Would it be prohibitively expensive to use more than one pot?Well, it has come down to this: A 1K or 2K wirewound hybrid linear 10 turn pot, with series/parallel switching up to 47K. Any ideas, anybody?

I'm thinking that instead of switching series/parallel resistors to extend the range, it might be better to have e.g. a 1K pot and a 47K pot and switch between them with a "high-range/low-range" switch.

Here i have some information about the TKD potmeters and the inner structure. It is conuctive plastic with laser trimmed resistors around it. That is the way they hold such tight tolerances.

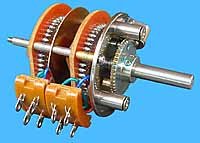

I also send picktures of their top model. It is a stepped attenuator.

Concerning loading : when you called Spiral Groove, John, did you talk to Allen, Brian or Sterling ?

Anyway i designed a phonostage for Spiral Groove that has two inputs. Both have INA topology but made out of sepertae OP amps. One is a transimpedance and the other is a transresistance input, so that stage can load the cartridge from Zerro Ohm ( Virtual Ground) to several hundred kOhms. I think my partners talked about the High Z input and with that input we usually do not load the Lyras down more then 1kOhm. In fact, with the new Lyra cartridges come a calculation done by Jonathan Carr about ideal loading. As far as i understand it it has to do with the used arm and phonostage because contribution of capacitance from that sources ad up. Under certain circumstances Lyra now promots lower loading then 1kOhm. I try to find the paper and will post the text. Stig Björge told me is has to do with the response in the extrem treble where a resonance can happen under unfortunate circumstances and then lower loading damps that problem.

I also send picktures of their top model. It is a stepped attenuator.

Concerning loading : when you called Spiral Groove, John, did you talk to Allen, Brian or Sterling ?

Anyway i designed a phonostage for Spiral Groove that has two inputs. Both have INA topology but made out of sepertae OP amps. One is a transimpedance and the other is a transresistance input, so that stage can load the cartridge from Zerro Ohm ( Virtual Ground) to several hundred kOhms. I think my partners talked about the High Z input and with that input we usually do not load the Lyras down more then 1kOhm. In fact, with the new Lyra cartridges come a calculation done by Jonathan Carr about ideal loading. As far as i understand it it has to do with the used arm and phonostage because contribution of capacitance from that sources ad up. Under certain circumstances Lyra now promots lower loading then 1kOhm. I try to find the paper and will post the text. Stig Björge told me is has to do with the response in the extrem treble where a resonance can happen under unfortunate circumstances and then lower loading damps that problem.

Attachments

The third picture in post 3802 shows the inner structure of an Elna attenuator, so it is not the inner workings of the TKD attenuator. Here is what they say about their attenuator Nachdem die Leitplastikpotiserie 2CP2500 lange Zeit klanglich fast jedem Stufenpoti überlegen war, ließ es den Entwickler von TKD keine Ruhe, bis er das Meisterwerk eines Schalters geschaffen hat, das jetzt in Bezug auf Klang und Präzision die unangefochtene Spitze im TKD-Programm darstellt.

Jeder Anschluss-Pin für einen Widerstand bildet zusammen mit der Schleiffläche ein einziges übergangsloses Werkstück aus Reinsilber. In Verbindung mit dem Präzisionsrastwerk aus edler Mechanik ist ein handwerkliches Meisterstück entstanden, das an die Grenzen der Physik reicht. Allein dadurch lässt sich schon erahnen, dass hier der klangliche Overkil zu erwarten ist.

Durch drei separate Frontplatten-Befestigungsbolzen wird eine hohe Stabilität erreicht, wodurch die Achse entlastet wird und der gesamte Aufbau frei von Verwindung bleibt.

Das HF-dichte Gehäuse rundet die Ruhe und Harmonie der akustischen Wahrnehmung auf perfekte Weise ab.

