Whilst I'll probably never enjoy a V15V

And the ebay fairy strikes. One on with a BIN of £250. Reduced from £28,000! I think I can resist...

Did you get as far as trying transimpedance loading, bondini ? LD

No. I have considered building your Aurak 2.3 with a Forsell discrete jfet op-amp as the input device and an NE5532 as the output device. That may yet happen, though pentode input phono stages currently hold my attention and will do so for some time yet.

Is there a separate thread with details of your Transimpedance MM pickup preamp?

This was fairly common in da 60's with valves but of course has to be matched to the cartridge.

There was once a thread on another forum, a bit of a stream of consciousness, and it got purged along with much of my stuff a few years back. Apparently, all traces of it disappeared...... aliens, it must be aliens.........

....though pentode input phono stages currently hold my attention and will do so for some time yet.

In the intervening years, I finalised a version of Aurak for my own use, and still use it today as my main preamp. Since you mention pentode input stages, I also designed an EF184 based transimpedance preamp based on the same topology, which is cute, and I use this as my 2nd preamp.

These preamps drew the line for me on loading decisions, and cartridge choices. Interchangable styli means replacement costs are manageable, and there's choice of stylus profiles to suit specific vinyl and programme material. There was a certain peace of mind from settling on a playback topology, and I've spent a happy few years quietly enjoying the music.

I never realised there were valve transimpedance preamps in the 60s, kgrlee.........

LD

Last edited:

He said he didn't procede in that design because of the difficulty of tuning the input impedance for each cartridge manufacturer/type, amongst a few other reasons. However, in Aurak 3 schematic, there's a cute trick that brings the burden down to one resistor with an easy to calculate value.Interesting to note Leach was into the 'damped' 75us pole idea as well, even if he then abandoned it as too much effort

LD

These preamps drew the line for me on loading decisions, and cartridge choices. Interchangable styli means replacement costs are manageable, and there's choice of stylus profiles to suit specific vinyl and programme material. There was a certain peace of mind from settling on a playback topology, and I've spent a happy few years quietly enjoying the music.

.

LD

I do hope to get to the same place eventually. I have a few more MCs to get out my system first then I should finally get sensible again. Who knows I might even get as sensible as Scott by the time I too retire

TCO is a rabbit hole of its own and a daft one to get into for vinyl. So of course I have

Also fascinating is how, outside of serious archivists no one can agree on the stylus to use for monos. It's almost comical

Well, AFAIK it's seldom just the 'tip' that is changed. So the outcome is presumably either well calculated and devised or empirical. If it's the former, then mechanical resonance is understood but just not published I suppose....... ? I wouldn't like to guess.Now if you trust in re-tipping this opens up a whole new world in tuning but is more a badger set than a rabbit hole.

It's true that MM stylus replacement cost converges with MC, year on year.

I have spent many a happy hour wondering about 'true' relapping of a stylus in situ, which AFAIK is not done but seems plausible...........

LD

I have spent many a happy hour wondering about 'true' relapping of a stylus in situ, which AFAIK is not done but seems plausible...........

LD

I don't see the point so to speak.

Well, AFAIK it's seldom just the 'tip' that is changed. So the outcome is presumably either well calculated and devised or empirical. If it's the former, then mechanical resonance is understood but just not published I suppose....... ? I wouldn't like to guess.

LD

There is a vogue for changing stylus and cantilever (I suspect they are supplied premade for the sapphire ones ) at the moment, but pretty sure Expert if you ask will just unglue/reglue (or decrimp and glue). Now how the tip mass will change I suspect they will tell you*. Expert have been in the business over 30 years so I would hope they know what they are talking about.

Some hard data would be nice. I suspect that will require someone to actually measure OEM vs retip. Would be an interesting experiment. Interwebs say the expert paratrace retip starts at £100 so I could actually consider that unless I start hoarding AT150 stylii for when AT stop making them

*Just realised I have no idea what manufacturers actually mean by effective tip mass. Off to learn myself summat.

Effective tip mass - Audio, March 1978

The Effective Tip Mass is the lumped mass which, if located at the tip of the stylus and acting over the cantilever length from tip to pivot, would have the same rotational moment of inertia as the entire stylus+cantilever+generator assembly.

Roger Anderson from Shure wrote a nice little article on the subject in Audio, March 1978, titled "Equivalent Mass - Fact or Fiction". It is available through the Vinyl Engine website and is worth a couple of reads.

Being a good engineer, Roger explains that effective tip mass is a calculated parameter, not a measured parameter. It is an abstract concept that is solidly grounded in physics but it is not directly measured. The measured parameter is trackability. It is the gap between the measured trackability and the ideal trackability (calculated using the effective tip mass) that is of interest. As Roger puts it:

Some notes of caution: the calculations of effective tip mass and ideal trackability are separate from not to be confused with:

Just realised I have no idea what manufacturers actually mean by effective tip mass. Off to learn myself summat.

