Thesis is that movement of a stylus is not immediately conveyed to the generator at the other end of a cantilever. Rather, propagated as a transverse or 'flex' wave along the cantilever at a finite and relatively slow velocity.

Propagation velocity is far slower than the speed of sound in the material which is a compression wave: at issue is transverse or bending propagation. It can be both calculated from beam physics, and observed directly because at cantilever self-resonance both wavelength and frequency are known. These two results, differently derived, typically match well.

That a cantilever can be considered rigid at all is a lumped approximation, and works well enough at frequencies below the mechanical resonance because the propagation delay is short compared to the period. In the same way audio cables might be considered as lumped capacitance and inductance, so can cantilevers be considered as lumped mass and spring for most practical purposes.

However, in terms of understanding what might physically be going on with the mechanical resonance, it does matter whether the true explanation is lumped or distributed, and whether the spring lies in the cantilever or vinyl. Because the wrong explanation of that fundamental principle leads to fundamentally wrong conclusions about what's important about cantilevers and styli, IMO.

LD

Propagation velocity is far slower than the speed of sound in the material which is a compression wave: at issue is transverse or bending propagation. It can be both calculated from beam physics, and observed directly because at cantilever self-resonance both wavelength and frequency are known. These two results, differently derived, typically match well.

That a cantilever can be considered rigid at all is a lumped approximation, and works well enough at frequencies below the mechanical resonance because the propagation delay is short compared to the period. In the same way audio cables might be considered as lumped capacitance and inductance, so can cantilevers be considered as lumped mass and spring for most practical purposes.

However, in terms of understanding what might physically be going on with the mechanical resonance, it does matter whether the true explanation is lumped or distributed, and whether the spring lies in the cantilever or vinyl. Because the wrong explanation of that fundamental principle leads to fundamentally wrong conclusions about what's important about cantilevers and styli, IMO.

LD

Last edited:

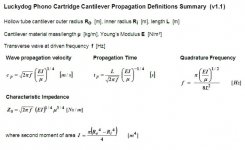

Hoorah, found the equations I derived some years ago for a cantilever as a transmission line, thought might as well put them up here......

The frequency term crops up because transverse vibrations are dispersive, ie waves propagate at different velocities depending on sq rt frequency. Mechanics is stranger than electronics by far

Quadrature frequency is the frequency at which phase shift between ends of a cantilever is 90 deg.

Interesting ? I can't vouch for correctness, BTW.

LD

The frequency term crops up because transverse vibrations are dispersive, ie waves propagate at different velocities depending on sq rt frequency. Mechanics is stranger than electronics by far

Quadrature frequency is the frequency at which phase shift between ends of a cantilever is 90 deg.

Interesting ? I can't vouch for correctness, BTW.

LD

Attachments

Hoorah, found the equations I derived some years ago for a cantilever as a transmission line, thought might as well put them up here......

Real men use the internet as backup. (Linus Torvalds)

Real men use the internet as backup. (Linus Torvalds)

LD

Mechanics is stranger than electronics by far

SAW/BAW filters have always done my head in

Mechanics is stranger than electronics by far

Except that all electronic components are at some level mechanical.

Yes, Rayleigh waves in solids are weird. Left to their own devices, they are dispersive (ie different frequencies propagate at different velocities), but by careful design SAW filters can have constant prop velocity versus f. Can also make long TLs or delay lines from them, of course.SAW/BAW filters have always done my head in

Fortunately, I think what happens in cantilevers is classic beam flex, rather than Rayleigh waves. Though they are cousins. But even in classic beam theory, the surface layers and boundary plays a big part in determining TL properties overall, esp as to damping.

LD

In trying to digest all of this I have gone and fallen down a rabbit hole. As (in my case) I will be using miniDSP for most of the corrections I need to take into account how good (and at what frequency its LPF is set when sampling at 96kHz and whilst gleefully chasing a super flat ultrasonic response do have to work out.what I might be sending down the line.

As soon as I emerge will continue digesting all the useful information

As soon as I emerge will continue digesting all the useful information

For me, the practically useful outcome of understanding the mechanical resonance is to make better informed decisions about what is good/bad/ugly in cantilevers and styli.In trying to digest all of this I have gone and fallen down a rabbit hole. As (in my case) I will be using miniDSP for most of the corrections I need to take into account how good (and at what frequency its LPF is set when sampling at 96kHz and whilst gleefully chasing a super flat ultrasonic response do have to work out.what I might be sending down the line.

