This Belgium company used a form of supended fixing for the tweeter. http://www.floating-systems.be/home.htm

you can find some pictures here https://zelfbouwaudio.nl/forum/viewtopic.php?t=19080

you can find some pictures here https://zelfbouwaudio.nl/forum/viewtopic.php?t=19080

Last edited:

Get yourself a 15. Solder some wires to the terms or otherwise ensure rock solid connection. Hold it in your hands and light it up, live at a pretty normal level. Hold it by the magnet. Hold it by the basket legs. Hold it by the rim. All will become clear

I first did it on OB experiments so I could knife-up various posterboard baffles and take some curves and mess around listening. Stole the idea from Darrell Hawthorne (his was prettier). Mine isn't even fastened/glued--the "cups" fall right out when things aren't tightened--and you just cut new ones for a new diameter when messing about.

Doing it permanently in a real cab is a pain in the shorts. After busting my brain, brute force is always simplest/cheapest--simple normal (but thick) and brace brace brace. It's not only panel radiation, but what's conducted (transmitted) through the things as we all know. When I was young, I liked "warmth". Now, I can't stand the stuff and prefer clean. It's speakers, man--everything costs something (or three other things).

I first did it on OB experiments so I could knife-up various posterboard baffles and take some curves and mess around listening. Stole the idea from Darrell Hawthorne (his was prettier). Mine isn't even fastened/glued--the "cups" fall right out when things aren't tightened--and you just cut new ones for a new diameter when messing about.

Doing it permanently in a real cab is a pain in the shorts. After busting my brain, brute force is always simplest/cheapest--simple normal (but thick) and brace brace brace. It's not only panel radiation, but what's conducted (transmitted) through the things as we all know. When I was young, I liked "warmth". Now, I can't stand the stuff and prefer clean. It's speakers, man--everything costs something (or three other things).

Attachments

Energy did this in two different ways in their Veritas line: cup supporting the woofer magnet in the 1.8 (and likely in the 2.8) and a threaded nut in the back of the woofer in the 2.2/2.3/2.4 line, with a threaded rod that went through the cabinet from the back of the magnet to the rear of the cabinet.

In the 2.x series, there is a hex nut in the back, that tightens to pull the woofer in towards the back of the cabinet. In fact, there are no screws around the speaker rim - it's held on via that threaded rod.

They had problems with the first iteration of the 2.x series, because the glue that held the magnet to the basket would eventually dry out and give way. This was resolved in the "i" series (2nd iteration) of those speakers, where the magnet was held on to the frame with 3 pretty hefty screws.

Here's an example of the later "i" series woofers

In the 2.x series, there is a hex nut in the back, that tightens to pull the woofer in towards the back of the cabinet. In fact, there are no screws around the speaker rim - it's held on via that threaded rod.

They had problems with the first iteration of the 2.x series, because the glue that held the magnet to the basket would eventually dry out and give way. This was resolved in the "i" series (2nd iteration) of those speakers, where the magnet was held on to the frame with 3 pretty hefty screws.

Here's an example of the later "i" series woofers

Attachments

Yes, for horn speakers the sagging problem is more dominant as horns are usually long and they 'fit' from far away (say ~1ft). Besides, when the bass develops in the woofer (often in the same cabinet), part of that energy could cause vibrational movements in the horn driver as well.Yes, one of the cases i found as well, however if i read thecimage and text correctly it prevents thecheavy magnet from sacking under itsxweight. It does nod provide axridgid support in the axial direction.

Horn drivers do not generally make bass frequencies, but if axial support is necessary (in addition to radial), it may very well be provided. Assuming the woofer to be in the same cabinet, some enclosure volume would be lost, but that should be straightforward to calculate and compensate for.

Hi,

if You have access to the cabinet's inside, then one can mount the driver from inside against the front by using a large-headed machine screw pressing against the magnet.

I did that with my A-style folded Dipole, that btw. was too small to even use the original basket holes for fixing.