The Effective Tip Mass is the lumped mass which, if located at the tip of the stylus and acting over the cantilever length from tip to pivot, would have the same rotational moment of inertia as the entire stylus+cantilever+generator assembly.

Roger Anderson from Shure wrote a nice little article on the subject in Audio, March 1978, titled "Equivalent Mass - Fact or Fiction". It is available through the Vinyl Engine website and is worth a couple of reads.

- Roger walks through a calculated example (imperial and CGS units);

- shows the relative contributions of the tip, shank and generator; and

- shows (in two nice little appendices) how to use the result to calculate the "ideal" limits of trackability for any given stylus downforce.

Being a good engineer, Roger explains that effective tip mass is a calculated parameter, not a measured parameter. It is an abstract concept that is solidly grounded in physics but it is not directly measured. The measured parameter is trackability. It is the gap between the measured trackability and the ideal trackability (calculated using the effective tip mass) that is of interest. As Roger puts it:

Therefore, the answer to the original question "Equivalent Mass - Fact or Fiction?" must be an emphatic "Yes!"

Some notes of caution: the calculations of effective tip mass and ideal trackability are separate from not to be confused with:

- calculating the cartridge/tonearm resonance; or

- calculating the flexural or torsional motions of the tip,cantilever/suspension/generator assembly.

Yes if the cantilever is rigid..... and that's often the misassumption at the outset in such papers, unfortunately, IMO.The Effective Tip Mass is the lumped mass which, if located at the tip of the stylus and acting over the cantilever length from tip to pivot, would have the same rotational moment of inertia as the entire stylus+cantilever+generator assembly.

Consider what happens if the tip is free to move due to cantilever flex, just as a thought experiment, for the case of a very flexible cantilever. It's then apparent that rigid body mechanics of the cantilever don't apply, and moment of inertia of the cantilever as a body doesn't mean anything useful.

Mechanical impedance to stylus movement can't then be determined from MOI of the cantilever, or considered to be it's mass equivalent as inertia or 'tip mass'.

- Roger walks through a calculated example (imperial and CGS units);

- shows the relative contributions of the tip, shank and generator; and

- shows (in two nice little appendices) how to use the result to calculate the "ideal" limits of trackability for any given stylus downforce.

Which is all good stuff based on a premise that the cantilever is rigid, but not so good if it isn't. IMO, it's not that such physics is wrong, it's just misapplied.

Well, enough dots are there, they just need joining slightly differently, IMO.Being a good engineer, Roger explains that effective tip mass is a calculated parameter, not a measured parameter. It is an abstract concept that is solidly grounded in physics but it is not directly measured. The measured parameter is trackability. It is the gap between the measured trackability and the ideal trackability (calculated using the effective tip mass) that is of interest. As Roger puts it:

Therefore, the answer to the original question "Equivalent Mass - Fact or Fiction?" must be an emphatic "Yes!"

What determines trackability is mechanical impedance to stylus motion. For tracking high acceleration, ie high curvature grooves, this impedance is typically limited by inertia of whatever moves. One can work backwards from measured trackability and determine mechanical impedance, from the limit of trackability versus VTF for swept frequency.

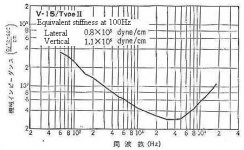

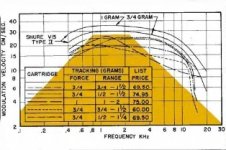

Attached is such a published mechanical impedance measurement for a V15, along with Shure's published trackability chart, for interest, one can see the approximate inverse correlation quite well, I think.

Such real deduction of mechanical impedance naturally embraces what is really going on, whatever that be, in terms of contribution from suspension spring, damping, and inertia from the moving parts.

By choosing different specific frequencies, classically one might estimate cartridge suspension spring, damping, and inertia of moving parts, based on assumption that impedance is pure spring, damping, or inertia.

So, determined this way, 'tip mass' would be a restatement of measured trackability, and would seem bound to differ from inertia calculations, mostly because real cantilevers aren't rigid, and non-zero contribution from suspension spring and damping.

However, a few years back dlaloum noted a strong correlation between his measured mechanical resonant f and published tip mass figures, from many and various cartridge manufacturers. Thesis is that tip mass, as published, might be a restatement of mechanical resonant f, worked backwards assuming a standard spring constant. This correlated far better than tracking performance, IIRC, and was tough to explain otherwise I thought......

Anyways, 'Fact or Fiction?', I agree it's probably both, but for sure isn't what is commonly understood to be !

