With the ISO talk and 4 driver sub configuration have you considered using an amp to drive just the outer pair and the inner iso pair with yet another amp to control the excursion issue?

This was one way I reduced the risk of slamming the ISO drivers years ago. Important when they are hidden from view

Merry Christmas

This was one way I reduced the risk of slamming the ISO drivers years ago. Important when they are hidden from view

Merry Christmas

Happy Holidays

That was a irritating problem with a 4 driver 10" woofer, ISO - BR, box, one woofer (1of 4) would end up pinned into the basket if played too loud-too long. Some others have said that's pretty common.

The dust caps were off 10" so that might have caused some air pressure issue between the speaker

The 4 shared one large box, maybe 2 individual cells would have helped.

A second amp? - no no never thought of that, the 4 drivers were wired parallel then-series.

That was a irritating problem with a 4 driver 10" woofer, ISO - BR, box, one woofer (1of 4) would end up pinned into the basket if played too loud-too long. Some others have said that's pretty common.

The dust caps were off 10" so that might have caused some air pressure issue between the speaker

The 4 shared one large box, maybe 2 individual cells would have helped.

A second amp? - no no never thought of that, the 4 drivers were wired parallel then-series.

Merry Christmas Doug

Back around '89-90 I built a dual 10" ISO 6th order bandpass subs which had four 10"ers in it eg dual opposed clamshells using sonotubes. The inner driver would always bottom out if you were not careful as you have discovered. Solution was to not series parallel for 8Ω, but wired each of the inner drivers parallel to a seperate amp rated for 4Ω's. This worked very well for controlling the pressure / displacement difference. Built several and sold them all for a profit < a rarity. At a start to finish cost of $120 each invested was a decent design, would hit 20Hz no problem.

Added benefit was that the central port would fire vortex rings at you from across the room

Mike

Back around '89-90 I built a dual 10" ISO 6th order bandpass subs which had four 10"ers in it eg dual opposed clamshells using sonotubes. The inner driver would always bottom out if you were not careful as you have discovered. Solution was to not series parallel for 8Ω, but wired each of the inner drivers parallel to a seperate amp rated for 4Ω's. This worked very well for controlling the pressure / displacement difference. Built several and sold them all for a profit < a rarity. At a start to finish cost of $120 each invested was a decent design, would hit 20Hz no problem.

Added benefit was that the central port would fire vortex rings at you from across the room

Mike

Last edited:

WHAT!!!!...that's all I had to do??

I'll give that a try, still have mega box in garage. It sounds nice and has low bass, but it had the pegging problem.

Tunnels - more fun than than a barrel of monkeys - I've been gluing up round mdf disks, and then gluing the stack to the back of the front baffle; of course minimizing the space/distance. Very easy to route here and there to attach/center the drivers. Glued in some cork in one of the tunnels, I though that also was a good idea.

Iso's they seem to make sense with drivers with huge vas - I was never put off that they Need More Power Scotty and that was only a pinch of a turn on the amp, hardy noticeable.

Thanks for the help Mike!

I'll give that a try, still have mega box in garage. It sounds nice and has low bass, but it had the pegging problem.

Tunnels - more fun than than a barrel of monkeys - I've been gluing up round mdf disks, and then gluing the stack to the back of the front baffle; of course minimizing the space/distance. Very easy to route here and there to attach/center the drivers. Glued in some cork in one of the tunnels, I though that also was a good idea.

Iso's they seem to make sense with drivers with huge vas - I was never put off that they Need More Power Scotty and that was only a pinch of a turn on the amp, hardy noticeable.

Thanks for the help Mike!

Last edited:

One of the issues tubes have is they exhibit infinite standing waves. Not a good thing, but there is a simple solution to this one minor issue; subdivide lengthwise. A 1/2" or better straight panel down the middle. Easy peasy for a guy that knows how to stump grind properly

Port lengths get very long, added them externally

Also if this was to be taken to a much higher frequency, time delay the outer woofer so it is in time with the inner woofer and cross the internal woofer just like a sub. This reduces the distortion and allows the external woofer to carry the weight of the upper bass were the ISO is not required for the sub to function properly. With a miniDSP 2x4 ($80+s/h) it's a no brainer

Also since these tube come in half inch increments for example an 8" >7.5 & 8.5 in this size range (is also true of the larger sizes). When slid together leaves an 1/8" gap around the circumference. This space can be filled with a wide variety of materials which acts as a constrained layer. Take your pick, am thinking some low expanding latex foam (cheap) would be great. A couple of end caps and BOOM you're done. Added benefit is a massive weight reduction and portability. A few I sold required simple strap handles for carrying, no problem toting around two at a time.

Port lengths get very long, added them externally

Also if this was to be taken to a much higher frequency, time delay the outer woofer so it is in time with the inner woofer and cross the internal woofer just like a sub. This reduces the distortion and allows the external woofer to carry the weight of the upper bass were the ISO is not required for the sub to function properly. With a miniDSP 2x4 ($80+s/h) it's a no brainer

Also since these tube come in half inch increments for example an 8" >7.5 & 8.5 in this size range (is also true of the larger sizes). When slid together leaves an 1/8" gap around the circumference. This space can be filled with a wide variety of materials which acts as a constrained layer. Take your pick, am thinking some low expanding latex foam (cheap) would be great. A couple of end caps and BOOM you're done. Added benefit is a massive weight reduction and portability. A few I sold required simple strap handles for carrying, no problem toting around two at a time.

