It isn't complete yet. I am stuck trying to figure out how to make an arm pod that is in proportion to the plinth and the needed 8" tall. I don't yet have an answer. I think it is going to be a 4" steel tube filled with sand and a fiberglass shell around it to get the needed bulk needed to make not look like a needle holding the arm up. The glass piece can also be filled with lead/sand to make the center of gravity of the whole thing more reasonable.

Attachments

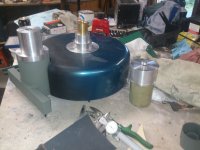

The first spin... using the motor stolen from my Musichall MMF. Speed was a bit off due to a slightly larger diameter platter. Motor pod getting a fill of lead shot and then some heavy weight oil to fill in the gaps.

I still need to get an updated pic of the finished motor pod with the Mark Kelly speed controller.

This is by far the best sounding table I've encountered. Dave is a very happy boy.

I still need to get an updated pic of the finished motor pod with the Mark Kelly speed controller.

This is by far the best sounding table I've encountered. Dave is a very happy boy.

Attachments

Hi,where did you get the delrin for the platter and do you remember the cost.? You were wise to add the magnets I think. The thrust pad should send you a thank you card. Very lucky finding those weights for free. I shudder to think of their cost if you went out to buy them.

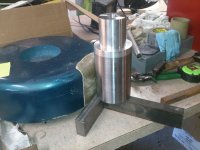

I started assembling pieces and parts when the Teres bearing group buy happened. The piece of Delrin was bought from McMaster Carr by my former employer. The guy who ordered it was fired for the design that required a $350 piece of plastic to make parts for a $500 end product. Doh!!. So, it sat on the shelf for 2 years. When I got another job and left the company, I traded them for a hydraulic press I had been lending the company.

I still have a pile of the brass weights too. 100 and 200 gram. They would indeed be pricey to buy. They came as calibration weights to scales we used in another product. They were going in the scrap bin, but one of the 3 boxes ended up in my car instead of the scrap. Not in a stolen way, but in a "hey, do you mind if I take some of those for a project I am working on?" sort of way.

So, the old & dry rotted belt I was using snapped the other night. I've replaced it with waxed dental floss. That seems to work well.

I still have a pile of the brass weights too. 100 and 200 gram. They would indeed be pricey to buy. They came as calibration weights to scales we used in another product. They were going in the scrap bin, but one of the 3 boxes ended up in my car instead of the scrap. Not in a stolen way, but in a "hey, do you mind if I take some of those for a project I am working on?" sort of way.

So, the old & dry rotted belt I was using snapped the other night. I've replaced it with waxed dental floss. That seems to work well.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- My Teres bearing project