LD

Attachments

Last edited:

Let's not dispense with effective tip mass, please

One of the things I like about Roger Anderson’s paper is that he doesn’t try to explain in any detail the gap between measured trackability and the ideal trackability indicated by the effective tip mass. Rather, he says that it:

The flexural or torsional vibration of the cantilever/elastomer/generator system can easily be one such ‘flexibility’. And it can be important, hopefully at higher frequencies.

And now the principle of superposition lurches into play. A separate model of cantilever flexure can be superimposed on the effective tip mass model. As can the model of the cartridge/tonearm resonant system. And the models of any other systems you may identify. Without the sum total losing fidelity at the frequencies of interest.

This is a method of analysis in the mechanics of vibration, based on the premise that, at the frequencies of interest, the systems of interest behave linearly. That is to say, masses stay constant (easy!), spring compliance stays constant (not quite as easy but sometimes not too hard...), and damping coefficients stay constant (not easy...ever).

Mechanical impedence (like electrical) is a dynamic variable in the complex plane - it has magnitude (modulus) and phase. Thanks to Harry Olson (and others) we can think of mass as analogous to inductance, the spring compliance as an analog of capacitance, and damping coefficient as resistance. The force acting on the stylus is analogous to the driving voltage.

Mechanical impedence is susceptible to the same kind of analysis as electronic impedence. Except that mass is way better behaved than any inductance. And, while the cantilever is a “capacitor” with fabulous characteristics (like a picofarad milspec AVX glass capacitor) it’s in parallel with the kludgy electrolytic of the elastomer compliance. Which does double duty as something worse than the least linear resistor ever foisted on the world of electronics (I hope).

In fact, the variability of the damping coefficient is what is shown in the first chart for the Shure V-II, not mechanical impedence. That poor old elastomer – we want it to be highly compliant and lightly damped at low frequencies, but highly damped and stiffer at higher frequencies. It just can't win and the first chart shows how far the damping is from linear or even the ideal for a phono cartridge. Maybe we should ask EAR Specialty Composites to try their hand...

In short, the mechanical system of cantilever/elastomer/generator (with its own resonant frequency, q-factor etc) is soaking there in the bathwater along with the tonearm/elastomer system (with its lower resonant frequency etc etc), and the cantilever flexural system (with its hopefully higher resonant frequency) and so on and so on.

The analytic challenge is to ensure that, at the frequencies of interest, we sum the models of the right systems.

One of the things I like about Roger Anderson’s paper is that he doesn’t try to explain in any detail the gap between measured trackability and the ideal trackability indicated by the effective tip mass. Rather, he says that it:

represents the extent to which other mechanical characteristics influence the performance of the pickup. Incidentally, the frequently observed effect of a flexibility in the drive system is to cause a resonance to appear which decreases the actual trackability!

The flexural or torsional vibration of the cantilever/elastomer/generator system can easily be one such ‘flexibility’. And it can be important, hopefully at higher frequencies.

And now the principle of superposition lurches into play. A separate model of cantilever flexure can be superimposed on the effective tip mass model. As can the model of the cartridge/tonearm resonant system. And the models of any other systems you may identify. Without the sum total losing fidelity at the frequencies of interest.

This is a method of analysis in the mechanics of vibration, based on the premise that, at the frequencies of interest, the systems of interest behave linearly. That is to say, masses stay constant (easy!), spring compliance stays constant (not quite as easy but sometimes not too hard...), and damping coefficients stay constant (not easy...ever).

Mechanical impedence (like electrical) is a dynamic variable in the complex plane - it has magnitude (modulus) and phase. Thanks to Harry Olson (and others) we can think of mass as analogous to inductance, the spring compliance as an analog of capacitance, and damping coefficient as resistance. The force acting on the stylus is analogous to the driving voltage.

Mechanical impedence is susceptible to the same kind of analysis as electronic impedence. Except that mass is way better behaved than any inductance. And, while the cantilever is a “capacitor” with fabulous characteristics (like a picofarad milspec AVX glass capacitor) it’s in parallel with the kludgy electrolytic of the elastomer compliance. Which does double duty as something worse than the least linear resistor ever foisted on the world of electronics (I hope).

In fact, the variability of the damping coefficient is what is shown in the first chart for the Shure V-II, not mechanical impedence. That poor old elastomer – we want it to be highly compliant and lightly damped at low frequencies, but highly damped and stiffer at higher frequencies. It just can't win and the first chart shows how far the damping is from linear or even the ideal for a phono cartridge. Maybe we should ask EAR Specialty Composites to try their hand...

In short, the mechanical system of cantilever/elastomer/generator (with its own resonant frequency, q-factor etc) is soaking there in the bathwater along with the tonearm/elastomer system (with its lower resonant frequency etc etc), and the cantilever flexural system (with its hopefully higher resonant frequency) and so on and so on.

The analytic challenge is to ensure that, at the frequencies of interest, we sum the models of the right systems.

