Bobken said:John,

If there is any interest in fuses, their disastrous effects on HQ sound, and ways of ameliorating these problems whilst retaining some safety-measures, I can talk a bit about this subject.

Regards,

I'm not John but please,

André

O.K. I'll put some thoughts together over the weekend, if not sooner, but if anyone has a short attention-span they had probably better not bother to read it, nor hold their breaths whilst doing so!

This is a serious and quite involved topic as far as I am concerned, both from the spoiling of sound viewpoint, and from the personal risks aspect, so it cannot be dismissed lightly in merely a couple of sentences.

I am very happy to share my extensive findings here, but I won't get involved in ensuing arguments, so any subsequent provocative comments will be ignored (by me, anyway).

Regards,

This is a serious and quite involved topic as far as I am concerned, both from the spoiling of sound viewpoint, and from the personal risks aspect, so it cannot be dismissed lightly in merely a couple of sentences.

I am very happy to share my extensive findings here, but I won't get involved in ensuing arguments, so any subsequent provocative comments will be ignored (by me, anyway).

Regards,

Go for it! As long as 'they' let us. The Blowtorch uses a solid state fuse the BOB found years ago, to replace the normal fuses, such as we used in the Vendetta Research. I always hated those fuse holders, as much as the fuses, as cheap, (but reliable), push connectors. The solid state fuses removed all that, but then, they are difficult to replace. One of the upgrades that we do with Vendetta, when we modify the power supplies, is to remove the fuse holders and replace the assembly with a solid state fuse. I also have some silver, German made fuses, and I hope to put them in my power amps, someday.

Hi Bob,

thanks for the info! You surely seem to know your relais.

25 * 26 = 650 resisotors, huh, that is a lot of money, and a kinda weird attenuator

Sigurd

thanks for the info! You surely seem to know your relais.

25 * 26 = 650 resisotors, huh, that is a lot of money, and a kinda weird attenuator

Sigurd

Bobken said:

Hi Sigurd,

I will try the latest 'Nudes' as already mentioned, but with 26 values required for one attenuator, 26 x 25 x approx $7 (for TX2352s) does amount to a substantial outlay for further experimentation, and even if they will make me a "handful" of each value, it won't be cheap as I guess the 2575s are rather more costly per piece, too.

The company I did this design for are quite satisfied with the existing results, so they are unlikely to help out financially here either, and I still have some supplies of the original TX2352s to hand.

I am reminded of being restricted by an NDA which precludes me from divulging the relay I finally ended up using here, but I found several of the miniature types (20mm x 10mm footprint) which were 'acceptable'. I would not go for anything smaller like sub-miniature (nor low-profile) as with smaller packages the coils will inevitably be physically closer to the contacts and signal paths, which I don't consider to be good for the best (untainted) sound.

Different makers use alternative internal mechanical arrangements/layouts and I look for ones which have the greatest distance between the coils and signal areas. One high-isolation type was particularly good in this respect (although more mechanically noisy), and don't be tempted to use a poorly-filtered PS for energising these coils. It may not be intuitive, as there should not (usually) be any direct electrical connection between the coil's circuits and the signal areas, but I have experienced unwanted effects when using a relatively poor supply which would otherwise be perfectly acceptable for energising relays. These problems were fully eradicated when I went over to a well-smoothed DC source, so there is clearly some kind of 'bleedthrough' possible in relays, perhaps due to an internally radiated field from the coils. It goes without saying that any coil-energising PS source and grounds should be entirely separated from the signal PS and grounds, for similar reasons.

There is little to beat making certain there is adequate distance between these regions to ensure there is no possible 'contamination', and I have seen other circuits where for easy PCB layout the tracks from the coils have run between, and far too close to IMO, the tracks and solder-pads carrying signals, so care in PCB layout is important here too. A lot of good achieved elsewhere in the circuit can be very easily countered by careless PCB layouts, unfortunately, and all of these details are important if you wish to achieve the finest possible sonic results.

