Very early on in my electronics heyday, I was replacing some capacitors in an old RTR I had and I replaced the electrolytic motor capacitors with other electrolytic, of same value. After I was done rebuilding it I ran it and a few seconds later I heard a big pop. That is when I learned that you can’t just put regular old electrolytic capacitors in place of ones rated for motor use. is the case the same for polypropylene? I see that many people now use poly propylene for the capacitors, do they need to be rated for that or pretty much any poly propylene work in that position?

I have a 2.5 µF at 250 V AC and a 6.8 µF at 125 V AC. I know that capacitor is ready for 400 V DC are also rated for 250 V AC, so could I just swap something like this in? Or is it absolutely necessary I get one rated for motor use.

Thank you,

Dan

I have a 2.5 µF at 250 V AC and a 6.8 µF at 125 V AC. I know that capacitor is ready for 400 V DC are also rated for 250 V AC, so could I just swap something like this in? Or is it absolutely necessary I get one rated for motor use.

Thank you,

Dan

I bet you used polarized caps there.Very early on in my electronics heyday, I was replacing some capacitors in an old RTR I had and I replaced the electrolytic motor capacitors with other electrolytic, of same value. After I was done rebuilding it I ran it and a few seconds later I heard a big pop.

Absolutely unsuitable.

That.That is when I learned that you can’t just put regular old electrolytic capacitors in place of ones rated for motor use

Film caps are non polarized so much better.. is the case the same for polypropylene? I see that many people now use poly propylene for the capacitors, do they need to be rated for that or pretty much any poly propylene work in that position?

But in any case they STILL need to be AC/motor run rated.

No they are not.I have a 2.5 µF at 250 V AC and a 6.8 µF at 125 V AC. I know that capacitor is ready for 400 V DC are also rated for 250 V AC,

125 and 250V AC rated caps must stand 1000V and 1500 V peaks respectively.

Your 400VDC cap is not even close.

Get the proper motor run capsso could I just swap something like this in? Or is it absolutely necessary I get one rated for motor use.

No they are not.

125 and 250V AC rated caps must stand 1000V and 1500 V peaks respectively.

Your 400VDC cap is not even close.

