GRollins said:Steve,

The laser thing is of potential interest, but it sounds like I'd need a bi-color plastic, black & clear layers--not undoable, granted (hell, guitar pickguards have as many as four or five layers).

No, you wouldn't need a bi-color plastic. Just a piece of clear plastic. You spray paint the back surface the color you want. The laser then vaporizes the paint where the lettering is to go.

Your observation about diffusion is correct--my default plan is to use a clear front, laser printed negative image of the words, and a translucent white back plane to handle the diffusion. Actually, to be more particular, I'll use several separate white pieces, one for each word, and paint/Magic Marker them along the edges to eliminate back/side scatter of the light, so that if one word is lit the others stay dark. Translucent white plastic would give a smoother, more even "texture" to the backlighting, although I can see how someone might prefer a more granular texture.

That'd work.

se

GRollins said:Yeah, but if I can stencil-paint the thing with black paint, then I'm already done...why take the extra step of lasering it?

Stensil-paint? I'm not following you here. How exactly would that be done?

se

Steve,

Once I've got a stencil of some sort sufficient to keep the letters clear of paint, then there's no point in going further...by definition, I'll have clear letters with a black background, which is what I wanted in the first place. Why complicate matters by lasering the whole thing, when I've already arrived at my desired end result?

Grey

Once I've got a stencil of some sort sufficient to keep the letters clear of paint, then there's no point in going further...by definition, I'll have clear letters with a black background, which is what I wanted in the first place. Why complicate matters by lasering the whole thing, when I've already arrived at my desired end result?

Grey

I still think OH transparency film would work. The backlight would be fairly dim compared to sunlight or a UV exposure tube, and the reflectivity of the perspex front would improve contrast even further. why not just try it? What do you lose if it doesn't work - 20 pence for a sheet of film?

GRollins said:Once I've got a stencil of some sort sufficient to keep the letters clear of paint, then there's no point in going further...by definition, I'll have clear letters with a black background, which is what I wanted in the first place. Why complicate matters by lasering the whole thing, when I've already arrived at my desired end result?

Oh, so you mean the reverse of a stencil, or a mask.

Hmmm.

How do you figure on creating the mask for the lettering that will give you precise locating and good clean edges once it's painted over and the mask removed?

se

This should get you a even opaque black from a laser printout, Laser Buddy .

Regards

James

Just spray your documents with Laser Buddy® and watch those pin holes in the toner areas close up -- those gray areas turn solid black. It makes laser printer documents look like phototypeset copy or PMT prints.

Regards

James

Steve Eddy said:

How do you figure on creating the mask for the lettering that will give you precise locating and good clean edges once it's painted over and the mask removed?

se

Steve,

Precisely my point, all along. That's the problem with the whole concept of "painting" (I use the term in the broadest possible sense) anything on the clear plastic.

The term mask works for me. I am perpetually short on sleep and was grasping for terms. Stencil was the closest thing I could come up with.

tvi,

That sounds interesting. I'm about willing to bet that Laser Buddy is nothing more than acetone or some similar solvent; clearly something that can dissolve the toner, which is itself nothing more than a thermoset plastic.

The problem I see is that anything that dissolves toner will also dissolve the plastic transparency base. Paper would shrug off acetone (or any number of other solvents), but the transparency would almost certainly shrivel and haze over.

Anyone know where to find an MSDS for Laser Buddy? I'm curious to see what's in it.

At thirteen bucks for a single spray can, I can see myself going into business selling spray solvents. Always wanted a Porsche.

Chartal,

Good idea for the mask/stencil, but the problem remains: Once you get the lettering down and paint over it, how do you peel it up without disturbing the paint?

Perhaps you could have a black stencil made up, apply it, then peel the letters loose to leave clear areas. I'll ponder on this one.

Al,

Yeah, it's looking more and more as though I'm back to my backup concept. I was hoping for something easy, economical, and quick. If nothing nifty pops up in the next day or two, I'll try to experiment with it this weekend.

(What? You thought I could just fire up the laser and try it on a moment's notice? Silly fellow...you've obviously never had twin boys who needed feeding, bathing, etc. My time is not my own.)

Grey

GRollins said:Precisely my point, all along. That's the problem with the whole concept of "painting" (I use the term in the broadest possible sense) anything on the clear plastic.

Well, the lasering process I was speaking of involved simply painting one side of the plastic or glass solid black. Then the laser vaporizes the paint where the lettering would be, leaving a very precise, sharp image.

Yeah, it's looking more and more as though I'm back to my backup concept. I was hoping for something easy, economical, and quick. If nothing nifty pops up in the next day or two, I'll try to experiment with it this weekend.

The lasering process would be easy, economical, and quick. Not to mention very high quality.

If you'd like, I'll ask my laser guy if he'd be willing to do a sample for you so you can see it for yourself.

se

Laser Budy MSDS

Ingredient.................................% by Weight

Isobutyl Acetate..........................40-50

Isobutane/Propane blend.............20-25

sobutyl Alcohol............................1-2

Acetone......................................10-15

Ethylene Glycol Monobutyl Ether...2-4

First heard of the product on a diy PCB forum, they use it to get rid of pinholes in transperacies berfore exposure. They do warn it can cause some fogging of the transperancies though.

Regards

James

Ingredient.................................% by Weight

Isobutyl Acetate..........................40-50

Isobutane/Propane blend.............20-25

sobutyl Alcohol............................1-2

Acetone......................................10-15

Ethylene Glycol Monobutyl Ether...2-4

First heard of the product on a diy PCB forum, they use it to get rid of pinholes in transperacies berfore exposure. They do warn it can cause some fogging of the transperancies though.