Jeder Anschluss-Pin für einen Widerstand bildet zusammen mit der Schleiffläche ein einziges übergangsloses Werkstück aus Reinsilber. In Verbindung mit dem Präzisionsrastwerk aus edler Mechanik ist ein handwerkliches Meisterstück entstanden, das an die Grenzen der Physik reicht. Allein dadurch lässt sich schon erahnen, dass hier der klangliche Overkil zu erwarten ist.

Durch drei separate Frontplatten-Befestigungsbolzen wird eine hohe Stabilität erreicht, wodurch die Achse entlastet wird und der gesamte Aufbau frei von Verwindung bleibt.

Das HF-dichte Gehäuse rundet die Ruhe und Harmonie der akustischen Wahrnehmung auf perfekte Weise ab.

here the rest

Reminds me of the vol pot in my TA-E88. A 3k vol pot! Now THAT would make a 'passive preamp'!

jd

Attachments

Joachim, thanks for the input. The big TKD is was we used for the CTC Blowtorch Preamp. They sound great, but are expensive, discrete, and clunky.

The second TKD is the cheaper model with motor. We evaluated it and even put it in the original Parasound JC-2 line preamp using a quad section. In any case, not the proper pot for my needs.

However, I still require some resistive switching arrangement to scale between a 1K pot, for example and 47K fairly elegantly, using passive relay controlled series and parallel precision resistors. I haven't done this for years, so I am a bit rusty, and I could appreciate any real professional help.

Joachim, I appreciate your enthusiasm, on this and other projects. It is rare to find that, these days. Take care, however, that many 'new' concepts to you have been well known in the USA for many decades. Others may 'claim' discovery, but it usually isn't the case. Of course, any idea, new to YOU is as good as a new idea, that even you might have discovered, yourself. So when you see a new example in a newly written book, you might think it to be a new idea, but it might have been first published 40 years ago. For example the 47K resistor reduction in noise was shown by Dick Burwen, one of the founders of ADI, about 40 years ago, in an AES paper. (I am pretty sure)

The second TKD is the cheaper model with motor. We evaluated it and even put it in the original Parasound JC-2 line preamp using a quad section. In any case, not the proper pot for my needs.

However, I still require some resistive switching arrangement to scale between a 1K pot, for example and 47K fairly elegantly, using passive relay controlled series and parallel precision resistors. I haven't done this for years, so I am a bit rusty, and I could appreciate any real professional help.

Joachim, I appreciate your enthusiasm, on this and other projects. It is rare to find that, these days. Take care, however, that many 'new' concepts to you have been well known in the USA for many decades. Others may 'claim' discovery, but it usually isn't the case. Of course, any idea, new to YOU is as good as a new idea, that even you might have discovered, yourself. So when you see a new example in a newly written book, you might think it to be a new idea, but it might have been first published 40 years ago. For example the 47K resistor reduction in noise was shown by Dick Burwen, one of the founders of ADI, about 40 years ago, in an AES paper. (I am pretty sure)

Joachim, Dave Wilson found the optimum loading of the top Lyra cartridge to be 138 ohms, from listening assessment. We had a long talk yesterday about 47K loading, its advantages, and disadvantages, Dave prefers about 130 ohms as a range, today. Decades ago, it was lower.

i found that the type of resistor is important too and not only the value. The best result in terms of transparency i got with Vishey naked Z foils. Charcroft, Texas components and even Vishey themselve make them awaillabe. The Charcroft is 45,- english pounds each and the Texas Components is around 15,-$ so much more aforadble. The resistive element looks absolutely the same, mechanics differ a bit. I did not test the Vishey.

I do not claim here that resistor "per se" sound different. Maybe it is just the tight tolerances, the low tempco or the low noise they claim.

I do not claim here that resistor "per se" sound different. Maybe it is just the tight tolerances, the low tempco or the low noise they claim.

john curl said:However, I still require some resistive switching arrangement to scale between a 1K pot, for example and 47K fairly elegantly, using passive relay controlled series and parallel precision resistors.

When you say a passive relay, I guess you mean not a solid state relay? Or do you mean some other relay that is different from a reed type relay.