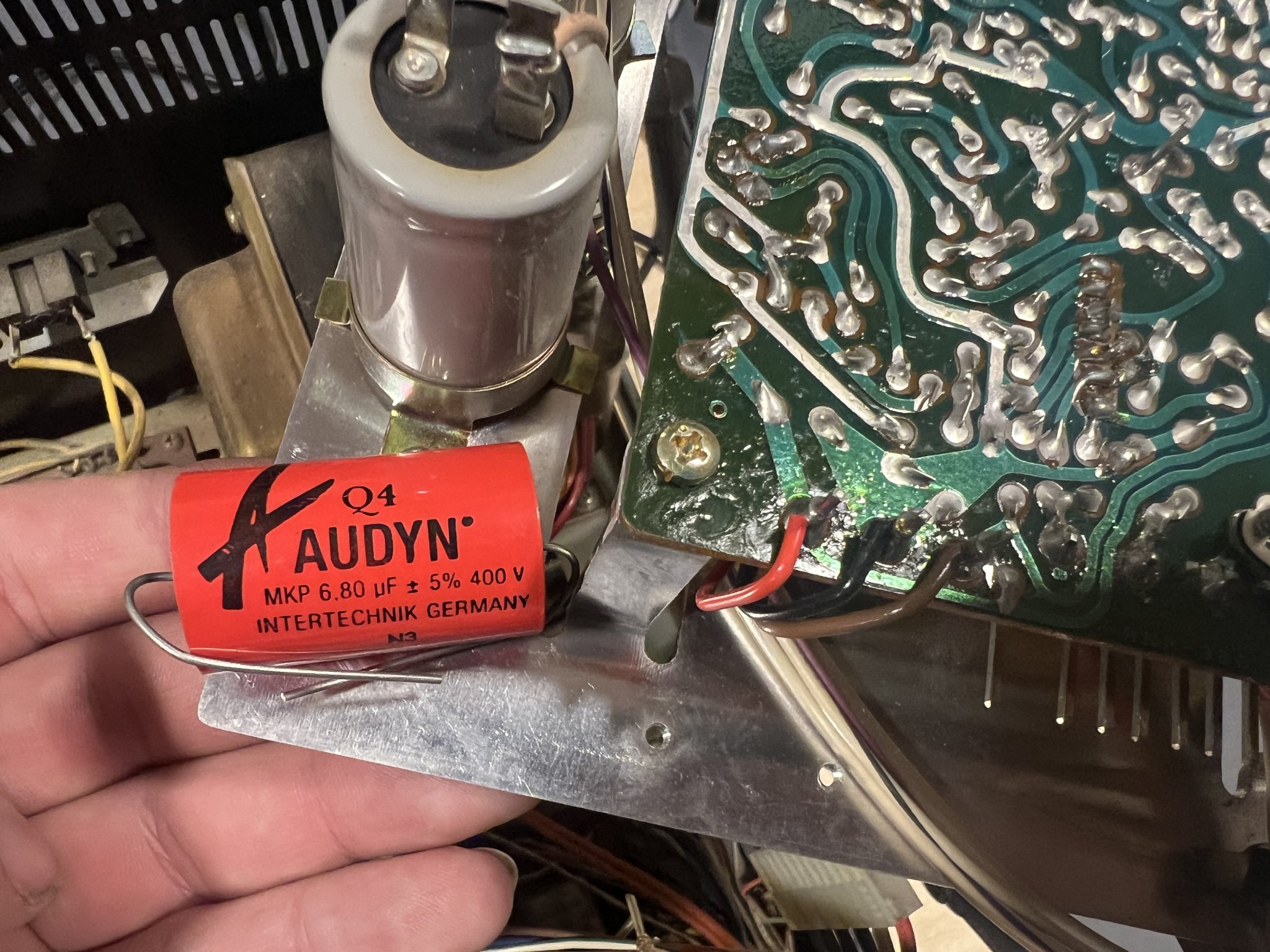

That was in reference to this, this is one of many films I have

where it clearly states it is rated at 400 Vdc and 250 Vac. Spec sheet says the same. What would make these capable of only 400 dc vs needing the 1500 dc? Are they just massively underrating the dc limit? The 400 rating on this cap and the polypropylene I took a pic of earlier would both be assumed to handle the same 400v.

Oh and yes, those electrolytics I used were polar, this was very early on in my tinkering days.

Dan

This particular cap carries both ratings, Wima factory decision, and applies to this ..model only, unless also specified in others.where it clearly states it is rated at 400 Vdc and 250 Vac. Spec sheet says the same. What would make these capable of only 400 dc vs needing the 1500 dc?

And is guaranteed 'user' voltage, actual test conditions may be much higher (and they are), only that datasheet does not include them.

But you can not infer that "all" 400VDC caps are 250VAC rated, by any means, which is my point.

Can't find now the datasheet I checked earlier but this one from a very similar, also high quality product says:

(One detail, this is the 300VAC rated cap, feel free to derate that test voltage by 250/300 or a 0.83 factor.)

Notice scary 2200VDC dielectric test voltage, way more than 1000-1500VDC I had seen in other datasheets, specifically discussing "RU/UR" rating.

Point being: nominal 125-250VAC mains lines can actually get 1000-1500V peaks (what I mentioned) often

In electrical storms lightning hits transmission lines regularly.

Companies add voltage limiters, maybe spark gaps, maybe huge varistors, gas discharge tubes, etc.. but even so peaks I mentioned appear at home lines

.So a "VAC" specified cap expects them and is properly rated and tested (meaning a lot of "headroom").

A regular 400VFC cap?

No way.

Maybe tested at 50% higher voltage, that's prudent design, but not way above that.

So I repeat myself: besides that excellent WIMA which states both (kudos to them) I would NOT blindly trust a regular 400V cap to stand 250VAC duty.