Regards

James

Having tried a lot of these methods, I'd say the paint and laser for best results.

Not cheap in my corner of the world, tho. I was having my logo laser burned into amp panels at $30 a pop. Ouch!

Fast and easy? Follow Pink Mouse's lead. Print onto film. Place film on plastic. Basta.

There was a procuct similar to Laser Budy on a TV craft show last week. Came in a big felt tip pen. The transfers did not look good. Very broken up. It was used for "effect."

Not cheap in my corner of the world, tho. I was having my logo laser burned into amp panels at $30 a pop. Ouch!

Fast and easy? Follow Pink Mouse's lead. Print onto film. Place film on plastic. Basta.

There was a procuct similar to Laser Budy on a TV craft show last week. Came in a big felt tip pen. The transfers did not look good. Very broken up. It was used for "effect."

Steve,

Either I'm not understanding the process you're describing, or you're not understanding what I'm seeking...perhaps both. Let me see if I can try the transparency route this weekend. If it works, great. If it doesn't then we'll prod this laser thing some more.

One benefit to the transparencies is that I can add/delete functions quickly and cheaply. Obviously, I'll want POWER. Okay, no problem. Later, if I decide that I want, say, a MUTE function, I can run off just the one word and strap it in, without having to go through the aggravation and expense of having a whole new panel done.

tvi,

Thanks, that's just what I wanted. And yes, it does look as though there are components in there that would attack plastics. I'm not saying that they should reformulate their product for transparencies, just that it's inconvenient from my point of view.

On the other hand, you could use that to sidestep the $13 per can price if you're working on paper instead of plastic.

Actually, pinholes aren't my main problem with the transparency strategy--it's getting sufficient toner to make it black enough to stop unwanted light from coming through. No spray can can help with that. I have had some success with running the image through my laser printer twice, but it requires care to get the two images to register decently. It works well at the top of the page; less well the further you go down.

Grey

Either I'm not understanding the process you're describing, or you're not understanding what I'm seeking...perhaps both. Let me see if I can try the transparency route this weekend. If it works, great. If it doesn't then we'll prod this laser thing some more.

One benefit to the transparencies is that I can add/delete functions quickly and cheaply. Obviously, I'll want POWER. Okay, no problem. Later, if I decide that I want, say, a MUTE function, I can run off just the one word and strap it in, without having to go through the aggravation and expense of having a whole new panel done.

tvi,

Thanks, that's just what I wanted. And yes, it does look as though there are components in there that would attack plastics. I'm not saying that they should reformulate their product for transparencies, just that it's inconvenient from my point of view.

On the other hand, you could use that to sidestep the $13 per can price if you're working on paper instead of plastic.

Actually, pinholes aren't my main problem with the transparency strategy--it's getting sufficient toner to make it black enough to stop unwanted light from coming through. No spray can can help with that. I have had some success with running the image through my laser printer twice, but it requires care to get the two images to register decently. It works well at the top of the page; less well the further you go down.

Grey

GRollins said:Either I'm not understanding the process you're describing, or you're not understanding what I'm seeking...perhaps both.

Perhaps so.

Let me see if I can try the transparency route this weekend. If it works, great. If it doesn't then we'll prod this laser thing some more.

Okie doke. Good luck!

se

tvi said:Laser Budy MSDS

Ingredient.................................% by Weight

Isobutyl Acetate..........................40-50

Isobutane/Propane blend.............20-25

sobutyl Alcohol............................1-2

Acetone......................................10-15

Ethylene Glycol Monobutyl Ether...2-4

First heard of the product on a diy PCB forum, they use it to get rid of pinholes in transperacies berfore exposure. They do warn it can cause some fogging of the transperancies though.

Regards

James

Off topic I know... Sorry.. and to... Well let me just appologize in advance...

Attachments

metalman said:Have a look at www.Lazertran.com. I think it might fit your bill.

Hey, that's pretty cool. 'Specially the water slide decals.

Thanks, Stuart!

se

troystg said:Off topic I know... Sorry.. and to... Well let me just appologize in advance...

Ha! Love it!

Apologize? You should be thanked.

Thanks!

se

Terry,

I'm in a hurry, will take a look later.

troystg,

Love it!

My wife loved it, too.

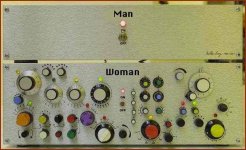

Somewhere in the bowels of this site there's a picture of two circuits. One is labelled "Man" and has a single on/off switch. The other is labelled "Woman" and has about thirty-eight controls, dials, and sundry weird, random indicators. I used to have the image on my computer, but suffered a hard drive crash and lost it. Someone here may know where it is.

Grey

I'm in a hurry, will take a look later.

troystg,

Love it!

My wife loved it, too.

Somewhere in the bowels of this site there's a picture of two circuits. One is labelled "Man" and has a single on/off switch. The other is labelled "Woman" and has about thirty-eight controls, dials, and sundry weird, random indicators. I used to have the image on my computer, but suffered a hard drive crash and lost it. Someone here may know where it is.

Grey

"Somewhere in the bowels of this site there's a picture of two circuits. One is labelled "Man" and has a single on/off switch. The other is labelled "Woman" and has about thirty-eight controls, dials, and sundry weird, random indicators. I used to have the image on my computer, but suffered a hard drive crash and lost it. Someone here may know where it is."

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Lettering on transparent panel