Besides only having to tighten 8 screws for 8 drivers -instead of 64- the cabinet considerably 'deadend' under the pressure/tension.

jauu

Calvin

if You have access to the cabinet's inside, then one can mount the driver from inside against the front by using a large-headed machine screw pressing against the magnet.

I did that with my A-style folded Dipole, that btw. was too small to even use the original basket holes for fixing.

Besides only having to tighten 8 screws for 8 drivers -instead of 64- the cabinet considerably 'deadend' under the pressure/tension.

jauu

Calvin

The remark about kef rr104 by @markbakk reminded me of the kef white papers. And this one https://images.salsify.com/image/upload/s--7J5Tne26--/89223f28d213a5abfbad9a9a7ba24e7be864c8cf.pdf

describes the attempts of Kef to isolatie the driver from the baffle, in summary: starting with the 104 in steps the best solution thusfar is in the blade 2 meta where for the coax the magnet is coupled to the basket with a damped flexible connection, the basket ridgidly to the baffle, and they show the benefits.

The approach described by @lrisbo is what i currently are designing, be it that the sagging mentioned by @newvirus2008 in this approach will lead to a unequal load on the 6 flexible mountings(flex washers). Therefore i will add a radial support for the magnet (which is about 1 kg).

Will post tomorrow some pictures on how ith might look like.

Also looking for an article i remember where an engineer described how to reduce vibrations reacties equipement in military helikopters, where weight/mass is not wanted to reduce transmission of vibrations.

Wright is not an issue for me, but the philosophy is interesting to see if can be applied in the baffle construction to reduce higher frequency transmissions from bass to midrange and from midrange to tweeter.

To be continued.

describes the attempts of Kef to isolatie the driver from the baffle, in summary: starting with the 104 in steps the best solution thusfar is in the blade 2 meta where for the coax the magnet is coupled to the basket with a damped flexible connection, the basket ridgidly to the baffle, and they show the benefits.

The approach described by @lrisbo is what i currently are designing, be it that the sagging mentioned by @newvirus2008 in this approach will lead to a unequal load on the 6 flexible mountings(flex washers). Therefore i will add a radial support for the magnet (which is about 1 kg).

Will post tomorrow some pictures on how ith might look like.

Also looking for an article i remember where an engineer described how to reduce vibrations reacties equipement in military helikopters, where weight/mass is not wanted to reduce transmission of vibrations.

Wright is not an issue for me, but the philosophy is interesting to see if can be applied in the baffle construction to reduce higher frequency transmissions from bass to midrange and from midrange to tweeter.

To be continued.

@JanRSmit

It's definitely worth doing. My apologies for the delay in getting back to you. Here's the data that I promised:

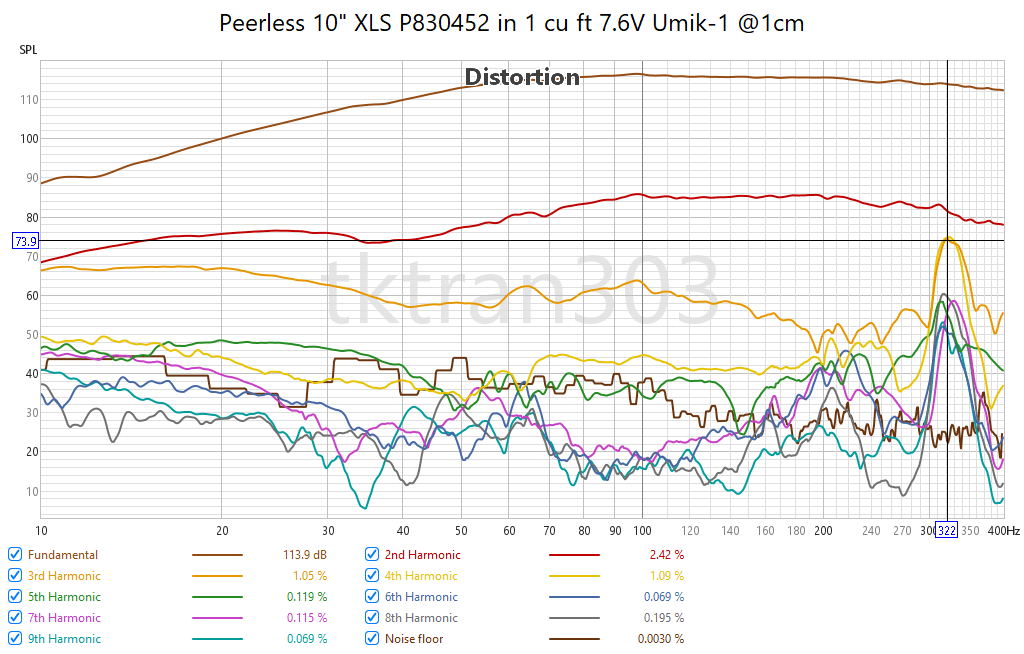

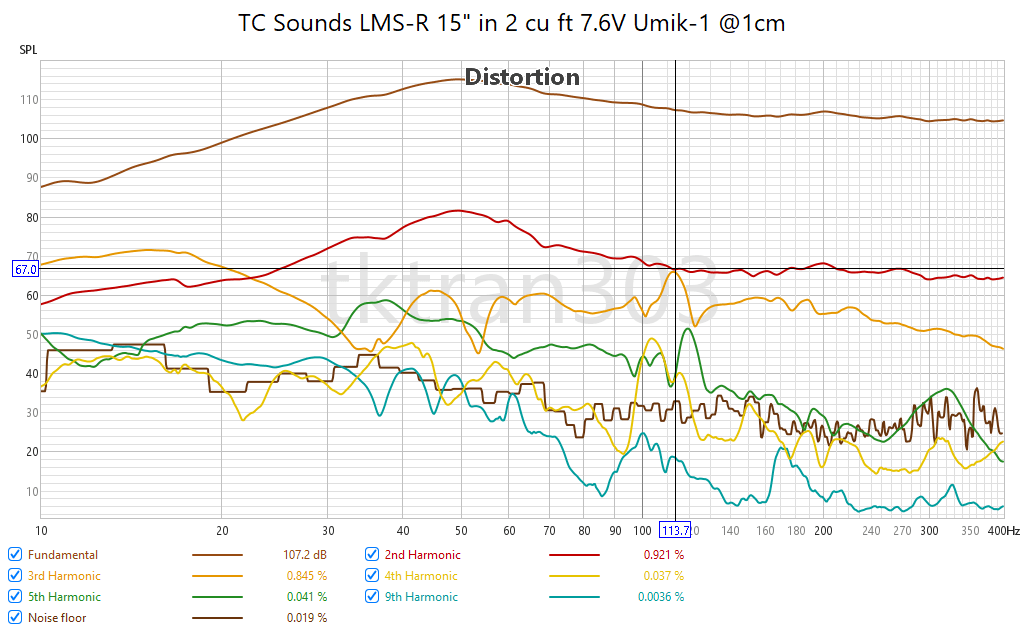

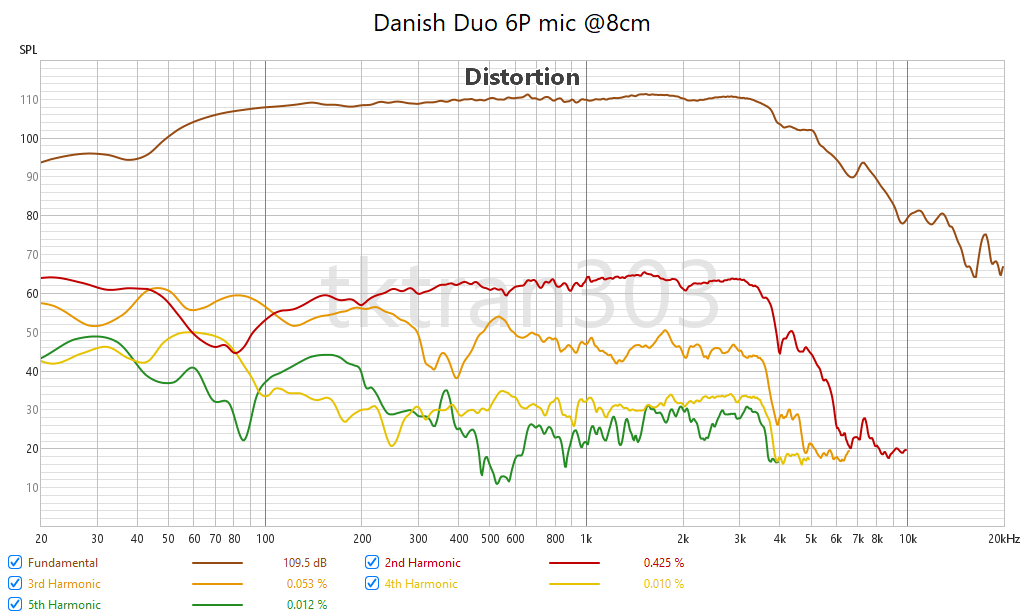

Below are measurements of 2 woofers, a 10" and a 15". In seaed boxes, taken in the near field.