That's my point.

I think people often don't realise how high big the switching transients and lightning pulses are on the mains - for instance old fluorescent light fittings regularly put out kV pulses on switching to the local mains, due to the massive ballast inductor - especially if some of the starters in a building are on their way out. Old fridges too could put out big pulses from their induction motors when the snubber capacitor aged and failed. Also mains equipment should be as robust as possible from nearby lightning, so rating mains components at

several kV pulse or so makes sense, given the wiring can survive that.

several kV pulse or so makes sense, given the wiring can survive that.

Okay, very good thank you for explaining that, makes more sense. So out of curiosity, if that Wima was a 2.5 uF would it be considered a good option for the motors? Regardless I’m going to have to place an order with Mouser so I’ll pick the specific caps up. I’m curious what the cap above seeing 2200v for 2 seconds or a cap rated to do so at 1500v, what kind of voltage could they see continuously. The film I pictured earlier could see 400v all day long, I wonder how high you could actually go with a 250 vac rated cap, safely.This particular cap carries both ratings, Wima factory decision, and applies to this ..model only, unless also specified in others.

And is guaranteed 'user' voltage, actual test conditions may be much higher (and they are), only that datasheet does not include them.

But you can not infer that "all" 400VDC caps are 250VAC rated, by any means, which is my point.

Can't find now the datasheet I checked earlier but this one from a very similar, also high quality product says:

(One detail, this is the 300VAC rated cap, feel free to derate that test voltage by 250/300 or a 0.83 factor.)

View attachment 1309282

Notice scary 2200VDC dielectric test voltage, way more than 1000-1500VDC I had seen in other datasheets, specifically discussing "RU/UR" rating.

Point being: nominal 125-250VAC mains lines can actually get 1000-1500V peaks (what I mentioned) often

In electrical storms lightning hits transmission lines regularly.

Companies add voltage limiters, maybe spark gaps, maybe huge varistors, gas discharge tubes, etc.. but even so peaks I mentioned appear at home lines

.So a "VAC" specified cap expects them and is properly rated and tested (meaning a lot of "headroom").

A regular 400VFC cap?

No way.

Maybe tested at 50% higher voltage, that's prudent design, but not way above that.

So I repeat myself: besides that excellent WIMA which states both (kudos to them) I would NOT blindly trust a regular 400V cap to stand 250VAC duty.

That's my point.

Dan

No, those kV tests are very short ... but significant; 2 seconds are enough to destroy a lot of things.

Again, my point was that you can not assume a regular 400VDC cap is fit for 250VAC duty. Nothing more nothing less.

Worse is that it will work fine, maybe for a long time, until one day it shorts or explodes.

Magic? Gremlins? ... rather think that at that moment a bad combination happened.

FWIW: every day I see my LED lamps blink.

I would expect them to jump downwards, "brownout", some new load on the line (fridge, electric stove, water heater, etc.), you can only go down, no? but no, they flash brighter

Fractions of a second, eh?

Literally a blink/flash.

So I think that happens when an inductive load has dis-connected and created an inductive peak.

Also: Led lamps are, in principle, "regulated", so for a bright peak to be seen, it means the Mains electrical peak was important

Again, my point was that you can not assume a regular 400VDC cap is fit for 250VAC duty. Nothing more nothing less.

Worse is that it will work fine, maybe for a long time, until one day it shorts or explodes.

Magic? Gremlins? ... rather think that at that moment a bad combination happened.

FWIW: every day I see my LED lamps blink.

I would expect them to jump downwards, "brownout", some new load on the line (fridge, electric stove, water heater, etc.), you can only go down, no? but no, they flash brighter

Fractions of a second, eh?

Literally a blink/flash.

So I think that happens when an inductive load has dis-connected and created an inductive peak.

Also: Led lamps are, in principle, "regulated", so for a bright peak to be seen, it means the Mains electrical peak was important

- Home

- Design & Build

- Parts

- Motor run capacitors