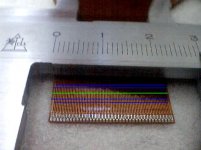

At first glance that cable looks like a double row, 0.3mm FPC connector (as has been said before), however 75 way isn't a common number of connections.

Has anyone had any joy coming up with a solution yet? It may be possible to extend it using a 90 way cable but it would need to be cut incredibly accurately to fit in the connector.

Has anyone had any joy coming up with a solution yet? It may be possible to extend it using a 90 way cable but it would need to be cut incredibly accurately to fit in the connector.

http://www.nec-lcd.com/english/products/industries/nl10276bc12-02.html

hmm wonder when such an item will come out for sale at a good price.

hmm wonder when such an item will come out for sale at a good price.

ywh - What is the other end of the cable like? I take it that it's directly soldered / fixed to the other board? From your pictures it's a lot wider and therefore maybe easier to work with however there's not enough res to see what's going on properly.

Also wondering if the driver board you were looking at would also drive the NL6448AC20-06, I can get one of these screens in the UK for about the equivalent of $10 which would be great for experimenting with (both lead extensions and case design).

Also wondering if the driver board you were looking at would also drive the NL6448AC20-06, I can get one of these screens in the UK for about the equivalent of $10 which would be great for experimenting with (both lead extensions and case design).

$160 USD is definitely cheap if IT IS NL10276BC12-02 !!

It has always been $250 (lcd only) everywhere i checked.i could recall the NL10276BC12-01 being cheaper.

i had mine last time for US$315 (...BC12-02) including controller with TV tuner.Since there were no solution for the FPC cabling for PJ purposes, i gave to my lil sis for her use in her car.

It has always been $250 (lcd only) everywhere i checked.i could recall the NL10276BC12-01 being cheaper.

i had mine last time for US$315 (...BC12-02) including controller with TV tuner.Since there were no solution for the FPC cabling for PJ purposes, i gave to my lil sis for her use in her car.

Yeah the 01 was a nice screen as well, just lacked a bit of contrast from what I remember when compared to the 02.

I'm currently under the impression that the university that I'm doing my doctorate at has the capability to manufacture custom FFC/FPC cables although I haven't confirmed how easy it is to get them to do this or how much it will cost. I'm also not sure if they could do double row or not.

I'm tempted to buy an NL6448AC20-06 panel to try, assuming I can use the same driver board (and I have no idea if I can or not). I don't suppose you know what controller card your 01 had do you? TV inputs would be an added bonus...

I'm currently under the impression that the university that I'm doing my doctorate at has the capability to manufacture custom FFC/FPC cables although I haven't confirmed how easy it is to get them to do this or how much it will cost. I'm also not sure if they could do double row or not.

I'm tempted to buy an NL6448AC20-06 panel to try, assuming I can use the same driver board (and I have no idea if I can or not). I don't suppose you know what controller card your 01 had do you? TV inputs would be an added bonus...

Do you know what are the price like for the NL6448AC20-06.

I could try and check the prices for the LCD+controller&TV combo locally but if it appears to be offstock then price would be

a tad higher to reorder.Controller&TV usually priced at US$70 but offcourse they normally insist on us buying the whole setup (with LCD) after the extra work programming those controller unit.

I could try and check the prices for the LCD+controller&TV combo locally but if it appears to be offstock then price would be

a tad higher to reorder.Controller&TV usually priced at US$70 but offcourse they normally insist on us buying the whole setup (with LCD) after the extra work programming those controller unit.

Another option for high res LCD i'm considering (if FPC is workable) would be the MITSUBISHI AA084XA03 a.k.a OPTREX T-51639D084JU-FW-A-AB in the U.S.

Yes a lil bigger at 8.4" but it holds all the promising specs similar/better than the NEC unit.

8.4" XGA full 16.7m color

Contrast 500:1

Brightness : 300cd

Response time : tr(6) + tf(19) ~25ms

a group buy may helps make it affordable for all.

Yes a lil bigger at 8.4" but it holds all the promising specs similar/better than the NEC unit.

8.4" XGA full 16.7m color

Contrast 500:1

Brightness : 300cd

Response time : tr(6) + tf(19) ~25ms

a group buy may helps make it affordable for all.

