Measuring at 1/32" is 'splitting hairs', i.e. the middle of a 1/16", so just 'eyeballing' it or even just measuring to the nearest 1/16" is sufficient unless the layout requires enough multiple 1/32" spacings that can stack up to be off enough to matter at the other end. For sure, a few 'fat' or 'thin' 1/32" scattered over a complete design won't affect the speaker's performance in any audible/measurable way. This level of accuracy on something the size of a speaker cab is for mass production assembly or similar.

That said, nowadays they sell inexpensive tape measures with both Imperial and metric scales at Lowes, etc., so with most plans being in metric these days and its even scaling along with ease of adding/subtracting/dividing numbers with less chance of errors since only specialized calculators $$$ allow fractions to be inputted, I went ahead and bought one awhile back rather than continuing to go through the hassle of conversion and all its potential for error.

Time for us 'Imperial' Americans to make good on our now decades old 'commitment' to convert to metric, at least when it comes to designing/laying out DIY speaker plans.

At the very least consider switching to SAE [1/10"] like I've historically used to allow easy adding/subtracting/dividing/converting numbers with a calculator: Shop Kobalt 25' Metric and SAE Tape Measure Measuring Tool at Lowes.com

GM

That said, nowadays they sell inexpensive tape measures with both Imperial and metric scales at Lowes, etc., so with most plans being in metric these days and its even scaling along with ease of adding/subtracting/dividing numbers with less chance of errors since only specialized calculators $$$ allow fractions to be inputted, I went ahead and bought one awhile back rather than continuing to go through the hassle of conversion and all its potential for error.

Time for us 'Imperial' Americans to make good on our now decades old 'commitment' to convert to metric, at least when it comes to designing/laying out DIY speaker plans.

At the very least consider switching to SAE [1/10"] like I've historically used to allow easy adding/subtracting/dividing/converting numbers with a calculator: Shop Kobalt 25' Metric and SAE Tape Measure Measuring Tool at Lowes.com

GM

Measuring at 1/32" is 'splitting hairs', i.e. the middle of a 1/16", so just 'eyeballing' it or even just measuring to the nearest 1/16" is sufficient unless the layout requires enough multiple 1/32" spacings that can stack up to be off enough to matter at the other end. For sure, a few 'fat' or 'thin' 1/32" scattered over a complete design won't affect the speaker's performance in any audible/measurable way. This level of accuracy on something the size of a speaker cab is for mass production assembly or similar.

That said, nowadays they sell inexpensive tape measures with both Imperial and metric scales at Lowes, etc., so with most plans being in metric these days and its even scaling along with ease of adding/subtracting/dividing numbers with less chance of errors since only specialized calculators $$$ allow fractions to be inputted, I went ahead and bought one awhile back rather than continuing to go through the hassle of conversion and all its potential for error.

Time for us 'Imperial' Americans to make good on our now decades old 'commitment' to convert to metric, at least when it comes to designing/laying out DIY speaker plans.

At the very least consider switching to SAE [1/10"] like I've historically used to allow easy adding/subtracting/dividing/converting numbers with a calculator: Shop Kobalt 25' Metric and SAE Tape Measure Measuring Tool at Lowes.com

GM

Thanks GM, there is a lowes fews miles from where i live.

i agree,but for the program it makes no difference.Measuring at 1/32" is 'splitting hairs'

GM

like you said eyeball it between 2 lines.

