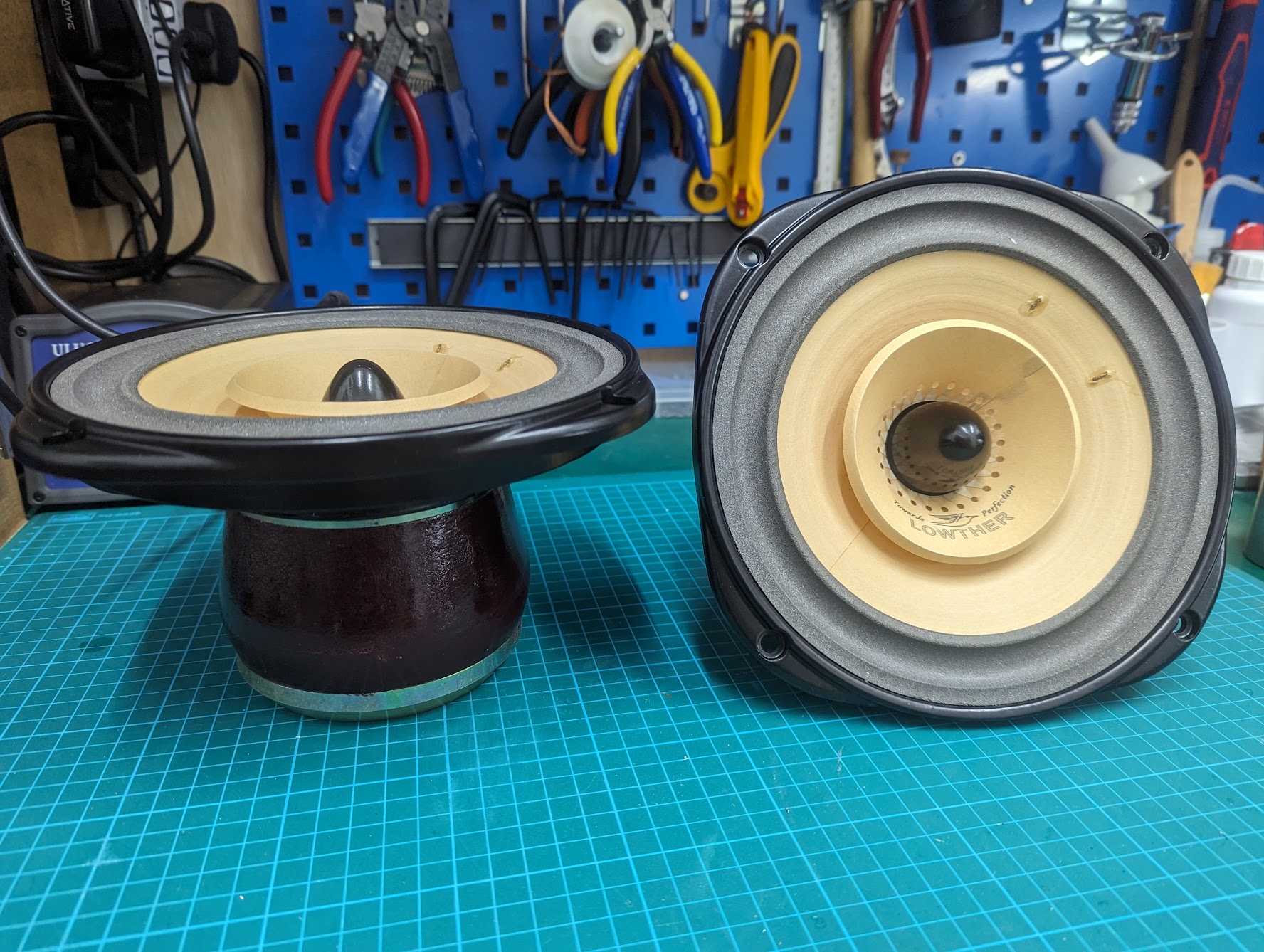

Just got them delivered from the UK. Doing up a Lowther Acousta Enclosure for them pretty soon

Premium Drivers information sheet

Standard specifications: Many misleading terms have been used to describe the paper preparation of the Lowther diaphragms, doping, age-conditioning, curing, varnishing, etc., leading to discussions & myths around old preparations, similar to the legend of Stradivari’s varnish. There is no magic formula. The standard process, used for many years, is to apply freshly prepared 'special pale' French polish to the made-up cone/voice coil sub-assembly prior to fitting to the motor. This soaks through the paper leaving pure shellac distributed through the paper fibres as the spirits dry. Sugar-like crystals can be seen on the surface of a freshly treated cone. A few months sees a uniform yellowing of the diaphragm due to the reaction of light & air with the shellac. The paper fibres are locked with the shellac to be stiff yet flexible; It is generally accepted that the driver performs optimally after this point, though the foam suspensions co-incidentally loosen up over this period, and this has more of an influence at the early 'break-in' period. Older drivers (pre-Thornton) mostly exhibit a dirty, patchy yellow appearance due to poorly prepared lower grade shellac, which does not cure well over time. Controlling the quality & preparation of the shellac is an all-round long-term improvement, but due to the cleaner appearance, some still think we do not shellac the cones. Standard spec. drivers will continue to be available as usual.