As soon as I emerge will continue digesting all the useful information

It seems a bad idea to have a mechanical resonance in the audioband, where there is stimulus from programme material, not least because of degraded trackability. Yet, many carts do.......

For all the wrong reasons, spec tip-mass can be a good indicator of mech resonance frequency IMO. Because spec tip-mass is typically 'determined' by observing resonant frequency directly, and assuming a vinyl spring constant. As a rule, low spec tip-mass styli tend to get paired with good generators, and so there's less, if any, dependency on mech resonance to prop up hf audioband f response.

As to what to look for in cantilevers to obtain resonance above the audioband, short and fat is far more significant than mass or material modulus, says the TL equations.

As to how much signal headroom to allow at ultrasonic frequencies, programme material above -20dB ref 0dB=5cm/s won't be trackable, and there's nowhere near that much in normal programme material anyway. So applying reverse RIAA suggests that other parts of the audioband will determine headroom, especially clicks/pop. The Q of mech resonance is not very high IME and allowing 6dB for it should be fine I think, which changes nothing.

Good luck in the rabbit hole, Bill. If I'm wrong and vinyl spring, rather than cantilever flex, is the mechanism for mech resonance, properties of the resonance will vary from record to record, of course !

LD

Last edited:

Thanks LD,

Just as a matter of interest, where is the line on tip mass? looking at https://linearaudio.net/downloads you can see a table for some popular carts. The OM-30/40 is 0.3mg so I am assuming anything below that is certainly good.

The microline on my AT-150 is 0.22mg so also good. But oddly if you look at some of the sapphire cantilevers the blob of glue is huge and possibly doubles tip mass,

Oh btw for some needle pron, have a look at https://www.vinylengine.com/turntable_forum/viewtopic.php?f=19&t=92996

I should note, raw headroom wasn't my worry, it was more moving from a 4th order roll off to second without considering the ADC front end. Without measuring the output bandwith of a scratch in the record I have nothing to work on, other than Scott saying its really not a problem in reality.

Just as a matter of interest, where is the line on tip mass? looking at https://linearaudio.net/downloads you can see a table for some popular carts. The OM-30/40 is 0.3mg so I am assuming anything below that is certainly good.

The microline on my AT-150 is 0.22mg so also good. But oddly if you look at some of the sapphire cantilevers the blob of glue is huge and possibly doubles tip mass,

Oh btw for some needle pron, have a look at https://www.vinylengine.com/turntable_forum/viewtopic.php?f=19&t=92996

I should note, raw headroom wasn't my worry, it was more moving from a 4th order roll off to second without considering the ADC front end. Without measuring the output bandwith of a scratch in the record I have nothing to work on, other than Scott saying its really not a problem in reality.

Without measuring the output bandwith of a scratch in the record I have nothing to work on, other than Scott saying its really not a problem in reality.

So far overload recovery has not really been a problem especially with one of the better field recorders. My Tascam DR60D on a 10400 mAh USB battery allows plenty of headroom still keeping the LP noise well above the floor while clipping cleanly on the few big pops that it sees. Nasty pops still make it through the RIAA and clip most of the time anyway, but in this case the energy is spread out by the equalization.

I hope to get the whole signal chain on battery/silentswitchers soon.

Last edited:

Emerged from rabbit hole. Assuming I use Cordell/van Raalte damping starting a 5kHz will be around 20dB down by 50kHz for clicksnpops from electrical roll off plus whatever mechanical rolloff I have, so not an aliasing problem.

Have been looking a bit more into frequency data for cartridges based on tip mass to get a feel for things based on last couple of LD posts. Now AT is an interesting outfit as they sell MM and MC with same cantilever and diamond specs, sometimes with the MC costing less than the MM! In this case comparing AT150MLx and AT-OC9 as both have gold plated boron cantilevers with microline stylii.

Now annoyingly not all specs are there, so cannot compare compliance but the main differences are in VTF range (MM 0.75-1.75g, MC 1.25-1.75g) and FR (MM 10-30kHz, MC 15-50kHz). Now I had assumed before I checked the MC that 30kHz would have been the mechanical resonance, but if the same basic mechanicals can go (pointlessly) higher perhaps the HF limit is entirely electrical and I'm worrying unecessarily.

