing its almost not noticable at listening position. i wonder how it sounds with 2 of these.

the thing is tiny thats what i like, 12 cm in diameter and 13 cm tall. small enough to sit on small loudspeaker cabinet

but im still looking for thin shrinkable mylar

it has some suck out or cancelation around the 10Khz if i decrease angles this will be less. as for hearing its almost not noticable at listening position. i wonder how it sounds with 2 of these.

the thing is tiny thats what i like, 12 cm in diameter and 13 cm tall. small enough to sit on small loudspeaker cabinet

but im still looking for thin shrinkable mylar

Last edited:

Hi,

Yes, of course it does.

See the DS. It´s shrinkage rate is 2.5% MD and 2% TD.

I used it for all of my older wire stator ESLs.

For the curved metal stators I use different, slightly thicker stuff, that allows me to heat treat the curved things also.

jauu

Calvin

Yes, of course it does.

See the DS. It´s shrinkage rate is 2.5% MD and 2% TD.

I used it for all of my older wire stator ESLs.

For the curved metal stators I use different, slightly thicker stuff, that allows me to heat treat the curved things also.

jauu

Calvin

Last edited:

Your Cylindrical version sound pretty cool!!

I have always wanted to try something like that but I never followed through with it yet.

jer

well the funny thing is i tried it once 8 years ago, and that was a failure

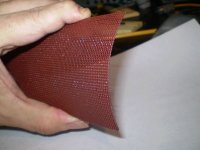

the picture is after aplying the shrink foil that i had at hand. nicly shrinked and all. next step was adding the second spacers. i wanted to use the foam tape again but this ofcourse failed. because the wire is under tension while winding it compressed the foam underneith it, so i ahd to cut small spacers from PVC and glue them on top of exsisting foam spacers that support the mylar. i then again winded the second stator on top of that. the windong is the nice part

could also be a nice design lamp when the support structure is made nicer

Attachments

Last edited:

Very Cool!!

I was thinking of ways to make one using my wire mesh stator's as they are very flexible.

I have been thinking about a a curved stator desktop version.

Kind of like a Mini-Micro ML.

I think that a small curved panel won't have as bad of the time delay issues that the much larger curved panels have.

You see I haven't given up on the curved panels completely, as I really believe in the Electrically segmented design.

But the cost of the resistors for my small panels is way more than what it cost for me to build them.

Beside the resistors needed are too bulky for the size of the panel to begin with.

I had really good results with the narrower 3" wide panel as they were.

But I think a small curve in them may very well help them as well.

"Keep on DYIin"

jer

I was thinking of ways to make one using my wire mesh stator's as they are very flexible.

I have been thinking about a a curved stator desktop version.

Kind of like a Mini-Micro ML.

I think that a small curved panel won't have as bad of the time delay issues that the much larger curved panels have.

You see I haven't given up on the curved panels completely, as I really believe in the Electrically segmented design.

But the cost of the resistors for my small panels is way more than what it cost for me to build them.

Beside the resistors needed are too bulky for the size of the panel to begin with.

I had really good results with the narrower 3" wide panel as they were.

But I think a small curve in them may very well help them as well.

"Keep on DYIin"

jer

Attachments

Very Cool!!

I was thinking of ways to make one using my wire mesh stator's as they are very flexible.

I have been thinking about a a curved stator desktop version.

Kind of like a Mini-Micro ML.

I think that a small curved panel won't have as bad of the time delay issues that the much larger curved panels have.

You see I haven't given up on the curved panels completely, as I really believe in the Electrically segmented design.

But the cost of the resistors for my small panels is way more than what it cost for me to build them.

Beside the resistors needed are too bulky for the size of the panel to begin with.

I had really good results with the narrower 3" wide panel as they were.

But I think a small curve in them may very well help them as well.

"Keep on DYIin"

jer

that mesh is it coated ? or do you coat it urself. also where do you get it ? it looks nice.

Yes, it is just common aluminium window screen here is my write up of the coating,

http://www.diyaudio.com/forums/plan...tric-coatings-fact-fiction-2.html#post2893839

It is the very same sample that I show as tested in post 85.

jer

http://www.diyaudio.com/forums/plan...tric-coatings-fact-fiction-2.html#post2893839

It is the very same sample that I show as tested in post 85.

jer

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Mylar that will shrink !?