OK a thought to just throw out there...........Attached is a masterpiece of an Artists rendition of what IM thinking  OK why not cut the flex cable ( Yikes) find the pitch of each of the "2" sets of contacts. Then use the appropriate FFC's(assuming some will work) and Clamp them Onto Edges of the FFC that have been sanded off........one above the other one on both sides of the FFC. Still sounds like a SOB to do But perhaps less work then hand soldering...........Any thoughts?????

OK why not cut the flex cable ( Yikes) find the pitch of each of the "2" sets of contacts. Then use the appropriate FFC's(assuming some will work) and Clamp them Onto Edges of the FFC that have been sanded off........one above the other one on both sides of the FFC. Still sounds like a SOB to do But perhaps less work then hand soldering...........Any thoughts?????

Attachments

Irwin AR said:Another option for high res LCD i'm considering (if FPC is workable) would be the MITSUBISHI AA084XA03 a.k.a OPTREX T-51639D084JU-FW-A-AB in the U.S.

Yes a lil bigger at 8.4" but it holds all the promising specs similar/better than the NEC unit.

8.4" XGA full 16.7m color

Contrast 500:1

Brightness : 300cd

Response time : tr(6) + tf(19) ~25ms

a group buy may helps make it affordable for all.

DO you have a link

any idea how much they cost without a group buy (so as to give an indication of what we could get them down to with a group buy)

There's some available for about $30 a time, but that's just the panel, no driver board included. Whilst the driver board is going to add a lot onto that, I'd be a lot happier experimenting with a $30 screen as opposed to the more expensive xga, especially as any flexi extensions could easily turn out badly!Do you know what are the price like for the NL6448AC20-06.

If the NEC screens aren't workable then I'll be up for getting an 8" as well, I kinda have my head set on getting the smallest screen possible at the moment though, the last thing I want is another monstrosity like my 15" MH setup.

Hi,

i'm very interested with these small xga screens... we could make some killer boxes with such screens!

i've seen the problem with the nec, the strange fcc cable...

may be it is possible to wire ourselves the electronic parts of the lcd by welding the different elements....

here is an example of some frenchies that have done such works:

http://www.allinbox.com/technique/trucs/trucs2.htm

may be it's possible to do the same thing with the nec?

and about the mitsubishi? nobody has new informations? the price? where we can get it? is it easily strippable?

i'm very interested with these small xga screens... we could make some killer boxes with such screens!

i've seen the problem with the nec, the strange fcc cable...

may be it is possible to wire ourselves the electronic parts of the lcd by welding the different elements....

here is an example of some frenchies that have done such works:

http://www.allinbox.com/technique/trucs/trucs2.htm

may be it's possible to do the same thing with the nec?

and about the mitsubishi? nobody has new informations? the price? where we can get it? is it easily strippable?

With an extraordinarily small-tipped soldering iron and a steady hand, extending this cable should not be so very difficult. Is quality soldering such a rare skill that this is an insurmountable challenge?

Don't tell me that this is the only reason nobody much is using these screens. Sure it's really fine work, but if there's solder at both ends, a good tech can do it.

Don't tell me that this is the only reason nobody much is using these screens. Sure it's really fine work, but if there's solder at both ends, a good tech can do it.

I've never seen soldering iron tips quite that fine, and my hands definitely aren't steady enough to solder those wires. Remember the wires are 0.3mm spacing, that's over 3 wires in every mm, I think I'd struggle to see them! Using surface mount soldering might be an option...

Digitalview.com has several controller boards that would support this monitor, some with S-video, and component connections as well. I had a hard time trying to get a price, but they have a prescence in the states and I could give them a call during the day. If the FFC is the only other problem, I think we are all capable enough to do a few solders here and there, and looking at that allinbox site I know I could do a better job than that guy! all you need is one of those magnifying glass dealies with the aliigator clips that hold things for you while you work.

Steamer

Steamer

all you need is one of those magnifying glass dealies with the aliigator clips that hold things for you while you work.

Helping Hands

Mine doesn't have the integrated soldering iron and sponge holder. It's been useful though I spend more time posing "him" in various threatening robot stances.

Steamer said:I know I could do a better job than that guy! all you need is one of those magnifying glass dealies with the aliigator clips that hold things for you while you work.

Steamer

Careful with the broad brush! 0.3mm pitch is doable but Very Fine Work. The pictures on the links are about what a pretty-good solder tech can do with small lands to solder to. A really top-notch pretty job would be several skill levels higher and probably take a much longer time.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.