My two cents is that it is a daft idea, for a start the dielectric contant for mineral oil is much greater then that of air making for a large interlead capacitance, secondly, it is a much poorer conductor of heat than say aluminium which will cause the chip to overheat in a short order, even if it does not overheat you still need to get rid of the heat from the oil somehow so the container neads to be a heatsink, i dont fancy having a container of hot oil near my hi-fi.

My question is... WHY ... what's wrong with a heatsink, and why would you want to vibration isolate a chip - how could it possibly affect the sound???

just my 2c

Alex

My question is... WHY ... what's wrong with a heatsink, and why would you want to vibration isolate a chip - how could it possibly affect the sound???

just my 2c

Alex

Hi,

For the same reason you want to isolate everything else from external vibrations???

And he did promise the guys at AA he'd come up with something errr....new?

Cheers,

and why would you want to vibration isolate a chip - how could it possibly affect the sound???

For the same reason you want to isolate everything else from external vibrations???

And he did promise the guys at AA he'd come up with something errr....new?

Cheers,

fdegrove said:

And he did promise the guys at AA he'd come up with something errr....new?

Cheers,

Exactly

Anyway I would be interested how it sounds isolated from all external influences. A small container the size of half pop can is more than enough, as this surface is similar to what I'm using now and the amp rarely gets hot.

I would say, I'm doing that as an experiment, and if it works well I might use it more seriously.

Water conducts heat well and takes alot of energy to heat it up, so it would be perfect for cooling. Now, just submerging the chip in oil or water wouldn't be the best way, you would still be limited by the surface area of the chip dissipating the heat.

What you could do is attach the chip to a relatively small heatsink, and submerge the pins or fins of the heatsink in water, you could isolate the heatsink from whatever will be suporting it anyway you like because it will be the water transfering the heat.

Or if you don't want to mount the chip on metal try putting it on a small (in area, but still high wattage) peltier element, then get rid of the heat any way you'd like. Then the chip won't be mounted on metal, since you seem to think that ain't good (I ain't going to argue about that, but I'll give any ideas Ihave) but instead on ceramic.

Maybe you could make a water block with one side made out of a someodd micron diamond sheet (saw these a while back on some crazy *** overclocking site) and mount the chip on that, again no metal and to boot you've got better heat transfer.

If you think that the pads make a difference, have you ever mounted the chip on a different metal than Al? Cu conducts heat better, radiates it less but most heat will be put off by convection anyways, maybe it resonates differently?

What you could do is attach the chip to a relatively small heatsink, and submerge the pins or fins of the heatsink in water, you could isolate the heatsink from whatever will be suporting it anyway you like because it will be the water transfering the heat.

Or if you don't want to mount the chip on metal try putting it on a small (in area, but still high wattage) peltier element, then get rid of the heat any way you'd like. Then the chip won't be mounted on metal, since you seem to think that ain't good (I ain't going to argue about that, but I'll give any ideas Ihave) but instead on ceramic.

Maybe you could make a water block with one side made out of a someodd micron diamond sheet (saw these a while back on some crazy *** overclocking site) and mount the chip on that, again no metal and to boot you've got better heat transfer.

If you think that the pads make a difference, have you ever mounted the chip on a different metal than Al? Cu conducts heat better, radiates it less but most heat will be put off by convection anyways, maybe it resonates differently?

And he did promise the guys at AA he'd come up with something errr....new?

Is that the Thirteenth Step?

along the line proposed by JoeBob, you can also use heatpipes. They can carry incredible amount of heat away in a very small and compact package.

Heat exchange is a useful idea. The nice thing about inert fluids, and the principle use for Fluorinert, is that you can pump them past the heat sink with very little noise compared to air, and run them through a heat exchanger. That strikes me as a great benefit, much more so than any incidental vibrational damping that one can get as a nice byproduct.

somewhere

in a thread with one of the kids, I suggested using one of the heat conductive epoxys to pot the chip and leads. Given you construction skills Peter, I could easily see you building a nice little cube that had 5 wires coming out of it. Place in water. The Artic Silver? guys make it.

in a thread with one of the kids, I suggested using one of the heat conductive epoxys to pot the chip and leads. Given you construction skills Peter, I could easily see you building a nice little cube that had 5 wires coming out of it. Place in water. The Artic Silver? guys make it.

It could be an idea to fix the chip to a very little heatsink and submerge this famous heatsink in oil, water or why not.... liquid nitrogen ?

You would have no problems related to dip your chip in liquid and you would reduce the problems related in fixing your chip to a large heatsink...

Well, it's only an idea

Potting the chip is also an idea but I'm not sure about how well they transfer energy (heat) to their environment...

hmmm it's late

edit :

d/$%m, forget it, looks like it has been already suggested in another post...

As I said previously, it's late...

You would have no problems related to dip your chip in liquid and you would reduce the problems related in fixing your chip to a large heatsink...

Well, it's only an idea

Potting the chip is also an idea but I'm not sure about how well they transfer energy (heat) to their environment...

hmmm it's late

edit :

d/$%m, forget it, looks like it has been already suggested in another post...

As I said previously, it's late...

Peter Daniel said:There are possible advantages to this approach of heat dissipation, mainly better damping and avoiding vibration pick up from the chassis.

How would it avoid picking up vibration from the chassis?

se

Re: Re: Is LM3875 chip waterproof?

The coupling between chip module and the cylinder containing the fluid would have to be soft (rubber, foam or something similar).