Also, it is vital to go for bifurcated contacts, which I believe most suitable relays will probably have anyway, for the following reason.

Due to customary tolerances in manufacture (nothing is perfect in life, nor in audio!) with every bifurcated-contact relay I have inspected internally, one contact will 'lead' the other, albeit by a very small margin. The effect of this is that the contacts will make and break at different times (maybe only by a few milli-seconds, but this helps here) which is an 'unintentional bonus' to us perfectionists, which I am very happy to take advantage of.

What happens in practice is that the leading contact will always take the brunt of the electrical/thermal shocks as it mates first, and (even better, so this is a real "double-whammy") it also breaks last, and this is usully when the contact deteroration is most likely to take place. So, whatever spark-erosion or other deterioration might occur will be heavily biased towards (if not completely - as in most cases) this one contact, leaving its 'partner' unscathed (or certainly less adversely affected) during its usable lifetime. The one remaining 'good' contact can then still pass the delicate audio signals with the least harm, and inspecting used relays with bifurcated contacts I have seen this one-sided deterioration result several times.

Apologies to John for hogging his thread, but I hope that the above is of some value/interest to others.

Regards,

Hi Sigurd,

I take such design work seriously, and the sonic results obtained from a well-constructed attenuator like this are really fantastic, provided that the rest of the system is of similar quality.

I felt it my duty to research all aspects most carefully before any design decisions were finally made, and this inevitably involved destructive investigation of several relays which I had previously selected through intuition/experience and by listening-tests. Of course, I have used many different relays over the years, but never in quite such a demanding application before, so this was partly virgin territory for me and (as always!) I needed to find the answers out for myself. If one is not prepared to go to such lengths, then I know from hard-won experience, that the results will not be as good as is possible.

Don't ever forget that the weakest link in the entire system will always be the overall performance-limiting factor when dealing with analogue audio. Any 'audio bottleneck' however caused will lose you some overall system resolution which affects the vitally-important minute sonic details which take one closer to the real event, which is surely our ultimate goal. Overlook even a seemingly innocuous area at your peril!

Unlike digital signals, where it is often possible to subsequently 'reconstruct' a good square-wave by various means so long as there is a reasonably 'readable' signal to work with, when dealing with analogue signals this is quite impossible.

Anything (wanted information) lost due to lousy components or poor circuit design etc. in any part of the entire audio chain between a cartridge (or CD laser) and the speaker coils, is unfortunately gone forever, and cannot be recovered. I think a fair analogy here is if you were looking through many panes of glass all put together in a sandwich, with one pane in the middle of the 'pack' being dirty. No matter how much you polish up the other panes, you will still not see so many fine details of the other side so clearly through this arrangement (not even if you use binoculars!)

That's a slight misunderstanding on the quantity of naked Vishays, actually.

You confirmed what I had been told by Texas Components that to have these new resistors made to specific values (as I would need here) the minimum quantity would be 25 pieces of each value.

Hence the 25 x 26 @ $7+, but still even a substantial outlay if they will do just a "handful" of each of the required 26 values, which you said they might do at a push.

We use 76 of these in the 6-channel attenuator I was responsible for, and this is just one of the many reasons why such high-end gear ends up being rather costly as John (vainly) attempted to explain much earlier in this thread, but there were a lot of "Doubting Thomases" then having a go at him, unfortunately. Regrettably, I was tied up (7 days per week) on a panic job at that time, and I only caught up on the thread much later on, or I would have pitched in to the affray!

Having just spent nearly a 'working year' on developing and finalising a 6-channel DAC, you might guess that this will not be given away either!

I'm supposed to be thinking about fuses now.

Regards,

I take such design work seriously, and the sonic results obtained from a well-constructed attenuator like this are really fantastic, provided that the rest of the system is of similar quality.

I felt it my duty to research all aspects most carefully before any design decisions were finally made, and this inevitably involved destructive investigation of several relays which I had previously selected through intuition/experience and by listening-tests. Of course, I have used many different relays over the years, but never in quite such a demanding application before, so this was partly virgin territory for me and (as always!) I needed to find the answers out for myself. If one is not prepared to go to such lengths, then I know from hard-won experience, that the results will not be as good as is possible.