3db is less on an issue with larger amps

Cutting wood rings is a snap - Pic

Haven't made Iso's in a while and don't remember if the ports were generally longer vs. a BR box. Not sure there's a need for them now days, with all the new drivers that work in smallish boxes.

However the Iso's do have a unique thick bass sound - very nice.

Cutting wood rings is a snap - Pic

Haven't made Iso's in a while and don't remember if the ports were generally longer vs. a BR box. Not sure there's a need for them now days, with all the new drivers that work in smallish boxes.

However the Iso's do have a unique thick bass sound - very nice.

Attachments

Arise, thread! Arise!

Any idea if the 21 X 50.5 horn can be scaled to 48 inches? I have four of these little subs gathering dust, but it would be really nice to be able to use the 2 X 4 ft panels that most of the big box stores sell instead of buying a full sheet of ply and cutting it to size.

What is the horn tuned to? Is the 100 inch path a quarter wavelength in this design? That would come out to a 33hz tuning, if my math is correct?

Any idea if the 21 X 50.5 horn can be scaled to 48 inches? I have four of these little subs gathering dust, but it would be really nice to be able to use the 2 X 4 ft panels that most of the big box stores sell instead of buying a full sheet of ply and cutting it to size.

What is the horn tuned to? Is the 100 inch path a quarter wavelength in this design? That would come out to a 33hz tuning, if my math is correct?

If I was to describe the sound, it’s a slam, bubble and/or chug. I have a MCM 8” Iso in the shop, it reaches out and grabs you.

The two in the HT I moved up on 12” metal stands; should have done that long ago, it was a big improvement (by adding detail in the bass).

I find them remarkable.

8 working Vifa woofers? What’s the model #?

I got improved bass sounds by raising my subs approx same height.

Hi Sodacose,

Post #490: "...the 21 X 50.5 horn can be scaled to 48 inches?"

Yes, it should work just fine, maintain the 21" dimension, shorten the box length.

Regards,

TB-

How about if I make the box a little deeper (9.25 vs 8)? That would lower the acoustic impedance (and efficiency of horn) but shouldn't affect tuning? Am I right on that?

The reason would be to incorporate 1x10 lumber cut to length instead of ripping sheets to 8 inches wide. I'm not lazy; I just don't trust the straightness of my cuts

Hi Sodacose,

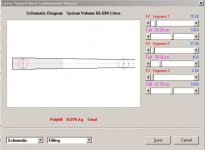

That would be fine too. I'll attach a hastily modified Hornresp simulation. You'll need to add just a little bit of stuffing (Polyfil) behind the speakers, see the attached Wizard printout. (I haven't looked at this in a while, and I hope that this is the correct simulation. I increased all cross-sections, and shortened L23.)

I don't know if you use Hornresp, if not: this is a nice case to get started with. It's a very forgiving design.

Regards,

That would be fine too. I'll attach a hastily modified Hornresp simulation. You'll need to add just a little bit of stuffing (Polyfil) behind the speakers, see the attached Wizard printout. (I haven't looked at this in a while, and I hope that this is the correct simulation. I increased all cross-sections, and shortened L23.)

I don't know if you use Hornresp, if not: this is a nice case to get started with. It's a very forgiving design.

Regards,

Attachments

The tall boxes are 21" x 9" x 50.5" (not including the 4.5" riser).

A couple of thoughts here:

I used the 48" length and added a small piece to add up to the length; which can be reinforced on the inside with bracing.

Still using the double tall box - it's not stealth-y but we do enjoy it. No problems so far and not using any protection filters (sub-sonic).

Other than that - this all started with folded boxes that are more compact.

pic is a double folded box using 4 drivers.

Yes - do not forget the damping material!

A couple of thoughts here:

I used the 48" length and added a small piece to add up to the length; which can be reinforced on the inside with bracing.

Still using the double tall box - it's not stealth-y but we do enjoy it. No problems so far and not using any protection filters (sub-sonic).

Other than that - this all started with folded boxes that are more compact.

pic is a double folded box using 4 drivers.

Yes - do not forget the damping material!

Arise, thread! Arise!

Any idea if the 21 X 50.5 horn can be scaled to 48 inches? I have four of these little subs gathering dust, but it would be really nice to be able to use the 2 X 4 ft panels that most of the big box stores sell instead of buying a full sheet of ply and cutting it to size.

What is the horn tuned to? Is the 100 inch path a quarter wavelength in this design? That would come out to a 33hz tuning, if my math is correct?

Attachments

Last edited:

The tall boxes are 21" x 9" x 50.5" (not including the 4.5" riser).

A couple of thoughts here:

I used the 48" length and added a small piece to add up to the length; which can be reinforced on the inside with bracing.

Still using the double tall box - it's not stealth-y but we do enjoy it. No problems so far and not using any protection filters (sub-sonic).

Other than that - this all started with folded boxes that are more compact.

pic is a double folded box using 4 drivers.

Yes - do not forget the damping material!

Thanks for the tips! This will end up under a 16" x 53" piece of granite behind the sofa as a sofa table, so I can be pretty flexible with dimensions. The port will probably be best on one of the short sides, unless I build some legs and make it down firing like that other folded box in your pic. Actually, my wife may prefer that, for aesthetic reasons.

My only limitations are small vehicles with which to transport plywood and how straight I can cut with my circular saw. Getting a repeatable width for the interior dividers would be tough, I think. I could match everything with my flush trim bit on my router, but I'd have to start with one perfect piece

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Isobaric - less then $20