For bragging rights, Ortofon have a couple of high end MCs that, as well as a list price more than I paid for my last 2 cars quote 10-80kHz.

Scott: You are making me wish I had got a silentswitcher now! Hopefully Jan will be able to do more production runs.

Have been looking a bit more into frequency data for cartridges based on tip mass to get a feel for things based on last couple of LD posts. Now AT is an interesting outfit as they sell MM and MC with same cantilever and diamond specs, sometimes with the MC costing less than the MM! In this case comparing AT150MLx and AT-OC9 as both have gold plated boron cantilevers with microline stylii.

Now annoyingly not all specs are there, so cannot compare compliance but the main differences are in VTF range (MM 0.75-1.75g, MC 1.25-1.75g) and FR (MM 10-30kHz, MC 15-50kHz). Now I had assumed before I checked the MC that 30kHz would have been the mechanical resonance, but if the same basic mechanicals can go (pointlessly) higher perhaps the HF limit is entirely electrical and I'm worrying unecessarily.

For bragging rights, Ortofon have a couple of high end MCs that, as well as a list price more than I paid for my last 2 cars quote 10-80kHz.

Scott: You are making me wish I had got a silentswitcher now! Hopefully Jan will be able to do more production runs.

I can't find the 'standard' assumed value for vinyl compliance at the moment. Doh! A close correlation, following a classical spring-mass equation relating resonant frequency to mass and spring constant, was first spotted by David Laloum of Zevaudio posting as dlaloum a few years back on VE AFAIK. I don't know if the posts are still up, but if so might reveal the necessary constant to determine mech resonant f from spec tip-mass.Thanks LD,

Just as a matter of interest, where is the line on tip mass? looking at https://linearaudio.net/downloads you can see a table for some popular carts. The OM-30/40 is 0.3mg so I am assuming anything below that is certainly good.

The microline on my AT-150 is 0.22mg so also good. But oddly if you look at some of the sapphire cantilevers the blob of glue is huge and possibly doubles tip mass,

IMO the reason stylus mass doesn't contribute to effective tip mass, and therefore why a huge blob of glue doesn't matter to resonant f, is because a stylus does not move during resonance, it is retained by the groove walls which do not move. It's further anecdotal evidence that cantilever self-resonance is the mechanism, rather than vinyl spring IMO. Further, a blob of glue might matter to hi-G trackability, or it might not, depending on the relative mechanical impedances of the cantilever and the true stylus mass. Imagine what happens if a cantilever is allowed to flex at hi stylus G.

Have been looking a bit more into frequency data for cartridges based on tip mass to get a feel for things based on last couple of LD posts. Now AT is an interesting outfit as they sell MM and MC with same cantilever and diamond specs, sometimes with the MC costing less than the MM! In this case comparing AT150MLx and AT-OC9 as both have gold plated boron cantilevers with microline stylii.

For once, gold as an exotic coating material might make sense as plating for a cantilever. But only if damping cantilever flex is relevent, so impicitly one is accepting this, and it is further anecdotal evidence. Gold is heavy, and its use here also suggests that bending dynamics are more important than tube mass, as per the equations I posted.

If mechanical resonance were vinyl spring based, there would be a classic 2nd order roll-off above resonance. But there isn't, otherwise response to 80kHz and the like would be impossible. However, the cantilever flex model has no roll-off, just a series of peaks and troughs which can be smoothed by damping. Are we convinced yet ?Now annoyingly not all specs are there, so cannot compare compliance but the main differences are in VTF range (MM 0.75-1.75g, MC 1.25-1.75g) and FR (MM 10-30kHz, MC 15-50kHz). Now I had assumed before I checked the MC that 30kHz would have been the mechanical resonance, but if the same basic mechanicals can go (pointlessly) higher perhaps the HF limit is entirely electrical and I'm worrying unecessarily....(..).... For bragging rights, Ortofon have a couple of high end MCs that, as well as a list price more than I paid for my last 2 cars quote 10-80kHz.

LD

I'm starting to wonder. I need to revist the B&K papers George found and look at the impulse tests they did. Something is odd, but the temptation is to ignore the 'cheap' units I have and just focus on the OM and AT generators which both appear to not have trickery propping up their HF. I am certainly piqued to discover more.