Don't ever forget that the weakest link in the entire system will always be the overall performance-limiting factor when dealing with analogue audio. Any 'audio bottleneck' however caused will lose you some overall system resolution which affects the vitally-important minute sonic details which take one closer to the real event, which is surely our ultimate goal. Overlook even a seemingly innocuous area at your peril!

Unlike digital signals, where it is often possible to subsequently 'reconstruct' a good square-wave by various means so long as there is a reasonably 'readable' signal to work with, when dealing with analogue signals this is quite impossible.

Anything (wanted information) lost due to lousy components or poor circuit design etc. in any part of the entire audio chain between a cartridge (or CD laser) and the speaker coils, is unfortunately gone forever, and cannot be recovered. I think a fair analogy here is if you were looking through many panes of glass all put together in a sandwich, with one pane in the middle of the 'pack' being dirty. No matter how much you polish up the other panes, you will still not see so many fine details of the other side so clearly through this arrangement (not even if you use binoculars!)

That's a slight misunderstanding on the quantity of naked Vishays, actually.

You confirmed what I had been told by Texas Components that to have these new resistors made to specific values (as I would need here) the minimum quantity would be 25 pieces of each value.

Hence the 25 x 26 @ $7+, but still even a substantial outlay if they will do just a "handful" of each of the required 26 values, which you said they might do at a push.

We use 76 of these in the 6-channel attenuator I was responsible for, and this is just one of the many reasons why such high-end gear ends up being rather costly as John (vainly) attempted to explain much earlier in this thread, but there were a lot of "Doubting Thomases" then having a go at him, unfortunately. Regrettably, I was tied up (7 days per week) on a panic job at that time, and I only caught up on the thread much later on, or I would have pitched in to the affray!

Having just spent nearly a 'working year' on developing and finalising a 6-channel DAC, you might guess that this will not be given away either!

I'm supposed to be thinking about fuses now.

Regards,

Bobken said:

I'm supposed to be thinking about fuses now.

I chose the easy way out in '84. Been entirely fuseless ever since, not counting fuses between my premises and the local substation. Extremely not pc, but all this time of enjoyment may even be worth some fireworks. Besides, compared to anything else in SA it's such a tiny risk factor

Yes, actually I have also been "fuseless" for a number of years in my domestic system, but for other than DIY, there are many snags lurking with this approach.

There will always be someone (a customer) who is determined to blow himself up, or even stage such an event to claim the insurance payout, but there are some ways of getting around this.

Regards,

There will always be someone (a customer) who is determined to blow himself up, or even stage such an event to claim the insurance payout, but there are some ways of getting around this.

Regards,

You be crazy. Fuses are possible, at least circuit breakers, without any real loss in audio quality. If you have problems with 'anything' try to find out where the AC line garbage is leaking into your audio. Use Bybees, in line chokes, or common mode chokes, and add a 10uF cap across the power line, (internally fused of course). Still: SAFETY FIRST!

Bobken said:

For some recordings, I would even like to have an intermediate setting of a 0.5dB step as one setting is marginally subdued for my tastes, but 1 dB higher output seems a little over the top!

I know this may sound bit off, but I suspect thats we get further along on our little journeys, we become more attuned, and you seem like you are quite attuned.

And that sometimes it takes someone else saying it.

I think you've either got room overload, physical vibrational issues with equipment, or a rising distortion issue that's coming from ~somewhere~. Otherwise what you said would not be happening. IMHO and experience. Yah got a demon in the system somewhere. Once more we go around, chasing those last little bits. The good thing, is that as the last masks come off..it's like filling in the last holes in a bucket or a boat. Finally..the damn thing starts to work like it should. Thus the ability to NOTICE it happening over a level of 1 db or so. It could be cables, as that is a topic that many in the design crowd relegate to a lesser status. That's fine, but after a certain point one must come to terms with their effects and issues. The laws of diminishing returns and whatnot will sooner or later place them upon the altar of being the more offensive item in the given system.

