Henkjan said:let me refrase maybe: has anyone done a listening comaprison between a long and short line? because that's what really counts of course

Glad I never had to do "comaprison"

I made three different lines, all aprox. 1/4 wavelength.

1. The original (aprox. 180 cm length shallow and long)

2. A rolled-up enclosure rather steep and short (aprox. 160cm).

3. A rolled-up enclosure little less shallower than the original and long (aprox. 210 cm).

The only 4" small driver performs best in housing 3. to my opinion. But differences are rather small. Correct me if I'm wrong but more dampening material slows down the air speed as I've once read. This would make the line shorter (given the steepness remains the same) wouldn't it? I didn't have calculating software/knowledge back than so built them all by gut feeling and listening...

Was and still am very pleased with them thou..even when compared to my newer 10" monsters

Differences in behavior in different rooms seem much less dramatic with TL's if you ask me (compared to more standard type enclosures).

Re room independence, probably quite true to a great extent, as a 'pure' TL is a non-resonant line -the damping in the line should theoretically eat the entire back-wave from the driver. Conversely, a QWR is highly resonant, and the resonance is deliberately used to prop up the bass. Most common is a hybrid between the two types, where one is blananced against the other.

Longer line -but is it straight or tapered? Line resonant frequency is a function of both length and taper, not length alone. That's why the old 'design frequency /4 = line length doesn't work for tapered lines. A narrowing line can be considerably shorter than a straight one. An expanding line needs to be considerably longer. Stuffing is a 2nd, not a 1st order effect, and should be used only to damp line harmonics (in a 'pure' TL the cabinet fundamental resonance is also damped). With a longer line, the back-wave has to travel through a longer run of resistive damping, which will start to absorb the fundamental if you're not careful. Stuffing is at its most effective however when positioned at the point of maximum air velocity of the frequency you wish to attenuate. The lower the frequency, the further toward the terminus it will be -the fundamental resonance occuring at (or very near) the terminus itself. So it's usually a good idea, for best bass performance, to leave the last few inches of a classic TL empty of stuffing, and stuff the rest of the line. That usually provides a good compromise.

Longer line -but is it straight or tapered? Line resonant frequency is a function of both length and taper, not length alone. That's why the old 'design frequency /4 = line length doesn't work for tapered lines. A narrowing line can be considerably shorter than a straight one. An expanding line needs to be considerably longer. Stuffing is a 2nd, not a 1st order effect, and should be used only to damp line harmonics (in a 'pure' TL the cabinet fundamental resonance is also damped). With a longer line, the back-wave has to travel through a longer run of resistive damping, which will start to absorb the fundamental if you're not careful. Stuffing is at its most effective however when positioned at the point of maximum air velocity of the frequency you wish to attenuate. The lower the frequency, the further toward the terminus it will be -the fundamental resonance occuring at (or very near) the terminus itself. So it's usually a good idea, for best bass performance, to leave the last few inches of a classic TL empty of stuffing, and stuff the rest of the line. That usually provides a good compromise.

Thank y'all for the good input!

That must be the reason why good designs are stuffed 'till only halfway. The housing 3. is slightly less tapered than the original design by the way. All housing types sounded best with wool stuffing (bailey's longhair) and housing 3. seemed to need less stuffing in order to produce good bass.

Type 2. and 3. were an interesting build, I designed them in "3d studio max" by starting with a round crossection-rolled up sort of "shell" shape, sliced it into 16 layers, printed the layers enlarged to real size on several A4 papers, taped them on 12mm MDF and cut the shapes out, glued the layers together and ended up with a smooth and round TL enclosure.

Had to do more than 100 meters on the electric saw per speaker , and it's a lot more expensive this way than with a standard MDF housing like type 1.

, and it's a lot more expensive this way than with a standard MDF housing like type 1.

Next ones I'm gonna cast from my own type of polycrete (synthetic and dampening concrete).

That must be the reason why good designs are stuffed 'till only halfway. The housing 3. is slightly less tapered than the original design by the way. All housing types sounded best with wool stuffing (bailey's longhair) and housing 3. seemed to need less stuffing in order to produce good bass.

Type 2. and 3. were an interesting build, I designed them in "3d studio max" by starting with a round crossection-rolled up sort of "shell" shape, sliced it into 16 layers, printed the layers enlarged to real size on several A4 papers, taped them on 12mm MDF and cut the shapes out, glued the layers together and ended up with a smooth and round TL enclosure.

Had to do more than 100 meters on the electric saw per speaker

, and it's a lot more expensive this way than with a standard MDF housing like type 1.

, and it's a lot more expensive this way than with a standard MDF housing like type 1.Next ones I'm gonna cast from my own type of polycrete (synthetic and dampening concrete).

If you haven't already, got to www.quarter-wave.com & download the Classic TL Alignment Tables. You'll find them useful.

so, after trying a few different folds (the TL did have to be below 2ft in height, not too deep, golden ration baffle, and have to have space for the plate amp as well) in the sections sheet, the long thin did not do as well as the simpler driver-offset model made me expect.

I added some definitions to the sheet so that I would enter some dimensions of the box and the lengths, widhts etc of the sections would be calculated from that. not a single number was entered into the transmission line definition part, only variables

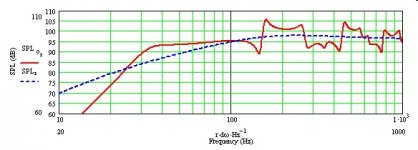

so back to the fat short, line length 1.68m, area from 1.8Sd - 0.66Sd (well, not that fat anymore, it's been on a diet) with some 100g stuffing in the beginning of the closed end. this gave a nice response, only small -5dB ripple @~130Hz.

so, let's buy & saw MDF....

I added some definitions to the sheet so that I would enter some dimensions of the box and the lengths, widhts etc of the sections would be calculated from that. not a single number was entered into the transmission line definition part, only variables

so back to the fat short, line length 1.68m, area from 1.8Sd - 0.66Sd (well, not that fat anymore, it's been on a diet) with some 100g stuffing in the beginning of the closed end. this gave a nice response, only small -5dB ripple @~130Hz.

so, let's buy & saw MDF....

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- long-thin vs fat-short TL