At the cursor position is a resonance that can be measured by an elevation in all the harmonics.

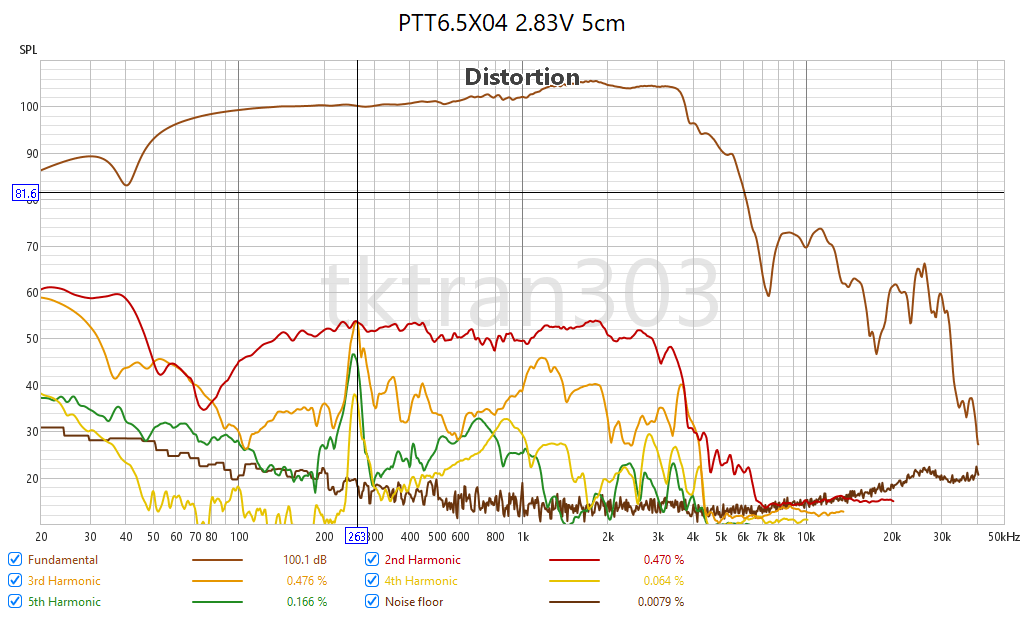

Here is a woofer that I also noted this:

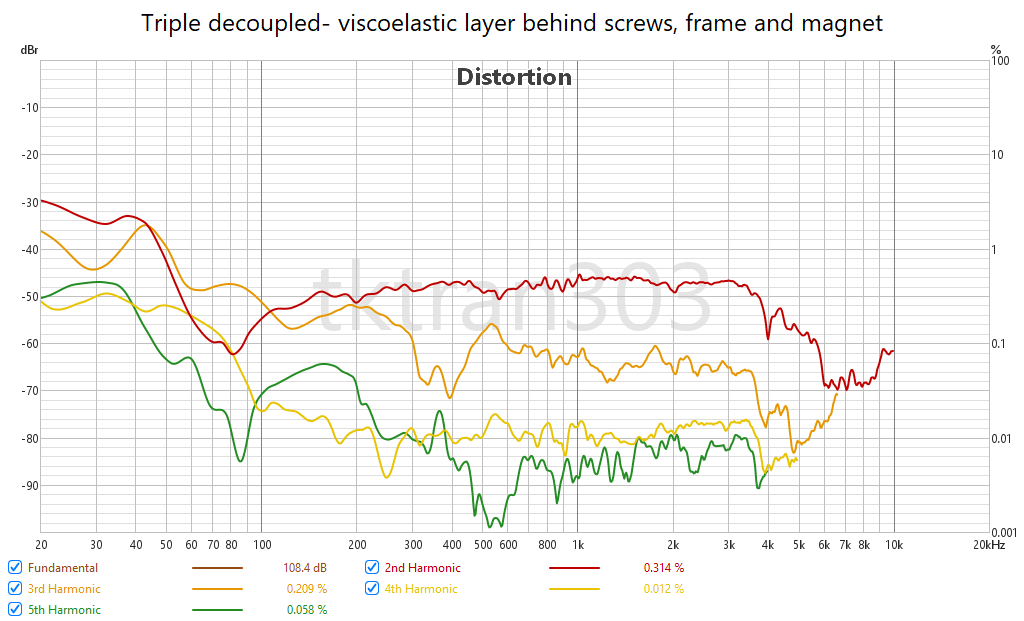

I used a viscoelastic layer behind the screws (between the mounting screws and the frame), behind the frame (between the frame/basket and the baffle) and behind the magnet (between magnet and brace). After this triple decoupling, this is how it measured:

As you can see, all harmonics that was previously seen has disappeared.

I shared this work with a few people privately, but thought it would be good to put it here for other to explore. A lot depends on your cabinet weight/stiffness and your driver. You may have to do some empirical testing to see the before and after effects.

You don't need an excellent microphone to be able to detect there. In fact I use the USB connected umik-1, which has a relatively high level of H2 as a 2nd mic to detect these. In fact, even if you don't have the ability to take distortion measurements in the nearfield, a logarithmic (or zoomed) impedance trace is also helpful. The resonances appears as blips in the impedance response that isn't seen in the manufacturer's datasheet.

Some manufacturers go even further- by dampening the contact point between the magnet and the basket. Some use polymer baskets (!)

Have a peaceful Easter!

It's definitely worth doing. My apologies for the delay in getting back to you. Here's the data that I promised:

Below are measurements of 2 woofers, a 10" and a 15". In seaed boxes, taken in the near field.

At the cursor position is a resonance that can be measured by an elevation in all the harmonics.

Here is a woofer that I also noted this:

I used a viscoelastic layer behind the screws (between the mounting screws and the frame), behind the frame (between the frame/basket and the baffle) and behind the magnet (between magnet and brace). After this triple decoupling, this is how it measured:

As you can see, all harmonics that was previously seen has disappeared.

I shared this work with a few people privately, but thought it would be good to put it here for other to explore. A lot depends on your cabinet weight/stiffness and your driver. You may have to do some empirical testing to see the before and after effects.

You don't need an excellent microphone to be able to detect there. In fact I use the USB connected umik-1, which has a relatively high level of H2 as a 2nd mic to detect these. In fact, even if you don't have the ability to take distortion measurements in the nearfield, a logarithmic (or zoomed) impedance trace is also helpful. The resonances appears as blips in the impedance response that isn't seen in the manufacturer's datasheet.