Something is resonating and overloading in your system. Due to your description, It is likely to be occurring at a 'line level'. It's likely source or source connectivity.

IMHO, the more perfected a system the greater the urge to continually crank it up and up and UP!!! Until it sounds like it is going to explode..but is still very clean. The better the system, the more pronounced this effect and desire. Linear and dynamic at any setting-until it explodes. That's the ticket.

We also build and design our own speakers, so that could also be the source of your issue. We design so there is not even a -hint- of anything being troublesome..until a woofer goes 'crack!'..then it is advised to turn it down 'just a bit'. A guy who designed and worked on loudspeaker systems for years got ahold of a set of our speakers and was shortly quite embarrassed. For the first time in his life, he blew two woofers. The effect is that pronounced, as he never even heard the onset of distortion. Even the experts are fooled. Of course..our 'wire' does the same trick.

KBK said:We also build and design our own speakers, so that could also be the source of your issue. We design so there is not even a -hint- of anything being troublesome..until a woofer goes 'crack!'.

.then it is advised to turn it down 'just a bit'.

A guy who designed and worked on loudspeaker systems for years got ahold of a set of our speakers and was shortly quite embarrassed. For the first time in his life, he blew two woofers.

You are perfectly right

KBK

KBKHere is my story.

I bought 'test winner' speakers.

Floor standing 1 meter high

with bass reflex port towards the floor = under the speaker.

They are the best speakers I have ever owned.

It has never happend to me before,

but with this pair of speakers I once got too high volume.

Result:

- both woofers blown

Now luckily, I could order replacement woofers from the support.

Today I am a bit more wise.

I will not blow my dear hi-fi speakers once again.

Just because they are able to produce some very good sounds at very high levels.

Lineup

Most relay architectures don't lend them selves to a make-before-break scheme like a switch. Its more of a complex gray code sequence to prevent the loud before quiet steps when switching. if you use a 1,2,4,8,16,32,64(?) binary sequence the 16, 32 and 64 steps are potentially explosive. The software needs to keep them straight.KBK said:Anyone ever bother to try making a make-before-break shunted (aka shunt volume) relay system?

Although relay failure might have a bit of a higher cost than usual. But, in reality, no more dangerous than a failing wiper in a shunt set-up.

A make before break scheme would have one relay for each step (potentially 24-64 relays) and a make before break would be possible-in fact essential. Some of the electronic volume control IC's do this using FET's for switches.

Hi all;

Sorry I couldn't respond, it was my wifes birthday which prompted a visit to the coast. Ft. Bragg if any of you are familiar with the Northern California area.

I have seen a mini Shallco or at least an excellent counterfeit, both the larger and the smaller Shallco have detents from hell. Without the detents a stepper should work, one of those small toothed belts would at least get the magnetics farther away.

see www.sdp-si.com

I understand the mercury whetted (the position insensitive mercury film type) was used in the Cello preamp. While in general I agree that magnetic fields should be kept at "arms length", once you are aware of the problem cautious use should be possible. All relays have magnetic fields, but the comments about reed relay armature metals deserve some testing for validation.

Cost of Vishays; lets see this is a Blowtorch thread those excessively sensitive to cost should probably look elsewhere. In the case of the Blowtorch you could buy it or a car.

I've done a little experimenting with the light sensitive resistors. they want very small signal voltages to keep the distortion within reason. Maybe inside a servo loop where the voltage across the light sensitive element remains close to zero? At least all the distortions seem to be even order. SET folks should love them.

See Perkin Elmer VTL5C Series

John: The sarcasm ill becomes you, just cause you're descended directly from the gods does little for the rest of us.

Sorry I couldn't respond, it was my wifes birthday which prompted a visit to the coast. Ft. Bragg if any of you are familiar with the Northern California area.

