it is hard to be more specific.Sorry Ionmw, but your last post makes almost no sense to me. What are you trying to say?

Imagine Graham working 2 or 5 years just to make a layover (ussualy simple looking) some copper onto some substrate. And then imagine for this work to be paid quite good. You tell me Bill, is this something easy to explain to the world?

For him prototypes exists only to be tested and modified and then to submit them to production engineering (to be eventually further modified). So, Released Products are those prototypes made by production engineering, not those made by designer.

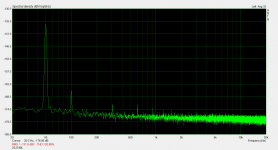

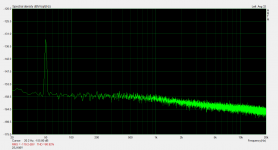

We tried different driver mosfets, different output bias, etc, with little success. I had to add another 2 pairs of output parts per channel to get better performance. Looking deeper, we found that they had used the wrong P channel input jfet,(this gave higher 2'nd harmonic than usual) the smallest surface mount parts on the driver board, etc. We had them fix all that. The final result is better, but not perfect.

Chris: Nope me an Ionmw are trying to find common ground

Ionmw: If you need 2 years to lay out a design you need to find another career! Now industries vary, but my paradigm is that the design authority remains just that and the production team do not mess about with the delivered gerbers. Obviously a contract design where the designer is not a full time employee is a different matter.

Ionmw: If you need 2 years to lay out a design you need to find another career! Now industries vary, but my paradigm is that the design authority remains just that and the production team do not mess about with the delivered gerbers. Obviously a contract design where the designer is not a full time employee is a different matter.

Ah ok. I have to disagree. A pick and place machine will always do a better assembly job than a designer. That's why a good lab tech is worth their money as designers are often lousy at precision soldering.

Now clearly hand crafted boutique products and volume production are worlds apart, but a couple of spins is not abnormal. Annoying, but not abnormal.

I bet some beers that Graham is working in a good lab tech; and maybe is easy for him to have help (any day and any time) from quite good professional solder guys - who are paid to assist him too along with their production duties.

"Handcrafted boutique" is then also the CTC Blowtorch and any high-end products, right?

Comparison to volume production = wrong thread maybe?

Chris: Nope me an Ionmw are trying to find common ground

Ionmw: If you need 2 years to lay out a design you need to find another career! Now industries vary, but my paradigm is that the design authority remains just that and the production team do not mess about with the delivered gerbers. Obviously a contract design where the designer is not a full time employee is a different matter.

Indeed, design authority remains the same in PLC but most modern projects insert now this abominable proxy called PE (production engineering). They -PE - are delegated by RnD authority, but this authority is maybe not Graham, yet.

Well PCB antenna prototypes would suggest Graham is also in the wrong thread. For one offs you use the PCB mill or copper tape (or horror etch your own).

ok.Why would that be so?

Graham only had a problem to understand what prototype means for"volume production". He actually meant correctly: for high-end world (default assumption on John Curl workplace and for this thread!) any prototype exists only for improvement.

TBH, I also asked myself where JC worked in 2002 (date from measurement sheet) to have colleagues that output such crap almost released... Maybe it was a low end product?

I am also lucky, same as you

But this only because I am planning/delegate the PE, so keeping them at safe distance (i.e. only for not-needing-new-release jobs)

But to answer someone earlier: I personally did released my own prototypes without any further workout. Sometimes was a good idea, sometimes not and I "paid" like 7+ years for this

But this only because I am planning/delegate the PE, so keeping them at safe distance (i.e. only for not-needing-new-release jobs)

But to answer someone earlier: I personally did released my own prototypes without any further workout. Sometimes was a good idea, sometimes not and I "paid" like 7+ years for this

Can you share, if you remember this detail, the name for wrong P-channel and for its fix?We tried different driver mosfets, different output bias, etc, with little success. I had to add another 2 pairs of output parts per channel to get better performance. Looking deeper, we found that they had used the wrong P channel input jfet,(this gave higher 2'nd harmonic than usual) the smallest surface mount parts on the driver board, etc. We had them fix all that. The final result is better, but not perfect.

We used to have a manual pick and place machine and oven in the lab, but got rid of them a couple of years ago.

Now all builds are done on the main manufacturing line, even a 10 board prototype.

The biggest difference between Prototype, Vorserie and Nulserie is the Prototype does not have ICT (in-circuit test), Vorserie has flying probe test, Nulserie (and subsequent production) has bed of nails final test.

There may not be any difference in the circuitry between the three builds. They are differentiated by their purpose. Prototype is for FW engineers to develop FW,and make minor changes to functionality, perform pre-Type Test evaluation for noise immunity etc. Vorserie is for Type Test and agency certification, Nulserie is per-production for manufacturing to prepare for sales, and they go into the warehouse for sale.

Now all builds are done on the main manufacturing line, even a 10 board prototype.

The biggest difference between Prototype, Vorserie and Nulserie is the Prototype does not have ICT (in-circuit test), Vorserie has flying probe test, Nulserie (and subsequent production) has bed of nails final test.

