One more thing. A fellow Lowther owner suggested cutting the edge of the whizzer on my DX4 drivers to unfurl the reverse roll (to make the whizzer straight), based on his claims that the high frequencies sound better. After some careful consideration, I did so and I also thought that the high frequencies improved. When I ordered the DX65 drives I ordered them without the reverse roll.

Repairing a coil on an existing Lowther cone without damaging the former is probably near-impossible, Have you contacted Lowther to find out how much it costs for a new cone? Since the new cone would likely look different than the old one, it would probably makes sense to purchase two new cones. The cones come mounted on the baskets, and you just need to attach your existing magnets.

If you do get new cones, they require extensive break-in.

Retsel

If you do get new cones, they require extensive break-in.

Retsel

Great work and good specs. Appreciate the structured cone design bringing more stiffness without more weight.

Very thin whizzer cones made from plastic could be an alternative. Or putting very thin aluminum foil from the goldsmith on cone and whizzer.

Did that in year 2000 with a Fostex FE208 sigma.

Here some Fotos.

https://www.diyaudio.com/community/threads/how-to-make-a-loudspeaker-sandwich-cone.402917/

Very thin whizzer cones made from plastic could be an alternative. Or putting very thin aluminum foil from the goldsmith on cone and whizzer.

Did that in year 2000 with a Fostex FE208 sigma.

Here some Fotos.

https://www.diyaudio.com/community/threads/how-to-make-a-loudspeaker-sandwich-cone.402917/

There is someone in the Lowther Facebook group planning to do that, he boughta pair of my voice coil with intention to cut and remove the old one from the cone, and replace with the new ones.Repairing a coil on an existing Lowther cone without damaging the former is probably near-impossible, Have you contacted Lowther to find out how much it costs for a new cone? Since the new cone would likely look different than the old one, it would probably makes sense to purchase two new cones. The cones come mounted on the baskets, and you just need to attach your existing magnets.

If you do get new cones, they require extensive break-in.

Retsel

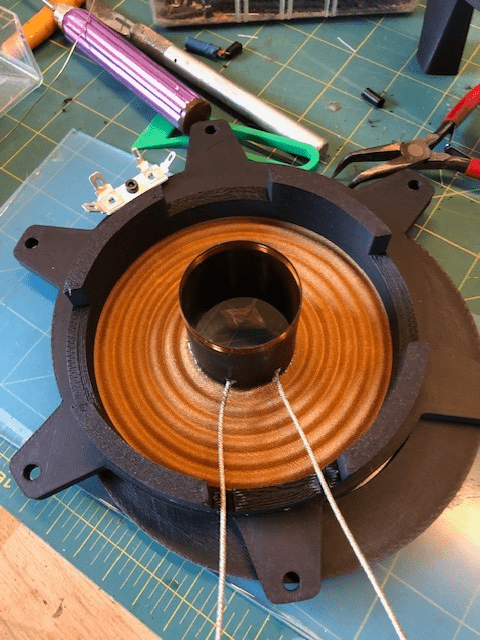

Not a simple work and takes lots of patience and time

Wow... So happy to have found this post @ghemml. I have been climbing up this ladder for a while without any idea what I am doing.

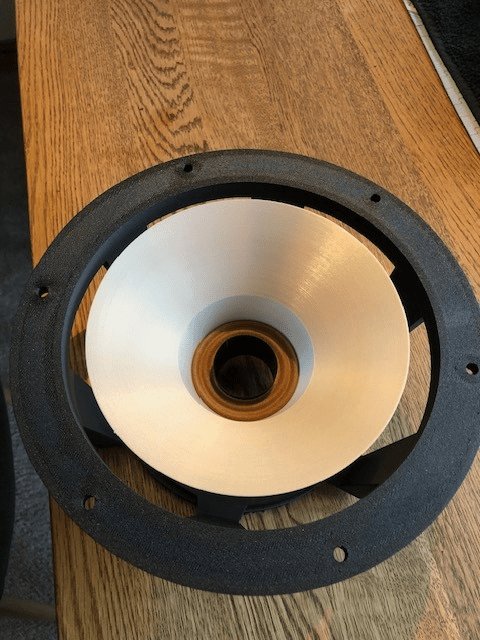

I have a pair of Tannoy speakers I am very fond of and took up the challenge to repair them after I stupidly blew them by accident.

In the process I had to work out a way of replacing the spiders too as they got damaged in the deconstruction process. I 3D printed mine which I'm happy to say are a little like the ones you have made. I will post pictures in due course.

I have a pair of Tannoy speakers I am very fond of and took up the challenge to repair them after I stupidly blew them by accident.

In the process I had to work out a way of replacing the spiders too as they got damaged in the deconstruction process. I 3D printed mine which I'm happy to say are a little like the ones you have made. I will post pictures in due course.

@BruceH

If you are interested using 3D printing for Loudspeaker, you can look at Frank Jensen's creation

https://www.facebook.com/frank.jensen.5891004

https://www.facebook.com/groups/lowthermodificationsupportgroup/permalink/1483408992211151/

If you are interested using 3D printing for Loudspeaker, you can look at Frank Jensen's creation

https://www.facebook.com/frank.jensen.5891004

https://www.facebook.com/groups/lowthermodificationsupportgroup/permalink/1483408992211151/

- Home

- Loudspeakers

- Full Range

- Lowther DX4 rebuild