Speaking of which how is the workshop plan going?

Speaking of which how is the workshop plan going?

I need to revist the B&K papers George found and look at the impulse tests they did.

Here's another B&K technical document specifically about the test record QR2010 and sweep analysers used. Note figure 7 which shows sweeps for 2 quality cartridges up to 45kHz (test record limit), which shows no classic post-mechanical resonance roll-off up the limit of the test record 45kHz (where there is the expected cutting limit roll-off).

http://www.technicalaudio.com/pdf/B...Test_Records_4416_QR-2009_QR-2010_QR-2011.pdf

(PS: is there a picture of Anne Nightingale sneaked in there ?!)

As to B&K's impulse tests, suggest look only at measured results from various cartridges vinyl playback of the same B&K QR2010 10Hz - 45kHz sweep test record, rather than the somewhat wooky synthetic stimulus (which could be anything IMO). I think one sees various limitations of generators, over classic TL response of 1st two resonant modes, but no 2nd order roll-off. Remember the test record cut off is 45kHz

Very well, thanks Bill. I hope to be sorted and settled within the next few weeks, really looking forward to being able to run tests and build stuff again !Speaking of which how is the workshop plan going?

LD

Last edited:

That is my experience, and, if one can eliminate LCR effects, f response well into ultrasonics is well possible even from some of the better MM carts. Not that I can explicitly hear much above 12kHz these days unless it's pretty loud, which I think is normal, but hey maybe I can sense it with my toes or something so might as well reproduce whatever's there accurately I figure.just focus on the OM and AT generators which both appear to not have trickery propping up their HF....

The B&K test record has fairly insane continuous recorded levels at ultrasound, far higher than many carts would track, perhaps 1000G or so ! This maps on to slew rate of programme material, which is an aspect I believe is worth conserving in playback. Real programme content seldom gets anywhere near that though, IME.

LD

Someone is selling QR2010 on the swap meet. I would get killed if I spent £150 on a record, despite it being a good investment. The doc I still need to dig out is where they used a rip saw to cut a step in a record to get a good impulse response.

That does look like Anne, but the table doesn't look like one the BBC used . On inspection you do look right, but I'd want to draw a few lines to prove it to myself first.

. On inspection you do look right, but I'd want to draw a few lines to prove it to myself first.

Hmm, this does beg the question on whether the Shure M97 does have the mechanical resonance people say, or if it really is due to the electrical resonance. Hopefully George can shed light on that as he has one. Does drive the conclusion that van Raalte/van Maanen corrections are only needed for cheaper MMs. Now that Jico want $200+ for the SAS tip and ortofon OMs are cheap its only really for interest.

Let me know when you are ready to test a super-OM.

That does look like Anne, but the table doesn't look like one the BBC used

Hmm, this does beg the question on whether the Shure M97 does have the mechanical resonance people say, or if it really is due to the electrical resonance. Hopefully George can shed light on that as he has one. Does drive the conclusion that van Raalte/van Maanen corrections are only needed for cheaper MMs. Now that Jico want $200+ for the SAS tip and ortofon OMs are cheap its only really for interest.

Let me know when you are ready to test a super-OM.

Self preservation is a very strong instinct, I'd trust it ! I have Decca SXL and LXT frequency reference records from the late 50's, but not the B&K references and it will probably stay that way for such good reasonsSomeone is selling QR2010 on the swap meet. I would get killed if I spent £150 on a record, despite it being a good investment.

The doc I still need to dig out is where they used a rip saw to cut a step in a record to get a good impulse response.

Thanks about the super OM, will do.

LD

Found the paper http://www.theanalogdept.com/images/spp6_pics/TT_Design/MechanicalResonances.pdf . Page 10 discusses sawing a record to get a 0.2mm step.

It must have been fun working at B&K in the 70s!

It must have been fun working at B&K in the 70s!

Hmm, this does beg the question on whether the Shure M97 does have the mechanical resonance people say, or if it really is due to the electrical resonance. Hopefully George can shed light on that as he has one

Hi Bill

Tell me what do I have to do to shed some light on this.

George

- Home

- Source & Line

- Analogue Source

- mechanical resonance in MMs