There may not be any difference in the circuitry between the three builds. They are differentiated by their purpose. Prototype is for FW engineers to develop FW,and make minor changes to functionality, perform pre-Type Test evaluation for noise immunity etc. Vorserie is for Type Test and agency certification, Nulserie is per-production for manufacturing to prepare for sales, and they go into the warehouse for sale.

Last edited:

Hi TheGimp,

Completely agree!If there are no dogs in Heaven, I don't want to go there.

Some questions here take a little more than a comment to explain.

Here is some jfet history:

Complementary jfets first became generally available from Motorola back in about 1970. These parts were the low Gm type, with a Gm of perhaps 3-5K umho. They have remained useful, but not as useful as what came later from Siliconix. Siliconix in the early 70's started to make complementary jfets with higher Gm, so we started using them in newer designs, including the complementary differential jfet input stage that we first started to use commercially in 1973. Since then, and now about 45 years later, we still make preamps and power amps with this same input stage. By 1980, there was a revolution in complementary jfets that were released by a number of Japanese manufacturers initially, and later many dropped out of production, but Toshiba remained essentially a single source supplier of various configurations of the 2SK170 and the 2SJ74. The apparent superiority of this parts pair in some form, became a mainstay of Parasound's preamp and power amp designs for the last 25 years. Unfortunately, much like many other Japanese manufacturers, they pulled the plug, so to speak, and we were left with a deficit of these jfets, especially the 2SJ74, and the prices started to rise, perhaps 20 or more times, due to the scarcity of these parts, with no cost effective substitute. Parasound, itself, started to run out of these parts, so in some amps (the cheaper ones at first) they substituted the 2SJ103 that looks and acts similar, but has much lower Gm than the part it replaced. This effectively creates a gain difference in the differential stages, and this actually changes the second (driver) stage more by creating an unbalanced drive to the complementary pairs that are driving each other. This caused a lot of extra 2'nd (even order) harmonics that would normally be balanced out with the proper part.

The amp that I was testing was not a cheap amp, but a more expensive, mid-priced amp, this replacement was inappropriate for its position in the amp lineup.

Now here are some spec sheets of the two fets that were used, note the Gm of each.

Here is some jfet history:

Complementary jfets first became generally available from Motorola back in about 1970. These parts were the low Gm type, with a Gm of perhaps 3-5K umho. They have remained useful, but not as useful as what came later from Siliconix. Siliconix in the early 70's started to make complementary jfets with higher Gm, so we started using them in newer designs, including the complementary differential jfet input stage that we first started to use commercially in 1973. Since then, and now about 45 years later, we still make preamps and power amps with this same input stage. By 1980, there was a revolution in complementary jfets that were released by a number of Japanese manufacturers initially, and later many dropped out of production, but Toshiba remained essentially a single source supplier of various configurations of the 2SK170 and the 2SJ74. The apparent superiority of this parts pair in some form, became a mainstay of Parasound's preamp and power amp designs for the last 25 years. Unfortunately, much like many other Japanese manufacturers, they pulled the plug, so to speak, and we were left with a deficit of these jfets, especially the 2SJ74, and the prices started to rise, perhaps 20 or more times, due to the scarcity of these parts, with no cost effective substitute. Parasound, itself, started to run out of these parts, so in some amps (the cheaper ones at first) they substituted the 2SJ103 that looks and acts similar, but has much lower Gm than the part it replaced. This effectively creates a gain difference in the differential stages, and this actually changes the second (driver) stage more by creating an unbalanced drive to the complementary pairs that are driving each other. This caused a lot of extra 2'nd (even order) harmonics that would normally be balanced out with the proper part.

The amp that I was testing was not a cheap amp, but a more expensive, mid-priced amp, this replacement was inappropriate for its position in the amp lineup.

Now here are some spec sheets of the two fets that were used, note the Gm of each.

Attachments

Measurement was done with the P-JFET version of Scott's LNA :

http://www.diyaudio.com/forums/grou...-measurement-amp-ikoflexer-5.html#post5007920

2SJ74BL was tested at 1.3nV/sqrtHz

2SJ103Y at 12nV/sqrtHz

Patrick

.

http://www.diyaudio.com/forums/grou...-measurement-amp-ikoflexer-5.html#post5007920

2SJ74BL was tested at 1.3nV/sqrtHz

2SJ103Y at 12nV/sqrtHz

Patrick

.

Attachments

Someone PM me when this thread finishes playing speculation on what they can and cannot hear, as my eyes only have so far to roll and I don't want to strain a muscle.

Do you consider Foobar with the A/B/X plugin a valid test for determining if one can or can not hear a difference in two files?

With the A/B/X plugin for Foobar, one can listen to file A, File B, and an unknown playback which can be A or B. One has to determine which it is.

I did not say I had a preference for either, only that I was able to hear a difference which was statistically significant (>80% probability).

That 103 looks to have bad GR noise, in fact I would check all late production lots for that. I found a few SK170's with it.Measurement was done with the P-JFET version of Scott's LNA :

http://www.diyaudio.com/forums/grou...-measurement-amp-ikoflexer-5.html#post5007920

2SJ74BL was tested at 1.3nV/sqrtHz

2SJ103Y at 12nV/sqrtHz

Patrick

.

We have measured multiple examples all with similar results.

Probably all from same batch.

Patrick

It's a problem 1 wafer at this size could be 10 thousand or more a whole lot 100's of thousands.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II