I have seen a mini Shallco or at least an excellent counterfeit, both the larger and the smaller Shallco have detents from hell. Without the detents a stepper should work, one of those small toothed belts would at least get the magnetics farther away.

see www.sdp-si.com

I understand the mercury whetted (the position insensitive mercury film type) was used in the Cello preamp. While in general I agree that magnetic fields should be kept at "arms length", once you are aware of the problem cautious use should be possible. All relays have magnetic fields, but the comments about reed relay armature metals deserve some testing for validation.

Cost of Vishays; lets see this is a Blowtorch thread those excessively sensitive to cost should probably look elsewhere. In the case of the Blowtorch you could buy it or a car.

I've done a little experimenting with the light sensitive resistors. they want very small signal voltages to keep the distortion within reason. Maybe inside a servo loop where the voltage across the light sensitive element remains close to zero? At least all the distortions seem to be even order. SET folks should love them.

See Perkin Elmer VTL5C Series

John: The sarcasm ill becomes you, just cause you're descended directly from the gods does little for the rest of us.

Hermanv, I have no idea what you are talking about. Was it because I expressed serious concern that most electronic products should be fused? Well, I once worked at UL and came to appreciate fuses, and know better. I won't even not put a circuit breaker on a lead acid battery. It is just too dangerous. Fires, you know.

Hermanv, I have no idea what you are talking about. Was it because I expressed serious concern that most electronic products should be fused? Well, I once worked at UL and came to appreciate fuses, and know better. I won't even not put a circuit breaker on a lead acid battery. It is just too dangerous. Fires, you know.

John,

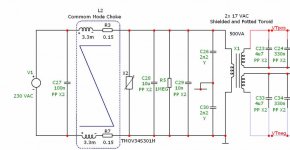

I do agree on having some form of filter for the AC mains garbage. Attached is part of a power amp power supply I did for a guy. He did NOT want to have any fuses although I strongly recommended it to him. He do not use any fuses at all except for the large one in the central.

I added a transorb, too.

He is very happy about the shielded and potted toroid.

Sigurd

I do agree on having some form of filter for the AC mains garbage. Attached is part of a power amp power supply I did for a guy. He did NOT want to have any fuses although I strongly recommended it to him. He do not use any fuses at all except for the large one in the central.

I added a transorb, too.

He is very happy about the shielded and potted toroid.

Sigurd

john curl said:You be crazy. Fuses are possible, at least circuit breakers, without any real loss in audio quality. If you have problems with 'anything' try to find out where the AC line garbage is leaking into your audio. Use Bybees, in line chokes, or common mode chokes, and add a 10uF cap across the power line, (internally fused of course). Still: SAFETY FIRST!

Attachments

Bob,

OK, now I see why you wrote 25 * 26.

The TX2575 is a new resistor type for Texas Components and they do not have that much raw material and that is probably why they want min quantaties. As far as I know they get all the bulk metal foil raw material from Vishay.

In the future, T.C. will hopefully have more stock of raw material (like they do of the K-foil for the TX2352s) so we can buy lower quantaties.

76 pcs for 6-channels is only 25 pcs for stereo, ie about 12 per channel and that is a bargain! That means that you need to have several of the resistors in series and or in parallel to get all the volume settings that you want. My current preamp has 10 TX2352s and 64 volume steps so it is similar in operation to the one you designed. A compromise - life's full of them.

It is one of the weak links I have.

BTW, the TX2575 costs about 9.5 USD each (for "normal values")so they are a bit more costly than the TX2352:s.

Like you, I am taking every component seriously trying to make that weak link less and less influential on sonics. Still, there is always a weak link and this target is always moving, so it is not always easy to "hit" the target, ie find what part of an amplifier that is the weak link.

Sigurd

OK, now I see why you wrote 25 * 26.

The TX2575 is a new resistor type for Texas Components and they do not have that much raw material and that is probably why they want min quantaties. As far as I know they get all the bulk metal foil raw material from Vishay.