Premium Specifications: The main difference over the standard range is the treatment of the paper. In this process the paper is impregnated with our own in-house formular before cutting, forming & assembling. The 'curing' process is mostly complete by the time the unit is tested & packed, though improvements will still be noticed over the 'break-in' period. The new treatment reacts with the paper fibres differently to the shellac process, resulting in a more stable, consistent & dimensionally accurate cone. The impregnation formular, however, can only be made in small batches in our own workshop and will not scale up to industrial preparation. This limits production to the ‘premium-hand-made' scale,

with the inevitable expense involved. The premium diaphragms are also fitted with the new back centre, replacing the foam standard. The entire set of components is laser-cut, enabling greater control of consistency & accuracy over the die-cut standards. Laser cutting also allows us to make small detail modifications like rounding the points of the 'pips' that hold the voice coil to the inner cone, cut elliptical 'pressure-relief' holes to control the dual cone phase errors, adapt the turned edge of the inner cone to a more suitable paper weight & composition and re-design the assembly relationship of the inner / outer cone / back centre / voice coil - most of which

would have been adopted before, but not possible because of the limitations of the old die cutting. The result of all these adaptations is a diaphragm which excels in all areas, including appearance, with the Lowther logos, radial embossing, and consistency of paper surface & colour. The legendary hand-crafted double-wound speech coil and overall <>10.5g moving mass of the assembly are retained. Foam surround suspension is the same as standard.

Sound: Initially developed for use in the Edilia, testing in all driver models & cabinets showed a marked improvement in all areas. Diaphragms prepared straight-out-of-the box for our most critical 'test bed' - the Lowther-Hegeman with field coils - were received by everyone with amazement; described by various judges as 'game-changer', 'most significant positive step for Lowther in years', 'improvement in all areas of presentation of natural sound'. We are confident that the premium 'upgrade' easily justifies the enhanced price, and all customers are encouraged to hear the difference at our studio showroom. All of our top range handmade cabinets (TP2, Almira/Edilia, LHSR, Audiovector) will be fitted premium regardless of driver type. The premium diaphragms can be fitted to almost all existing Lowthers as an enhanced Re-cone, or LFL trade in.

Premium diaphragms: Key points - Changes / Improvements

Paper gsm weight & fibre type

Laser cutting & CAD design.

Lowther's own paper treatment impregnation process

Inner Cone improved, so:

Enhanced choice of phase plug /centre pole treatment

Aluminum or Silver voice coil

Radial embossing

Logos printed onto cones.

New back centre & assembly

Improvements in quality consistency, appearance, longevity.

Significant improvement in all aspects of sound presentation.

Attachments

New. In the US. They are available from Refined Audio, and I have a pair on order.

not on their website yet either but please keep us updated on the drivers, how they sound and where you'd say they fit with the other exotics, AER, Cube, Voxativ etc

Last edited by a moderator:

It would be interesting to have CSD

With Periods instead of mSec, much better for teasing out resonances and comparing them.

dave

Exactly. The branding stops me from being tempted. Looking forward to hearing real world reports though.I could live without the “designer” logo on the cones.

Which would be similar accumulation of energy at different frequencies, if it were the same throughout the entire frequency range and during the same period of time.....wow, the perfect speaker, I think I understand.Found some nice examples.

...............

The more parallel the curves ar etghe better (ie even spacing)

dave

I found this, I remember that TG was not very kind in a study on Lowther, that is why I mentioned the analysis by CSD, perhaps the manufacturer has published it and it is not in that brief report. Just for my own knowledge, I don't intend to hijack a thread.....

https://audioxpress.com/article/testing-loudspeakers-which-measurements-matter-part-1

Measurements I took using DATS

- Piston Diameter = 160 mm

- f(s)= 60.327 Hz

- R(e)= 7.4708 Ohms

- Z(max)= 191.91 Ohms

- Q(ms)= 9.9365

- Q(es)= 0.40248

- Q(ts)= 0.38681

- V(as)= 32.761 liters (1.1569 cubic feet)

- L(e)= 0 mH

- n(0)= 1.7039 %

- SPL= 94.415 1W/1m

- M(ms)= 12.062 grams

- C(ms)= 0.577 mm/N

- BL= 9.2124

- K(r)= 6.8252

- X(r)= 0.055289

- K(i)= 0.059708

- X(i)= 0.4164

Measurements I took using DATS

From my experience, gives results useful for matching but not for designing boxes. As per the author, parameters are determined by guessing from the impedance curve instead of directly measuring them. Also uses insuffiecient voltage to match (good) actory data.

dave

Member

Joined 2009

Paid Member

Looks to me as if Lowther made a much-needed well-overdue update to their finicky manufacturing process, allowing new hires to be able to build their product, all of which bodes well for their future. Nevertheless, somebody will find a subjective reason why the old cone is to be preferred and the prices of those old-cone drivers will rise.......

Measurements I took using DATS

- Piston Diameter = 160 mm

- f(s)= 60.327 Hz

- R(e)= 7.4708 Ohms

- Z(max)= 191.91 Ohms

- Q(ms)= 9.9365

- Q(es)= 0.40248

- Q(ts)= 0.38681

- V(as)= 32.761 liters (1.1569 cubic feet)

- L(e)= 0.07642 mH

- n(0)= 1.7039 %

- SPL= 94.415 1W/1m

- M(ms)= 12.062 grams

- C(ms)= 0.577 mm/N

- BL= 9.2124

- K(r)= 6.8252

- X(r)= 0.055289

- K(i)= 0.059708

- X(i)= 0.4164

Updated the Le value. Went missing during export

- Home

- Loudspeakers

- Full Range

- Lowther's New Premium Range