Well, that's the sort of loose end that just has to be pulled IMO, and I think when one does that, quite a lot unravels IME.One of the things I like about Roger Anderson’s paper is that he doesn’t try to explain in any detail the gap between measured trackability and the ideal trackability indicated by the effective tip mass. Rather, he says that it:

represents the extent to which other mechanical characteristics influence the performance of the pickup.

Yes it would at the resonant frequency. But whatever lowers impedance to stylus motion improves trackability up to a point.......Incidentally, the frequently observed effect of a flexibility in the drive system is to cause a resonance to appear which decreases the actual trackability!

It's unnecessary to consider cantilever flex and inertia separately, rather a transmission line vibration model wraps it all up very elegantly IME. Otherwise, one ends up combining two imperfect models and it's all a bit of a fudge and defies physical explanation, which is unsatisfying I find. Or leadsThe flexural or torsional vibration of the cantilever/elastomer/generator system can easily be one such ‘flexibility’.

to temptation to duck issues like why there is a gap between model and reality, which is surely the more interesting question ?....

Just don't go there ! If a cantilever flexes, it's not rigid so effective tip mass model, as described, doesn't apply......And now the principle of superposition lurches into play. A separate model of cantilever flexure can be superimposed on the effective tip mass model.

Well not necessarily ! Inertia is the issue, and that depends on the instantaneous shape and flex/coupling along the length of the cantilever.This is a method of analysis in the mechanics of vibration, based on the premise that..(..).. masses stay constant (easy!)

I've never understood why this analogy is deemed useful, ie why mechanics is not deemed perfectly understandable on its own merit and terms, and yet electrical systems somehow are !?!Mechanical impedence (like electrical) is a dynamic variable in the complex plane - it has magnitude (modulus) and phase. Thanks to Harry Olson (and others) we can think of mass as analogous to inductance, the spring compliance as an analog of capacitance, and damping coefficient as resistance. The force acting on the stylus is analogous to the driving voltage.

Well no, the published plot is mechanical impedance to motion of the stylus. Well, strictly the magnitude of mechanical impedance at a specific frequency. It was derived from measured VTF required at the onset of mistracking of a given velocity. It's not great physics, but is OK and it's what was done in the day.In fact, the variability of the damping coefficient is what is shown in the first chart for the Shure V-II, not mechanical impedence.

So all effects contributing to trackability are rolled up in there, including, but not limited to, damping provided by the elastomer. Incidentally, impedance at 100Hz was read off, expressed as if it was pure spring, and this is the meaning of compliance at 100Hz as used by Japanese cartridge manufacturers. Even though at 100Hz impedance is more damping than spring, and not much inertia.............whatever !

LD

Last edited:

Dang, trying to find a post I saw a couple of nights ago. Should have saved it*. Ah well. Back on the retip thoughts. If the theory that mass of the diamond has little effect then changing that should not change resonant frequency. If the cantilever is changed as long as the replacement is either lighter for same stiffness or stiffer for same mass, then first resonance should move upwards all other things being equal?

That so I am intrigued. If you look at the ortofon OM series stock pics the cantilever looks the same (looking more closely it IS the same, they've photoshopped the numbers). Now I assumed that they wouldn't bother with a different cantilever for each model and would just change tip and possibly the rubber donut. But the quoted compliance is the same for 10 through 40 so maybe same rubber.

Trackability does change as you go up the line, but doesn't entirely line up with quoted effective tip mass. Same tip mass, same compliance, different 315Hz trackability at 1.5g VTF. And the S-120 with a huge DJ proof stylus** out tracks the lot at 315Hz.

Note I'm only looking at this from the point of view of cheapest donors should I ever decide to wast d^ experiment.

*This was the list of what affected resonant frequency of mech system and the law

** would appear that the trick suspension doesn't hold the cantilever in as well as some and many reports of gorilla DJs ripping the whole thing out when scratching. Not as issue we should have.

That so I am intrigued. If you look at the ortofon OM series stock pics the cantilever looks the same (looking more closely it IS the same, they've photoshopped the numbers). Now I assumed that they wouldn't bother with a different cantilever for each model and would just change tip and possibly the rubber donut. But the quoted compliance is the same for 10 through 40 so maybe same rubber.

Trackability does change as you go up the line, but doesn't entirely line up with quoted effective tip mass. Same tip mass, same compliance, different 315Hz trackability at 1.5g VTF. And the S-120 with a huge DJ proof stylus** out tracks the lot at 315Hz.

Note I'm only looking at this from the point of view of cheapest donors should I ever decide to wast d^ experiment.

*This was the list of what affected resonant frequency of mech system and the law

** would appear that the trick suspension doesn't hold the cantilever in as well as some and many reports of gorilla DJs ripping the whole thing out when scratching. Not as issue we should have.

Last edited:

- Home

- Source & Line

- Analogue Source

- mechanical resonance in MMs