In the future, T.C. will hopefully have more stock of raw material (like they do of the K-foil for the TX2352s) so we can buy lower quantaties.

76 pcs for 6-channels is only 25 pcs for stereo, ie about 12 per channel and that is a bargain! That means that you need to have several of the resistors in series and or in parallel to get all the volume settings that you want. My current preamp has 10 TX2352s and 64 volume steps so it is similar in operation to the one you designed. A compromise - life's full of them.

It is one of the weak links I have.

BTW, the TX2575 costs about 9.5 USD each (for "normal values")so they are a bit more costly than the TX2352:s.

Like you, I am taking every component seriously trying to make that weak link less and less influential on sonics. Still, there is always a weak link and this target is always moving, so it is not always easy to "hit" the target, ie find what part of an amplifier that is the weak link.

Sigurd

Bobken said:Hi Sigurd,

I take such design work seriously, and the sonic results obtained from a well-constructed attenuator like this are really fantastic, provided that the rest of the system is of similar quality.

I felt it my duty to research all aspects most carefully before any design decisions were finally made, and this inevitably involved destructive investigation of several relays which I had previously selected through intuition/experience and by listening-tests. Of course, I have used many different relays over the years, but never in quite such a demanding application before, so this was partly virgin territory for me and (as always!) I needed to find the answers out for myself. If one is not prepared to go to such lengths, then I know from hard-won experience, that the results will not be as good as is possible.

Don't ever forget that the weakest link in the entire system will always be the overall performance-limiting factor when dealing with analogue audio. Any 'audio bottleneck' however caused will lose you some overall system resolution which affects the vitally-important minute sonic details which take one closer to the real event, which is surely our ultimate goal. Overlook even a seemingly innocuous area at your peril!

Unlike digital signals, where it is often possible to subsequently 'reconstruct' a good square-wave by various means so long as there is a reasonably 'readable' signal to work with, when dealing with analogue signals this is quite impossible.

Anything (wanted information) lost due to lousy components or poor circuit design etc. in any part of the entire audio chain between a cartridge (or CD laser) and the speaker coils, is unfortunately gone forever, and cannot be recovered. I think a fair analogy here is if you were looking through many panes of glass all put together in a sandwich, with one pane in the middle of the 'pack' being dirty. No matter how much you polish up the other panes, you will still not see so many fine details of the other side so clearly through this arrangement (not even if you use binoculars!)

That's a slight misunderstanding on the quantity of naked Vishays, actually.

You confirmed what I had been told by Texas Components that to have these new resistors made to specific values (as I would need here) the minimum quantity would be 25 pieces of each value.

Hence the 25 x 26 @ $7+, but still even a substantial outlay if they will do just a "handful" of each of the required 26 values, which you said they might do at a push.

We use 76 of these in the 6-channel attenuator I was responsible for, and this is just one of the many reasons why such high-end gear ends up being rather costly as John (vainly) attempted to explain much earlier in this thread, but there were a lot of "Doubting Thomases" then having a go at him, unfortunately. Regrettably, I was tied up (7 days per week) on a panic job at that time, and I only caught up on the thread much later on, or I would have pitched in to the affray!

Having just spent nearly a 'working year' on developing and finalising a 6-channel DAC, you might guess that this will not be given away either!

I'm supposed to be thinking about fuses now.

Regards,

hermanv said:Hi all;

Sorry I couldn't respond, it was my wifes birthday which prompted a visit to the coast. Ft. Bragg if any of you are familiar with the Northern California area.[snip]

Herman,

Surely you are visiting your wife more often than that ?

hermanv said:[snip]While in general I agree that magnetic fields should be kept at "arms length", once you are aware of the problem cautious use should be possible. All relays have magnetic fields, but the comments about reed relay armature metals deserve some testing for validation.[snip]

Electromagnetic fields from the coil can be easily overcome by using bi-stable relays. You pulse them to change position after which you cut the power. No electromagnetic field.

Jan Didden

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- John Curl's Blowtorch preamplifier