Steve Eddy said:

How would it avoid picking up vibration from the chassis?

se

The coupling between chip module and the cylinder containing the fluid would have to be soft (rubber, foam or something similar).

DSummer said:If just avoid from vibration, why don't oil the the transformers instead, like the old British Partridge/Pameko...They are still the best transformers in my opinion..

I'm not that much concerned with vibrations coming from transformers. My current amp has separate PS.

fdegrove said:Hi,

Some oils have dielectric properties that isolate upto 23KV/mm...think that should be good 'nuff?

Cheers,

Transformer oil, mineral oil (drug store), lightweight, non-detergent motor oil (the really cheap stuff) all work fine in high voltage transformers, so I don't see why it won't here. A word of caution: oil exposed to the air will hydrate, thereby ruining the insulative properties.

If you clean everything really, *really*, *really* good, you can use laboratory-grade distilled water (pure water is an insulator with a dielectric constant in the high 80s). But the slightest amount of contaminants drastically reduce the resistance, so things have to be extremely clean. And water has a way of "disolving" things, like certain metals, to create conductive water...... I had several discussions about this with a chem prof in college when I considered making a 30kV water pulse cap.

After the discussions I opted to go for a "normal" design instead.

After the discussions I opted to go for a "normal" design instead.Cheers,

Mark

Re: Re: Re: Is LM3875 chip waterproof?

So you mean the chip amp in fluid in some soft container in some cylinder?

se

Peter Daniel said:The coupling between chip module and the cylinder containing the fluid would have to be soft (rubber, foam or something similar).

So you mean the chip amp in fluid in some soft container in some cylinder?

se

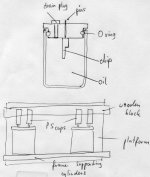

Here's some rough idea. The cylinder can be done out of copper tubing used for plumbing (maybe 2" dia). The bottom can be soldered, as there are copper caps available. The lid on top could be machined out of acrylic, with a groove for O-ring. The O-ring both seals the cylinder and isolates the acrylic lid from cylinder, as most vibrations will be picked up here. All I have to figure out, is how to keep the lid attached to the cylinder. The drain plug is there to assure that the cylinder is filled in full. In case better heat transfer from the chip is required, I can always attach to it additional copper plate.

The chip goes from the bottom through the lid, so I could even use a small PCB on top to hold few parts and 2 filter capacitors. The size of a cylinder has to be large enough to dissipate enough heat from the oil.

Actually, if I use wooden block to hold 2 pairs of caps (like my polycarbonate block in Amp-1) on one side and something to hold the cylinders on the other side and common platform for everything, I have a self supporting assembly, which also takes care of the lids attachment to the cylinders.

If I put all this together in a nice package, it may be the L'AMP

The chip goes from the bottom through the lid, so I could even use a small PCB on top to hold few parts and 2 filter capacitors. The size of a cylinder has to be large enough to dissipate enough heat from the oil.

Actually, if I use wooden block to hold 2 pairs of caps (like my polycarbonate block in Amp-1) on one side and something to hold the cylinders on the other side and common platform for everything, I have a self supporting assembly, which also takes care of the lids attachment to the cylinders.

If I put all this together in a nice package, it may be the L'AMP

Attachments

Peter Daniel said:Here's some rough idea. The cylinder can be done out of copper tubing used for plumbing (maybe 2" dia). The bottom can be soldered, as there are copper caps available. The lid on top could be machined out of acrylic, with a groove for O-ring. The O-ring both seals the cylinder and isolates the acrylic lid from cylinder, as most vibrations will be picked up here. All I have to figure out, is how to keep the lid attached to the cylinder. The drain plug is there to assure that the cylinder is filled in full. In case better heat transfer from the chip is required, I can always attach to it additional copper plate.

The chip goes from the bottom through the lid, so I could even use a small PCB on top to hold few parts and 2 filter capacitors. The size of a cylinder has to be large enough to dissipate enough heat from the oil.

Actually, if I use wooden block to hold 2 pairs of caps (like my polycarbonate block in Amp-1) on one side and something to hold the cylinders on the other side and common platform for everything, I have a self supporting assembly, which also takes care of the lids attachment to the cylinders.

Mmmm. Still don't see a whole lot of isolation there. At least not any more than if you'd mounted the chip to a heatsink and simply isolated the heatsink from the chassis.

If I put all this together in a nice package, it may be the L'AMP

Hehehe.

se

If you want to do something a little wilder (OK, a lot wilder), consider bonding a piezo film to the chip and using it actively to cancel out vibration. This can be combined with the fluid immersion idea, since piezo film couples very, very well to fluids with specific gravity near one.

Steve Eddy said:

Mmmm. Still don't see a whole lot of isolation there. At least not any more than if you'd mounted the chip to a heatsink and simply isolated the heatsink from the chassis.

The heatsink actually is a chassis in my amp. I can only isolate it from the supporting platform, and I hear a difference when I'm using spikes or rubber pucks. The platform itself affects the sound. So with this design I'm aiming at something that is not placement dependant.

I'm not sure myself how this would work out, but in my proposal the heatsink is actually in a liquid state (oil). The regular heatsing is a piece of metal. I imagine that the sound from a chip might be different in both instances. I'm only afraid, if the oil version wouldn't be sounding too slow and damped, without enough top end extension. OTOH, I shouldn't worry about "liquidity" of the sound

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Is LM3875 chip waterproof?