Regardless of the distinction between heatsink and heat spreader, the point is that my ALU plates are most likely inadequate for my needs.

I've fixed my amp but haven't run any more tests as I've been rebuilding my work bench. And to build a work bench, first one must tidy up ones entire basement.

Anyway, I have a plan. Well 3 plans. The ideal plan would be do conclude that 2 alu plates are enough.

Plan number 2 would involve scraping the plates and using a largish, well fined heat sink I pulled out of the trash last week end.

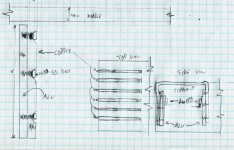

Plan number 3 would be to use some 5/16 (OD) copper pipe that I have a lot of. Crush some of it and grind it flat, bolt it to the ALU plates, bend it into artistic shapes and have it protrude along slots in the top/side of the case. Attached are some squetches that might confuse you more, or it might make my idea clearer.

Anyway, the advantages of this plan are that it brings the heat outside the case. And given that the slots won't be precise, will allow air to circulate. What's more, it will look cool; I'm going for a steam-punk look for the case and one common complaint about steamy stuff is that all the protrutions are just useless. But these protrutions will actually be part of the mechanism.

The disadvantage is that getting to the amp PCBs and attenuator will be that much more annoying. And it might not be possible to have adequate thermal contact between the ALU and the copper pipes.

I've fixed my amp but haven't run any more tests as I've been rebuilding my work bench. And to build a work bench, first one must tidy up ones entire basement.

Anyway, I have a plan. Well 3 plans. The ideal plan would be do conclude that 2 alu plates are enough.

Plan number 2 would involve scraping the plates and using a largish, well fined heat sink I pulled out of the trash last week end.

Plan number 3 would be to use some 5/16 (OD) copper pipe that I have a lot of. Crush some of it and grind it flat, bolt it to the ALU plates, bend it into artistic shapes and have it protrude along slots in the top/side of the case. Attached are some squetches that might confuse you more, or it might make my idea clearer.

Anyway, the advantages of this plan are that it brings the heat outside the case. And given that the slots won't be precise, will allow air to circulate. What's more, it will look cool; I'm going for a steam-punk look for the case and one common complaint about steamy stuff is that all the protrutions are just useless. But these protrutions will actually be part of the mechanism.

The disadvantage is that getting to the amp PCBs and attenuator will be that much more annoying. And it might not be possible to have adequate thermal contact between the ALU and the copper pipes.

Attachments

Leolo,

That drawing is awesome. I think you have a great idea for an original case. Might I suggest that you mount the 1875 directly to the flattened portion of the coppoer pipe? Copper is an excellent heat conductor, and leaving the top and bottom of the pipe open for air to pass through would provide cooling.

Louis

That drawing is awesome. I think you have a great idea for an original case. Might I suggest that you mount the 1875 directly to the flattened portion of the coppoer pipe? Copper is an excellent heat conductor, and leaving the top and bottom of the pipe open for air to pass through would provide cooling.

Louis

Air circulating in the pipe is a nice idea. However, this piping 5/16" OD, 1/32" wall thickness. So kinda flimsy to mount the chips directly too. And the pipe has to be crushed to a- maximise surface area with th Al and b- get a bolt through it.

Hmmm... maybe some sort of manifold config, like Zalman et al use for fan-less CPU heat sinks.

Or, have the bolts that attach the Cu to the Al low on the Al, a few holes above (but still inside the case) and a some holes outside of the case to promote air exchange.

OK, this is getting complicated.

Hmmm... maybe some sort of manifold config, like Zalman et al use for fan-less CPU heat sinks.

Or, have the bolts that attach the Cu to the Al low on the Al, a few holes above (but still inside the case) and a some holes outside of the case to promote air exchange.

OK, this is getting complicated.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.