kornnie

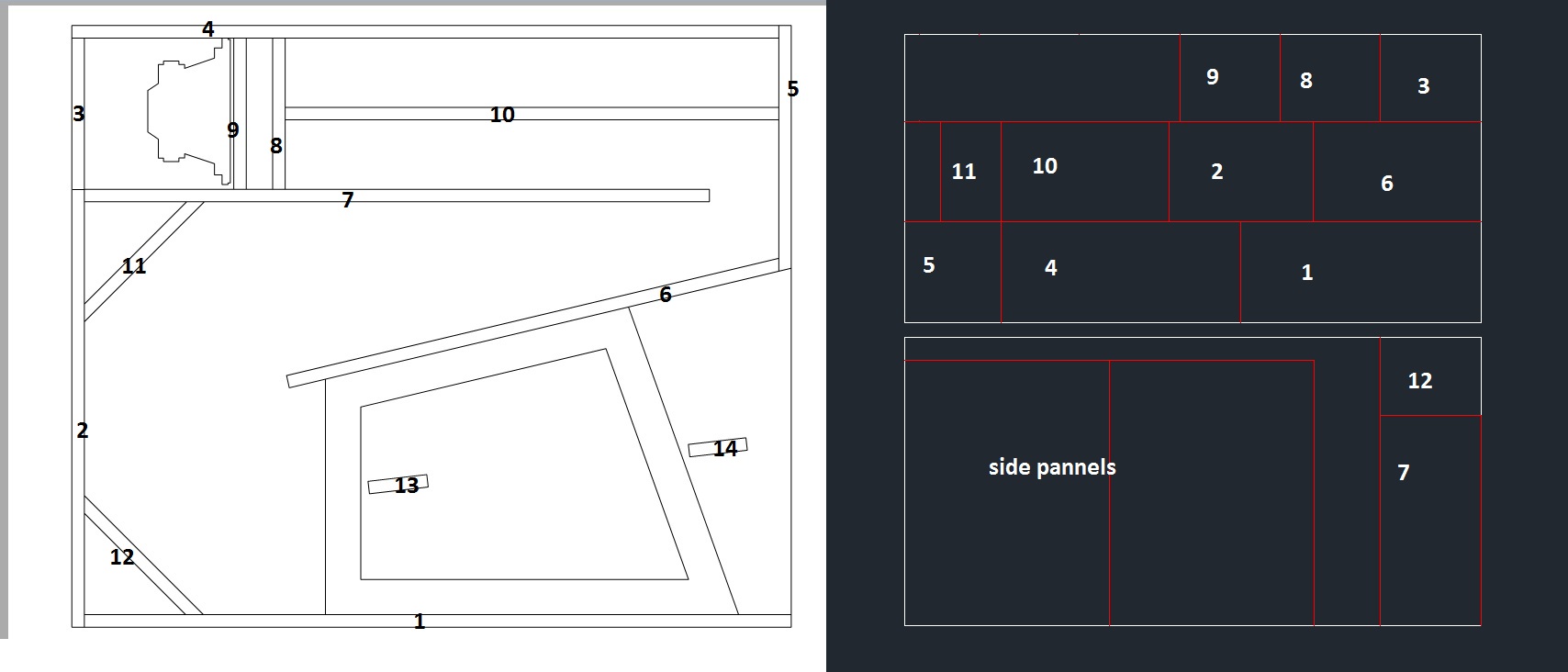

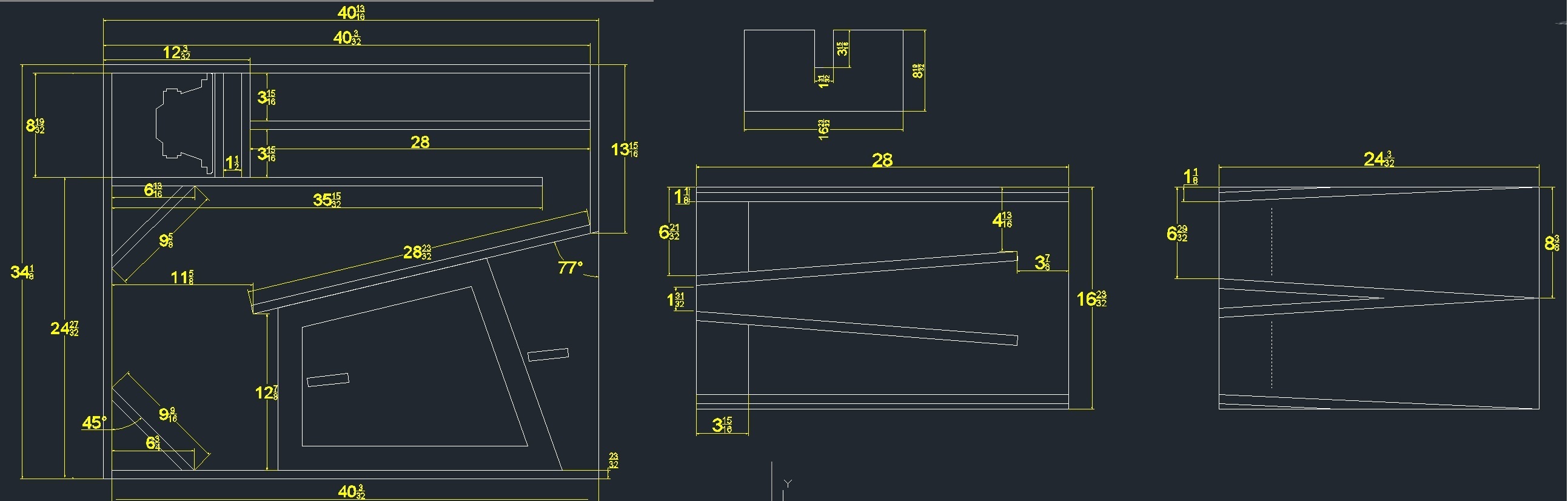

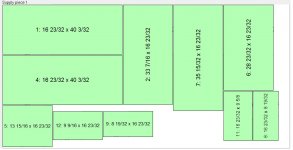

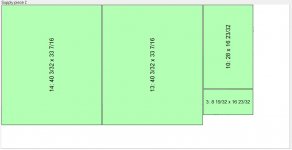

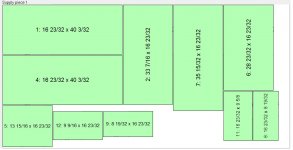

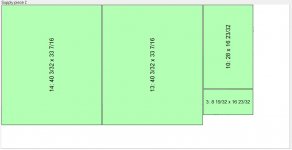

here are al the fractional dimensions,and 4 printfiles.

make sure they do a 1:1 copy

you can check this with the dimensions from the pic .

you can take every dimension from the prints(print model 3 is ideal situation,its up to you how accurate you want to make that)

also draw some bracing on it ,you can also trace that from the print.

print 1

print 2

print 3

print 4

make the top (first 2 parts of the horn)first,then mout this with the rest of the horn.

set the saw table @ 16 6/16(42,5cm) wide and cut al those pannels so they are al exactly the same width

Last edited:

Epa you make the cutlist to be print out as a template.

View attachment 238537

View attachment 238538

Epa the largest size paper the copy center print is 36x48

its 35*41 so it fits exactly.

the rest is up to carpenter with his tape measure

Epa thanks alot for every thing. It is time to make this project a reality.

hi kornny\

make sure the printfiles are correct/check it with the dimensions on post 143.

also print out the pics in post 143 and 145 and they can take all measurements from the print files and also the pic in 143.

make sure all pannels are the same cut/width(so 16 23/32 ,it doesn't matter if its 16 6/8 ,as long they are all 16 6/8 ,so the side pannels wil fit without gaps)

use polyuteran glue.

make sure the printfiles are correct/check it with the dimensions on post 143.

also print out the pics in post 143 and 145 and they can take all measurements from the print files and also the pic in 143.

make sure all pannels are the same cut/width(so 16 23/32 ,it doesn't matter if its 16 6/8 ,as long they are all 16 6/8 ,so the side pannels wil fit without gaps)

use polyuteran glue.

Cutlist

After you finish watching soccer can you take a look at this cutlist and let me know if it is correct.

Thanks

View attachment cutlist.txt

yust got home from work

so now dinner and tv(soccer)

After you finish watching soccer can you take a look at this cutlist and let me know if it is correct.

Thanks

View attachment cutlist.txt

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Mcm 8" 55-2421 Ts parameter