Some manufacturers go even further- by dampening the contact point between the magnet and the basket. Some use polymer baskets (!)

Have a peaceful Easter!

Last edited:

@tktran303 , thank you very much.

Using visco-elastic washers between baffle and chassis and between chassis and screw head is what i decided for, as well as a v-e layer between magnet and (very massive) rear wall . With the addition of a (small) vertical support of the magnet, to keep the load on the chassis and v-e even for all 6 screws.

For the v-e washers i found a butyl based material (sheet to cut them from) , actually a recycling of the butyl based layer in layered glass like car windows.

For the v-e layer between magnet and rear wall i have a stiff putty like material i am considering.

For the vertical support (attached to rear wall) a small block with a layer of the butyl based material .

Using visco-elastic washers between baffle and chassis and between chassis and screw head is what i decided for, as well as a v-e layer between magnet and (very massive) rear wall . With the addition of a (small) vertical support of the magnet, to keep the load on the chassis and v-e even for all 6 screws.

For the v-e washers i found a butyl based material (sheet to cut them from) , actually a recycling of the butyl based layer in layered glass like car windows.

For the v-e layer between magnet and rear wall i have a stiff putty like material i am considering.

For the vertical support (attached to rear wall) a small block with a layer of the butyl based material .

I have played around with this a bit too. Looking at impedance graphs, but also just flipping the woofer around with magnet outside the box and feeding sine signals while holding my hand on the magnet.

One was a cheap Dali speaker with plastic baskets where I put some oak braces behind the magnets and used putty to 'stick' the magnet so the brace. Impedance curve was a lot cleaner after. Only problem was that I was not able to remove the woofers again after they were mounted.

Second try was on my current DYI speakers where the 15" woofer had a basket resonance between basket and neo magnet clearly visible on impedance curve and felt by holding my hand on it. I think the basket was made for ferrite magnets, and the neo was an afterthought.. Putty between magnet and bracing improved it, but it was not totally gone (just visible on impedance). I learned from the previous and put masking tape on the driver to be able to get it out. However, it took some hard prying and bending before I got it out..

In both cases I used a flexible foam gasket between basket and baffle, and tightened the screws to get the driver to stick, and after that I could have removed the screws, but kept them there to avoid air leaks through screw holes.

Summary is that I have positive experiences from bracing/mounting at the magnet.

One was a cheap Dali speaker with plastic baskets where I put some oak braces behind the magnets and used putty to 'stick' the magnet so the brace. Impedance curve was a lot cleaner after. Only problem was that I was not able to remove the woofers again after they were mounted.

Second try was on my current DYI speakers where the 15" woofer had a basket resonance between basket and neo magnet clearly visible on impedance curve and felt by holding my hand on it. I think the basket was made for ferrite magnets, and the neo was an afterthought.. Putty between magnet and bracing improved it, but it was not totally gone (just visible on impedance). I learned from the previous and put masking tape on the driver to be able to get it out. However, it took some hard prying and bending before I got it out..

In both cases I used a flexible foam gasket between basket and baffle, and tightened the screws to get the driver to stick, and after that I could have removed the screws, but kept them there to avoid air leaks through screw holes.

Summary is that I have positive experiences from bracing/mounting at the magnet.

You mean that acoustically this is the only thing works?open cell foam works well.

It does and to quite some degree, but the higher modes are more damped.It should. The more the panels move, the more the damping is activated.

Btw Magico came to the same observation.

Bracing with cld as damper will probably be more effective for the first mode (i believe gedlee has done something in that direction). But then the bracing itself(being a panel) is a resonator. Ground rule applies always! ;-)

Basic acoustic fundamentals, straight raw and unsalted from the books.Ground rule applies always!

- Home

- Loudspeakers

- Multi-Way

- Is mounting a driver by its magnet beneficial?