Sorry for posting redundant information. Synthetic loading was new to me and i thought others whould not know about it too, so publishing it would not hurt. Actually the circuit i posted has a refinement in form of the buffer, isolationg the noise of the 1kOhm resistor from the input. As far as i know prior art did not have that feature.

On cartridge loading i found information send to me by Stig Bjoerge, CEO Lyra.

The information was computed by Jonathan Carr and is working for the new Delos.

I hope this is something new but i could swear that someboday out there has eevn seen that before.

On cartridge loading i found information send to me by Stig Bjoerge, CEO Lyra.

The information was computed by Jonathan Carr and is working for the new Delos.

I hope this is something new but i could swear that someboday out there has eevn seen that before.

Attachments

Joachim, thanks for the input. This loading does not appear to be based on listening, but it is interesting. It is much like the Ortofon 75 ohm recommended loading, from years ago, based on the characteristic impedance of the connecting wire.

This is a matter of language differences, but I did not intend to criticize you for bringing out the low noise loading, but the alert you to prior work that you have not known about. This happens often between countries.

This is a matter of language differences, but I did not intend to criticize you for bringing out the low noise loading, but the alert you to prior work that you have not known about. This happens often between countries.

We use a military grade gold on gold, hermetically sealed dpdt TO-5 relay. Solid state would probably be too noisy and have residual distortion. We never use reed relays.

If it is milspec hermetically sealed it is most likely silver on silver, the military wouldn't use gold on gold in my experience. The hermetic sealing is to keep the silver pristine, these may even be filled with inert gases. Probably the best small-signal relays you can get anywhere.

jd

Yes, they seem to know what they are doing.

Teledyne Relays Announces Its Most Revolutionary Relay Since the TO-5: The 10 GHz, Surface-Mount RF522 Relay

Teledyne Relays Announces Its Most Revolutionary Relay Since the TO-5: The 10 GHz, Surface-Mount RF522 Relay

John,

Let's talk a bit about the motor. Most of the audio remote control motors I have seen are DC motors. As such they are essentially current to torque converters. Since it is very difficult to obtain position accuracy the pots being controlled are ganged and a third one is used as position sensor. Obviously tracking is very important. The secondary consideration of termination resistance shows up a bit. Keep in mind the fixed resistance at the termination is not the exact same type as the resistance element.

A second method has been to use AC motors as they are synchronous, of course as any user can tell you there is some slippage which is why fractional HP or larger motors are often 1750 RPM as opposed to the 1800 they would be if perfect.

The third method is to use stepper motors. These require a reference position. Typically this is the end of travel. They then are pulsed so many times until the desired position is reached. The advantage here is that you can use two motors one for each pot. In the learning mode they can be stepped and the value of the pot recorded. Then when they are used the variations in pot tracking are greatly reduced. This requires two steppers and two pots along with a micro-controller. This should be the most accurate method and possibly the most cost effective! The same controller can also step in the range extender resistors through your relays.

There are also motors built with optical discs built in to provide precise position information. These would have the greatest accuracy. But I don't think they come small enough.

Let's talk a bit about the motor. Most of the audio remote control motors I have seen are DC motors. As such they are essentially current to torque converters. Since it is very difficult to obtain position accuracy the pots being controlled are ganged and a third one is used as position sensor. Obviously tracking is very important. The secondary consideration of termination resistance shows up a bit. Keep in mind the fixed resistance at the termination is not the exact same type as the resistance element.

A second method has been to use AC motors as they are synchronous, of course as any user can tell you there is some slippage which is why fractional HP or larger motors are often 1750 RPM as opposed to the 1800 they would be if perfect.

The third method is to use stepper motors. These require a reference position. Typically this is the end of travel. They then are pulsed so many times until the desired position is reached. The advantage here is that you can use two motors one for each pot. In the learning mode they can be stepped and the value of the pot recorded. Then when they are used the variations in pot tracking are greatly reduced. This requires two steppers and two pots along with a micro-controller. This should be the most accurate method and possibly the most cost effective! The same controller can also step in the range extender resistors through your relays.

There are also motors built with optical discs built in to provide precise position information. These would have the greatest accuracy. But I don't think they come small enough.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II